Method for preparing peptide of soybean through continuous enzyme membrane reaction of soyabean protein

A technology of soybean protease and soybean protein, applied in the direction of fermentation, can solve the problems of affecting the conversion rate and product quality, increasing the solid content and viscosity, and difficult to achieve continuous enzymatic hydrolysis, so as to improve the reaction conversion rate and product quality. Quality, high-converting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

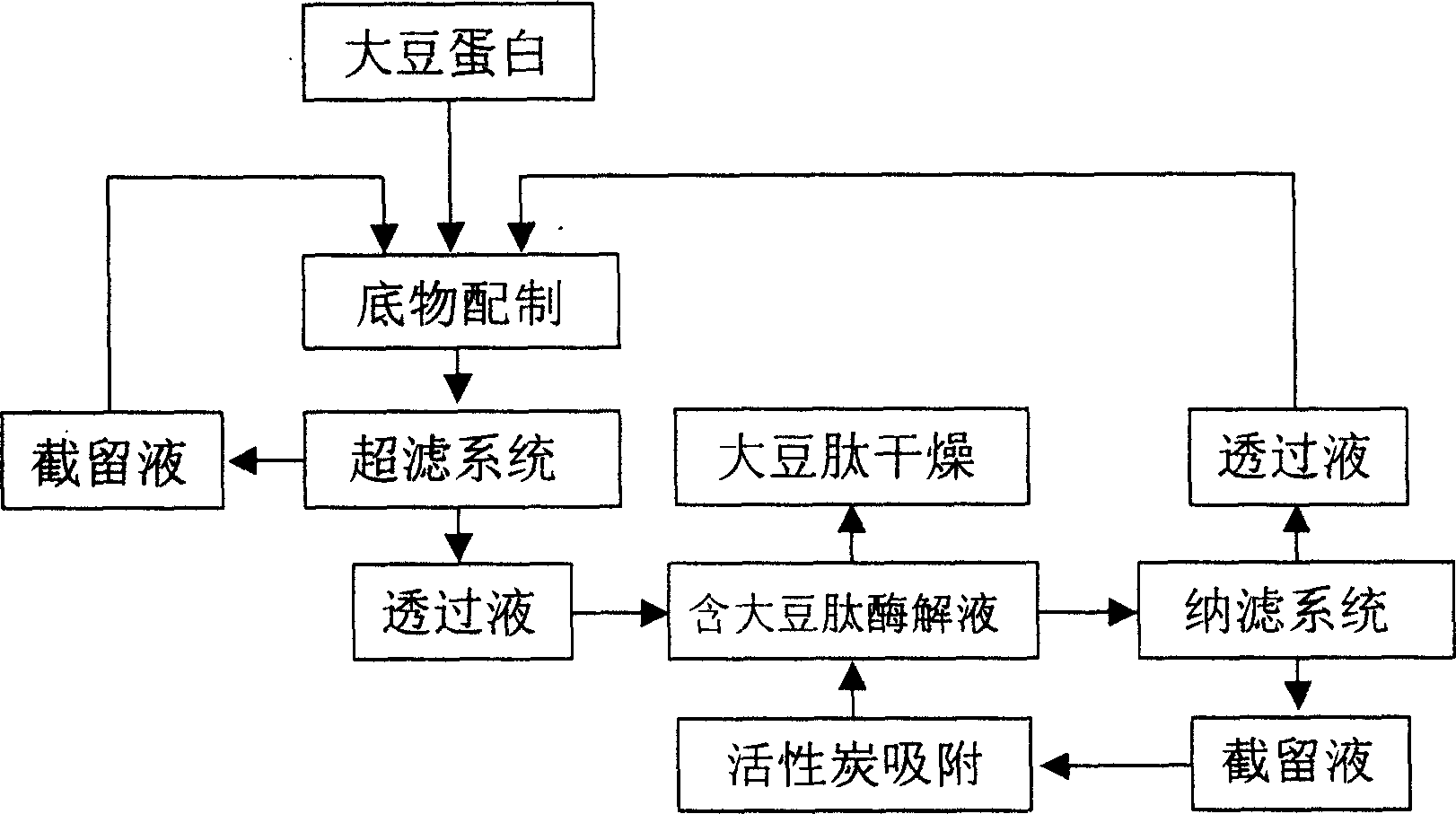

Image

Examples

Embodiment 1

[0022] Example 1 Alkaline enzymatic hydrolysis of soybean protein to prepare soybean peptides with a molecular weight of 300-5000

[0023] The first step: Enzyme-membrane reaction based on ultrafiltration separation

[0024] 500g of soybean protein was dissolved in 5L of distilled water to prepare a 10% (W / V) soybean protein solution, Alcalase alkaline protease was selected, and the amount of enzyme added was 1.0×10 -2 AU / g protein, mechanical stirring, rotating speed 50r / min, and use 0.5mol / L NaOH solution to adjust the pH of the mother liquor to 10, through the heat exchanger to make the temperature of the raw material system reach 85°C, after stirring for 1 hour, turn on the ultrafiltration system to carry out the enzyme membrane reaction , the reaction time of the enzyme membrane is 4h; the molecular weight cut-off is 5000, and the effective area is 0.7M 2 Roll-type ultrafiltration membrane, the ultrafiltration pressure is 0.08mPa; when the concentration ratio reaches 1.5...

Embodiment 2

[0029] Example 2 Preparation of soybean peptides with a molecular weight of 300-3000 by neutral enzymatic hydrolysis of soybean protein

[0030] The first step: Enzyme-membrane reaction based on ultrafiltration separation

[0031] 300g of soybean protein was dissolved in 10L of deionized water to prepare a 3% (W / V) soybean protein solution, Neutrase neutral protease was selected, and the amount of enzyme added was 3.0×10 -2 AU / g protein, mechanical stirring, speed 10r / min, the temperature of the raw material system reaches 50°C through a heat exchanger, and after stirring for 1 hour, the ultrafiltration system is turned on to carry out the enzyme membrane reaction, and the enzyme membrane reaction time is 6 hours; The area is 0.7M 2 Roll-type ultrafiltration membrane, the ultrafiltration pressure is 0.20mPa; when the concentration ratio reaches 1.1, the nanofiltration treatment starts. The retained liquid from the ultrafiltration process is sent back to the reaction tank to ...

Embodiment 3

[0036] Example 3 Preparation of soybean peptides with a molecular weight of 300-3000 by acidic enzymatic hydrolysis of soybean protein

[0037] The first step: Enzyme-membrane reaction based on ultrafiltration separation

[0038] Dissolve 600g of soybean protein in 10L of distilled water to prepare a 6% (W / V) soybean protein solution, select As3.350 acid protease, and add enzyme amount 2.0×10 -2 AU / g protein, mechanical stirring, rotating speed 100r / min, and use 1.0mol / L HCl solution to adjust the pH of the mother liquor to 3.0, the temperature of the raw material system reaches 55°C through a heat exchanger, and after stirring for 3 hours, open the ultrafiltration system to carry out the enzyme membrane reaction , the reaction time of the enzyme membrane is 8h; the molecular weight cut-off is 3000, and the effective area is 0.5M 2 The tubular hollow ultrafiltration membrane has an ultrafiltration pressure of 0.12mPa; when the concentration ratio reaches 2.0, nanofiltration t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com