Hydrothermal liquidization system and hydrothermal liquidization method for biomass

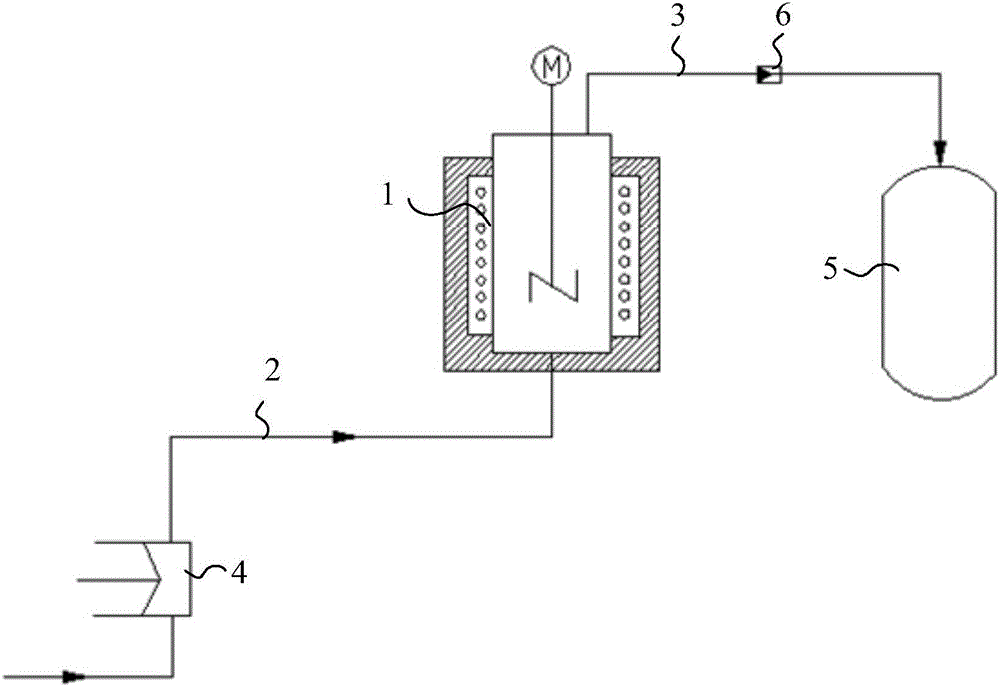

A technology for hydrothermal liquefaction and biomass, which is applied in the preparation of liquid hydrocarbon mixture, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of difficulty in realizing continuous reaction with continuous feeding and unfavorable large-scale production of biomass hydrothermal liquefaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

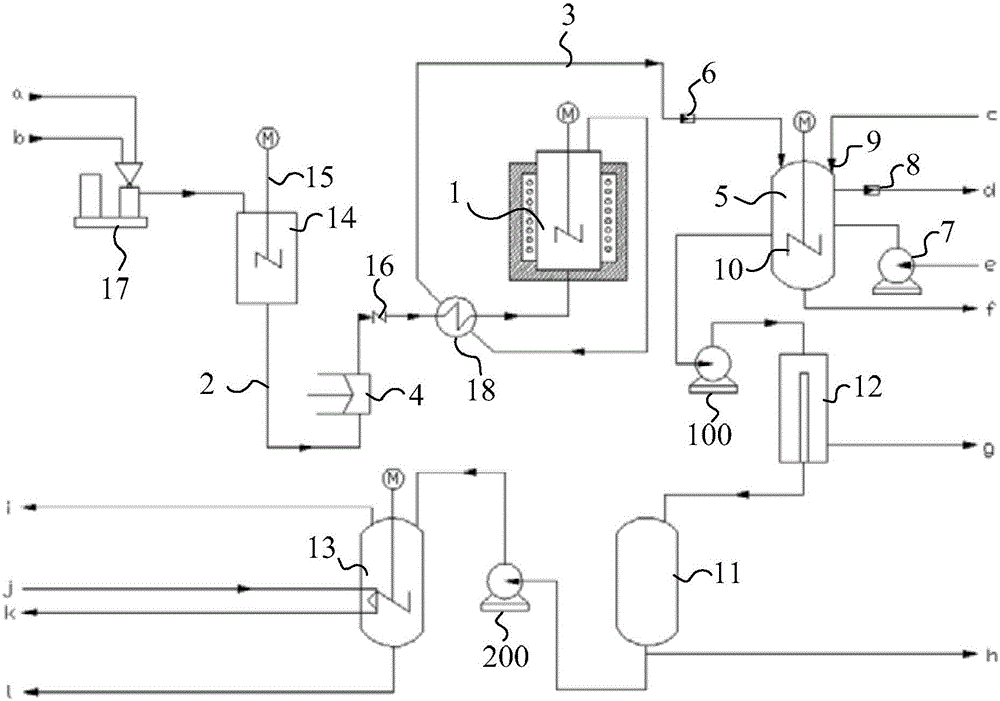

[0075] Taking silk algae (algae filament length 80cm) as an example to carry out the liquefaction test, it specifically includes the following test steps: first, mix the silk algae and deionized water in a ratio of 3:17, and add the crushing device to crush the material into The slurry with a particle size less than or equal to 1mm enters the material storage device and is ready for use; then, feed deionized water into the tubular reactor through the feed pipe and high-pressure plunger pump to preheat the tubular reactor, and at the same time pass the product The discharge pipe discharges the preheated product. When the temperature in the tubular reactor reaches 330°C and the pressure reaches 20MPa, start to replace the deionized water with the spare slurry, and open the stirring device in the material storage device and the outlet at the bottom of the material storage device. The material inlet valve is used to feed the slurry into the high-pressure plunger pump, and the outle...

Embodiment 2

[0078]The liquefaction test was carried out with coccus (3-8um in diameter) as an example, which specifically included the following test steps: mix coccus and deionized water at a ratio of 2:8 to form a slurry, and add it to the material storage device for standby; then , feed deionized water into the reactor through the feed pipe and high-pressure plunger pump to preheat the reactor, and at the same time discharge the preheated product through the product discharge pipe. When the temperature in the reactor reaches 330°C and the pressure reaches 20MPa, Start to replace deionized water with spare slurry, and open the stirring device in the material storage device and the outlet valve at the bottom of the material storage device to pass the slurry into the high-pressure plunger pump, and open the outlet of the high-pressure plunger pump The valve is used to feed the slurry into the reactor, and at the same time adjust the opening of the flow regulating valve, so that the system ...

Embodiment 3

[0081] Taking sludge as an example to carry out the liquefaction test, it specifically includes the following test steps: Concentrate the sludge to a water content of about 85%, and add a crushing device to crush the material into a slurry with a particle size of less than or equal to 1mm before entering the material The storage device is ready for use; then, pass deionized water into the reactor through the feed pipe and high-pressure plunger pump to preheat the reactor, and at the same time discharge the preheated product through the product discharge pipe, when the temperature in the reactor reaches 330 ° C , the pressure reaches 20MPa, start to replace the deionized water with spare slurry, and open the stirring device in the material storage device and the outlet valve at the bottom of the material storage device to pass the slurry into the high-pressure plunger pump and turn on the high-pressure The outlet valve of the plunger pump is used to feed the slurry into the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com