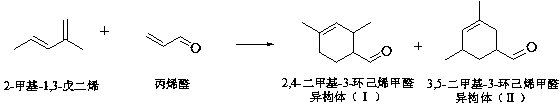

Method for continuous synthesis of ligustral in fixed bed reactor

A technology of fixed bed reactor and privet aldehyde, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve problems such as reaction temperature, high pressure, acrolein polymerization, difficult temperature control, etc. Achieve the effect of avoiding polymerization, low pressure and avoiding violent reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

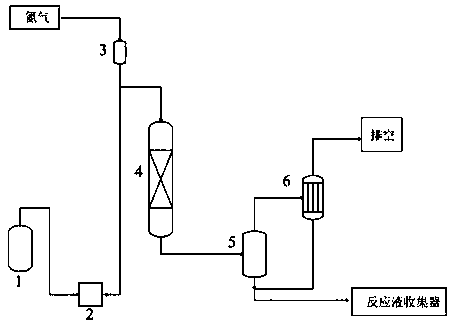

[0039] The method for continuously synthesizing privetal in a kind of fixed-bed reactor of embodiment 1

[0040] Include the following steps:

[0041] (1) Mixing of raw materials

[0042] 165.1g (2.01mol) 2-methyl-1,3-pentadiene and 114.9g (2.05mol) acrolein are mixed, and the molar ratio of 2-methyl-1,3-pentadiene and acrolein in the mixture is 1:1.02, put the mixed solution in the raw material solution 1 storage tank.

[0043] (2) Air replacement, preheating

[0044]The fixed-bed reactor 4 passes nitrogen from the nitrogen buffer tank 3 to replace the air, and the temperature is raised for preheating.

[0045] (3) Continuous response

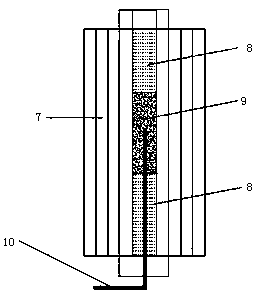

[0046] When the temperature of the catalyst bed in the reactor reaches the reaction temperature, feed the raw material liquid 1 into the reactor through the double-plunger micrometering pump 2, and fill the fixed bed reactor 4 with phosphomolybdic acid modified Al 2 o 3 Catalyst, catalyst loading is 15g, reaction temperature is 36°C, rea...

Embodiment 2

[0049] The method for continuously synthesizing privetal in a kind of fixed-bed reactor of embodiment 2

[0050] Include the following steps:

[0051] (1) Mixing of raw materials

[0052] 165.1g (2.01mol) 2-methyl-1,3-pentadiene and 129.6g (2.31mol) acrolein are mixed, and the molar ratio of 2-methyl-1,3-pentadiene and acrolein in the mixture is 1:1.15, put the mixed solution in the raw material solution 1 storage tank.

[0053] (2) Air replacement, preheating

[0054] The fixed-bed reactor 4 passes nitrogen from the nitrogen buffer tank 3 to replace the air, and the temperature is raised for preheating.

[0055] (3) Continuous response

[0056] When the temperature of the catalyst bed in the reactor reaches the reaction temperature, feed the raw material liquid 1 into the reactor through the double-plunger micrometering pump 2, and fill the fixed bed reactor 4 with phosphomolybdic acid modified Al 2 o 3 Catalyst, catalyst loading is 20g, reaction temperature is 40°C, re...

Embodiment 3

[0059] The method for continuously synthesizing privetal in a kind of fixed-bed reactor of embodiment 3

[0060] Include the following steps:

[0061] (1) Mixing of raw materials

[0062] 165.1g (2.01mol) 2-methyl-1,3-pentadiene and 123.9g (2.21mol) acrolein are mixed, and the molar ratio of 2-methyl-1,3-pentadiene and acrolein in the mixture is 1:1.10, put the mixed solution in the raw material solution 1 storage tank.

[0063] (2) Air replacement, preheating

[0064] The fixed-bed reactor 4 passes nitrogen from the nitrogen buffer tank 3 to replace the air, and the temperature is raised for preheating.

[0065] (3) Continuous response

[0066] When the temperature of the catalyst bed in the reactor reaches the reaction temperature, feed the raw material liquid 1 into the reactor through the double plunger micro metering pump 2, and fill the fixed bed reactor 4 with phosphotungstic acid modified Al 2 o 3 Catalyst, catalyst loading is 20g, reaction temperature is 40°C, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com