Sucralose continuous high-temperature reaction method and device thereof

A high-temperature reaction and sucralose technology, applied in series/parallel reactions, chemical instruments and methods, sugar derivatives, etc., can solve the problems of sucralose synthesis difficulties, increased production costs, and difficult control of the reaction, and achieve optimal pressure and warming environment, reducing energy consumption and equipment wear, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

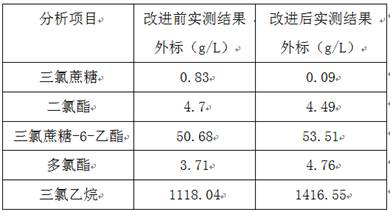

Embodiment 1

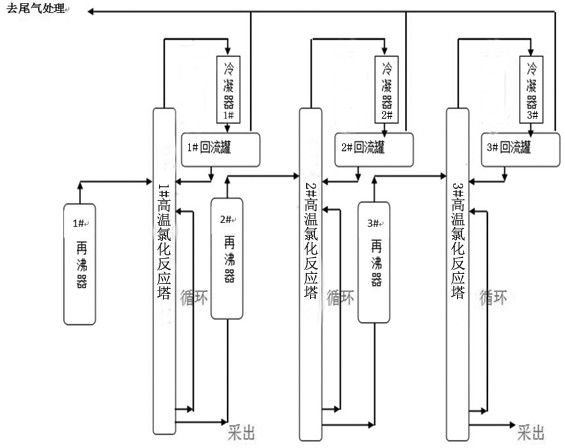

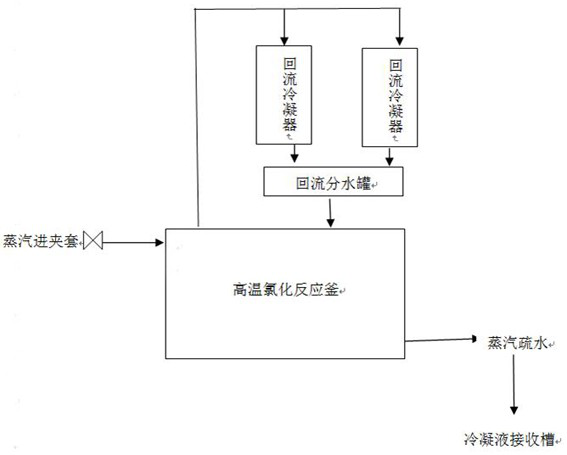

[0020] (1) Put the low-temperature chlorination liquid from the previous section into the 1# reboiler at an amount of 10m³ / h, and then send it to the 1# high-temperature chlorination reaction tower after being heated by the 1# reboiler to 35°C, and open the cycle. Control the temperature in the 1# high-temperature chlorination reaction tower to be 69°C and the pressure to be -3Mpa, and the gas (trichloroethane gas) from the top of the 1# high-temperature chlorination reaction tower is condensed by the condenser 1# (28°C) and enters 1# reflux tank, then return to 1# high-temperature chlorination reaction tower via 1# reflux tank, and circulate and heat for 30min to obtain solution A;

[0021] (2) Extract solution A from the bottom of 1# high-temperature chlorination reaction tower at an amount of 10m³ / h, heat it to 92°C with 2# reboiler, and then enter 2# high-temperature chlorination reaction tower, open the circulation, and control The temperature inside the 2# high-temperatu...

Embodiment 2

[0024] (1) Put the low-temperature chlorination liquid from the previous section into the 1# reboiler at an amount of 11m³ / h, and then send it to the 1# high-temperature chlorination reaction tower after being heated by the 1# reboiler to 32°C, and open the cycle. Control the temperature in the 1# high-temperature chlorination reaction tower to be 68°C and the pressure to be -4Mpa. The gas (trichloroethane gas) from the top of the 1# high-temperature chlorination reaction tower is condensed by the condenser 1# (22°C) and enters 1# reflux tank, then return to 1# high-temperature chlorination reaction tower via 1# reflux tank, and circulate and heat for 30min to obtain solution A;

[0025] (2) Extract solution A from the bottom of 1# high-temperature chlorination reaction tower at an amount of 11m³ / h, heat it to 90°C with 2# reboiler, and then enter 2# high-temperature chlorination reaction tower, open the circulation, and control The temperature inside the 2# high-temperature c...

Embodiment 3

[0028] (1) Put the low-temperature chlorination liquid from the previous section into the 1# reboiler at an amount of 12m³ / h, and then send it to the 1# high-temperature chlorination reaction tower after being heated by the 1# reboiler to 38°C, and open the cycle. Control the temperature in the 1# high-temperature chlorination reaction tower to be 71°C and the pressure to be -2Mpa. The gas (trichloroethane gas) from the top of the 1# high-temperature chlorination reaction tower is condensed by the condenser 1# (33°C) and enters 1# reflux tank, then return to 1# high-temperature chlorination reaction tower via 1# reflux tank, and circulate and heat for 30min to obtain solution A;

[0029] (2) Take solution A at 12m³ / h from the bottom of 1# high-temperature chlorination reaction tower, heat it to 93°C with 2# reboiler, then enter 2# high-temperature chlorination reaction tower, open the circulation, and control The temperature in the 2# high-temperature chlorination reaction tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com