Continuous reaction process and continuous reaction equipment of ammonium sulfamate

A technology of ammonium sulfamate and reaction equipment, applied in the direction of sulfamic acid, nitrogen and non-metallic compounds, etc., can solve the problems of inability to achieve continuous reaction, uneven heat distribution, long reaction time, etc., so that it is not easy to decompose raw materials and Hydrolysis, high raw material utilization rate, uniform and stable reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

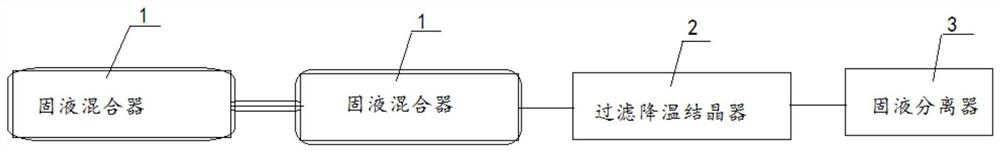

[0028] Such as figure 1 As shown, the present embodiment provides a kind of continuous reaction equipment of ammonium sulfamate, comprising reactor, and reactor is 2 solid-liquid mixers 1 connected in series by pipeline; Solid-liquid mixer 1 and connecting pipeline between are all arranged It has temperature control equipment; it also includes a filtration and cooling crystallizer 2 communicated with the discharge port of the solid-liquid mixer 1, and a solid-liquid separator 3 communicated with the discharge port of the filtration and cooling crystallizer 2 through pipelines. Wherein, the solid-liquid mixer 1 is a pump type high-speed shear mixer. The high-speed shear solid-liquid mixer is a high-speed shear solid-liquid mixer with a rotational speed greater than 2000r / min.

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that the solid-liquid mixer 1 is a horizontal pipeline high-speed shear solid-liquid mixer driven by a motor, and the motor shaft of the motor is arranged along the axial direction of the pipeline. The high-speed shear solid-liquid mixer is a high-speed shear solid-liquid mixer with a rotational speed greater than 2000r / min.

Embodiment 3

[0032] The difference between this embodiment and Embodiment 1 is that the temperature control equipment in the reactor is a jacket arranged on the outer ring of the solid-liquid mixer 1 and its connecting pipes, and a temperature control medium is introduced into the jacket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com