Method for carrying out hydrosilylation reaction by using activated carbon fiber immobilized noble metal catalyst

A noble metal catalyst and activated carbon fiber technology, which is applied in the field of modified synthesis of supported catalysts, can solve the problems of cumbersome filtration and low immobilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Take 15 pieces of activated carbon fiber (ACF) felts with a length of 0.9m, a width of 0.5m, and a thickness of 0.3cm, soak them in analytically pure ethanol solution for 15-30min, wash them three times with deionized water, and finally place them in an oven at 100°C. Dry inside and set aside. The treated activated carbon fiber (ACF) felt was soaked in 2% isopropanol solution of chloroplatinic acid, subjected to thermosonic treatment at 60°C for 60 minutes, taken out and put into an oven, and dried at 70°C. Put the dried activated carbon fiber (ACF) felt into the polytetrafluoroethylene tube to make fixed-bed reactor 1 and fixed-bed reactor 2. After calculation, the activated carbon fiber in each fixed-bed reactor is immobilized in the precious metal catalyst. The Pt loading is 0.35-0.5%.

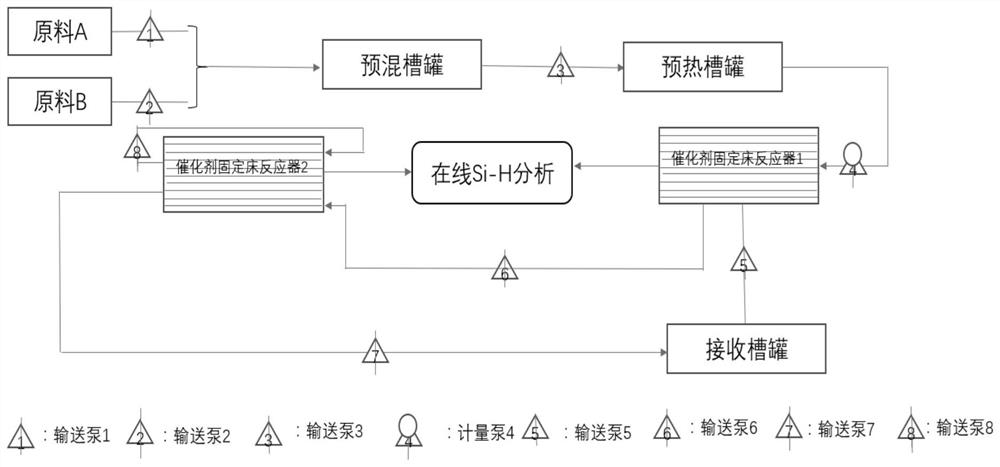

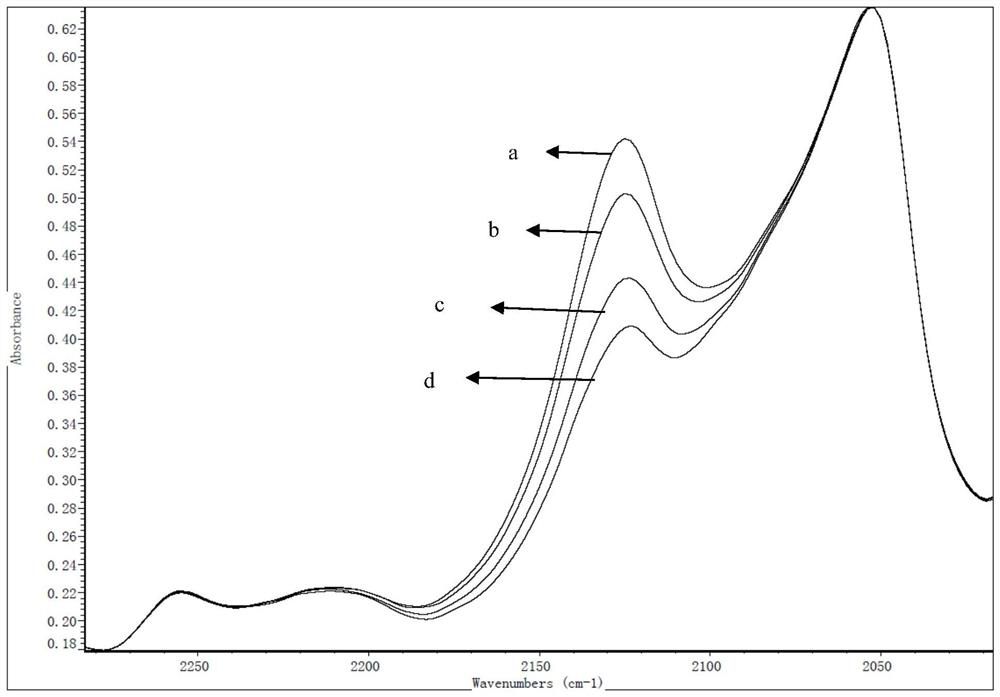

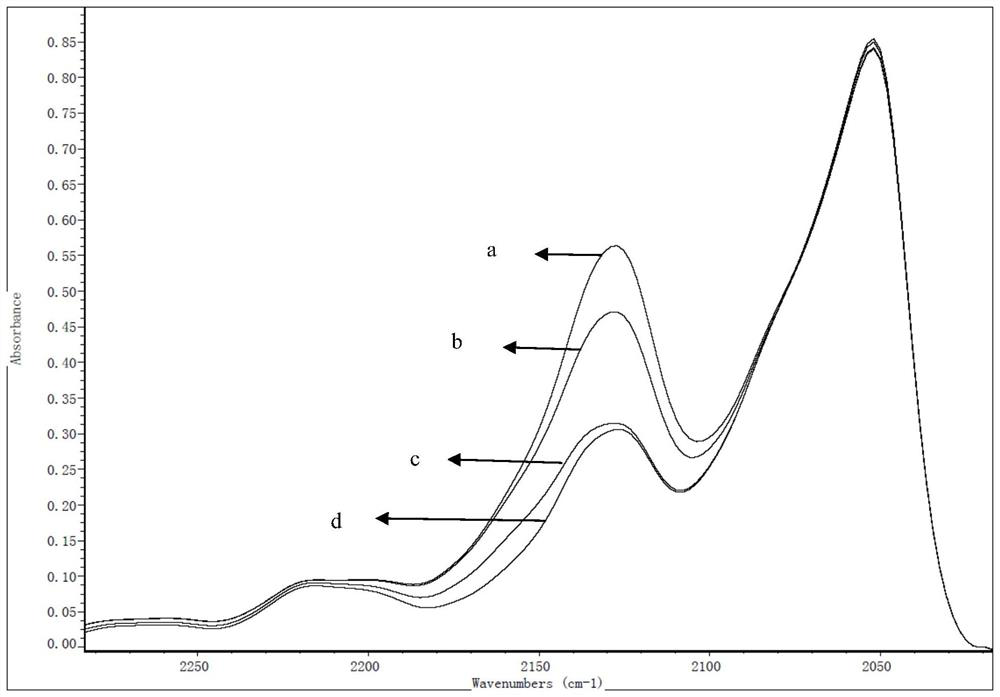

[0058] as attached figure 1 The schematic diagram of the process is used to assemble the reaction equipment. 25Kg of vinyl glycidyl ether was added to raw material tank A, and 110...

Embodiment 2

[0060] The reaction equipment in Example 1 was cleaned, and the fixed-bed reactor 1 was dried as the reaction equipment in Example 2. 36kg of vinyltriethoxysilane was added to raw material tank A, and 110Kg of terminal hydrogen-containing silicone oil with a molecular weight of 1100g / mol was added to raw material tank B. Turn on delivery pump 1 and delivery pump 2 to deliver the two raw materials to the premix tank for 30 minutes of premixing. Then the pre-mixed material is transported to the preheating tank with a delivery pump and heated to 60°C, and the preheated material is transported to the catalyst fixed bed reactor 1 with a temperature of 70°C at a delivery speed of 1.413ml / min reaction. On-line infrared was used to monitor the progress of the reaction, and it was found that after reacting in the fixed bed reactor 1 for 20 minutes, Si-H was basically reacted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com