System and process for continuous synthesis of 3-(n,n-dimethylamino)-n,n-dimethylpropionamide without catalyst

A technology of dimethylpropionamide and dimethylamino, which is applied in the system and process field of catalyst-free continuous synthesis of 3-(N,N-dimethylamino)-N,N-dimethylpropionamide, and can solve the problem of reaction Long time, equipment corrosion, unstable energy consumption and other problems, to achieve the effect of reducing the amount of by-products and the loss of dimethylamine, reducing the generation of side reactions, and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

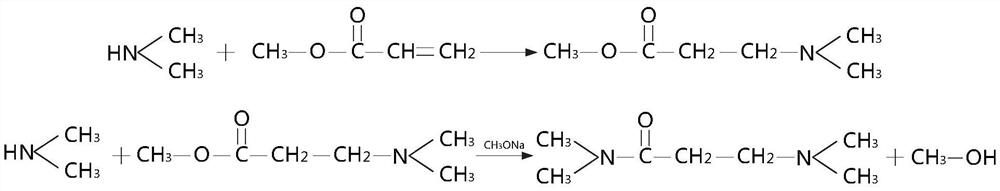

[0034] The third embodiment of the present invention provides a process for the continuous synthesis of 3-(N,N-dimethylamino)-N,N-dimethylpropionamide without catalyst, and provides the above-mentioned continuous synthesis of 3-(N,N-dimethylamino) without catalyst. N,N-dimethylamino)-N,N-dimethylpropionamide system, methyl acrylate and dimethylamine enter the plate heat exchanger and heat to 10~50℃ for reaction, and then enter the buffer storage tank for buffering , enter the pipeline reactor through the material pump for continuous reaction, and the temperature and pressure in the pipeline reactor are respectively adjusted to 180-260°C and 5.5-15MPa.

[0035] The residence time in the pipeline reactor affects the conversion rate of methyl 3-(N,N-dimethylamino)propionate. The longer the residence time, the higher the conversion rate of methyl 3-(N,N-dimethylamino)propionate. , the residence time of the present invention is 104-160min.

[0036] In some embodiments of this embo...

Embodiment

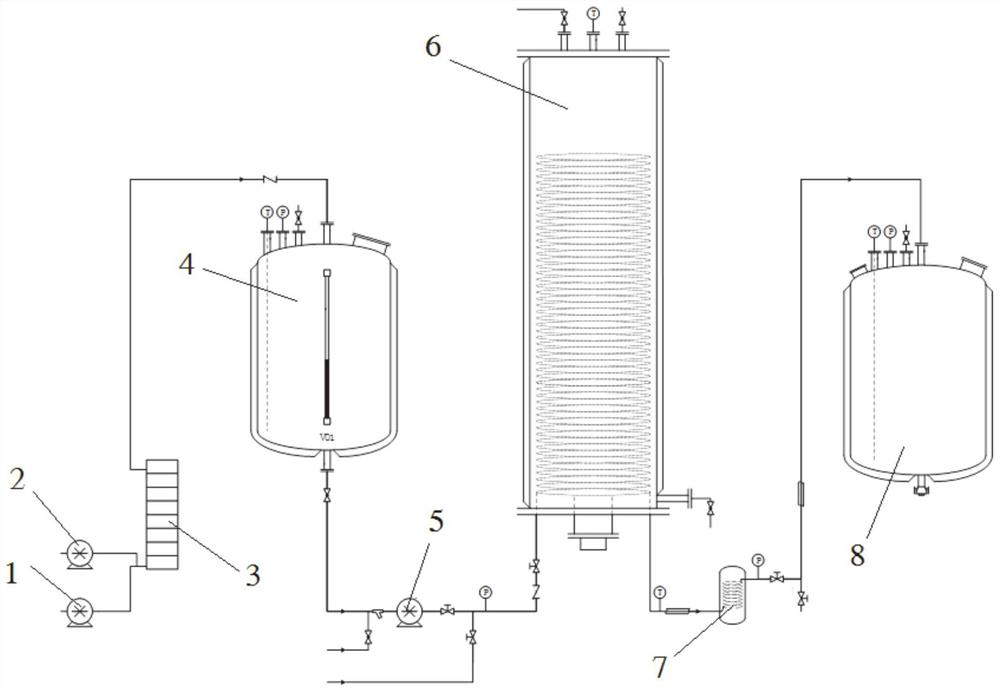

[0044] A system for the continuous synthesis of 3-(N,N-dimethylamino)-N,N-dimethylpropionamide without catalyst, such as figure 1 As shown, according to the material flow direction, it includes a plate heat exchanger 3, a buffer storage tank 4, an addition product mixing pump 5, a pipeline reactor 6, a cooler 7, and a product storage tank 8. The material inlet of the plate heat exchanger 3 is connected to the dimethylamine pump 1 and the methyl acrylate pump 2 at the same time.

[0045] Among them, the liquid holding capacity of the plate heat exchanger is 2100ml. The pipeline reactor is a pipeline reactor with a pipeline outer diameter of 6 mm, a wall thickness of 1 mm and a length of 1000 m. The pipeline reactor includes an outer shell and an inner coil. The outer shell is mainly used to heat the heat medium to provide heat for the inner coil. The inner coil is used as a material reaction container. The coil rises in a spiral shape to ensure compliance with the minimum bend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com