Preparation method of immobilized lipase with purified cotton towel as carrier

A technology for immobilizing lipase and lipase, which is applied in the direction of being immobilized on/in an organic carrier, can solve the problems of increasing the production cost of immobilized enzyme, long immobilization period, long cross-linking time, etc., and achieves good industrialization. Application prospects, good operating stability, and the effect of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

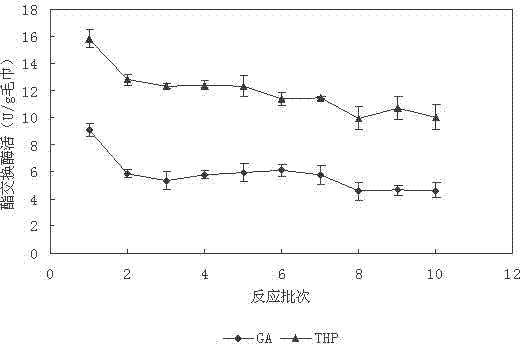

[0055] Embodiment 1, GA is the single factor optimization of cross-linking agent immobilized lipase

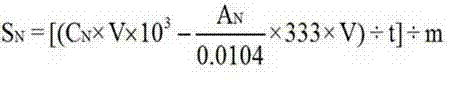

[0056] 1 Pure cotton towel absorbs 1.5~6.0mg / ml polyethyleneimine with a pH of 4.0~10.0. After the adsorption is completed, add porcine pancreas lipase aqueous solution prepared with distilled water and shake it on a constant temperature air shaker at 0~55°C. After the adsorption is completed, remove the supernatant, and then use 0.05-0.30% cross-linking agent GA with a pH of 4.0-10.0 to cross-link the towel adsorbed with enzyme and polyethyleneimine. The cross-linking time is 5-200min. After completion, take out the towel, wash the towel with pH 4.5 acetic acid buffer until no protein is eluted, dry at room temperature to obtain immobilized lipase, collect the supernatant, cross-linked solution and eluate, and measure the protein content. Then the protein load of immobilized lipase was calculated, and the best single factor condition of immobilized porcine pancreatic lipase w...

Embodiment 2

[0057] Embodiment two, the response surface experiment of immobilized porcine pancreatic lipase:

[0058]Based on the single factor experiment, the concentration of polyethyleneimine (2.0~4.0mg / ml), the concentration of glutaraldehyde (0.1%~0.3%), and the crosslinking time (10~110min) were the influencing factors, and stearic acid The specific enzyme activity (U / g towel) of transesterification between vinyl ester and pentanol was taken as the response value, and a three-factor three-level response surface experiment was designed using Design Expert 8.0.4.0 software to obtain the best condition for lipase immobilization: PEI concentration 3.37mg / ml, GA concentration 0.26%, cross-linking time 50.45min, the theoretical value of the specific enzyme activity of porcine pancreatic lipase catalyzing the transesterification reaction of vinyl stearate and amyl alcohol is 5.03U / g towel, and the actual verification value is 4.99 U / g towels.

Embodiment 3

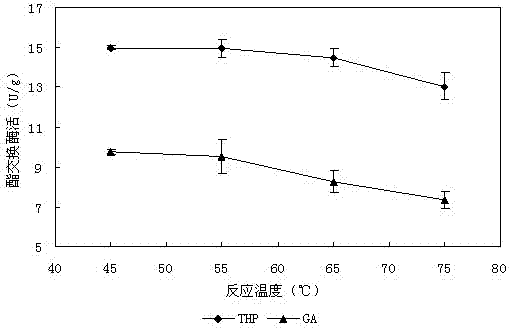

[0059] Embodiment three, using THP as cross-linking agent immobilized lipase:

[0060] 0.2g / piece of towel, add 0.1~0.9ml 3.37mg / ml PEI solution with pH 7.0, after the adsorption is completed, add the lipase solution for esterification prepared with distilled water, and add the lipase solution at 0~40℃ with the number of revolutions of the shaker Shake at 260rpm, the solution becomes clear, pour out the supernatant, put the PEI and enzyme-adsorbed towel into 2ml of 0.05%~0.50% THP solution, crosslink at 0~40℃ for 5~200min, crosslink After completion, take out the towel, wash the towel with acetate buffer solution of pH 5.0 until no protein is washed down, and dry at room temperature to obtain immobilized lipase, which is evaluated by the enzyme activity of catalyzing the transesterification of vinyl n-butyrate and amyl alcohol index. When the concentration of THP was 0.05%, 0.10%, and 0.50%, the ester exchange enzyme activity of lipase for immobilized esterification was 16.20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com