Preparation method for ionic liquid hybrid imprinted material

An ionic liquid and imprinted material technology, which is applied in the field of preparation of ionic liquid hybrid imprinted materials, can solve the problems of large workload, long time consumption and high cost, and achieves the effects of simple preparation method, environmental friendliness and simplicity, and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

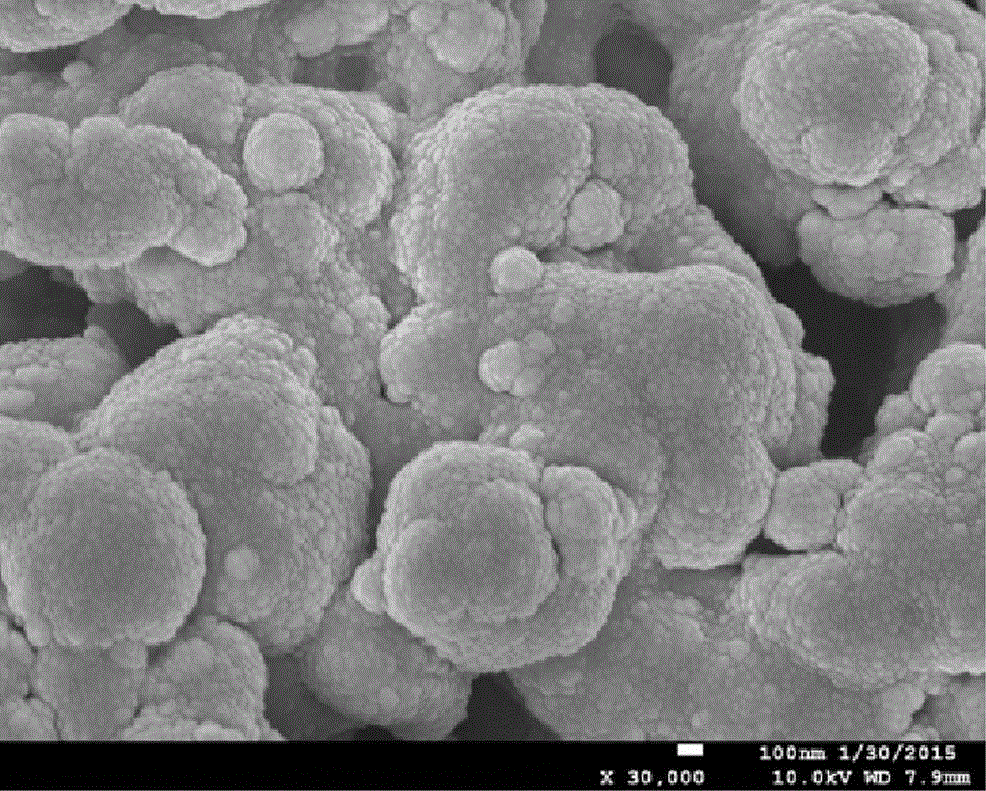

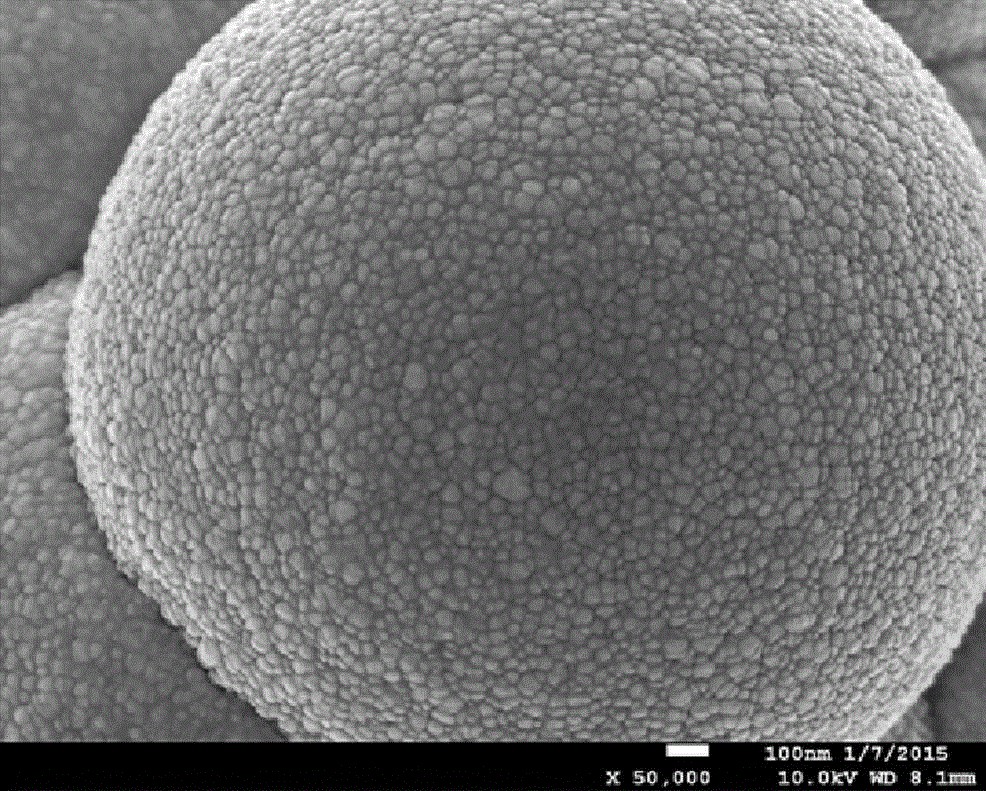

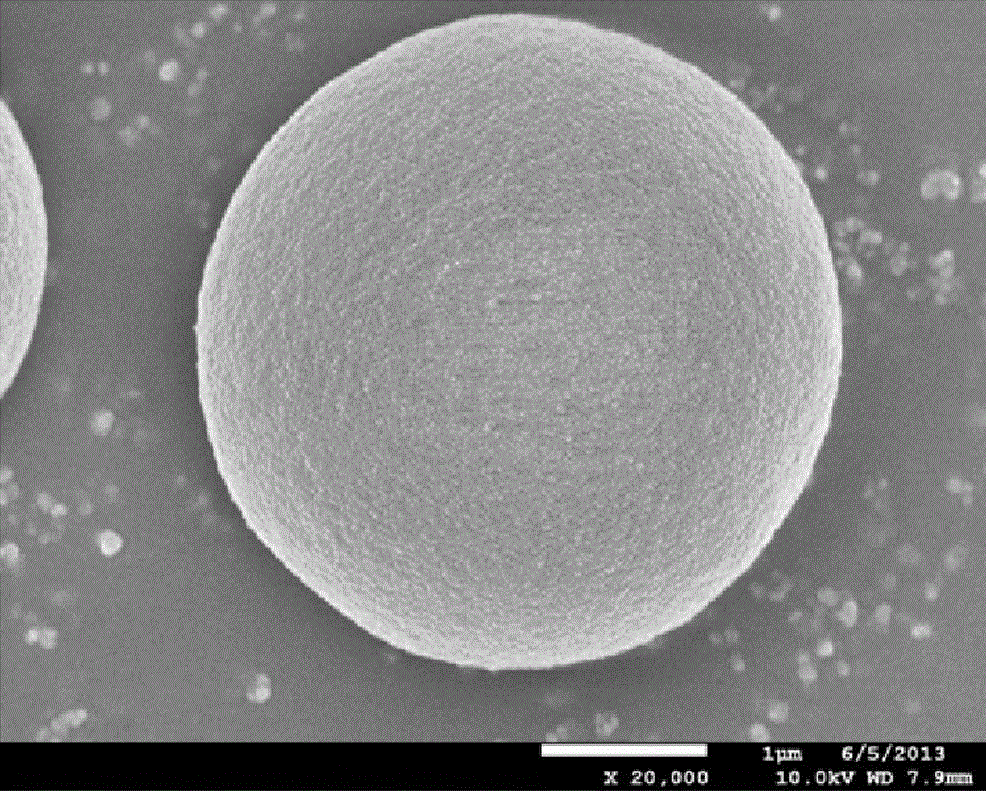

Image

Examples

Embodiment 1

[0038] (1) Preparation of ionic liquid: put 2mmol of 3-chloropropyltriethoxysilane and 2mmol of 1-allylimidazole into a reaction flask, mix them with ultrasonic waves, blow in nitrogen gas, seal them, and place them in an oil bath at 100°C Reaction under the conditions for 24h to obtain a hybrid ionic liquid;

[0039] (2) Preparation of the organic phase: take 2mmol of ionic liquid, add 0.5mmol of kinetin, 2mmol of methacrylic acid, 15mmol of ethylene glycol dimethacrylate and 0.4mmol of azobisisobutyronitrile in sequence, and add 10mL of acetonitrile fully dissolved to obtain an organic phase; the number of moles of the ionic liquid is calculated by the number of moles of allyl imidazole;

[0040] (3) Preparation of the inorganic phase: put 10 mmol of ethyl orthosilicate in 30 mL of acetonitrile, add 1 mL of water, and stir at room temperature with 1 mL of ammonia water to completely dissolve it to obtain the inorganic phase;

[0041] (4) Polymerization reaction: Introduce n...

Embodiment 2

[0046] (1) Preparation of ionic liquid: put 4mmol of 3-chloropropyltrimethoxysilane and 4mmol of 1-allylimidazole into a reaction bottle, mix them with ultrasonic waves, blow in nitrogen gas, seal them, and store them in an oil bath at 100°C Under reaction 12h obtains the hybrid ionic liquid;

[0047] (2) Preparation of the organic phase: Take 4 mmol of ionic liquid hybrid monomer, add 0.5 mmol of tryptophan, 2 mmol of acrylamide, 15 mmol of ethylene glycol dimethacrylate and 0.2 mmol of azobisisobutyronitrile in sequence, Fully dissolve with 10mL of acetonitrile to obtain an organic phase; the number of moles of the ionic liquid is calculated by the number of moles of allyl imidazole;

[0048] (3) Preparation of the inorganic phase: put 10 mmol of ethyl orthosilicate in 30 mL of acetonitrile, add 1 mL of water, and stir at room temperature with 1 mL of ammonia water to completely dissolve it to obtain the inorganic phase;

[0049] (4) Polymerization reaction: Introduce nitro...

Embodiment 3

[0053] (1) Preparation of ionic liquid: Put 2mmol of 3-chloropropyltriethoxysilane and 6mmol of 1-acetylimidazole into a reaction bottle, mix it with ultrasonic, blow in nitrogen gas, seal it, and store it in an oil solution at 80°C Under bath condition, react for 24h to obtain hybrid ionic liquid;

[0054] (2) Preparation of the organic phase: take 1 mmol of ionic liquid, add 1 mmol of p-sulfanilamide, 3 mmol of acrylamide, 17 mmol of ethylene glycol dimethacrylate and 0.6 mmol of azobisisoheptanonitrile in sequence, and use 10 mL Acetonitrile is fully dissolved to obtain an organic phase; the number of moles of the ionic liquid is calculated by the number of moles of 1-acetylimidazole;

[0055] (3) Preparation of the inorganic phase: put 20mmol of methyltrimethoxysilane in 120mL of acetonitrile, add 5mL of water, and stir at room temperature with 5mL of ammonia water to dissolve completely to obtain the inorganic phase;

[0056] (4) Polymerization reaction: Introduce nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com