Method for preparing 1,1,1,4,4,4-hexafluoro-2-butyne through gas phase method

A gas-phase method and butyne technology, which is applied in the field of gas-phase method for preparing 1,1,1,4,4,4-hexafluoro-2-butyne, can solve the problem of metal salt wastewater generation, high raw material price and low purity. problem, to achieve the effect of low cost, reduced production cost and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

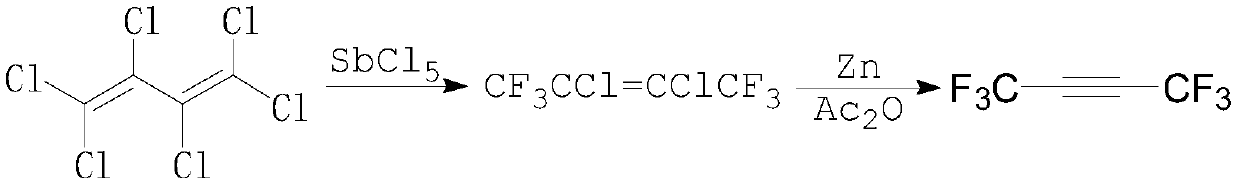

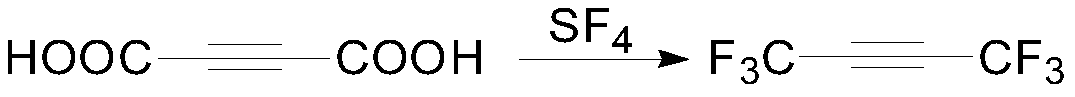

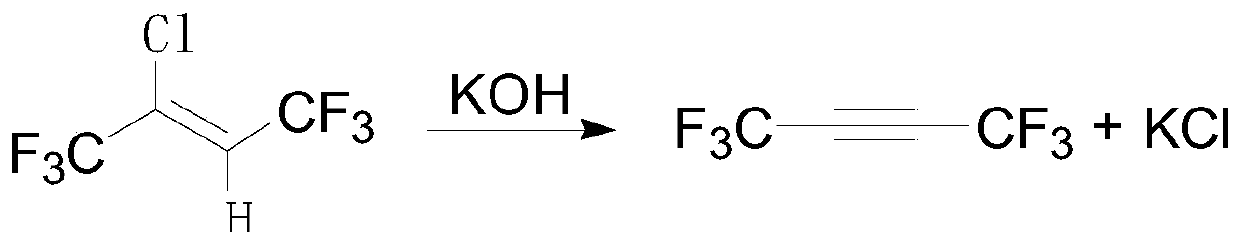

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Pass hexafluoro-2-chloro-2-butene at a flow rate of 15.9g / min into a Hastelloy tube fixed-bed reactor with 30ml of barium chloride catalyst and an inner diameter of 30mm, control the contact time for 1s, and the reaction temperature at 100 °C, the crude product was collected and analyzed by chromatography. The conversion rate of hexafluoro-2-chloro-2-butene was 97%, and the selectivity of 1,1,1,4,4,4-hexafluoro-2-butyne was 99%.

Embodiment 2

[0045] Pass hexafluoro-2-chloro-2-butene at a flow rate of 0.53g / min into a silicon carbide tube fixed-bed reactor with 30ml of ferric chloride catalyst and an inner diameter of 30mm, control the contact time for 30s, and the reaction temperature at 300°C , the crude product was collected and analyzed by chromatography, the conversion rate was 96%, and the selectivity of 1,1,1,4,4,4-hexafluoro-2-butyne was 98%.

Embodiment 3

[0047] Pass hexafluoro-2-chloro-2-butene at a flow rate of 3.18g / min into a 30mm lnconel tube fixed-bed reactor equipped with 30ml of cesium fluoride catalyst, control the contact time for 5s, and the reaction temperature at 150°C. After the crude product was collected and analyzed by chromatography, the conversion rate of hexafluoro-2-chloro-2-butene was 95.5%, and the selectivity of 1,1,1,4,4,4-hexafluoro-2-butyne was 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com