Method for synthesizing (3-amino-3-cyano) propyl methyl butyl phosphite based on micro-channel reactor

A technology of propyl methyl butyl phosphite and micro-channel reactor is applied in the field of glufosinate-ammonium intermediate synthesis, which can solve the problems of increased consumption of raw materials, low production efficiency, increased waste water and waste salt and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

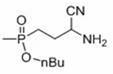

[0030] A method for synthesizing (3-amino-3-cyano) propylmethyl phosphite butyl based on a microchannel reactor, comprising the following steps:

[0031] A, open the heating system of microchannel reactor, make system warm up to reaction temperature 30 ℃;

[0032] B. Metering 3-(butoxymethylphosphoryl)-1-cyanopropyl acetate, water and ammonia gas into the microchannel reactor (wherein, 3-(butoxymethylphosphoryl)- 1-cyanopropyl acetate 0.3mol / min, ammonia gas 0.6mol / min, water 1.5mol / min), the reaction pressure is normal pressure;

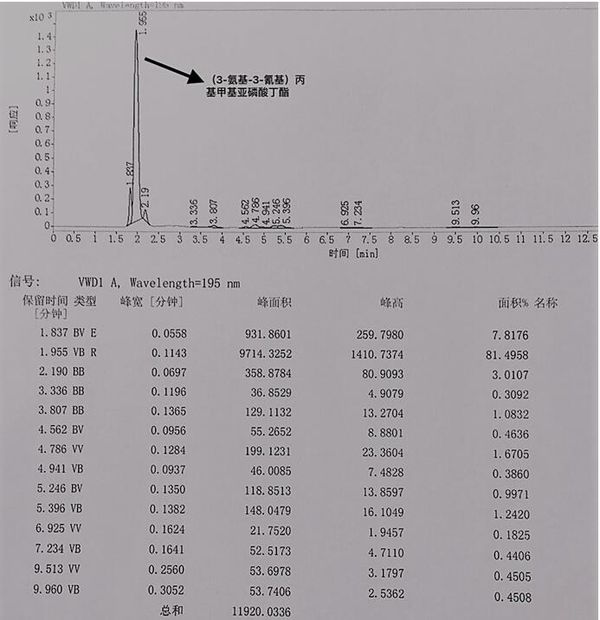

[0033] C. The three materials introduced in step B stay and react in the microchannel reactor for 1min, and after the ammonia gas is recovered by flash evaporation, the dilute ammonia solution of (3-amino-3-cyano)propylmethyl butyl phosphite is collected Product 1142.3g, as NH 3 The calculated ammonia content is 0.08%, and the external standard quantitative detection of high performance liquid chromatography shows that the content of (3-amino-3-cy...

Embodiment 2

[0035] A method for synthesizing (3-amino-3-cyano) propylmethyl phosphite butyl based on a microchannel reactor, comprising the following steps:

[0036] A, open the heating system of microchannel reactor, make system warm up to reaction temperature 70 ℃;

[0037] B. Metering 3-(butoxymethylphosphoryl)-1-cyanopropyl acetate, water and ammonia gas into the microchannel reactor (wherein, 3-(butoxymethylphosphoryl)- 1-cyanopropyl acetate 0.3mol / min, ammonia gas 3mol / min, water 6mol / min), the reaction pressure is 1.8MPa;

[0038] C. The three materials introduced in step B stay and react in the microchannel reactor for 10 minutes. After the ammonia gas is recovered by flash evaporation, the dilute ammonia solution of (3-amino-3-cyano)propylmethyl phosphite butyl is collected Product 1991.6g, in NH 3 The calculated ammonia content was 0.86%, and the external standard quantitative detection of high-performance liquid chromatography was carried out. The content of (3-amino-3-cyano)...

Embodiment 3

[0040] A method for synthesizing (3-amino-3-cyano) propylmethyl phosphite butyl based on a microchannel reactor, comprising the following steps:

[0041] A, open the heating system of microchannel reactor, make system warm up to reaction temperature 50 ℃;

[0042] B. Metering 3-(butoxymethylphosphoryl)-1-cyanopropyl acetate, water and ammonia gas into the microchannel reactor (wherein, 3-(butoxymethylphosphoryl)- 1-cyanopropyl acetate 0.3mol / min, ammonia gas 0.6mol / min, water 6mol / min), the reaction pressure is 1MPa;

[0043] C. The three materials introduced in step B stay and react in the microchannel reactor for 3 minutes, and after the ammonia gas is recovered by flash evaporation, the dilute ammonia solution of (3-amino-3-cyano)propylmethyl butyl phosphite is collected Product 1972.1g, in NH 3 The calculated ammonia content is 0.02%, and the external standard quantitative detection of high performance liquid chromatography shows that the content of (3-amino-3-cyano) pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com