Patents

Literature

242 results about "Ammonium glufosinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Agricultural thickening synergistic agent and glufosinate solution prepared from same

ActiveCN103210916AGood wetting and synergistic effectImprove performanceBiocideAnimal repellantsActive agentSurface-active agents

The invention discloses an agricultural thickening synergistic agent which comprises the following components by weight percent: 10-30% of fatty alcohol polyoxyethylene ether sulfate, 10-20% of alkyl glycoside, 5-25% of sodium lauroyl sarcosinate, 5-10% of fatty alcohol polyoxyethylene ether, 5-15% of ammonium sulfate and the balance of water. The invention also discloses a glufosinate solution containing the agricultural thickening synergistic agent. The agricultural thickening synergistic agent has the characteristics of being good in wetting synergistic action and stable in performances, and is good in thickening synergistic effect; the glufosinate solution prepared from the agricultural thickening synergistic agent has higher viscosity, is beneficial to improving the adhesive force and the moisturizing performance of a liquid medicine, is beneficial to the internal absorption and the conductivity of glufosinate, and can promote the pesticide effect to be fully exerted; and furthermore, the agricultural thickening synergistic agent also has excellent biodegradability, and is high in safety to the environment and organisms, thus well fitting the development requirements of future agricultural surface active agents.

Owner:范强

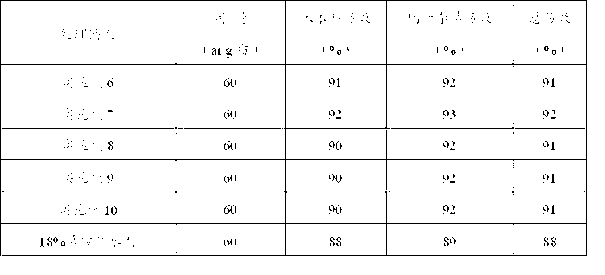

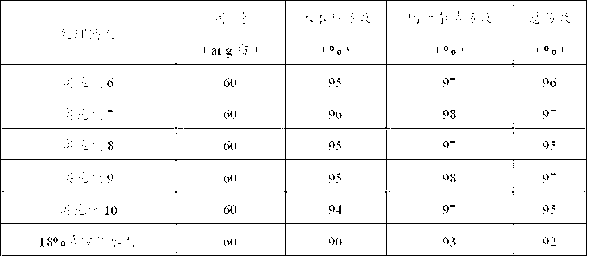

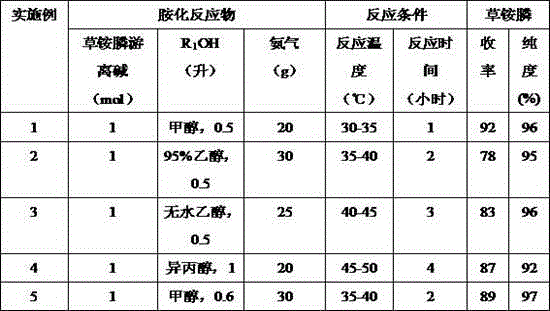

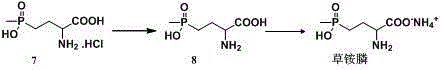

Method for preparing high-purity glufosinate-ammonium by adopting organic alkali deacidification method

InactiveCN104059102ALow Inorganic Salt ContentHigh purityGroup 5/15 element organic compoundsAmmonium chloride mixtureInorganic salts

The invention discloses a method for preparing high-purity glufosinate-ammonium by adopting an organic alkali deacidification method, belonging to the technical field of preparation of the glufosinate-ammonium. The method comprises the following steps: by taking glufosinate-ammonium hydrochloride as a raw material, dissolving the glufosinate-ammonium hydrochloride into alcohol R1OH, and thermally filtering out inorganic salt and mechanical impurities; partially concentrating the filtrate, adding organic alkali R2R3R4N for a deacidification reaction, cooling and filtering out glufosinate-ammonium free alkali; adding a crude glufosinate-ammonium free alkali product into the alcohol R1OH, introducing ammonia gas, cooling and filtering to obtain a glufosinate-ammonium product; and recycling an alcohol solvent from crystallization mother liquor of the free alkali, subsequently adding into an inorganic alkaline water solution for neutralization, separating out the organic alkali in the upper layer and directly using the organic alkali in the deacidification reaction. The method disclosed by the invention can be used for effectively removing a small amount of inorganic matters including ammonium chloride, sodium chloride, the mechanical impurities, hydrogen chloride and the like from the glufosinate-ammonium hydrochloride, also can be used for simply and conveniently preparing a high-purity glufosinate-ammonium product without introducing new impurities and organic byproducts and has good industrial application prospects.

Owner:ZHEJIANG UNIV OF TECH +2

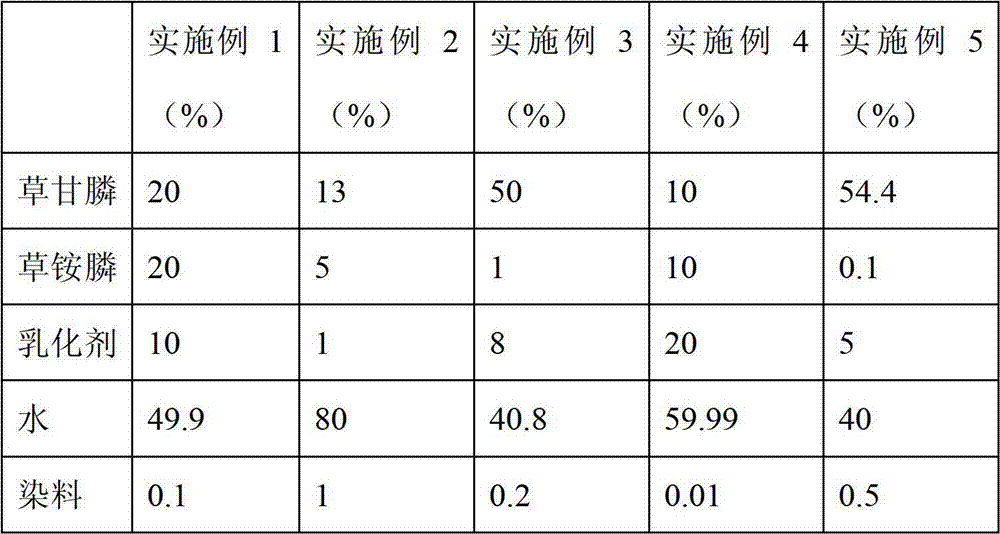

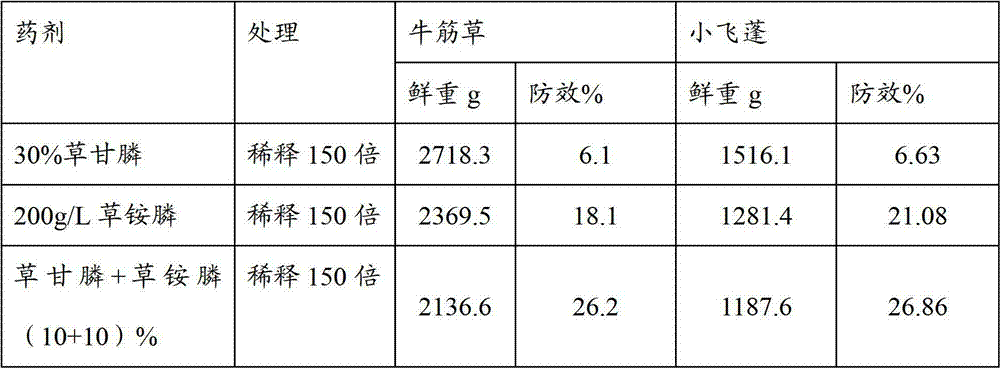

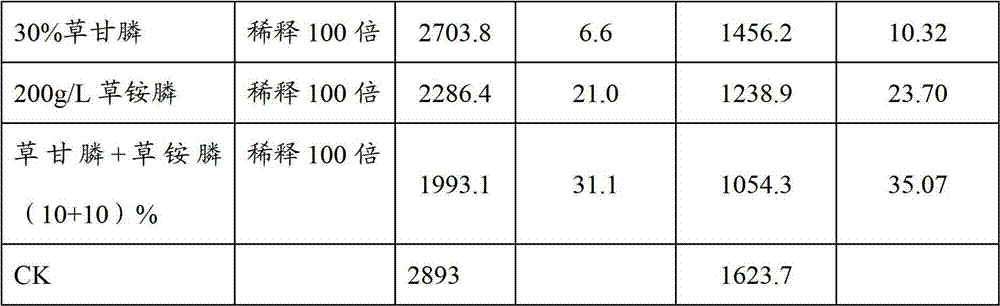

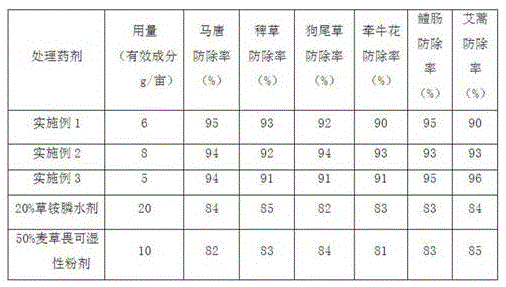

Weedicide composition and preparation method thereof

InactiveCN103168798AReduce use costFast weedingBiocideAnimal repellantsGlufosinate-ammoniumToxicology

The invention discloses a weedicide composition and a preparation method thereof, wherein the weedicide composition comprises the following components in percentage by weight: 1-50% of glyphosate and 0.1-50% of glufosinate-ammonium. The weedicide composition disclosed by the invention has the advantages that the glufosinate-ammonium can be compounded with the glyphosate, and the glufosinate-ammonium has no negative effect on the using effect of the glyphosate, so that the resistance problem of the single glufosinate is solved, the using cost of the glufosinate-ammonium is also effectively reduced, meanwhile, the weeding speed of the glufosinate is accelerated, and the using effect of a glufosinate product is also enhanced.

Owner:GUANGDONG ZHENGE BIOLOGICAL TECH CO LTD

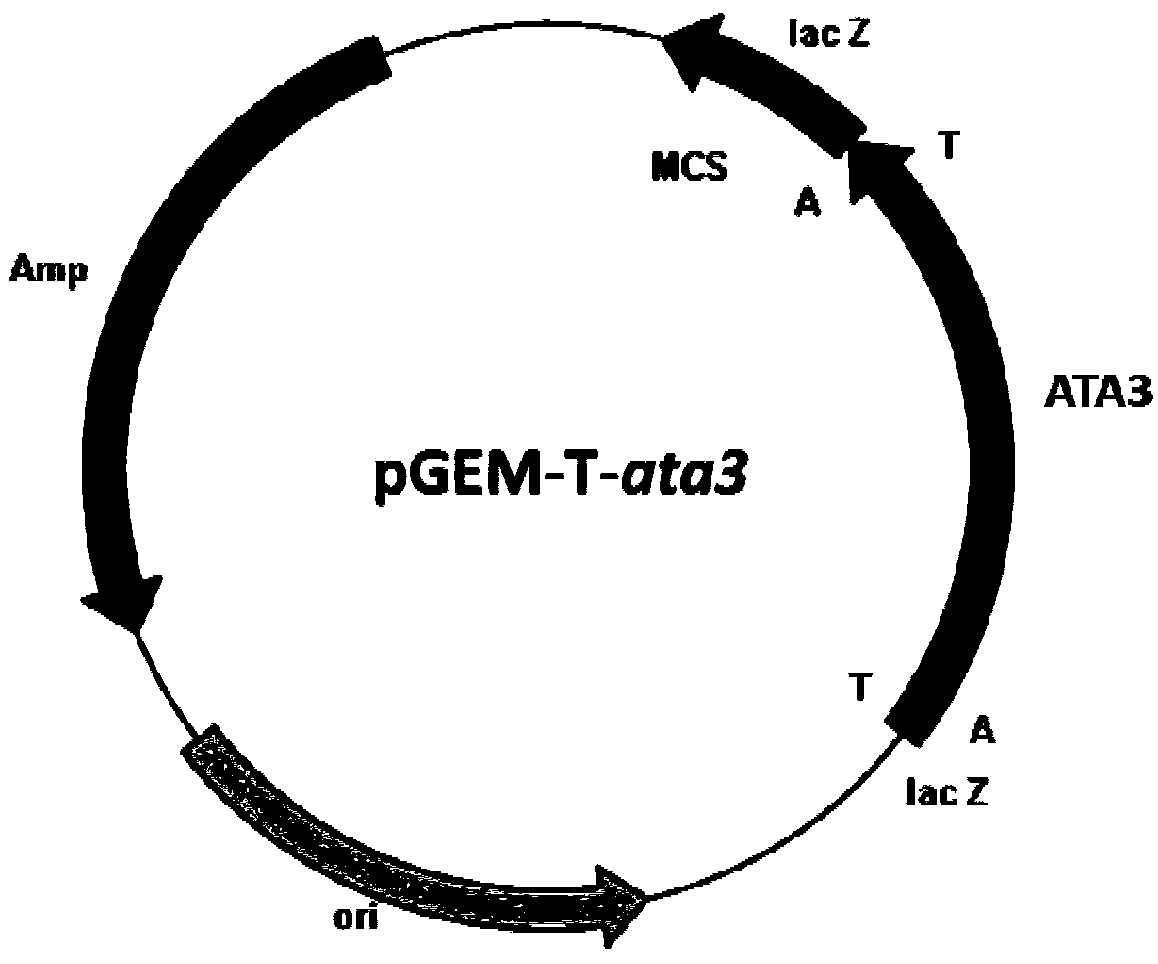

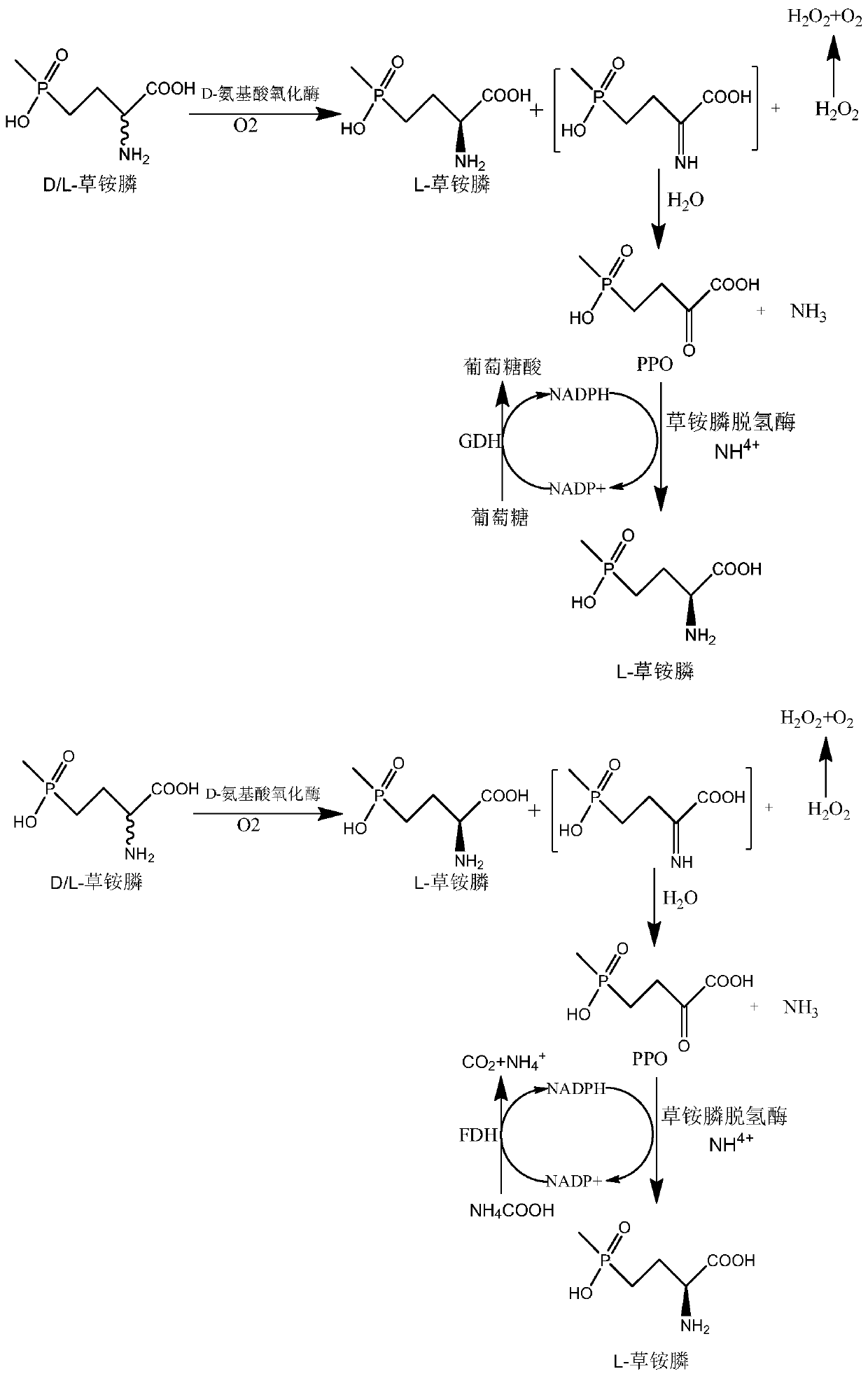

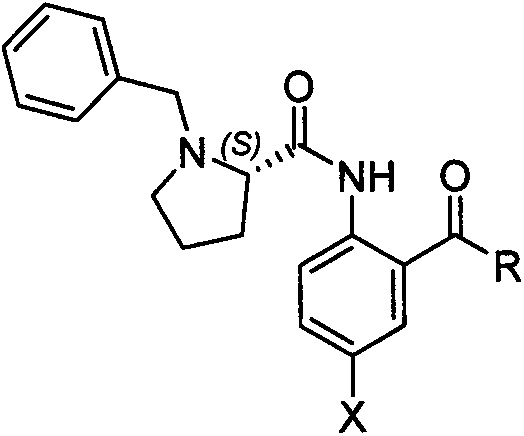

Transaminase, mutant and application thereof in production of L-glufosinate ammonium

The invention discloses transaminase, a mutant and application thereof in production of L-glufosinate ammonium. The mutant is characterized in that isoleucine at the 62nd site of amino acid in SEQ IDNO:2 is substituted by valine; serine at the 74th site is substituted by threonine; methionine at the 93rd site is substituted by isoleucine; tyrosine at the 167th site is substituted by phenylalanine; alanine at the 220th site is substituted by proline; arginine at the 282nd site is substituted by lysine; alanine at the 353rd site is substituted by serine; isoleucine at the 355th site is substituted by valine. The transaminase is characterized in that 4-(methyl hydroxyphosphoryl)-2-carbonyl-butyric acid is used as a primer to prepare the L-glufosinate ammonium, the transaminase product ee isgreater than 99.9%; the 4h primer conversion rate is 56.31%; the transaminase mutant product ee is greater than 99.9%, and the 4h primer conversion rate is 95.42%.

Owner:ZHEJIANG UNIV OF TECH

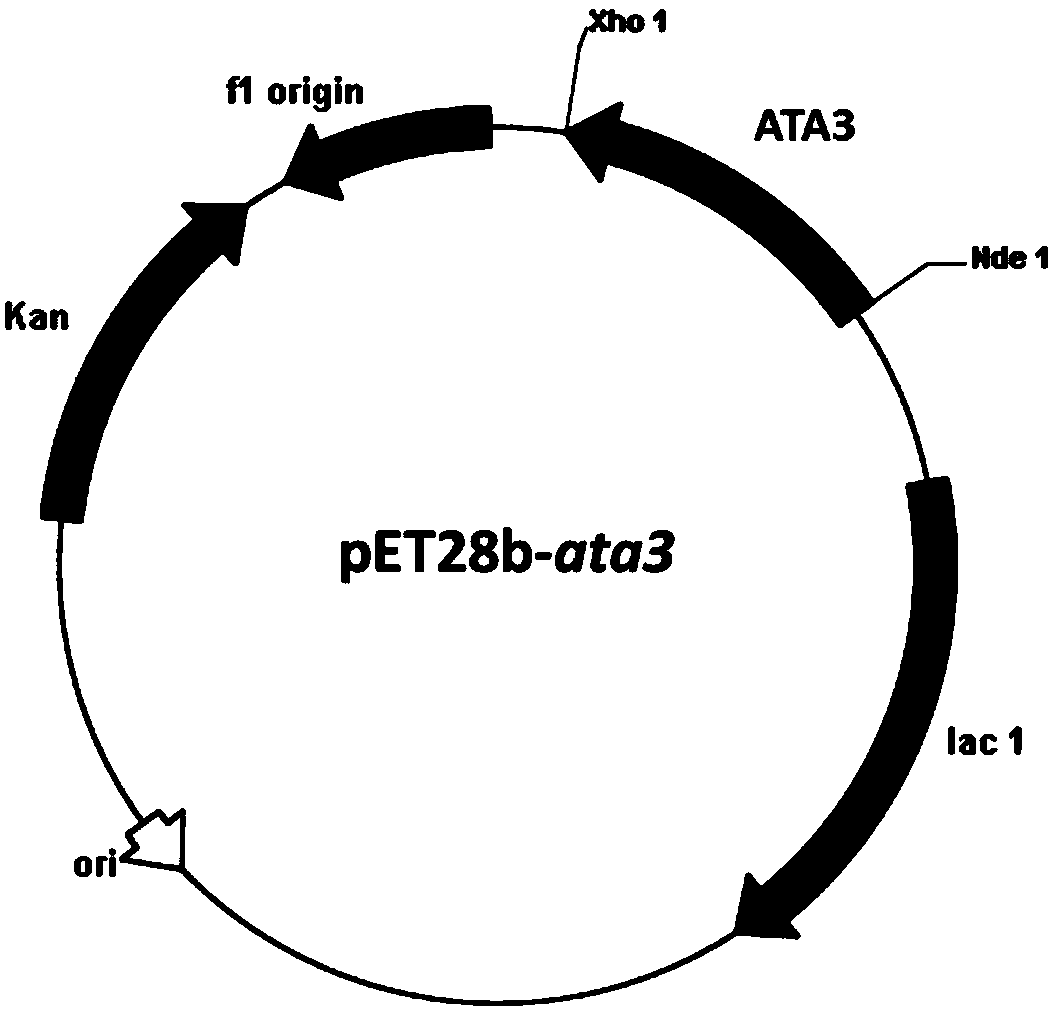

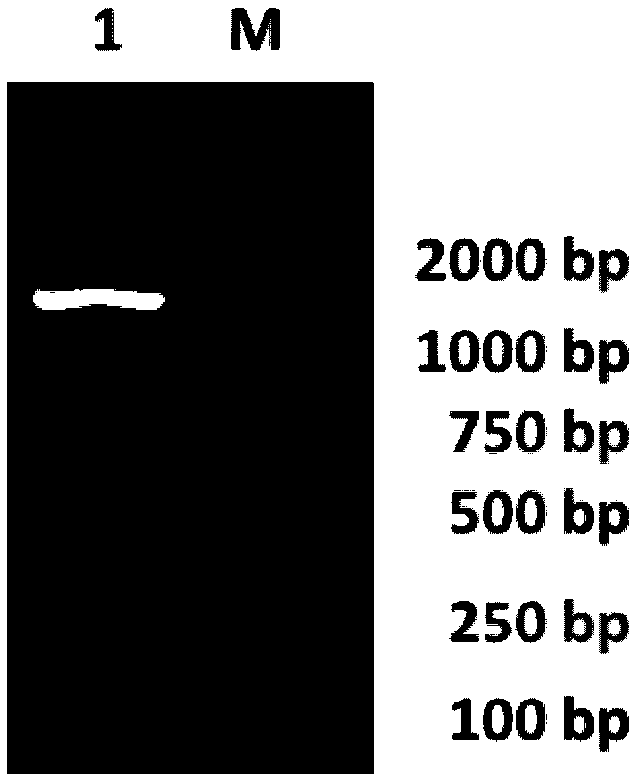

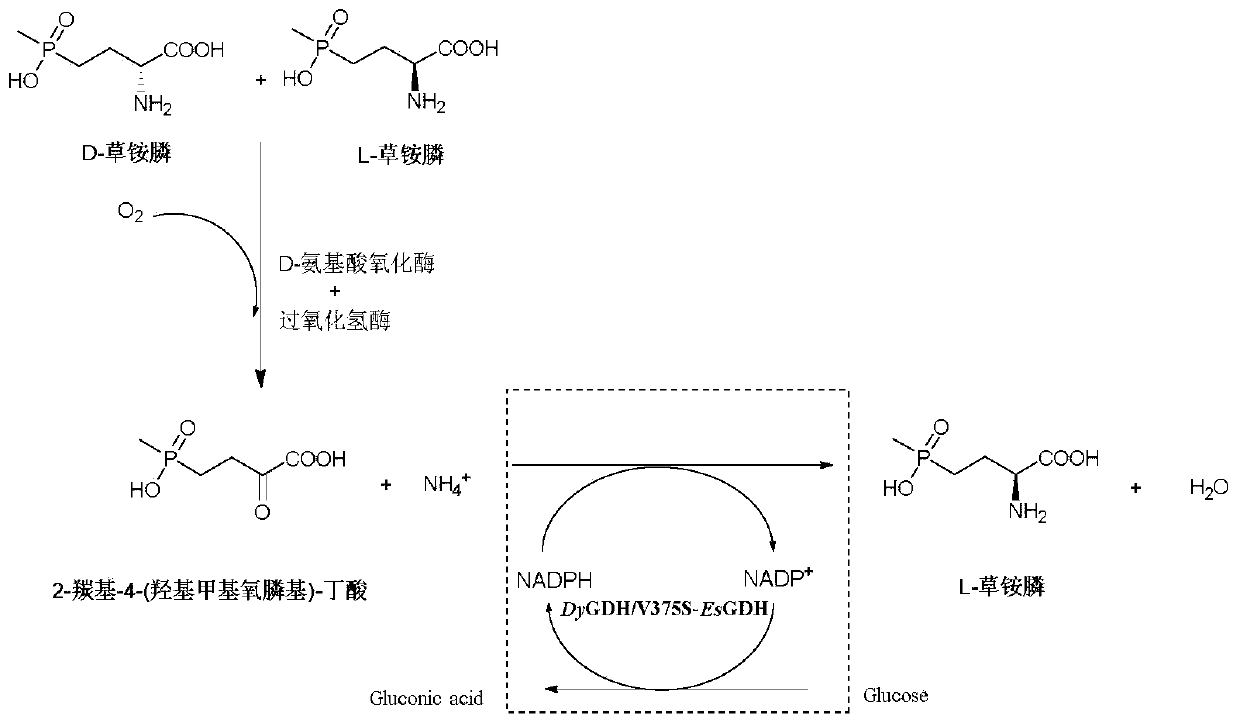

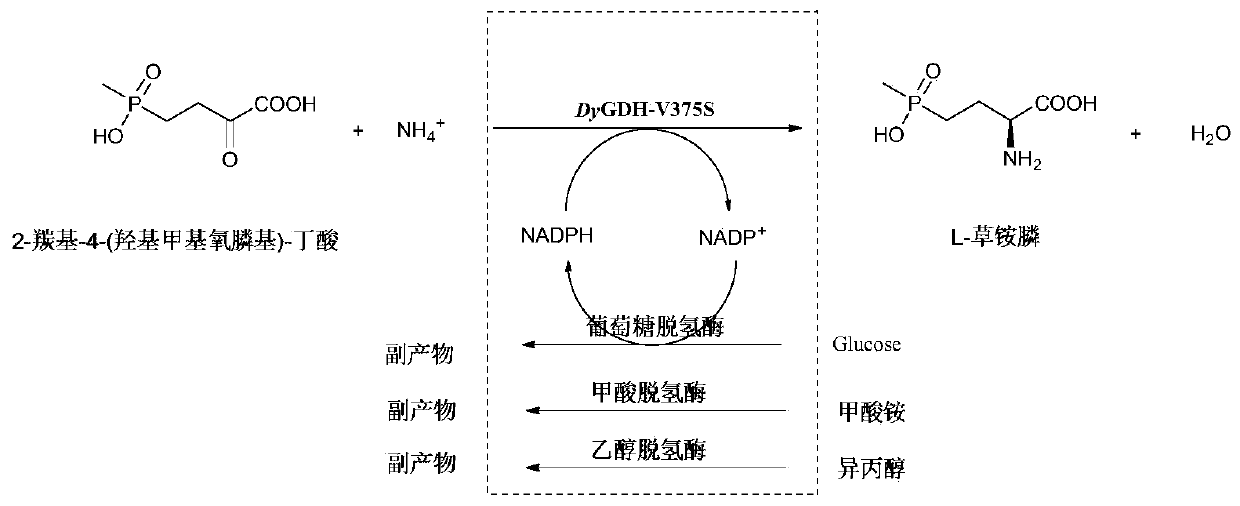

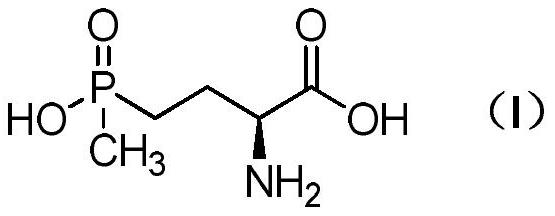

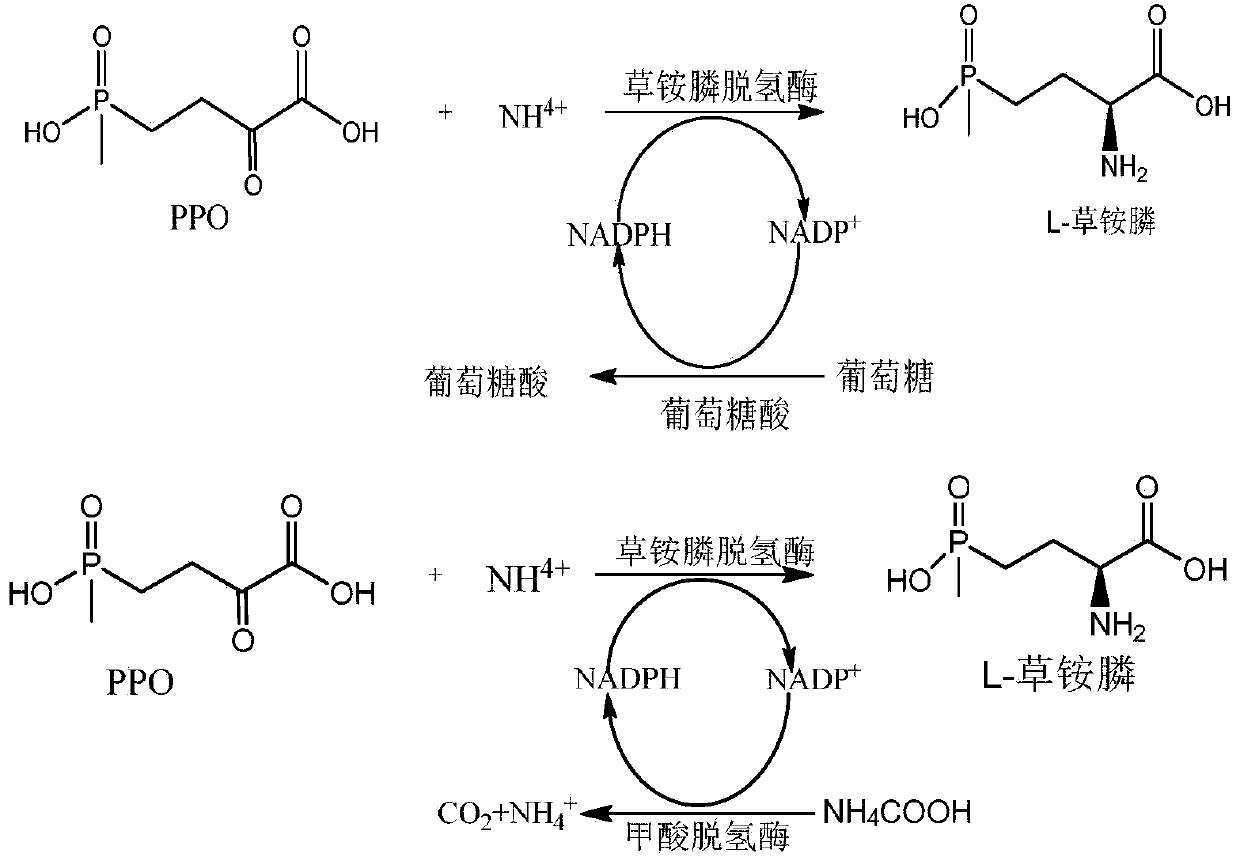

Glufosinate-ammonium dehydrogenase mutant, and application thereof in producing L-glufosinate-ammonium

ActiveCN110791484ASteps to remove the speed limitOxidoreductasesChemical recyclingSpecific enzymeButyrate

The invention discloses a glufosinate-ammonium dehydrogenase mutant, and application of the glufosinate-ammonium dehydrogenase mutant in producing ammonium 2-amino-4(hydroxymethylphosphinyl)-L-butanoate through multienzyme coupling. The glufosinate-ammonium dehydrogenase mutant is obtained through carrying out single mutation at a 375th site of amino acid as shown in SEQ ID No. 2, SEQ ID No. 4 andSEQ ID No. 6. The specific enzyme activity of the glufosinate-ammonium dehydrogenase mutant DyGDH-V3755 prepared through the invention is improved by 11 to 12 times compared with parent glufosinate-ammonium dehydrogenase, and the maximum feeding of the substrate ammonium 2-amino-4(hydroxymethylphosphinyl)-D / L-butanoate reaches to 800mM, so that the glufosinate-ammonium dehydrogenase mutant has abetter industrial application prospect.

Owner:ZHEJIANG UNIV OF TECH

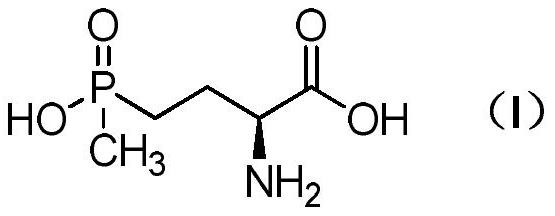

Method for preparing L-glufosinate-ammonium

ActiveCN111662325AHigh ee valueSimple stepsGroup 5/15 element organic compoundsHerbicides and algicidesChemical synthesisBiochemical engineering

The invention relates to a method for preparing L-glufosinate-ammonium. Compared with an existing method, the method of the invention is a new chemical synthesis route, is simple in steps, easily available in raw materials and controllable in cost, can obtain the L-glufosinate-ammonium product with the high ee value without chiral catalysis, and has potential industrial application value.

Owner:LIER CHEM CO LTD +1

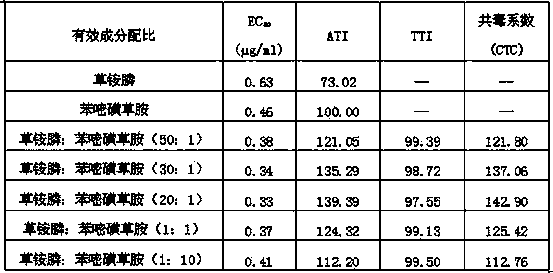

Herbicidal composition containing glufosinate-ammonium and saflufenacil

ActiveCN103392732ADelay drug resistanceEffective against weeds in non-cultivated landBiocideAnimal repellantsSaflufenacilPESTICIDE ADJUVANTS

The invention discloses a herbicidal composition containing glufosinate-ammonium and saflufenacil. The composition comprises active components of glufosinate-ammonium, and saflufenacil, and the balance of pesticide adjuvants. Glufosinate-ammonium and saflufenacil in the herbicidal composition are in a weight ratio of 50:1-1:10, and the total weight of glufosinate-ammonium and saflufenacil accounts for 2-80 wt% in the herbicidal composition. The herbicidal composition can be prepared into one of the followings: a suspension agent, an oil suspension agent, a water agent, a wettable powder and a water dispersion granule, according to the application requirements, and can be applied to control of weeds in no-crop field. The composition has control effect on weeds in no-crop field better than that of each single agent, and can reduce the dosage and delay drug resistance of weeds.

Owner:GUANGDONG ZHONGXUN AGRI TECH

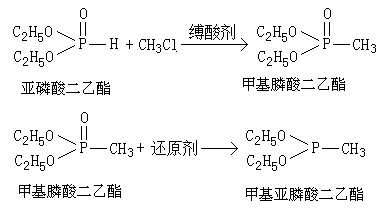

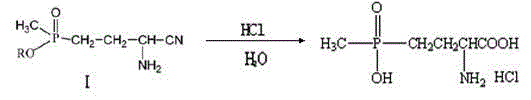

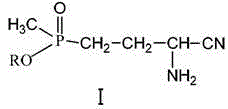

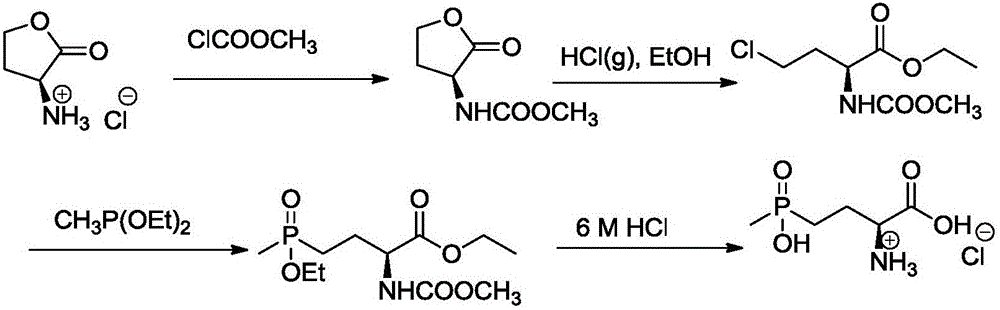

Synthetic method of diethyl methyl-phosphonite and glufosinate-ammonium

ActiveCN103319529AReduce manufacturing costReaction raw materials are cheap and easy to obtainGroup 5/15 element organic compoundsPhosphorous acidOrganic solvent

The invention discloses a synthetic method of diethyl methyl-phosphonite and glufosinate-ammonium. The synthetic method comprises the following steps: carrying out a reaction between diethyl phosphite and chloromethane gas in the presence of an acid binding agent to prepare diethyl methylphosphonite, and filtering after reaction, wherein the generated diethyl methylphosphonite exists in a filtrate; dropwisely adding an organic solvent, in which a reducing agent is dissolved, into the filtrate so as to reduce diethyl methylphosphonite into diethyl methyl-phosphonite, distilling a reaction solution after the reaction so as to obtain diethyl methyl-phosphonite, and preparing glufosinate-ammonium by using diethyl methyl-phosphonite as an intermediate. According to the invention, diethyl phosphite is used as a raw material; reaction raw materials are cheap and easily available; the reaction process is simple and easy to operate and is green and environmentally friendly; atom utilization rate is high; quality of the obtained product is good; yield is high; a new idea is provided for the synthesis of glufosinate-ammonium; preparation cost of glufosinate-ammonium is also reduced; and the synthetic method has wide application value.

Owner:SHANDONG WEIFANG RAINBOW CHEM

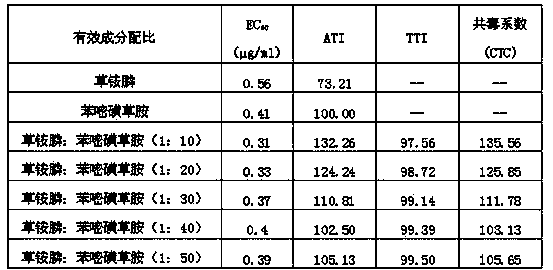

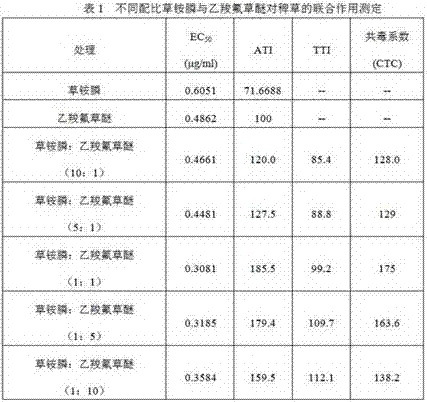

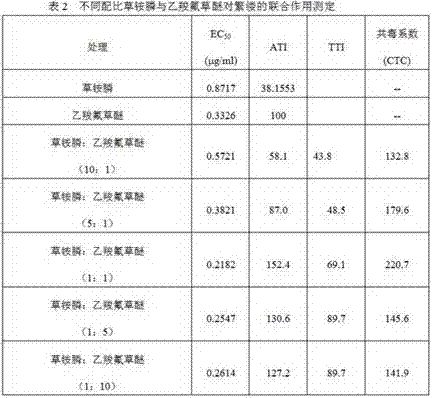

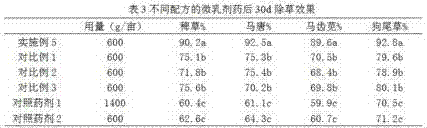

Pesticide micro-emulsion containing glufosinate ammonium and fluoroglycofen-ethyl

InactiveCN107156171AImprove control effectReduce the use of pesticidesBiocideAnimal repellantsSolventEmulsion

The invention discloses a pesticide micro-emulsion containing glufosinate ammonium and fluoroglycofen-ethyl. A weight part ratio of the glufosinate ammonium to the fluoroglycofen-ethyl in the micro-emulsion is 10:1 to 1:10, the weight sum of the glufosinate ammonium and fluoroglycofen-ethyl in the above pesticide composition is 1-30%, and the micro-emulsion also contains 3-20% of a solvent, 3-10% of an emulsifier, 1-15% of a synergist, and the balance of water. The pesticide micro-emulsion is suitable for controlling annual or perennial dicotylous and gramineous weeds and field broad leaf weeds. The micro-emulsion has an obvious synergistic control effect on the annual weeds than single doses, reduces the use dosage of a pesticide, reduces the pesticide use cost, prolongs the service life of medicines, reduces the unfavorable influences of the pesticides on the ecologic environment, and provides a certain technologic reference for the preparation of a high-salt system micro-emulsion.

Owner:PLANT PROTECTION RES INST OF GUANGDONG ACADEMY OF AGRI SCI

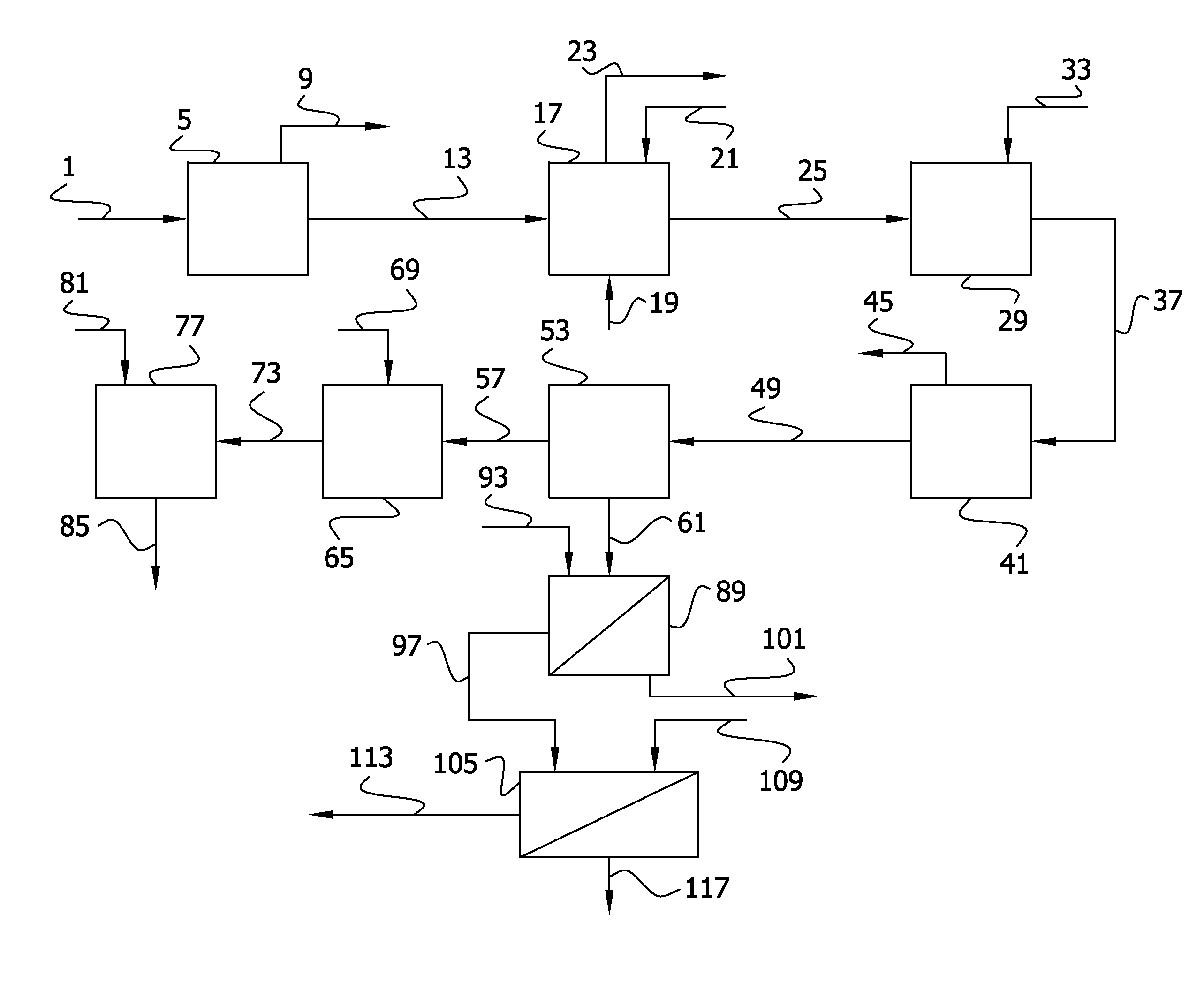

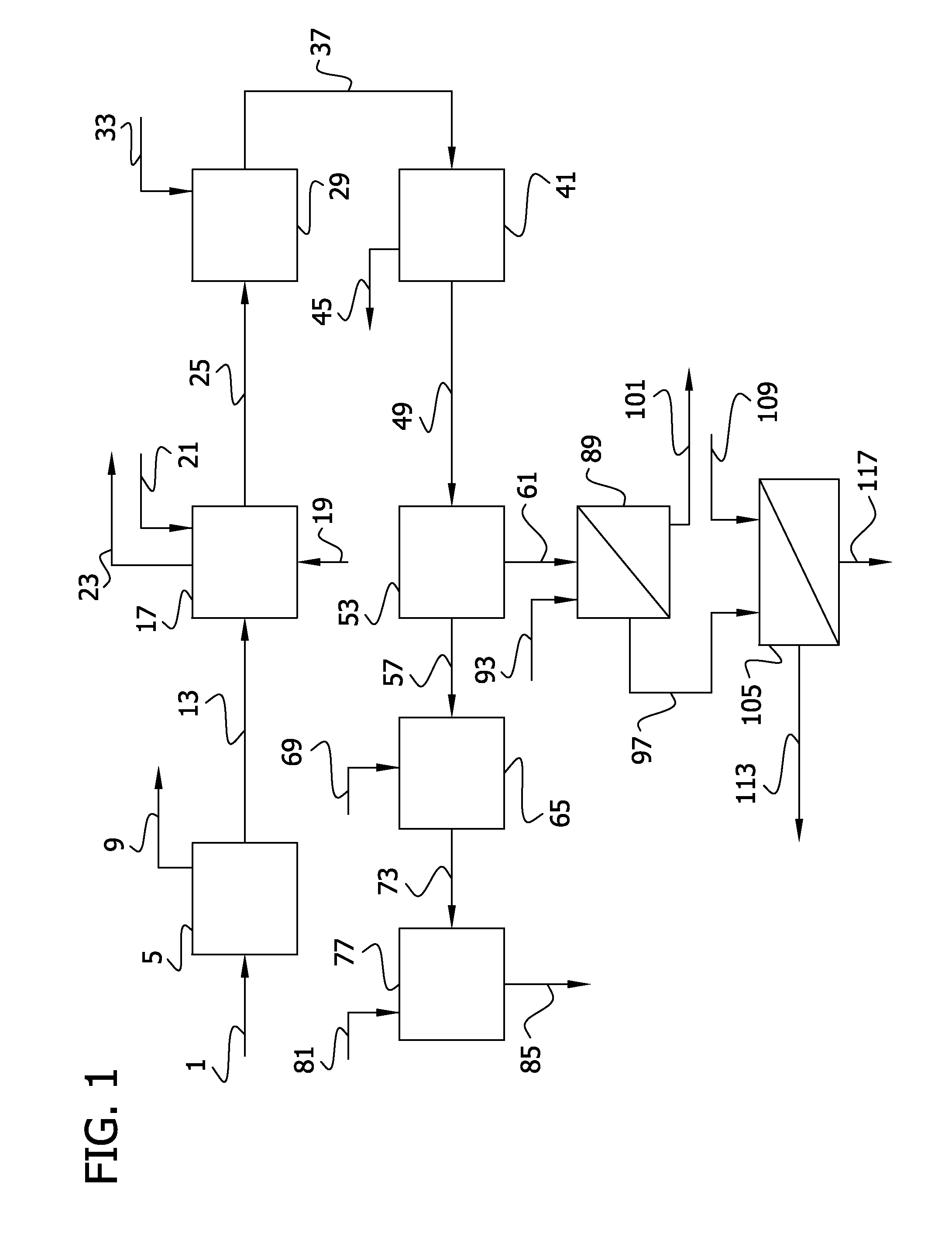

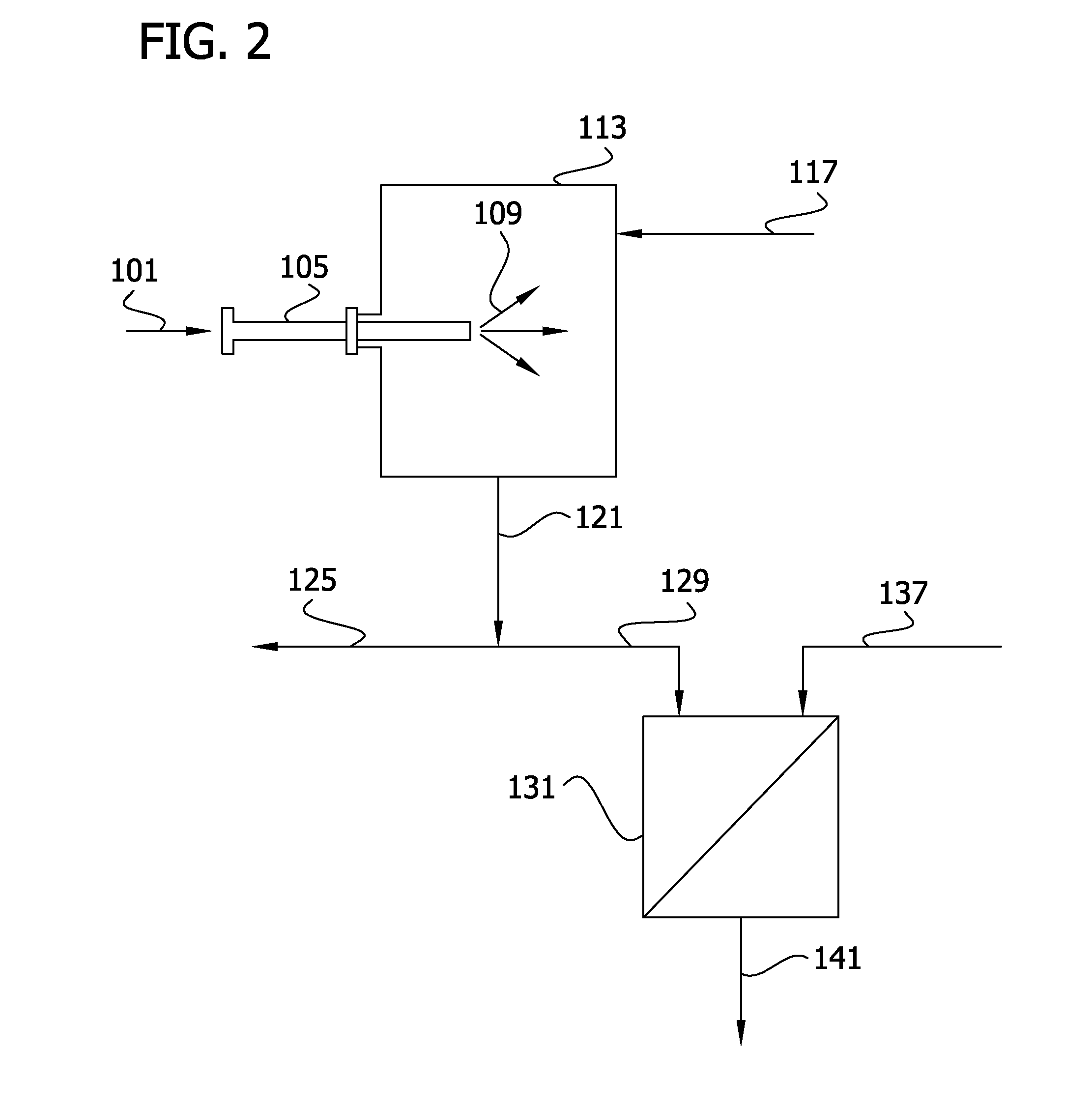

Recovery of phosphorus values and salt impurities from aqueous waste streams

The present invention generally relates to processes for recovery of phosphorus values and salt impurities from aqueous waste streams. In particular, the present invention relates to processes for recovery of phosphorus values and salt impurities from aqueous waste streams generated in the manufacture of phospho-herbicides, including N-(phosphonomethyl)glycine and glufosinate.

Owner:MONSANTO TECH LLC

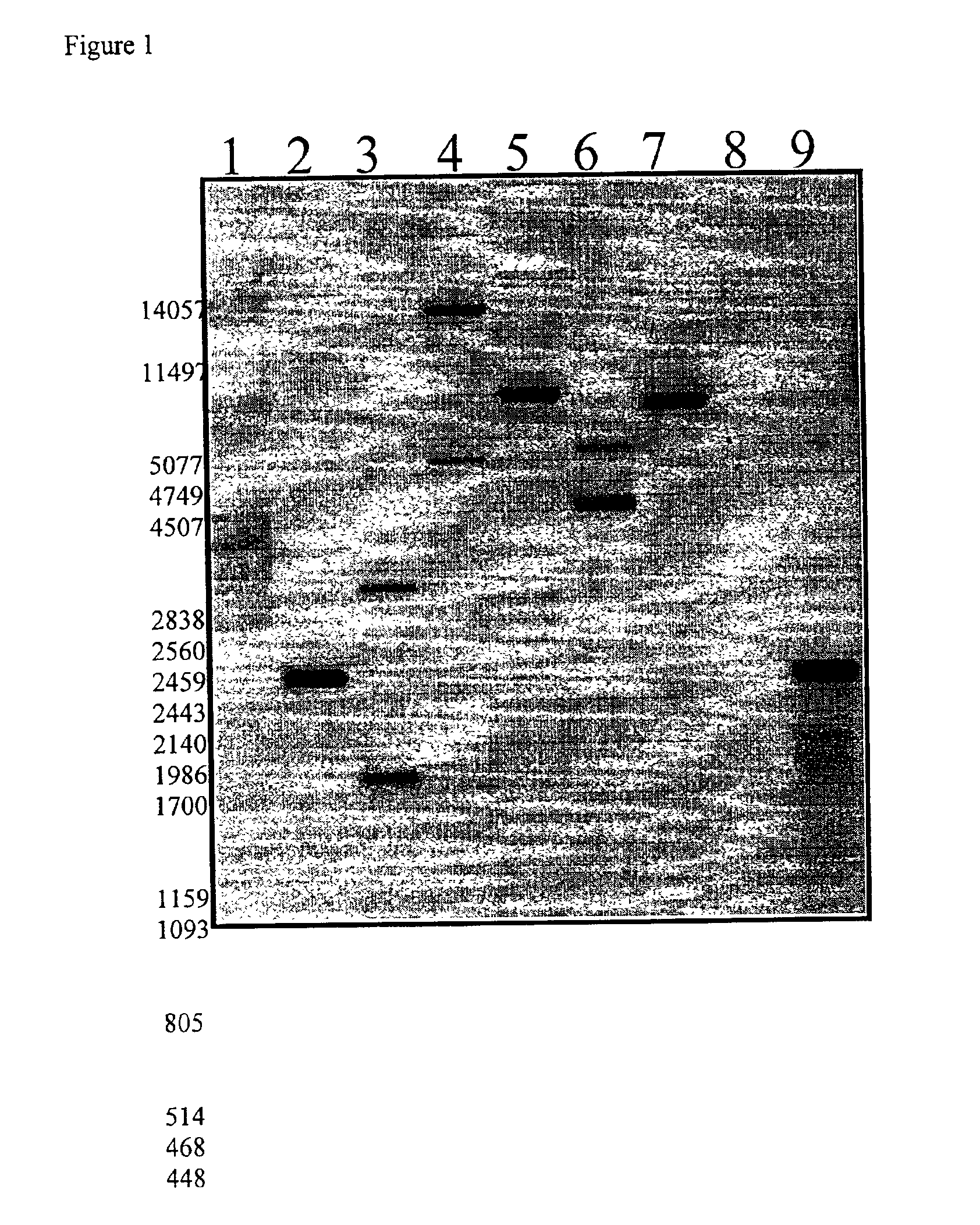

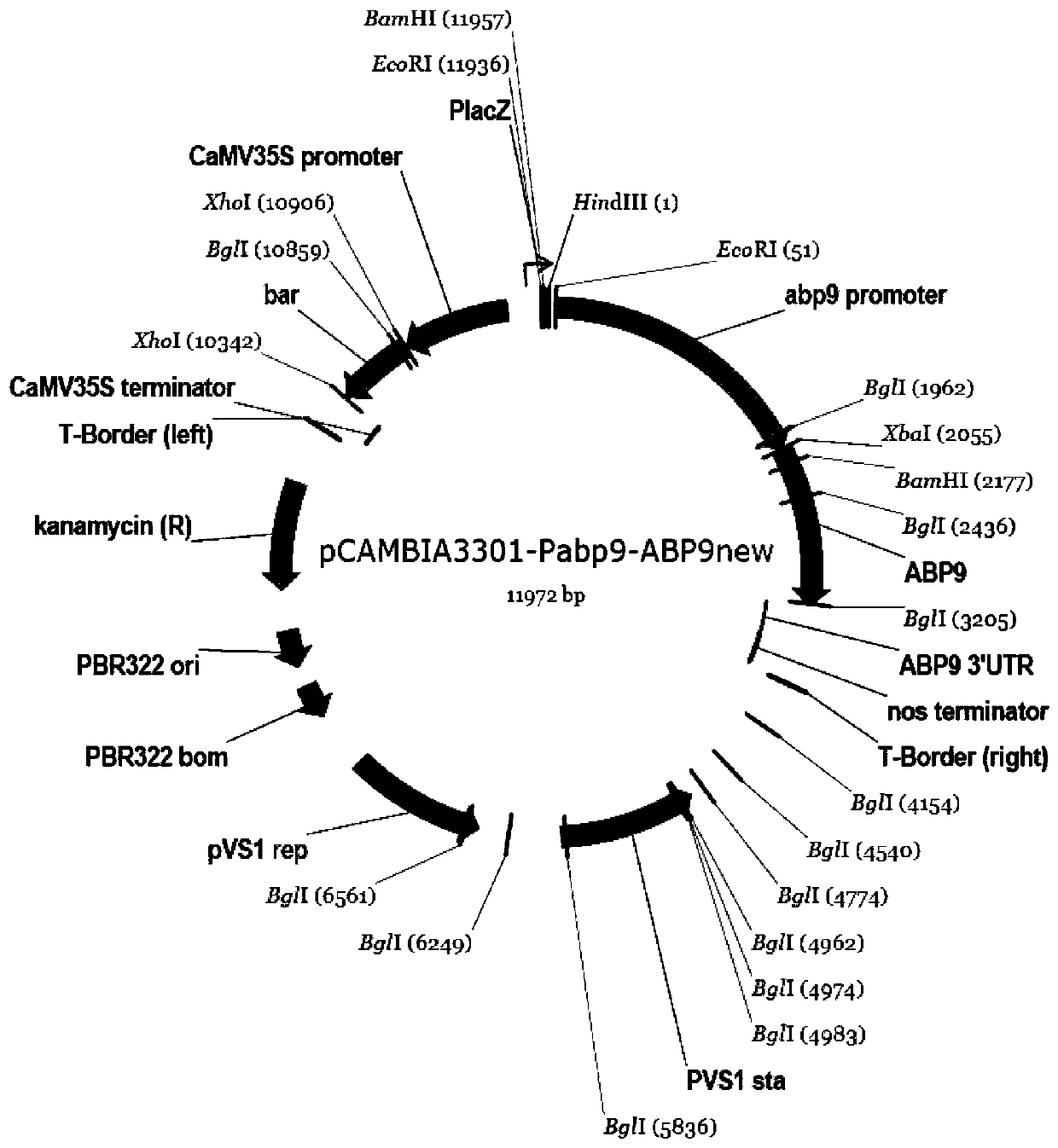

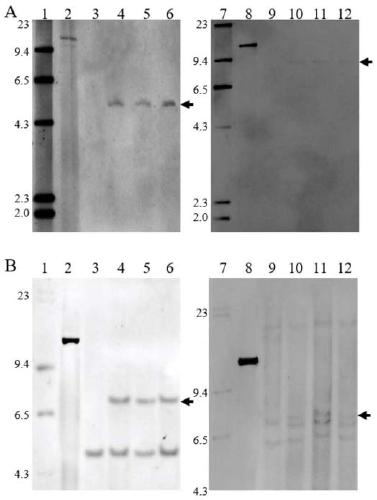

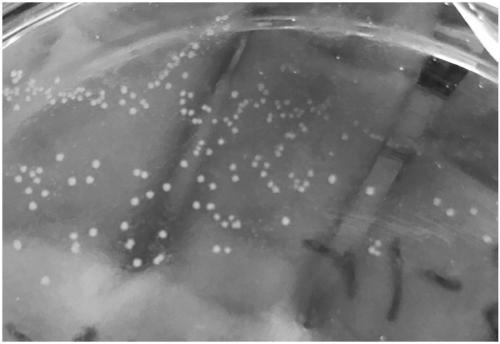

Glufosinate tolerant rice

InactiveUS6933111B1Improve scalabilityImproving yield and growthSugar derivativesMicrobiological testing/measurementRice plantsGenome

This invention pertains to plants, plant material and seeds characterized by harboring a specific transformation event particularly by the presence of the bar gene under control of a CaMV 35S promoter, at a specific location in the rice genome. The rice plants of the invention combine glufosinate tolerance with optimal overall agronomic performance, genetic stability and adaptability to different genetic backgrounds.

Owner:BAYER CROPSCIENCE NV

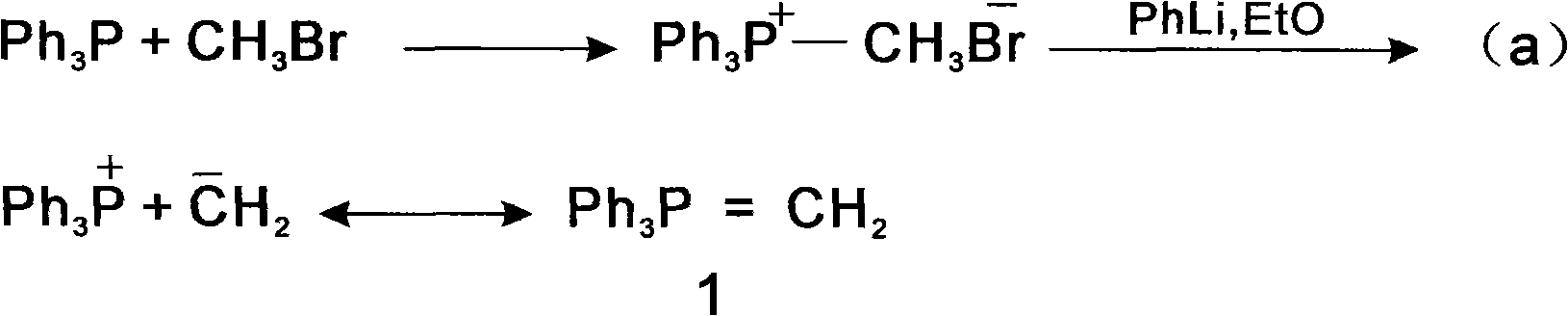

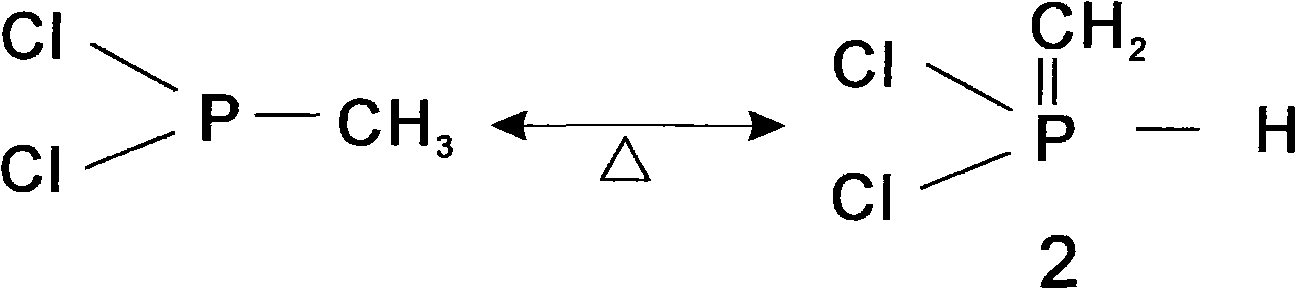

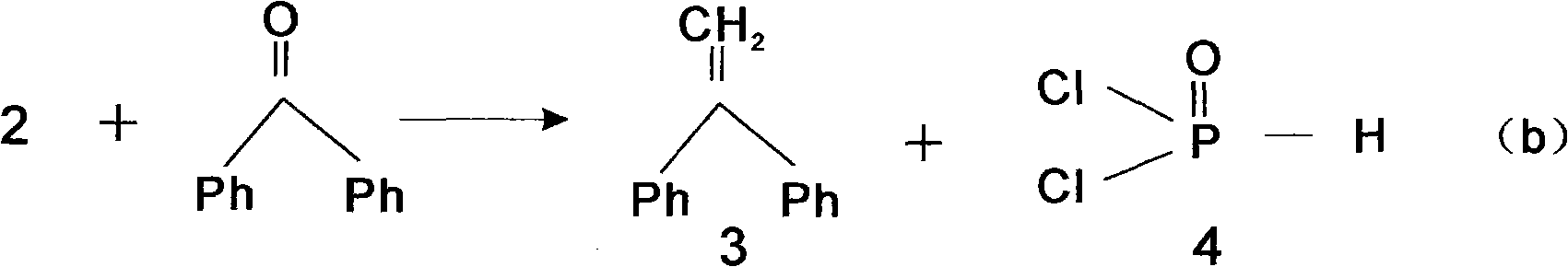

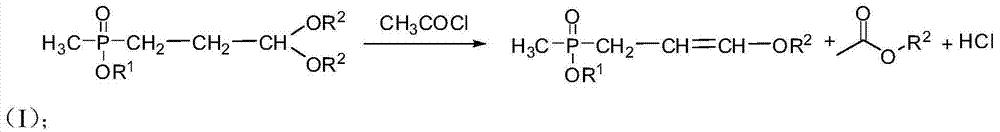

Application of LJ reaction in preparation of wittig reagent and glufosinate-ammonium

ActiveCN102372738AGroup 5/15 element organic compoundsHydrocarbonsGlufosinate-ammoniumWittig reaction

The present invention relates to an application of a new LJ intramolecular isomerization reaction in preparation of a wittig reagent and a herbicide of glufosinate-ammonium. With the application, a new approach of a synthesis route for preparing the wittig reagent and the glufosinate-ammonium is developed, the disadvantages of the existing wittig reaction are improved, and the industrial design of the glufosinate-ammonium production is improved.

Owner:PAPANNA BEIJING TECH

Aminopherase mutant and application thereof in production of L-glufosinate-ammonium

The invention discloses an aminopherase mutant and an application thereof in the production of L-glufosinate-ammonium. The application of the aminopherase mutant in the production of L-glufosinate-ammonium is as follows: a reaction system is formed by using a wet thallus obtained through the fermentation culture of recombinant escherichia coli containing a aminopherase mutant coding gene as a biocatalyst, 2-carbonyl-4 (methyl hydroxyl phosphoryl)-butyrate as a substrate, pyridoxal phosphate as a coenzyme, an amino donor as a cosubstrate, and a buffer solution with the pH value of 6-9 as a reaction medium, and is subjected to biocatalytic reaction at the temperature of 40 to 50 DEG C and the stirring speed of 150 to 250r / min to obtain the L-glufosinate-ammonium. According to the method, thetotal yield is 98%, and the e. e. value of the product reaches 99%.

Owner:ZHEJIANG UNIV OF TECH

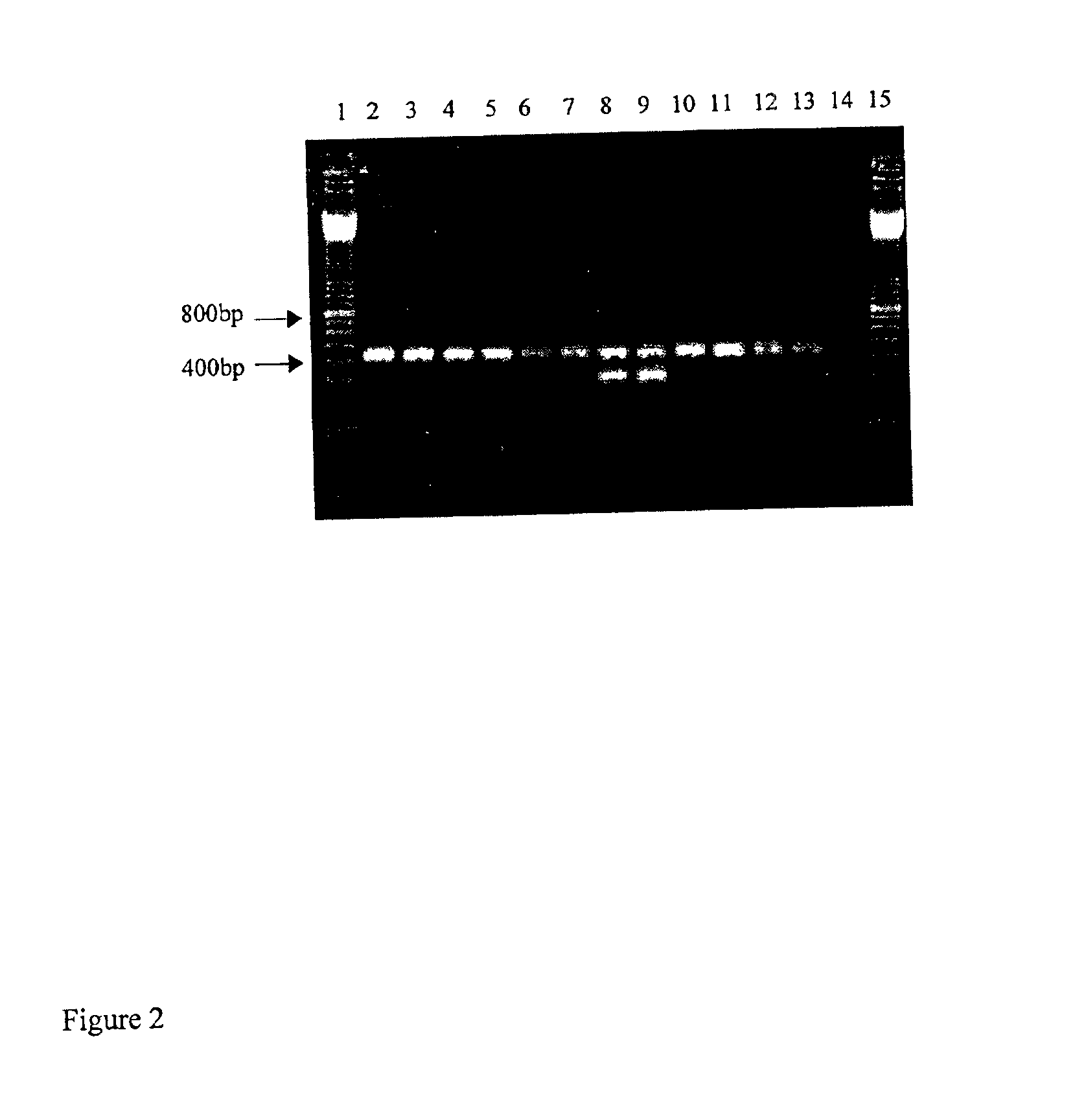

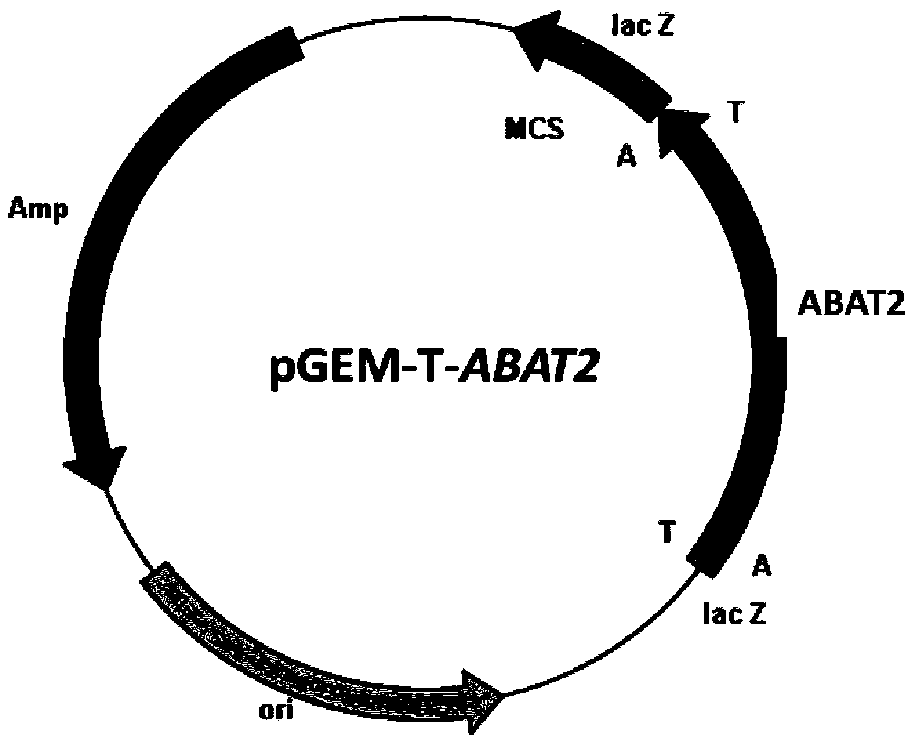

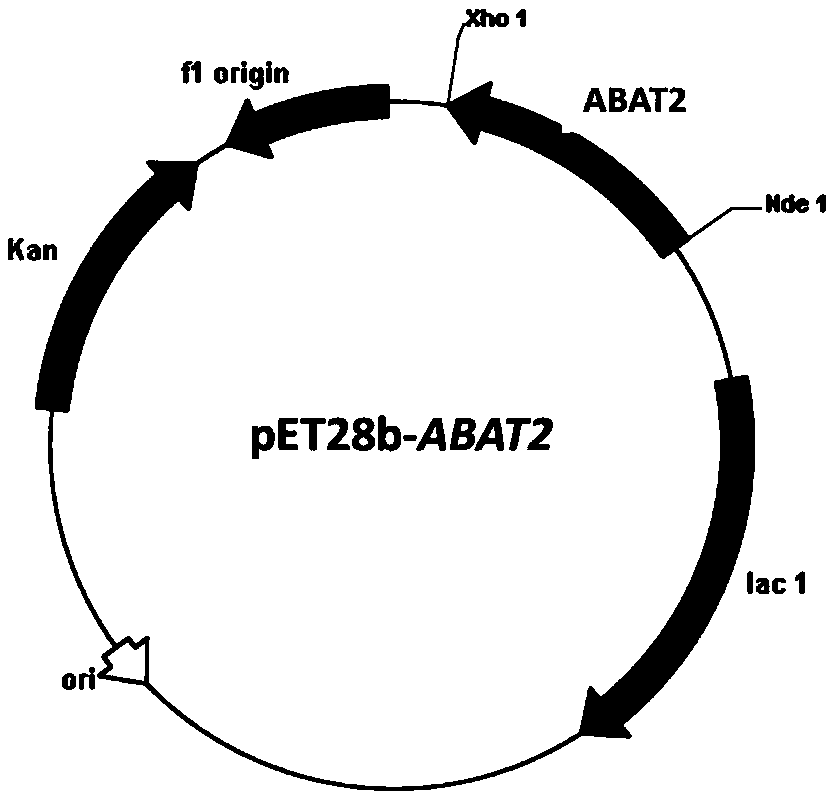

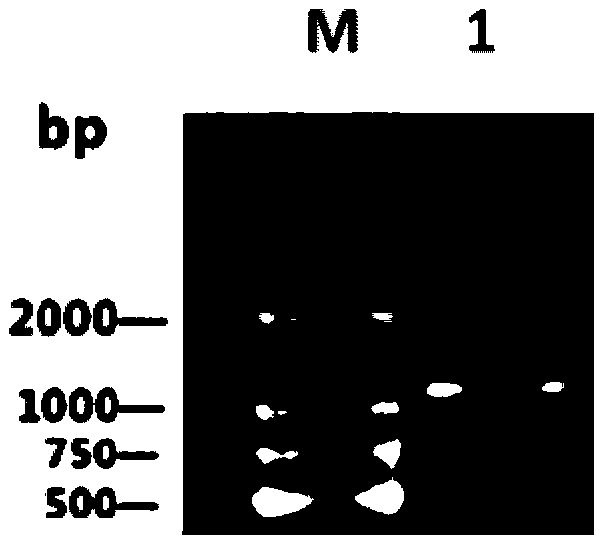

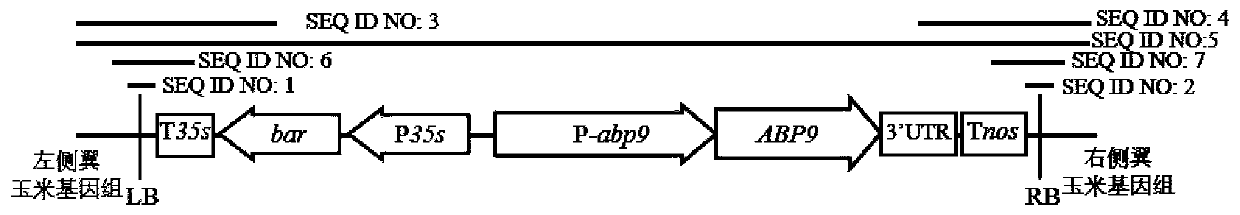

Nucleotide sequence for detecting maize plant NAZ-4 and detection method of nucleotide sequence

PendingCN111206031AMicrobiological testing/measurementCereal cultivationBiotechnologyNucleotide sequencing

The invention relates to a nucleotide sequence for detecting maize plant NAZ-4 and a detection method of the nucleotide sequence. The nucleotide sequence of the maize plant comprises a sequence shownin SEQ ID NO:1 or a complementary sequence of the sequence, or a sequence shown in SEQ ID NO:2 or a complementary sequence of the sequence. The maize plant NAZ-4 provided by the invention has good resistance to drought and glufosinate-ammonium herbicides, and by adopting the detection method, whether a biological sample contains DNA (deoxyribonucleic acid) molecules of a transgenic maize event NAZ-4 or not can be accurately and rapidly identified.

Owner:THE INST OF BIOTECHNOLOGY OF THE CHINESE ACAD OF AGRI SCI

Method for recovering useful constituents in mixed waste solvent during glufosinate ammonium production process

InactiveCN103880786AReduce one evaporation processLow costGroup 5/15 element organic compoundsDistillation purification/separationGlufosinate-ammoniumDiethyl phosphate

The invention discloses a method for recovering useful constituents such as tetrahydrofuran, methyl diethyl phosphate, triethyl phosphate and trimethylbenzene in a mixed waste solvent during a process of producing glufosinate ammonium by an integrated rectification process. The method comprises the following steps: using an integrated rectification process of discharging and rectifying in a single-tower side line and then connecting a single tower to rectify, directly extracting tetrahydrofuran from the top of the rectification tower in the side line and obtaining trimethylbenzene from the bottom of the tower; extracting the mixed solution of methyl diethyl phosphate and triethyl phosphate from the side line simultaneously, conveying the mixed solution to the rectification tower and carrying out single-tower separation, thereby obtaining methyl diethyl phosphate from the top of the tower and obtaining triethyl phosphate from the bottom of the tower. According to the method disclosed by the invention, the useful constituents in the mixed waste solvent during the glufosinate ammonium production process are recovered by the integrated rectification process, the total recovery rate of the mixed solvent exceeds 98%, and the quality achieves reuse standards. Compared with the conventional three-tower rectification method, the equipment cost and energy consumption of the method disclosed by the invention are obviously lowered.

Owner:江苏威格瑞斯化工有限公司

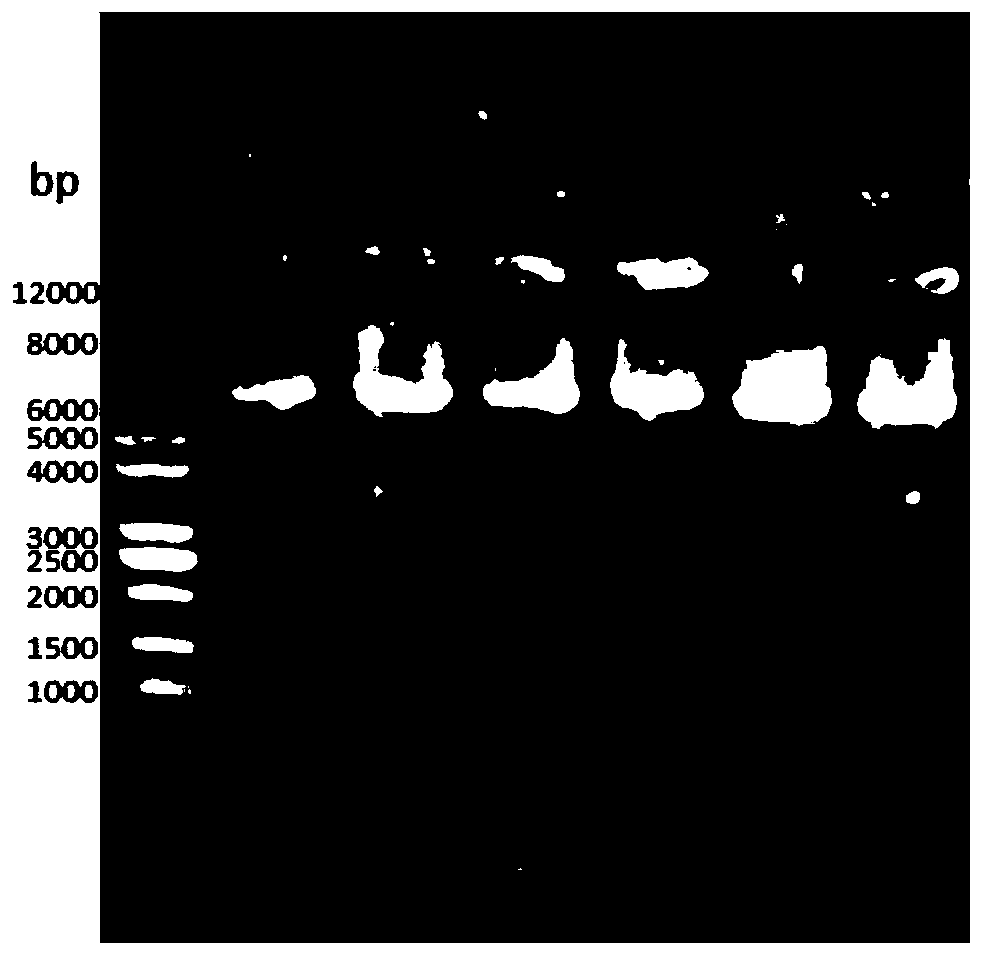

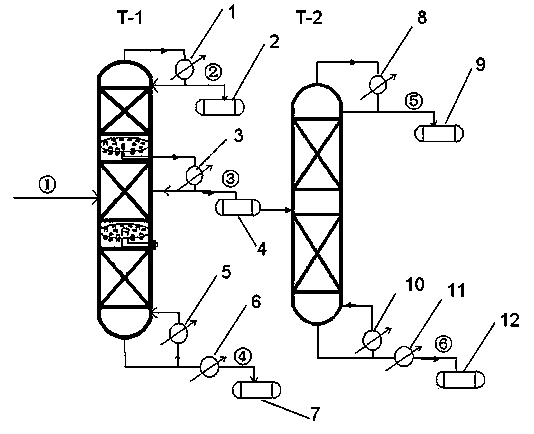

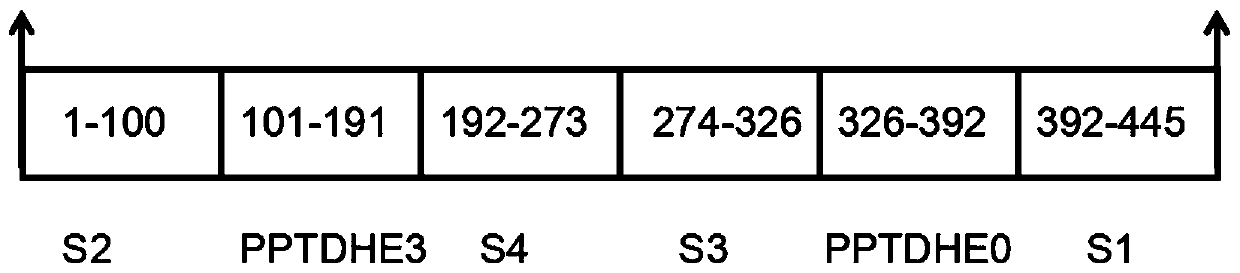

Recombinant glufosinate-ammonium dehydrogenase, genetically engineered bacterium and application of recombinant glufosinate-ammonium dehydrogenase in preparation of L-glufosinate-ammonium

InactiveCN110885803AIncrease enzyme activityImprove catalytic performanceBacteriaEnzymesEngineered geneticMutant

The invention discloses recombinant glufosinate-ammonium dehydrogenase, a genetically engineered bacterium and application of recombinant glufosinate-ammonium dehydrogenase in preparation of L-glufosinate-ammonium. The amino acid sequence of the recombinant glufosinate-ammonium dehydrogenase is shown as SEQ ID NO. 2. According to the invention, a gene library of the recombinant glufosinate-ammonium dehydrogenase is constructed through a staggered extension pcr gene rearrangement technology, and the recombinant glufosinate-ammonium dehydrogenase with high enzyme activity, catalytic performanceand stereoselectivity is screened from the gene library; the activity of the recombinant glufosinate-ammonium dehydrogenase is respectively improved by 31% and 35% in comparison with the activity of aprevious mutant PPTDHE3-A164G and the activity of a previous mutant PPTDHE0-V375S; and finally, 108 g / L of 2-carbonyl-4-(hydroxymethyl phosphine oxide)-butyric acid is completely catalyzed to producethe L-glufosinate-ammonium, and only 20min is needed (transaminase generally needs 40h), wherein the ee value is larger than 99.5%.

Owner:ZHEJIANG UNIV OF TECH

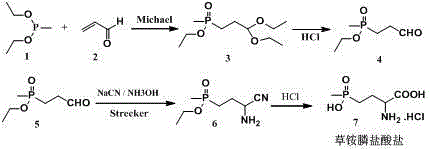

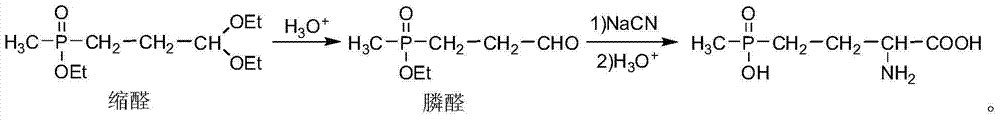

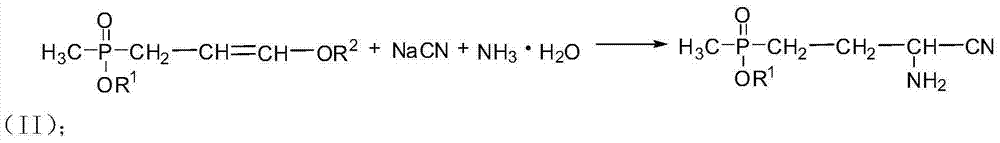

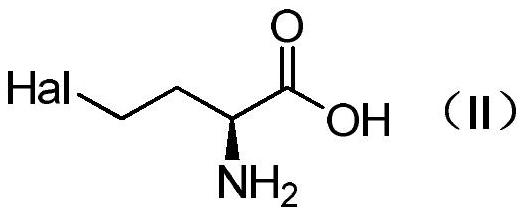

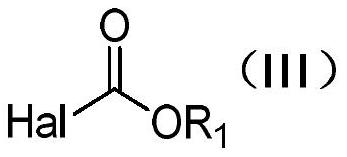

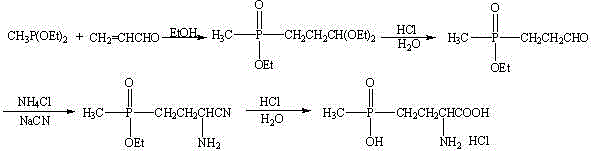

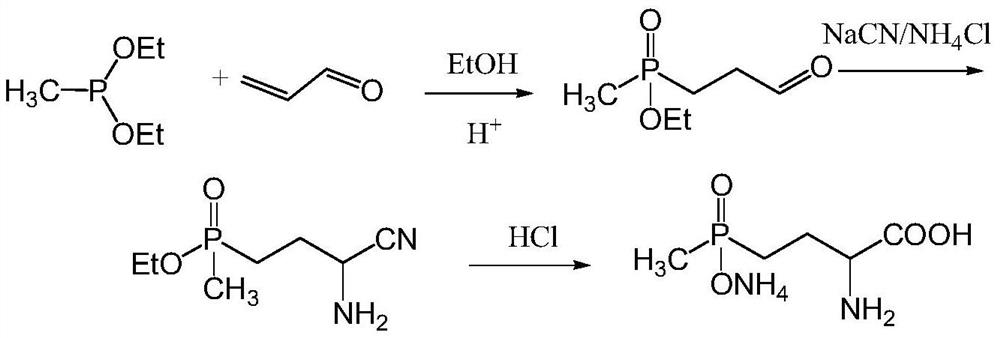

Preparation method of amino-nitrile and intermediate for preparing glufosinate-ammonium

ActiveCN104497039AHigh yieldSatisfy productivityGroup 5/15 element organic compoundsGlufosinate-ammoniumSodium cyanide

The invention discloses a preparation method of amino-nitrile and an intermediate for preparing glufosinate-ammonium. The preparation method disclosed by the invention aims at solving the problem of low glufosinate-ammonium yield by using acetal in the existing methods. Different from the existing methods for preparing glufosinate-ammonium, the method disclosed by the invention comprises the following steps: firstly reacting acetal with acetylchloride to obtain an enol ether intermediate, reacting the enol ether intermediate with sodium cyanide to obtain amino-nitrile, and finally hydrolyzing the amino-nitrile to obtain the glufosinate-ammonium. The method has the advantages of higher reaction yield and capacity of remarkably reducing the production cost of the glufosinate-ammonium.

Owner:GUANGAN LIER CHEM CO LTD

Concentrate herbicidal composition

The present invention is a herbicidal composition containing glyphosate or glufosinate-ammonium, a chloroacetamide, and a triazine, wherein the composition has an aqueous phase, an oil phase, and is dispersed in the aqueous phase and / or particles in the oil phase and are stabilized by a stabilizing amount of one or more emulsifiers.

Owner:MONSANTO TECH LLC

Method for preparing L-glufosinate-ammonium

ActiveCN111662324ALow costNo chiral catalysis requiredGroup 5/15 element organic compoundsOrganic chemistry methodsHomoserineCombinatorial chemistry

The invention relates to a method for preparing L-glufosinate-ammonium. According to the method, cheap and easily available L-homoserine is used as an initial raw material, L-glufosinate-ammonium witha high ee value is prepared through a three-step reaction, chiral catalysis is not needed, the cost is low, and the method has a potential industrial application value.

Owner:LIER CHEM CO LTD +1

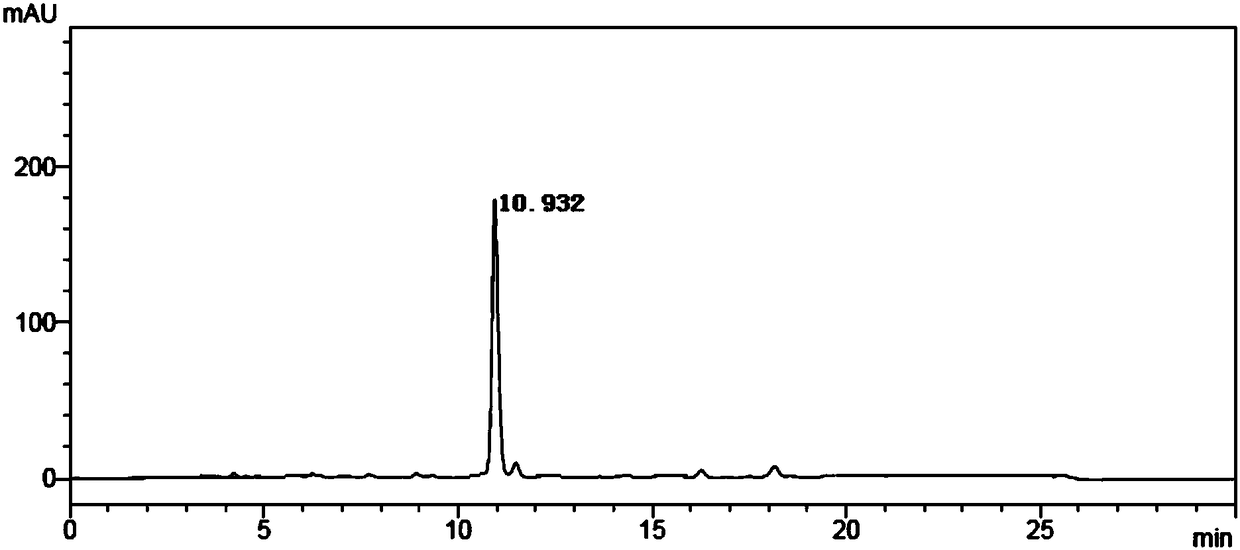

Glufosinate-ammonium separating and purifying method

ActiveCN105315303AHigh recovery rateHigh purityGroup 5/15 element organic compoundsPhosphoric Acid EstersAlcohol

The invention discloses a glufosinate-ammonium separating and purifying method. The method includes the steps of conducting ammoniation on a glufosinate-ammonium acidolysis solution or solid glufosinate-ammonium hydrochloride, conducting drying to obtain a glufosinate-ammonium crude product A, adding the glufosinate-ammonium crude product A to alcohol, conducting filtering to obtain a glufosinate-ammonium crude product B, adding the glufosinate-ammonium crude product B to phosphate ester, conducting filtering to obtain filtrate, washing a filter cake through phosphate ester, combining filtrate with washing liquid to obtain a glufosinate-ammonium crude product C, adding the glufosinate-ammonium crude product C to water to be extracted, and taking a water layer which can be directly used as a glufosinate-ammonium aqueous solution or obtaining high-purity glufosinate-ammonium active compounds after the water layer is spray-dried. The method is simple in step, the content of chloride impurities in the obtained glufosinate-ammonium aqueous solution or glufosinate-ammonium active compounds is extremely low, basically no organic impurities exist, the purity of the separated glufosinate-ammonium active compounds can reach 98% or higher, and the recovery rate of glufosinate-ammonium reaches up to 98% or higher. Compared with the traditional process, the method has the higher advantages of cost, safety, environmental friendliness and quality and has extremely-high social value and economic value.

Owner:SHANDONG WEIFANG RAINBOW CHEM

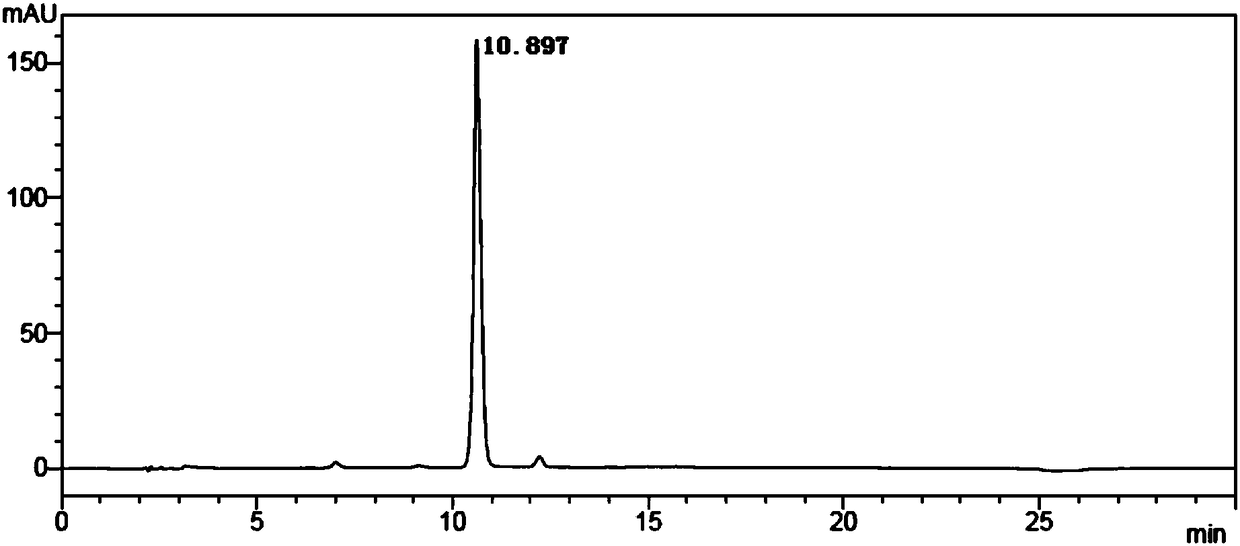

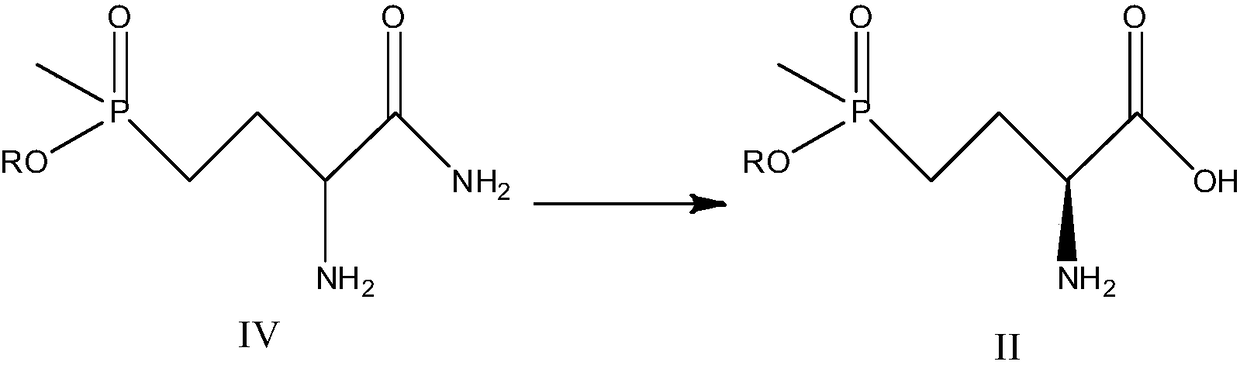

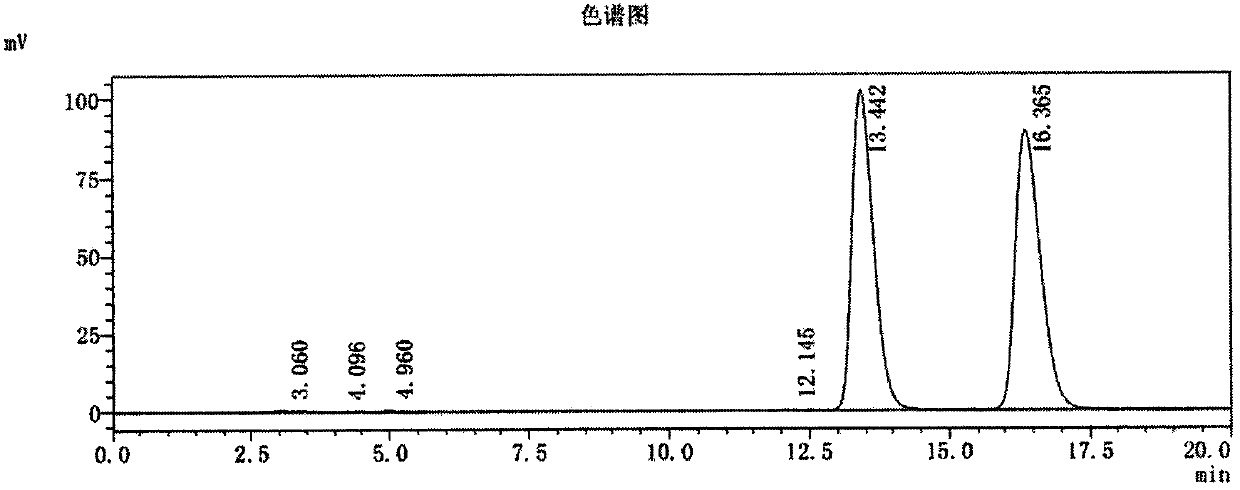

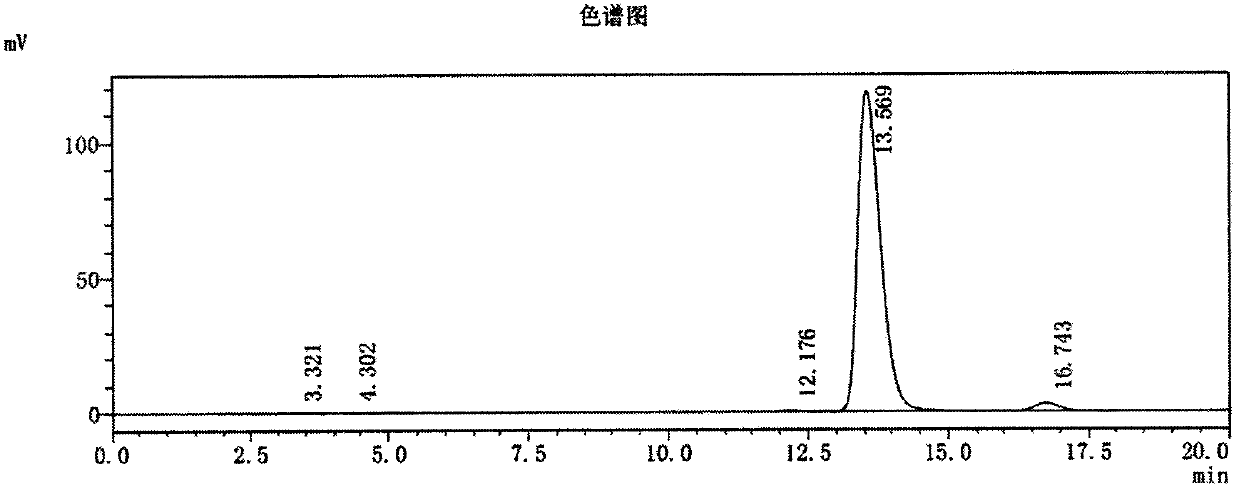

Biosynthesis preparation method of L-glufosinate

InactiveCN108342423ASimple processSuitable for industrial productionFermentationSolventProtecting group

The invention discloses a biosynthesis preparation method of L-glufosinate, and the method comprises the following steps: Step 1, constructing a reaction system by 2-amino-4-(Roxymethylphosphono)butanamide as a substrate and a solvent, adding a catalyst to the reaction system for bioconversion reaction to obtain a conversion liquid containing L-2-amino-4-(Rmethylphosphono)-butyric acid; and Step 2, removing a protecting group of the L-2-amino-4-(Rmethylphosphono)-butyric acid to obtain L-2-amino-4-(hydroxymethylphosphono)-butyric acid, namely the L-glufosinate. The biosynthesis preparation method is simple in process, has no special requirements for equipment, and is suitable for industrial production.

Owner:武汉茵茂特生物技术有限公司

Preparation method of L-glufosinate-ammonium

The invention discloses a preparation method of L-glufosinate-ammonium, and the method comprises the following steps: by using DL-glufosinate-ammonium as a starting raw material, complexing the DL-glufosinate-ammonium with a chiral auxiliary group and metal ions under the action of an inorganic alkali to form a coordination compound, and inversing the configuration of D-glufosinate-ammonium in theprocess to generate the L-glufosinate-ammonium. And by hydrolyzing the coordination compound, the L-glufosinate-ammonium is obtained, and meanwhile the chiral auxiliary group and the metal salt are recovered. The method is simple in process route, high in yield, low in cost and suitable for industrial production of the L-glufosinate-ammonium.

Owner:CHINA PHARM UNIV

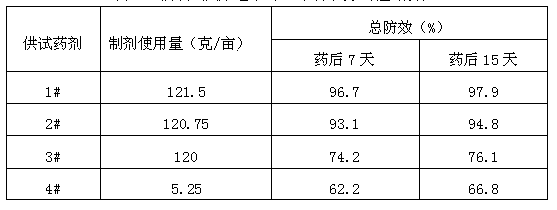

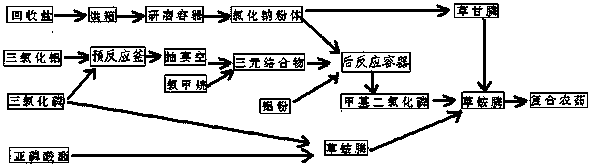

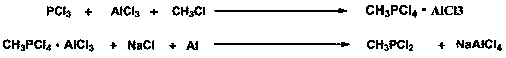

Method and apparatus to prepare glufosinate ammonium composite pesticide via recovered salts containing glufosinate ammonium and trimethyl phosphite

PendingCN107912446ARealize resource utilizationEmission reductionBiocideGroup 5/15 element organic compoundsPhosphorous acidAluminium chloride

The invention provides a method and apparatus to prepare glufosinate ammonium composite pesticide via recovered salts containing glufosinate ammonium and trimethyl phosphite. Chloromethane, aluminum trichloride and phosphorus trichloride are subjected as raw materials to reaction to generate a ternary complex; the ternary complex is distilled under the catalytic reduction of aluminum powder and double decomplexing action of sodium chloride to obtain methylphosphorus dichloride that is further used to synthesize the glufosinate ammonium composite pesticide. The method and apparatus according tothe scheme have the advantages that industrially-produced recovered salt wastes such as glufosinate ammonium and trimethyl phosphite are resourcefully utilized and the composite pesticide is more effective than common glufosinate ammonium.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

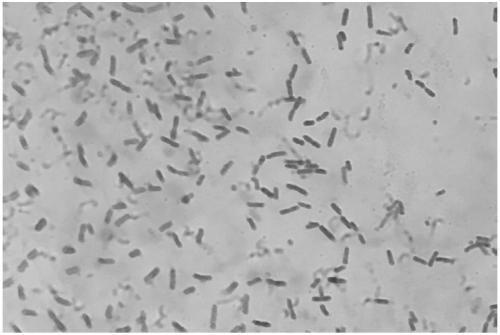

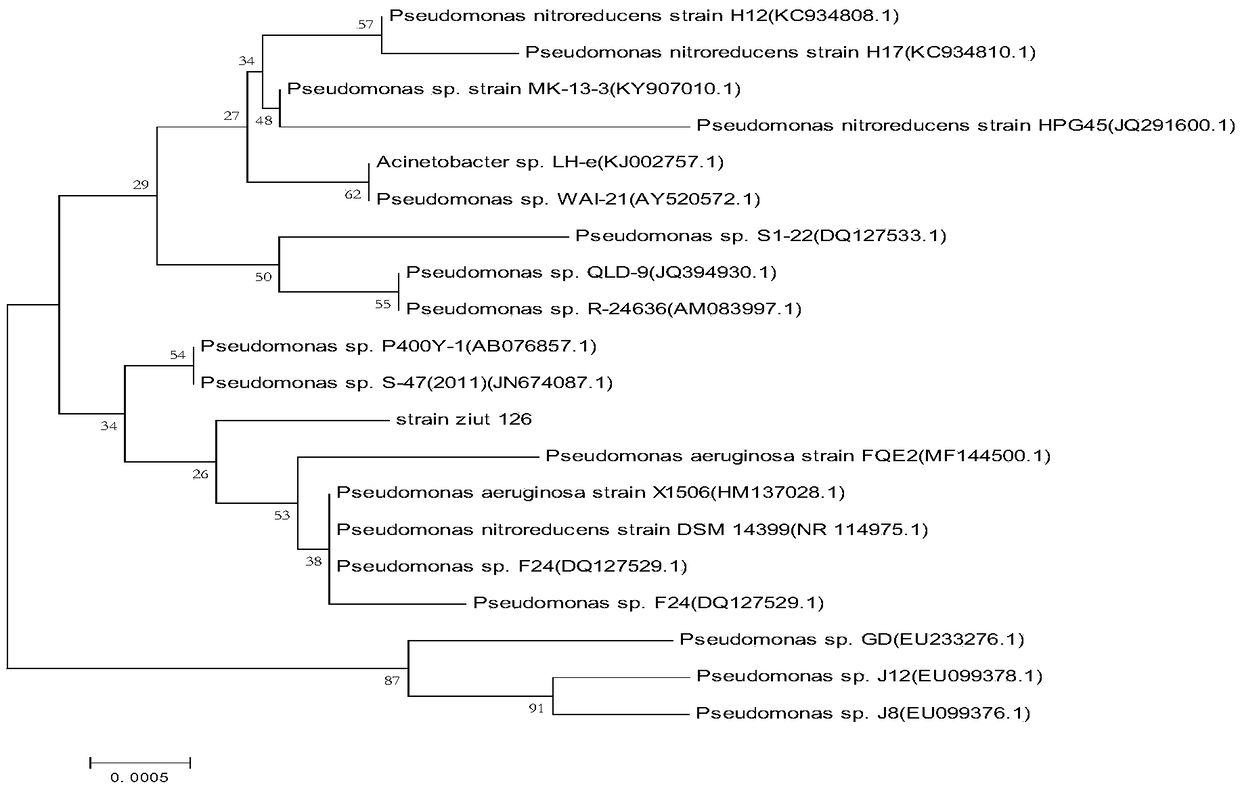

Pseudomonas sp. zjut 126 and application in production of L-glufosinate

ActiveCN109321487ALow costImprove efficiencyBacteriaMicroorganism based processesChemistryPseudomonas sp. UK4

The invention discloses a pseudomonas sp. zjut126 and application in the production of L-glufosinate. The pseudomonas sp. zjut126 can selectively hydrolyze racemic N-decanoyl-(D, L)-glufosinate to produce L-glufosinate, with selectivity close to 100%. Further, according to the invention, a mixture generated by the reaction is separated by an extraction method, and the raffinate is concentrated andfreeze-dried to obtain an L-glufosinate product. The yield of L-glufosinate extraction separation is 94.6%, the content of L-glufosinate in the product is 92%, and the ee value greater than 95.2%. The method disclosed by the invention has low cost, high efficiency and easiness for scale production.

Owner:ZHEJIANG UNIV OF TECH

Post-treatment method of L-glufosinase hydrolysate

PendingCN111574559AThe amount of three wastes is lessLow costGroup 5/15 element organic compoundsOrganic acidEnzymatic hydrolysis

The invention discloses a post-treatment method of an enzymatic hydrolysate of L-glufosinate-ammonium. The enzymatic hydrolysate of L-glufosinate-ammonium prepared by a biological enzyme resolution method is treated by four steps of pretreatment, extraction, desalination and crystallization; impurities such as unreacted D-glufosinate-ammonium derivatives, generated organic acids, ammonium salts and sodium salts are removed, and L-glufosinase of which the yield is greater than 98%, the content is greater than 98%, and the ee value is greater than 99% is obtained. According to the method, a traditional cation exchange resin passing mode is replaced with an extraction mode so that the method is simpler, more convenient and feasible, the purification efficiency is high, the extraction agent can be recycled, and the yield of three wastes is greatly reduced.

Owner:HEBEI VEYONG BIO CHEM

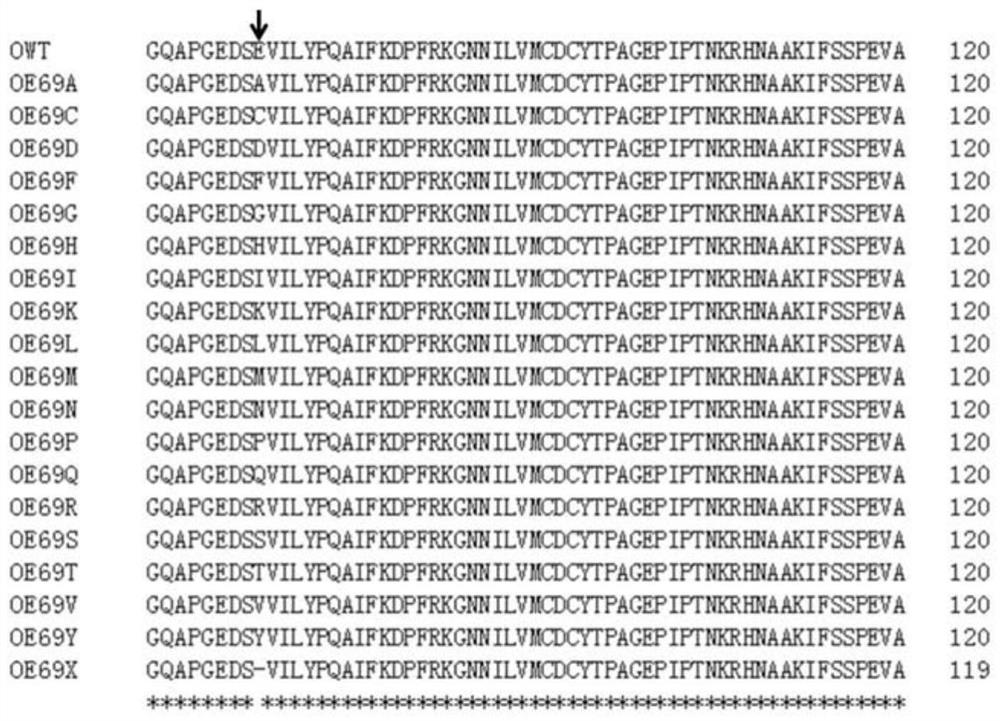

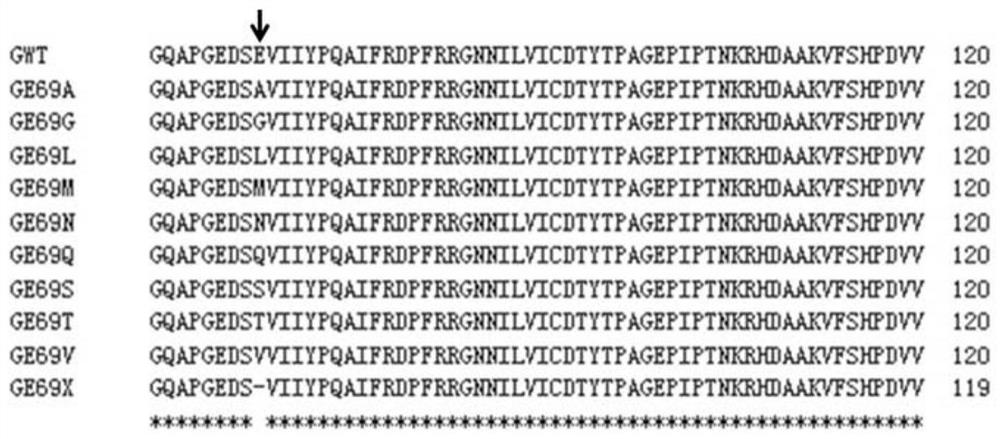

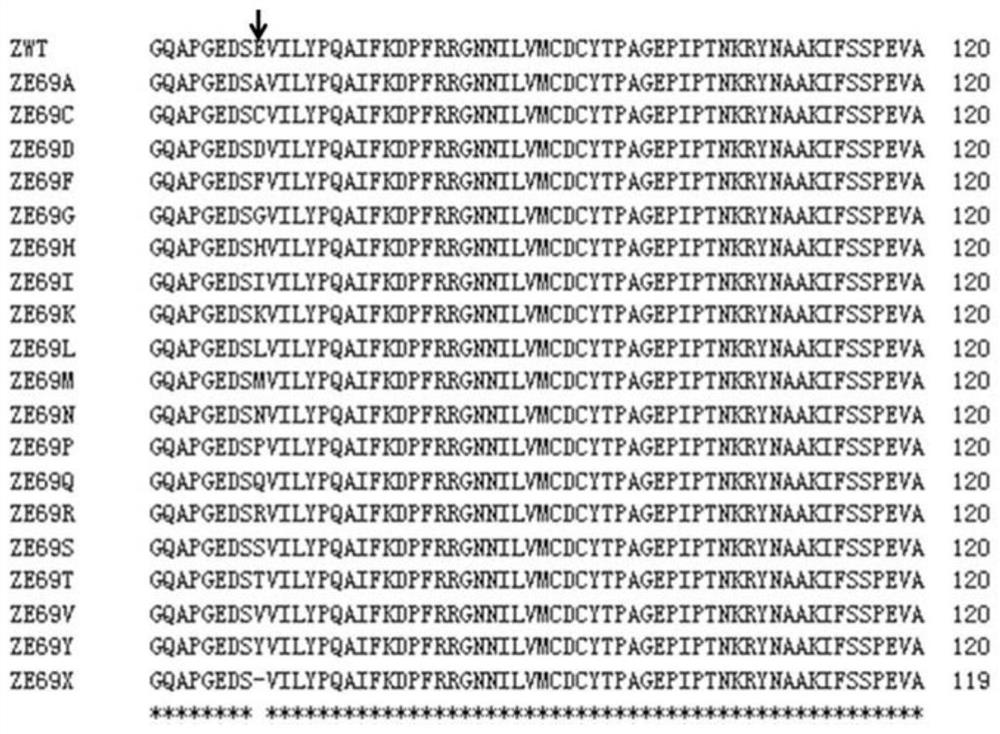

Glutamine synthetase mutant and application of glutamine synthetase mutant in culturing glufosinate-ammonium-resistant plant variety

PendingCN113604443ANormal Enzyme Catalytic ActivityNormal growthLigasesVector-based foreign material introductionAmmonium glufosinateGlutamine

The invention discloses a glutamine synthetase mutant and application of the glutamine synthetase mutant in cultivation of a glufosinate-ammonium-resistant plant variety. The inventor discovers that the glutamine synthetase mutant can be obtained by mutation at the nth site of wild glutamine synthetase, the mutant is A, G, M, N, Q, S, T and V or deleted after mutation, and the mutation can endow the glutamine synthetase with glufosinate-ammonium resistance suitable for commercial application. The glutamine synthetase mutant has the application potential of constructing an expression vector for transforming plants and cultivating glufosinate-ammonium-resistant crops.

Owner:SICHUAN GEVOTO BIOTECH CO LTD

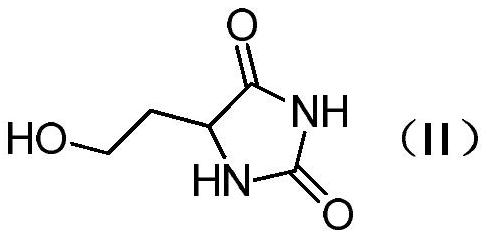

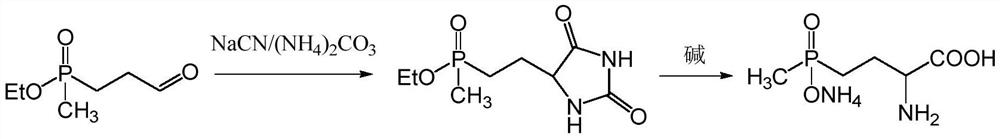

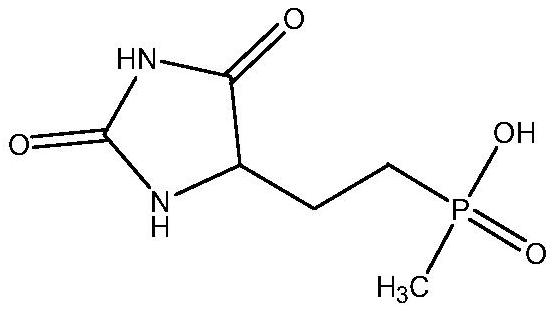

Preparation method of glufosinate-ammonium

ActiveCN113072579APromote hydrolysisReduce generationGroup 5/15 element organic compoundsInorganic saltsHydantoin derivatives

The invention relates to the field of pesticides, and in particular relates to a preparation method of glufosinate-ammonium. The preparation method of the glufosinate-ammonium comprises the following steps: introducing carbon dioxide into an aqueous solution of hydantoin derivatives until the system pressure is 1 to 4MPa, then heating to 120-180 DEG C for reaction, and after the reaction is finished, carrying out post-treatment to obtain the glufosinate-ammonium. Carbon dioxide is filled into an aqueous solution of the hydantoin derivatives until the system reaches specific pressure, so that more carbon dioxide is dissolved in water, that is, the hydantoin derivatives are in a weak acid environment, hydrolysis of the hydantoin derivatives is promoted by combining specific heating temperature, and meanwhile, generation of impurities is reduced. Inorganic salt is not generated in the whole preparation process, and subsequent desalting operation is not needed; a large amount of waste liquid is not generated, and the prepared glufosinate-ammonium is high in yield and good in purity; in addition, the whole glufosinate-ammonium preparation process is simple and convenient, low in cost and easy to industrialize.

Owner:HEBEI VEYONG BIO CHEM

Method for synthesizing L-glufosinate-ammonium intermediate (S)-3-amino-gamma-butyrolactone hydrochloride, and application of method

InactiveCN106045947AHigh optical purityEasy to operateGroup 5/15 element organic compoundsBromoacetic acidChloroacetic acids

The invention relates and belongs to the field of pesticide chemistry, and in particular relates to a method for synthesizing L-glufosinate-ammonium intermediate (S)-3-amino-gamma-butyrolactone hydrochloride, and application of the method. The method takes L-methionine, concentrated hydrochloric acid and chloroacetic acid or bromoacetic acid as raw materials, and the L-glufosinate-ammonium intermediate (S)-3-amino-gamma-butyrolactone hydrochloride is obtained by a one-pot reaction. The method is simple in operation process and purification process, and high in yield; after the method is adopted, the production cost of L-glufosinate-ammonium is remarkably lowered.

Owner:李建中

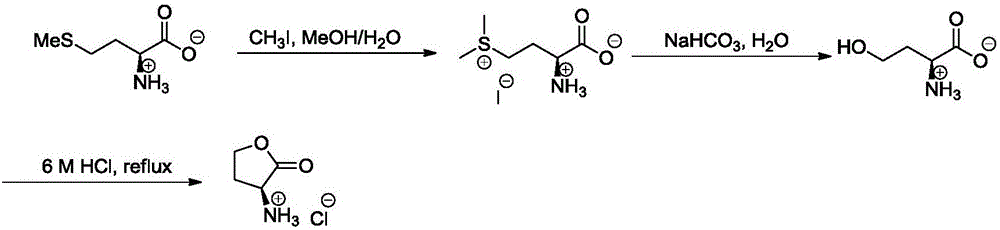

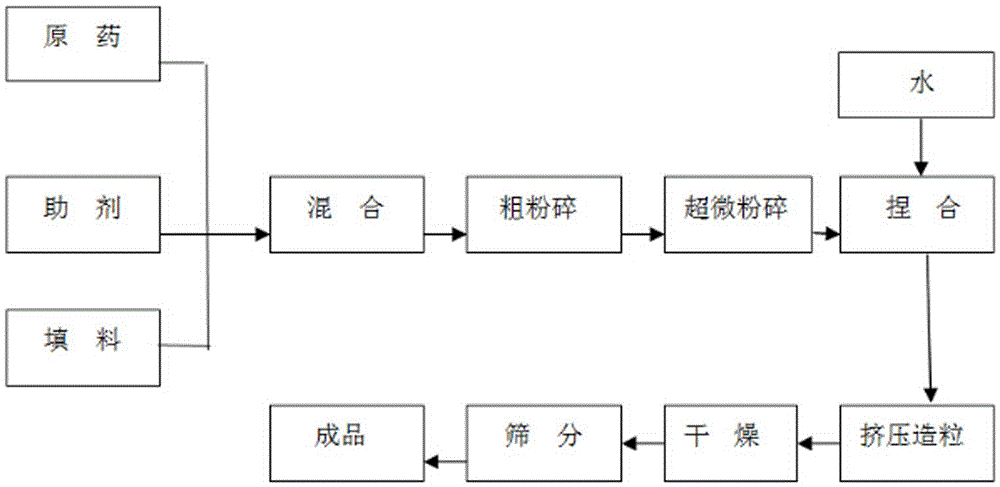

Water dispersible granules containing glufosinate-ammonium and dicamba and preparation method thereof

InactiveCN105475277APrevent dust from happeningEasy to transport and useBiocideDead animal preservationWeedChemistry

The invention discloses water dispersible granules containing glufosinate-ammonium and dicamba. The water dispersible granules are prepared from the following raw materials in weight percent: 1%-10% of glufosinate-ammonium, 5%-60% of dicamba, 4%-15% of a dispersant, 2%-6% of a wetting agent, 5%-15% of a disintegrating agent and the balance of fillers. A preparation method of the water dispersible granules containing glufosinate-ammonium and dicamba comprises the following steps: mixing and crushing, carrying out superfine grinding, kneading and granulating to obtain the water dispersible granules. When being used, a herbicide composition has no dust hazards and is convenient to pack and transport; an organic solvent is not used so that problems of flammability and chemical injury are not generated; the use effect is obviously better than that of single utilization of each single dosage and a current problem of weed drug resistance is greatly alleviated; the weeding spectrum is expanded and the dosage is reduced; and the water dispersible granules have low toxin and high efficiency, are environmentally friendly and safe to human and livestock, and accord with a development trend of green and environmental protection of the future society.

Owner:ANHUI RES INST OF CHEM IND

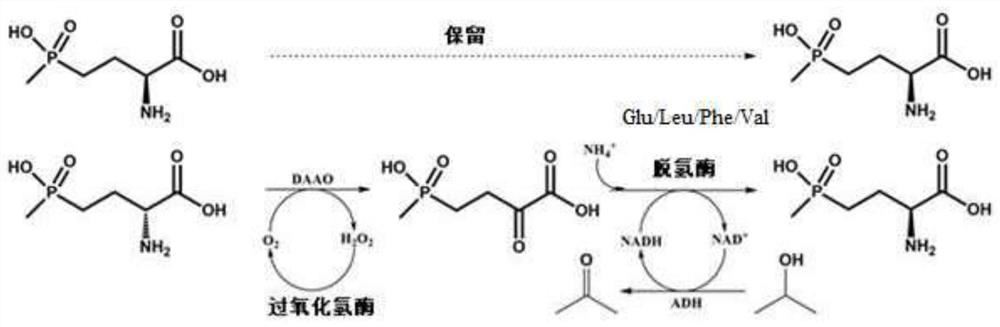

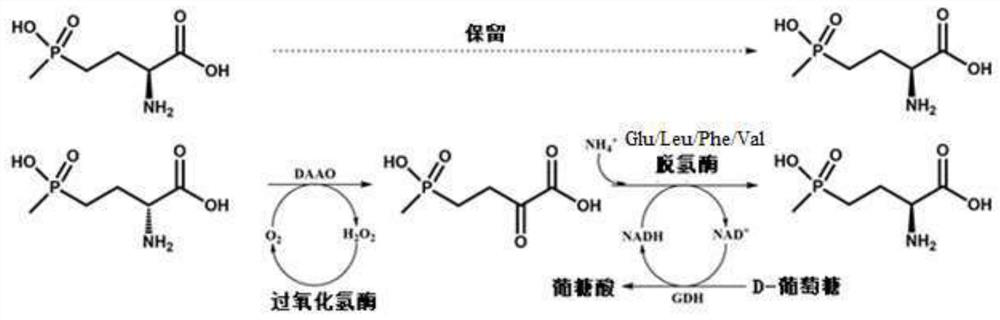

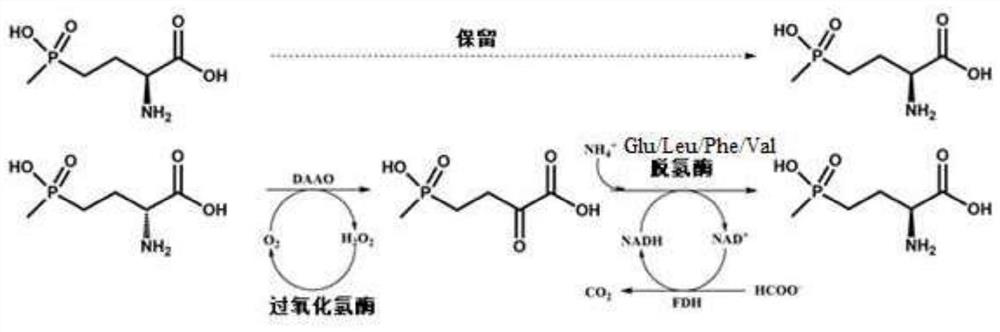

Glu/Leu/Phe/Val dehydrogenase mutant and application thereof in preparation of L-glufosinate

The invention relates to a Glu / Leu / Phe / Val dehydrogenase mutant and application thereof in preparation of L-glufosinate. When the Glu / Leu / Phe / Val dehydrogenase mutant is compared with an amino acid sequence of Glu / Leu / Phe / Val dehydrogenase containing a sequence shown in SEQ ID NO. 5, the amino acid sequence of the Glu / Leu / Phe / Val dehydrogenase mutant contains substitution of amino acid residues corresponding to the 91 position and / or the 168 position, the 91 position and the 168 position are defined by reference to the SEQ ID NO. 5, and the amino acid sequence of the Glu / Leu / Phe / Val dehydrogenase mutant and the sequence shown in the SEQ ID NO. 5 have at least 90% of identity.

Owner:YONGNONG BIOSCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com