Glufosinate-ammonium separating and purifying method

A technology for separation and purification of glufosinate-ammonium, applied in the field of separation and purification of glufosinate-ammonium, can solve the problems of violating the basic chemical principle of strong base to weak base, difficult process, low recovery rate, etc., and achieve novel process route and simplified purification Craft, Recycle Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

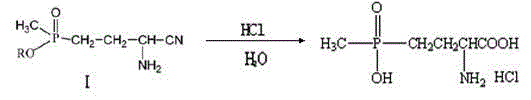

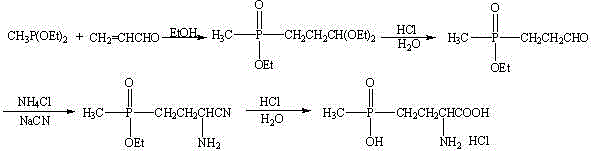

Problems solved by technology

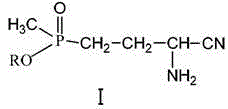

Method used

Image

Examples

Embodiment 1

[0048] Weigh 500g of glufosinate-ammonium acid hydrolysis solution (equivalent to 13.98% glufosinate-ammonium content) into a 1000ml four-neck flask, add 182.8g of 18% ammonia water to it dropwise to pH=6.07, and obtain 682.7g of ammonium solution, and ammonium The solution was spray-dried to obtain glufosinate-ammonium crude product A185.3g (moisture content 0.7%). Transfer the crude product A of glufosinate-ammonium into a 500ml four-necked bottle, add 185.3g of n-butanol, then raise the temperature to 100°C under stirring, keep it warm for 1 hour, and filter it while it is hot, and dry the filtered cake to obtain crude product B165.1g of glufosinate-ammonium . Transfer crude product B of glufosinate-ammonium into a 1000ml four-necked bottle, add 330.2g of trimethyl phosphate and then heat up to 80°C under stirring, keep warm for 1h and filter at this temperature and wash the filter cake with 165.1g of trimethyl phosphate to obtain Glufosinate-ammonium crude product C (ie f...

Embodiment 2

[0050] Weigh 500g of glufosinate-ammonium acid hydrolysis solution (equivalent to 13.98% glufosinate-ammonium content) into a 1000ml four-neck flask, add 205.4g of 18% ammonia water to it dropwise to pH = 8.13, and obtain 705.4g of ammonium solution, and ammonium The solution was spray-dried to obtain glufosinate-ammonium crude product A185.2g (moisture content 0.6%). Transfer the crude product A of glufosinate-ammonium into a 3000ml four-necked bottle, add 1852g of propanol, then raise the temperature to 40°C under stirring, keep it warm for 1 hour, then filter it while it is hot, and dry the filtered cake to obtain crude product B164.7g of glufosinate-ammonium. Transfer crude product B of glufosinate-ammonium into a 2000ml four-necked bottle, add 1154.3g tributyl phosphate and then heat up to 50°C under stirring, filter at this temperature after insulated for 1h and wash the filter cake with 164.7g tributyl phosphate to obtain Glufosinate-ammonium crude product C (i.e. filtr...

Embodiment 3

[0052] Weigh 500g of glufosinate-ammonium acid hydrolysis solution (equivalent to 13.98% glufosinate-ammonium content) into a 1000ml four-neck flask, add 193.8g of 18% ammonia water to it dropwise to pH = 7.01, and obtain 693.8g of ammonium solution. The solution was spray-dried to obtain glufosinate-ammonium crude product A185.4g (moisture content 0.3%). Transfer the crude product A of glufosinate-ammonium into a 2000ml four-neck bottle, add 741.6g of isopropanol, then raise the temperature to 60°C under stirring, keep it warm for 1 hour, then filter it while it is hot, and dry the filtered cake to obtain crude product B164.9g of glufosinate-ammonium . Transfer crude product B of glufosinate-ammonium into a 500ml four-necked bottle, add 164.9g of trioctyl phosphate and then heat up to 100°C under stirring, keep it warm for 1h, filter at this temperature and wash the filter cake with 164.9g of trioctyl phosphate to obtain Glufosinate-ammonium crude product C (ie filtrate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com