Water dispersible granules containing glufosinate-ammonium and dicamba and preparation method thereof

A technology of dicamba and dispersible granules, applied in the field of pesticides, can solve the problems that a single dose of herbicide cannot fully and effectively control weeds, residual toxicity of current crops or subsequent crops, excessive herbicide dosage, etc. Effects of grass resistance, reduced dosage, and ease of transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

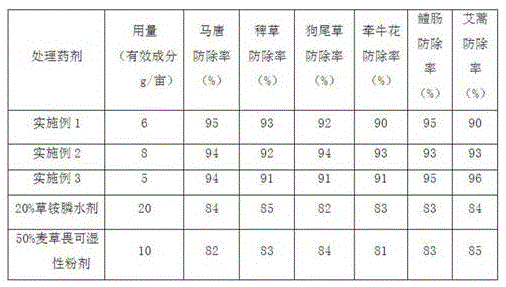

Embodiment 1

[0035] A water-dispersible granule containing glufosinate-ammonium and dicamba, the components of the water-dispersible granule and their mass percentages are: glufosinate-ammonium 5%, dicamba 45%, acrylic acid copolymer sodium salt 6%, dodecyl Sodium alkyl sulfate 2%, ammonium sulfate 5% and attapulgite 37%.

[0036] Furthermore, the composition of glufosinate-ammonium and dicamba in the water-dispersible granule accounts for 50% of the total amount.

Embodiment 2

[0038] A water-dispersible granule containing glufosinate-ammonium and dicamba, the components of the water-dispersible granule and their mass percentages are: 1% glufosinate-ammonium, 49% dicamba, 15% sodium lignosulfonate, alkane 2% aryl polyoxyethylene ether sulfate, 15% anhydrous sodium sulfate, 17% diatomaceous earth and talcum powder as filler.

Embodiment 3

[0040] A water-dispersible granule containing glufosinate-ammonium and dicamba, the components of the water-dispersible granule and their mass percentages are: glufosinate-ammonium 10%, dicamba 50%, acrylic acid copolymer sodium salt and lignosulfonic acid Sodium salt mixture 4%, naphthalene sulfonate and sodium lauryl sulfate mixture 6%, anhydrous sodium sulfate and sodium carboxymethyl starch 5%, filler is kaolin 35%.

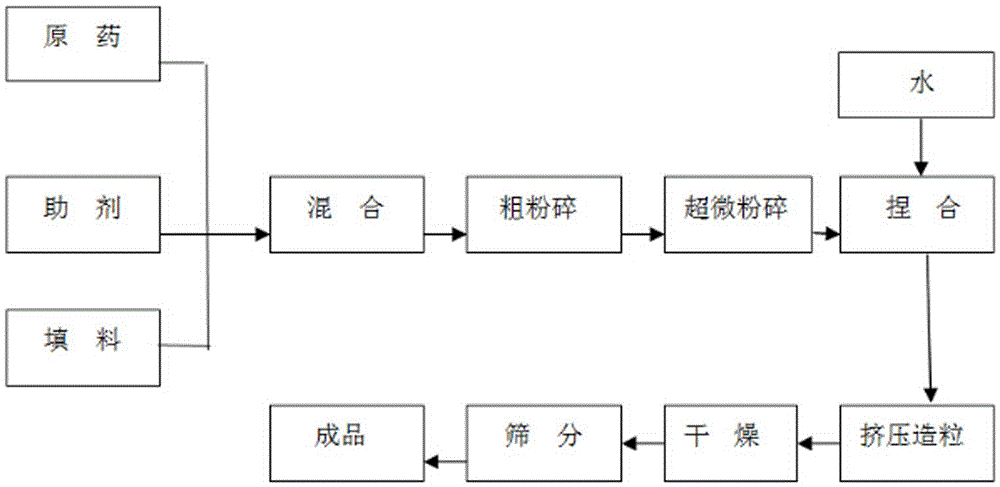

[0041] A kind of preparation method of the water dispersible granule containing glufosinate-ammonium and dicamba, concrete steps are as follows:

[0042] (1) Fully mix the original drug glufosinate-ammonium and dicamba, dispersant, wetting agent, disintegrant and filler according to the ratio required by the formula, and coarsely pulverize it by a pulverizer;

[0043] (2) The coarsely pulverized sample is subjected to superfine pulverization through a jet mill;

[0044] (3) Finally, add a certain amount of water to the sample obtained by superfine grinding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com