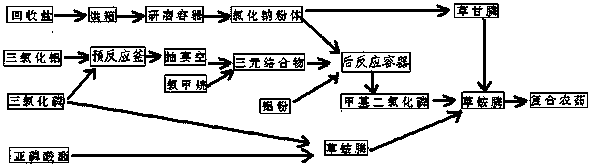

Method and apparatus to prepare glufosinate ammonium composite pesticide via recovered salts containing glufosinate ammonium and trimethyl phosphite

A technology of trimethyl phosphite and compound pesticides, which is applied in the direction of botany equipment and methods, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve the problems of slow weeding speed and reduce waste emissions, high efficacy, high economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

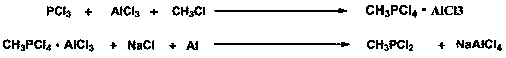

[0027] Add 277.4g of phosphorus trichloride and 377.4g of aluminum trichloride into the closed reaction kettle, pass in nitrogen to replace the air, then pass in 140g of methyl chloride, react at 80°C for 8 hours, transfer to a three-necked flask after the reaction is completed spare. Slowly heat the reacted ternary complex to 140°C, add 367.0 g of recovered salt and 27.0 g of aluminum powder, and distill while reacting to obtain 197.0 g of methyl phosphorus dichloride with a content of 97%, and the yield is 81.7% .

Embodiment 2

[0029] Add 277.4g of phosphorus trichloride and 377.4g of aluminum trichloride into the closed reaction kettle, pass in nitrogen to replace the air, then pass in 140g of methyl chloride, react at 80°C for 8 hours, transfer to a three-necked flask after the reaction is completed spare. Slowly heat the reacted ternary complex to 140°C, add 367.0 g of analytically pure sodium chloride and 27.0 g of aluminum powder, and distill while reacting to obtain 195.0 g of methyl phosphorus dichloride with a content of 98%. The yield is was 81.5%.

Embodiment 3

[0031] Add 277.4g of phosphorus trichloride and 377.4g of aluminum trichloride into the airtight reaction kettle, pass in nitrogen to replace the air, then pass in 150g of methyl chloride, react at 80°C for 6 hours, transfer to a three-necked flask after the reaction is completed spare. Slowly heat the reacted ternary complex to 140°C, add 414.1g of recovered salt and 36.0g of aluminum powder, and distill while reacting to obtain 190.0g of methyl phosphorus dichloride with a content of 99%, and the yield is 80.4% .

[0032] In the above-mentioned three embodiments, the reclaimed salt has been subjected to oven baking and grinding equipment grinding pretreatment, phosphorus trichloride, aluminum trichloride, and methyl chloride are carried out complexation reaction in the pre-reactor, and then in the post-reaction vessel Reduction reaction and decomplexation reaction are carried out together with aluminum powder and recovered salt, and the generated methyl phosphorus dichlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com