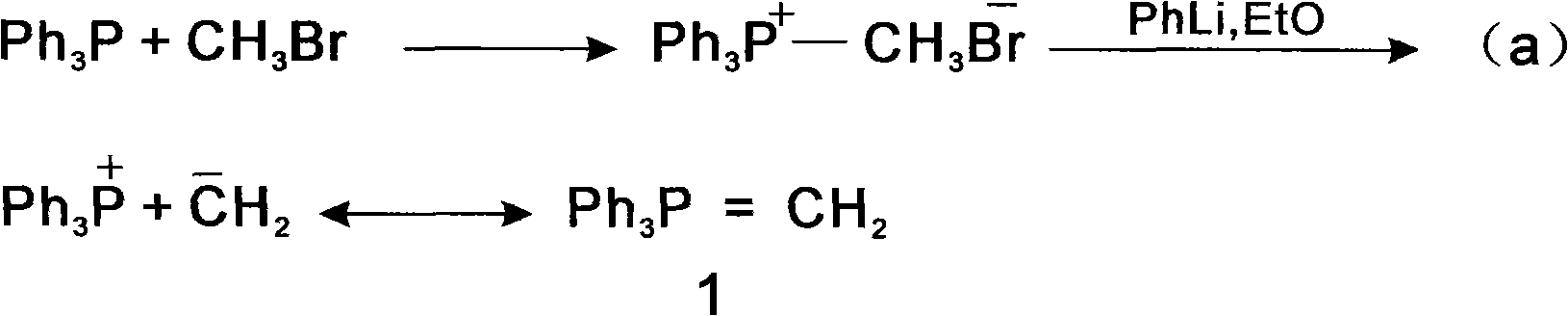

Application of LJ reaction in preparation of wittig reagent and glufosinate-ammonium

A glufosinate-ammonium reaction technology, applied in the application field of LJ reaction in the preparation of Wittig reagent and glufosinate-ammonium, can solve the problems of only 4% utilization rate, non-compliance, inconvenient product separation and purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

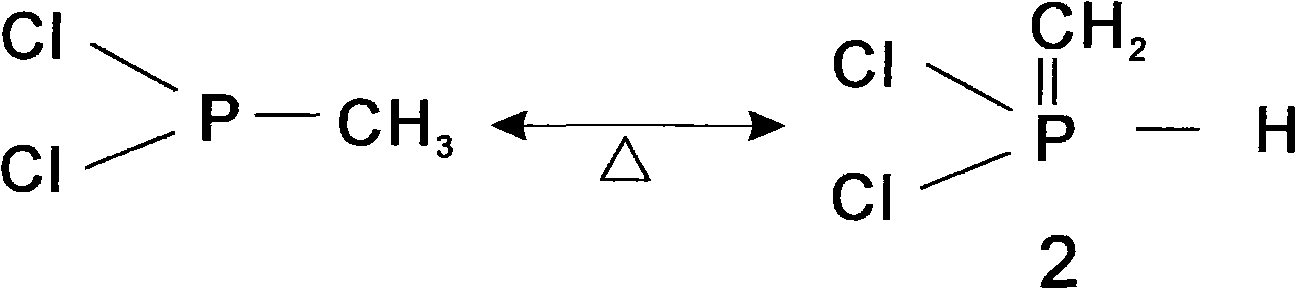

Method used

Image

Examples

Embodiment 1

[0088] Molecular ratio phosphorus trichloride: methyl chloride = 1:1

[0089] Throw 100 grams of 98% phosphorus trichloride into the pressure reactor, under the condition of isolating air and water, control 20-110 ℃, add the calculated amount of methyl chloride / chloroform saturated solution dropwise, keep warm for 2 hours, steam Remove the chloroform solvent, let it stand, crystallize, filter, dry, and obtain quarter Salt 6 is solid, the yield is 98%, and the content is 98%.

[0090] Because 6 is unstable in air and water, dissolve it in dichloroethane, control the temperature below 20°C, slowly add equal mol of aluminum trichloride, keep warm for 4 to 8 hours, then add dichloride dichloride dropwise. Phosphorus, a large amount of precipitates were precipitated, filtered, and the mother liquor was vacuum distilled, and the distillation substrate was 8 compounds, with a yield of 98% and a content of 98%.

Embodiment 2

[0092] Throw 100 grams of 98% phosphorus trichloride into the reaction bottle, under the condition of isolating air and water, control the temperature below 54°C, add dropwise a calculated amount of 20-40% trimethyl chloride phosphate solution, and generate in one step Simultaneously with compound 8, hydrogen chloride was produced. After reacting for 4 to 8 hours, a large amount of solids precipitated out. After standing still, crystallized, filtered, and dried in vacuo, compound 8 was obtained with a yield of 98% and a content of 98%.

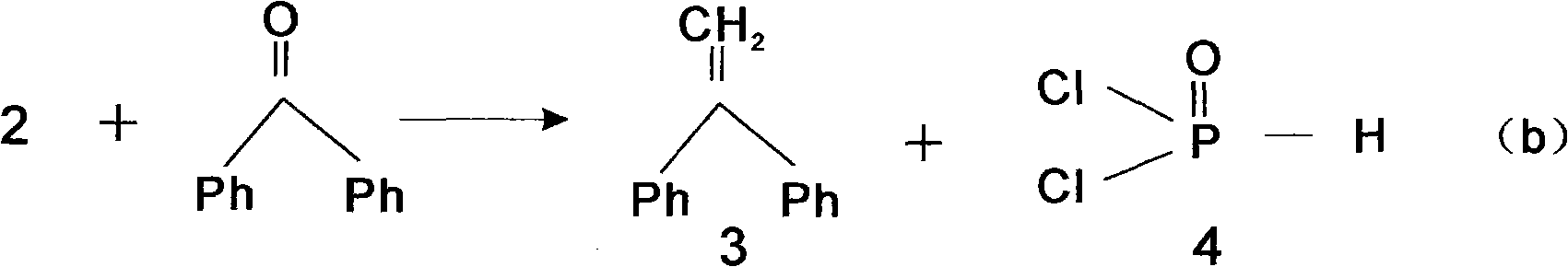

Embodiment 3

[0094] Prepare a 10-20% solution of 8 prepared in Example 2 and trimethyl phosphate, put it into a reaction flask, control the temperature below 5°C, add benzophenone in equal moles dropwise, and react for 2 hours to generate 1,1- Stilbene and phosphorus oxychloride, the yield is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com