Method for preparing high-purity glufosinate-ammonium by adopting organic alkali deacidification method

A technology for organic base and glufosinate-ammonium, which is applied in the field of preparing high-purity glufosinate-ammonium by deacidification of organic bases, can solve the problems of increasing production cost and three-waste treatment cost, unable to recover and dissolve in high yield, difficult to recover, etc. Efficient and simple recycling, easy operation, less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

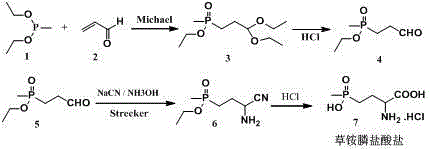

Method used

Image

Examples

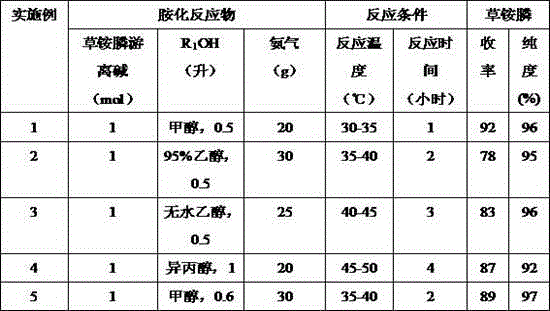

Embodiment 1-5

[0030] according to Table 1 Reaction conditions and process parameters shown, adding glufosinate-ammonium hydrochloride to alcohol R 1 OH, reflux to dissolve, filter to remove inorganic salts and mechanical impurities, concentrate and recover 50% of the total volume of R 1 OH solvent, the evaporated solvent can be used directly. Then add the organic base R 2 R 3 R 4 N neutralize 7 The hydrochloric acid in the solution is nearly neutral, cooled to 0-5°C, the glufosinate-ammonium free base is precipitated, and the free base is obtained by filtration, which can be directly used in the next step of ammonia reaction without purification. Purity was measured by liquid phase normalization method.

[0031] HPLC conditions: stainless steel column 125×4.6mm, filler SB, particle size 5mm, UV detection wavelength 195nm, injection volume 20μl, column temperature 30℃, flow rate 1.3ml / l, eluent: 0.1mol / lKH 2 PO 4 .

[0032] Table 1 Neutralization reaction conditions of glufosinate-...

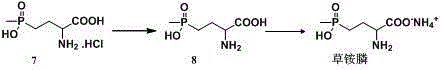

Embodiment 6-10

[0036] according to Table 2 The reaction conditions, the free base that embodiment 1-5 gained is added to corresponding alcoholic solvent R respectively 1 OH, and then pass ammonia gas at a certain temperature. After the reaction is complete, cool to 0-5°C, filter, and dry under reduced pressure to obtain glufosinate-ammonium. Purity was measured by liquid phase normalization method. The structure of glufosinate-ammonium 1 Confirmed by H-NMR and ESI-MS, it is consistent with the literature value. 1 H-NMR (400MHz, D 2 O, TMS): δ, 3.80 (1H, t), 2.11 (2H, t), 1,56-1.75 (2H, m), 1.28 (3H,d), ESIMS: 182[M+1], 198[ M+NH 3 ].

[0037] Table 2 Amination reaction conditions and results

[0038]

[0039] As can be seen from the above table, the reaction received more than 78%, the total reaction yield reached more than 64%, and the purity reached 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com