Patents

Literature

49results about How to "Strain stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

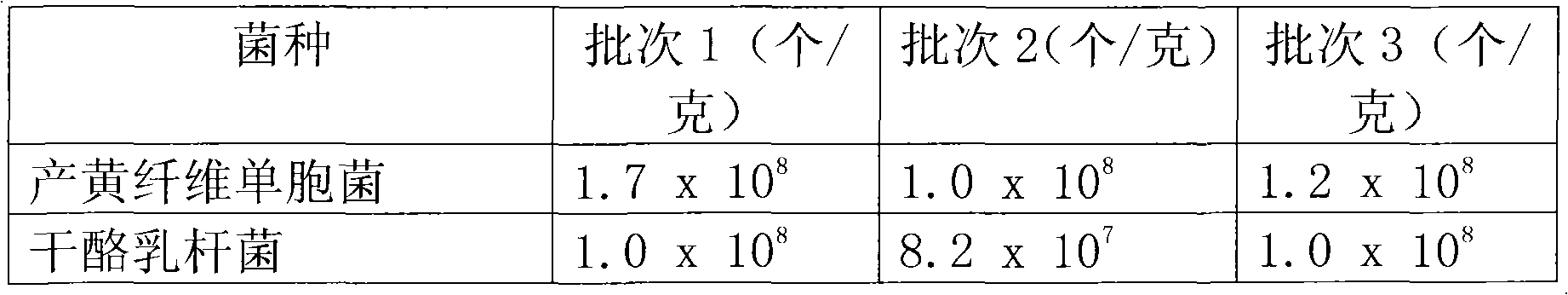

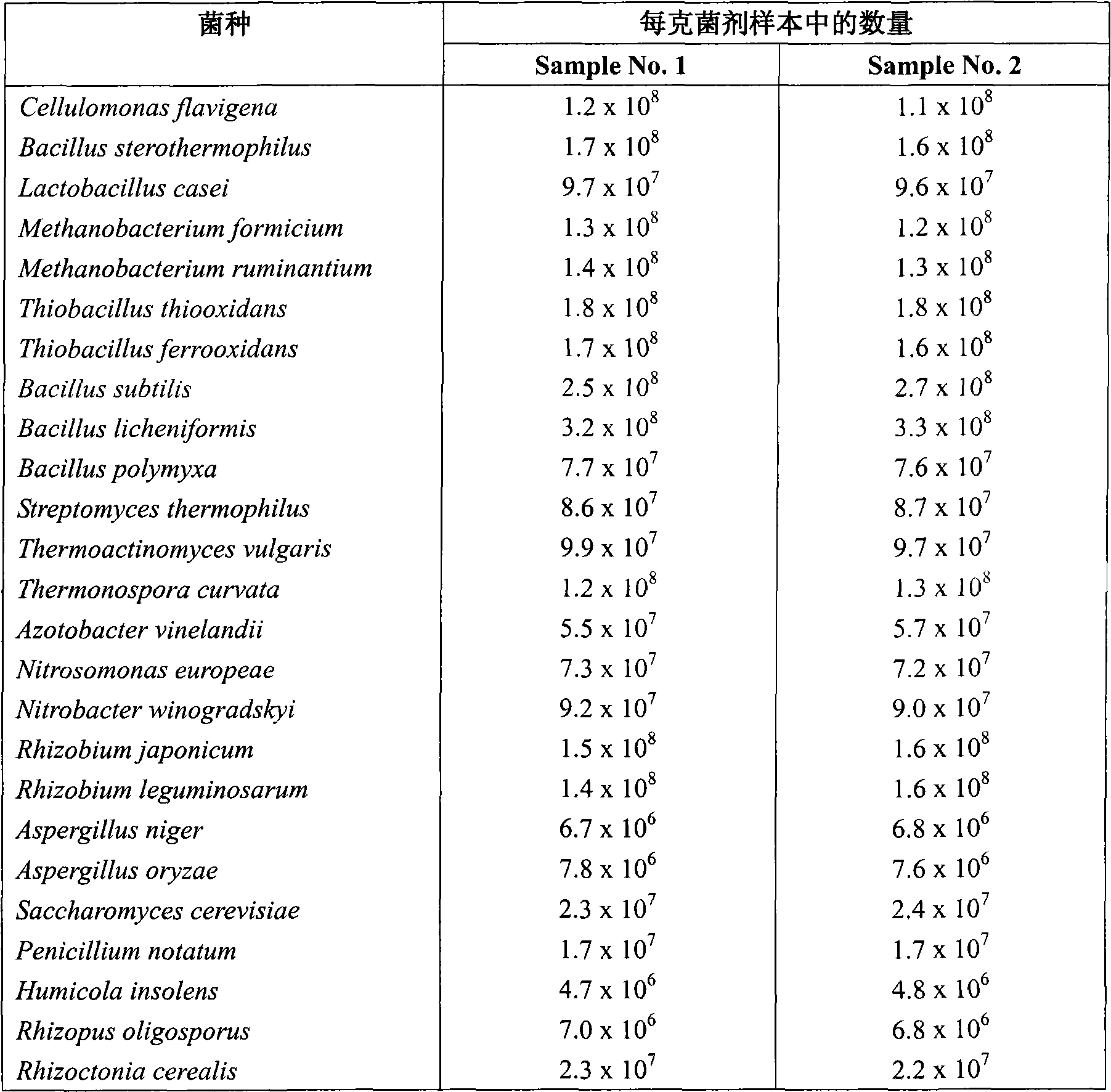

Microbial inoculum and organic fertilizers fermented by same

ActiveCN101643718AImprove adaptabilityImprove qualityFungiBio-organic fraction processingPenicilliumRhizobium

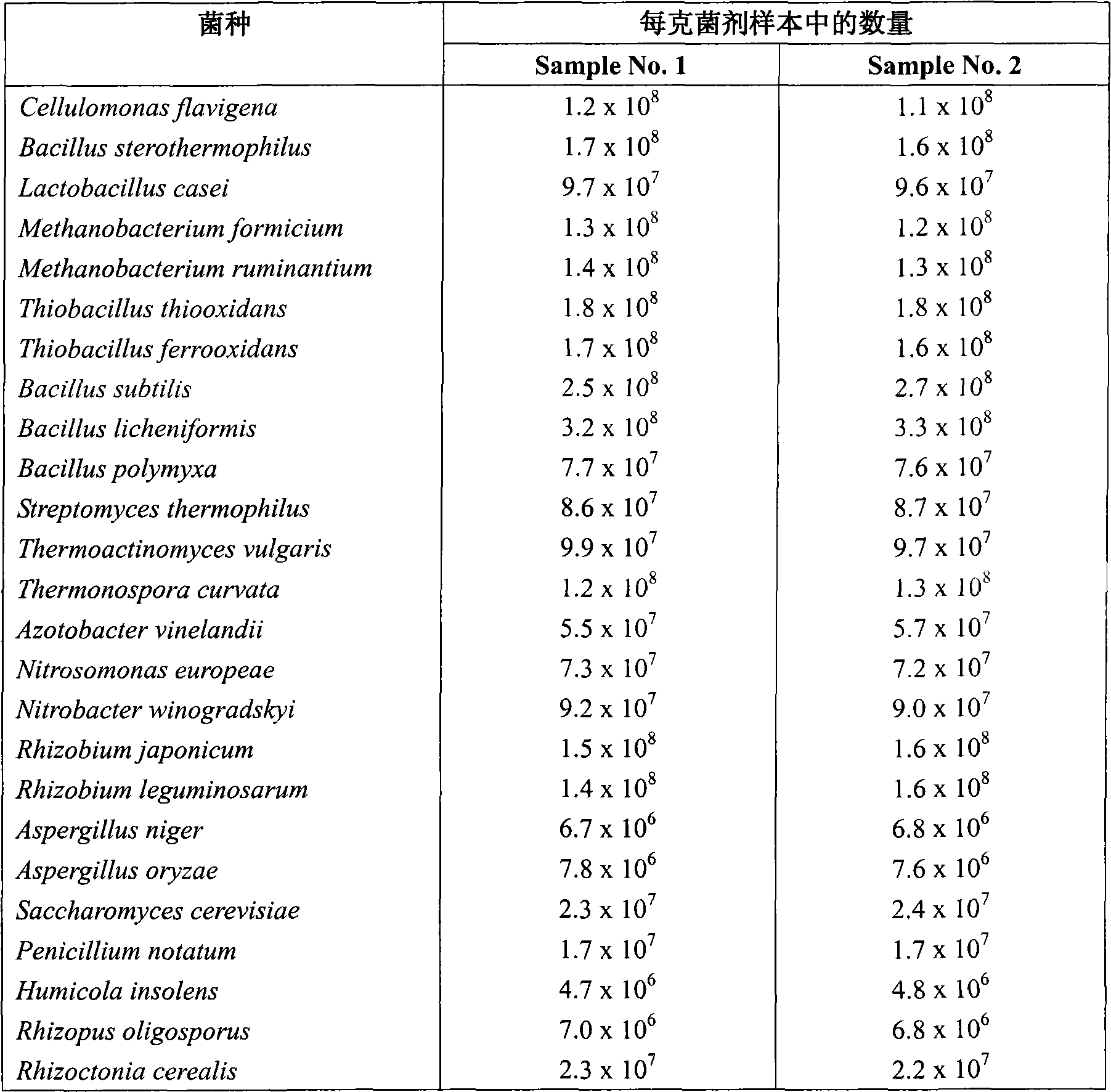

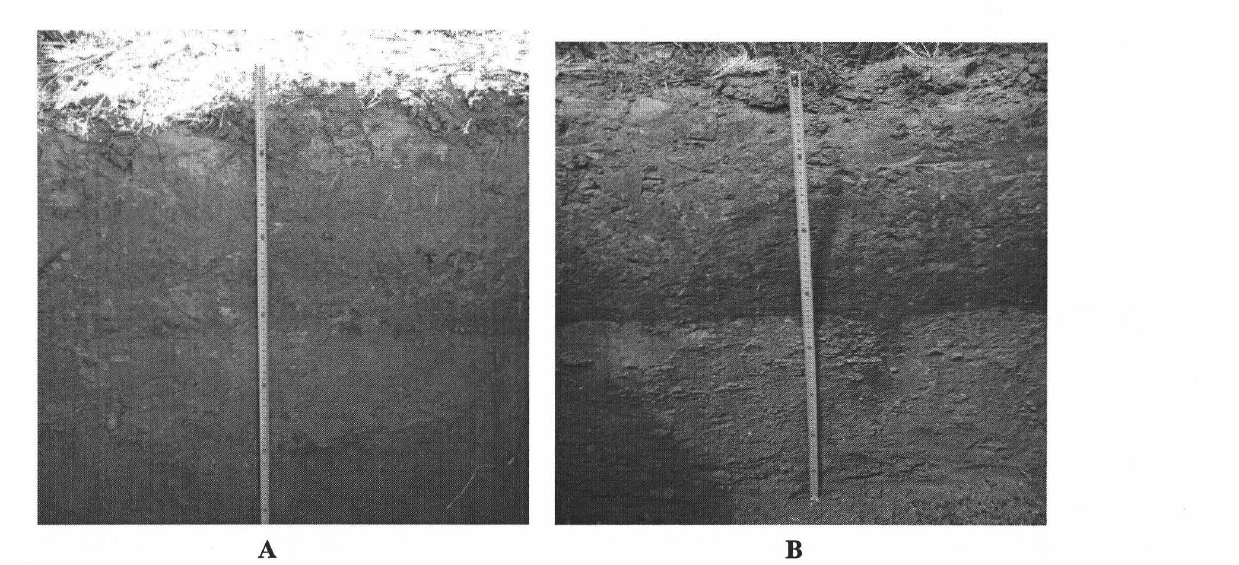

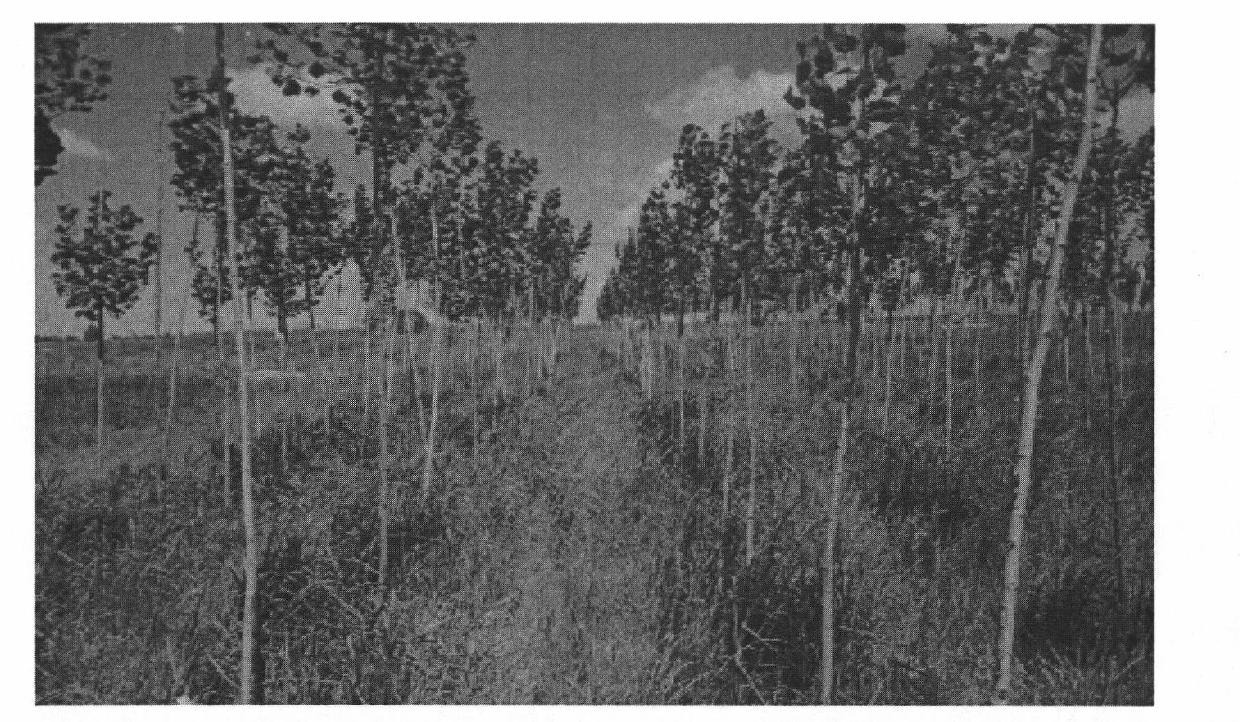

The invention relates to a microbial inoculum for fermenting and producing organic fertilizers, comprising cellulomonas, bacillus, lactobacillus, methagen, thiobacillus, streptomyces, thermoactinomyces, thermomonospora, azotobacter, nitrosomonas, nitrobacter, rhizobium, aspergillus, yeast, penicillium, humicola, rhizopus and mycorrhizal fungi. In addition, the invention also relates to organic fertilizers fermented and produced by using the microbial inoculum and a method for fermentation and production.

Owner:宋彦耕

Microbial agent and soil modifying agent produced by fermentation thereof

ActiveCN101629156AImprove adaptabilityImprove fertilityAgriculture tools and machinesFungiFiberMicrobial agent

The invention relates to a microbial agent used for producing a soil modifying agent by fermentation, consisting of fiber monad, bacillus, lactobacillus, methanobacteria, thiobacillus, streptomycete, high-temperature actinomyces, high-temperature monad, azotobacteria, nitration monad, nitration bacilus, rhizobium, koji mold, leaven, blue mold, detritus mold, rhizopus as well as mycorrhizal fungi and substrate. In addition, the invention also relates to a soil modifying agent produced by the fermentation of the microbial agent, application thereof and the like.

Owner:宋彦耕

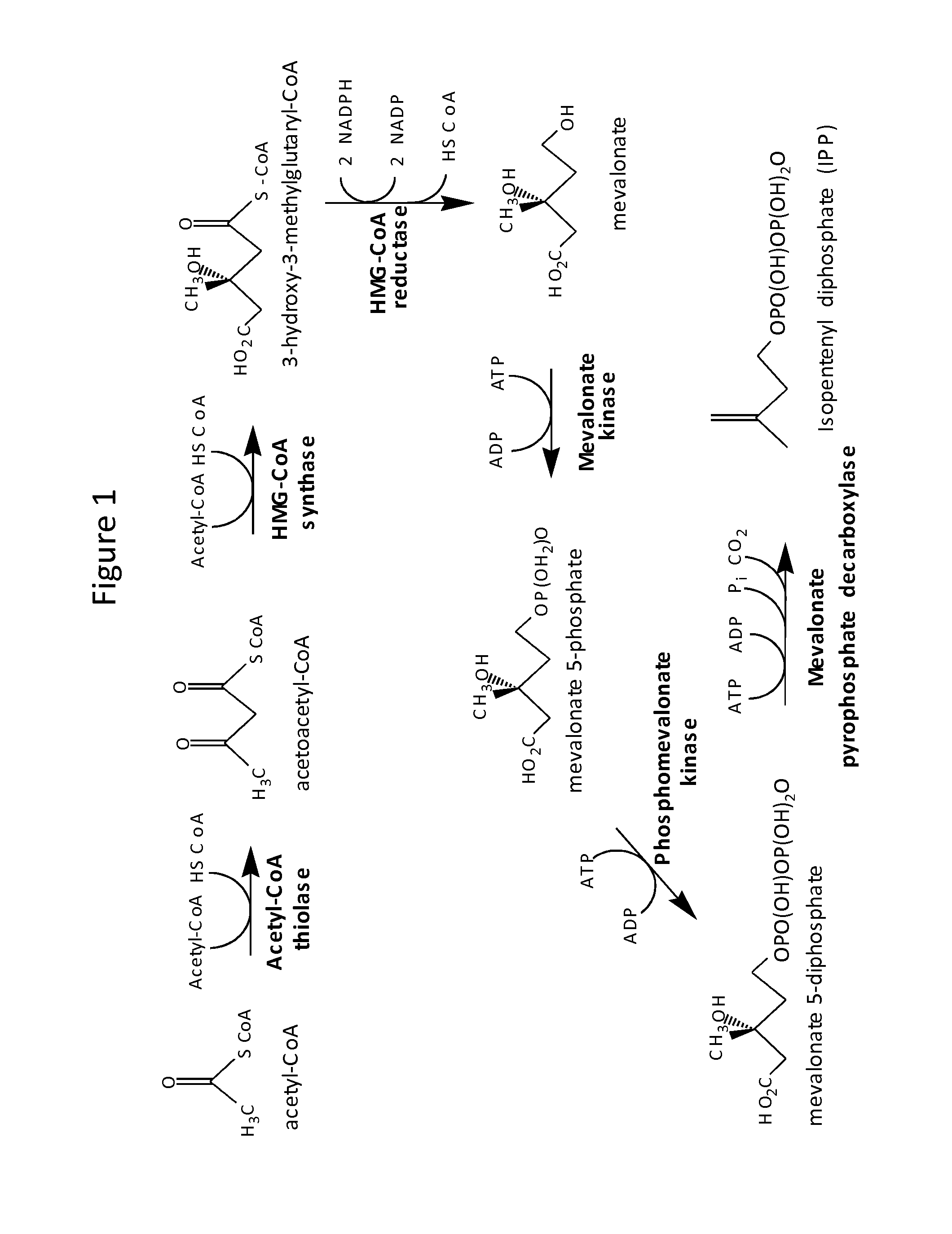

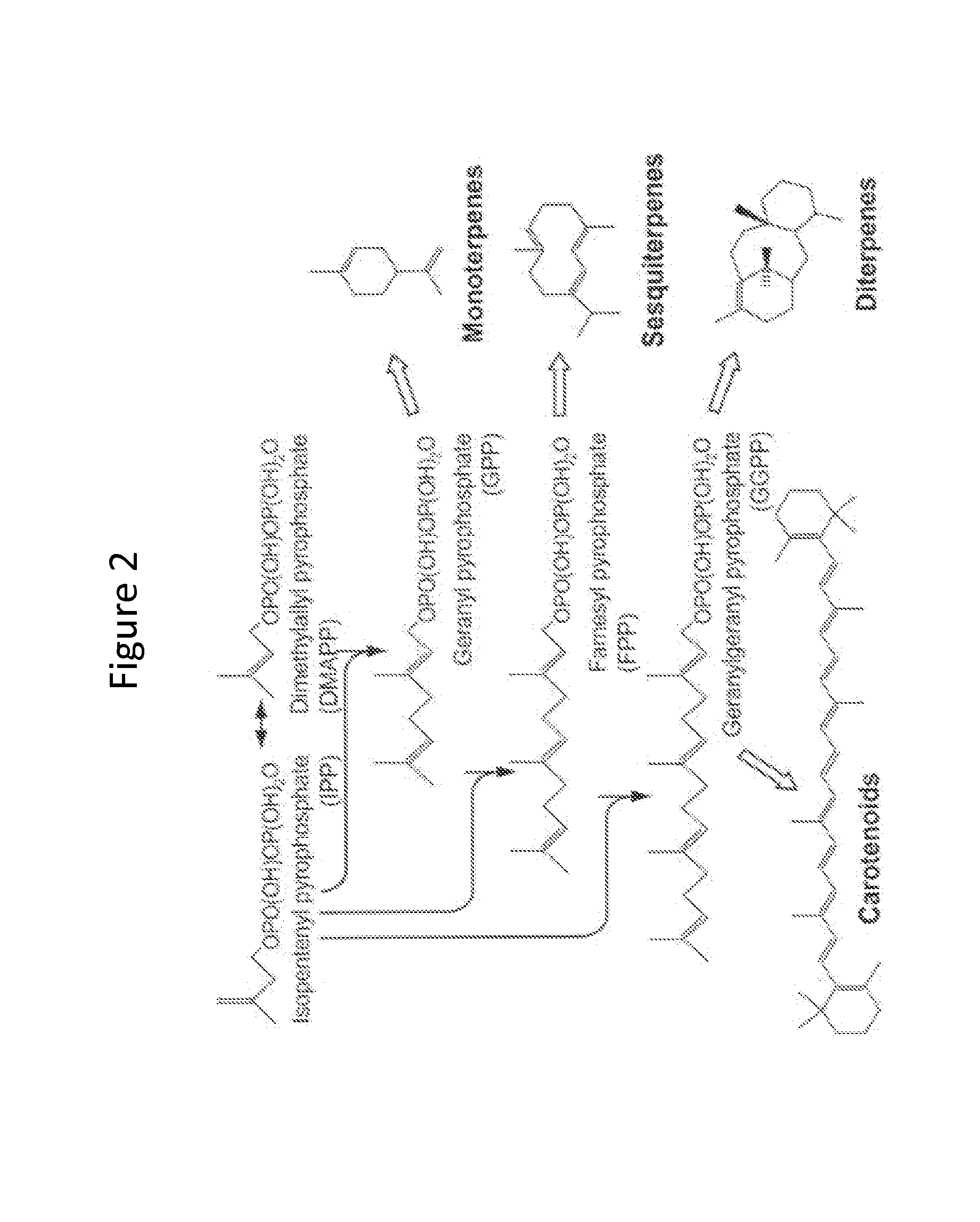

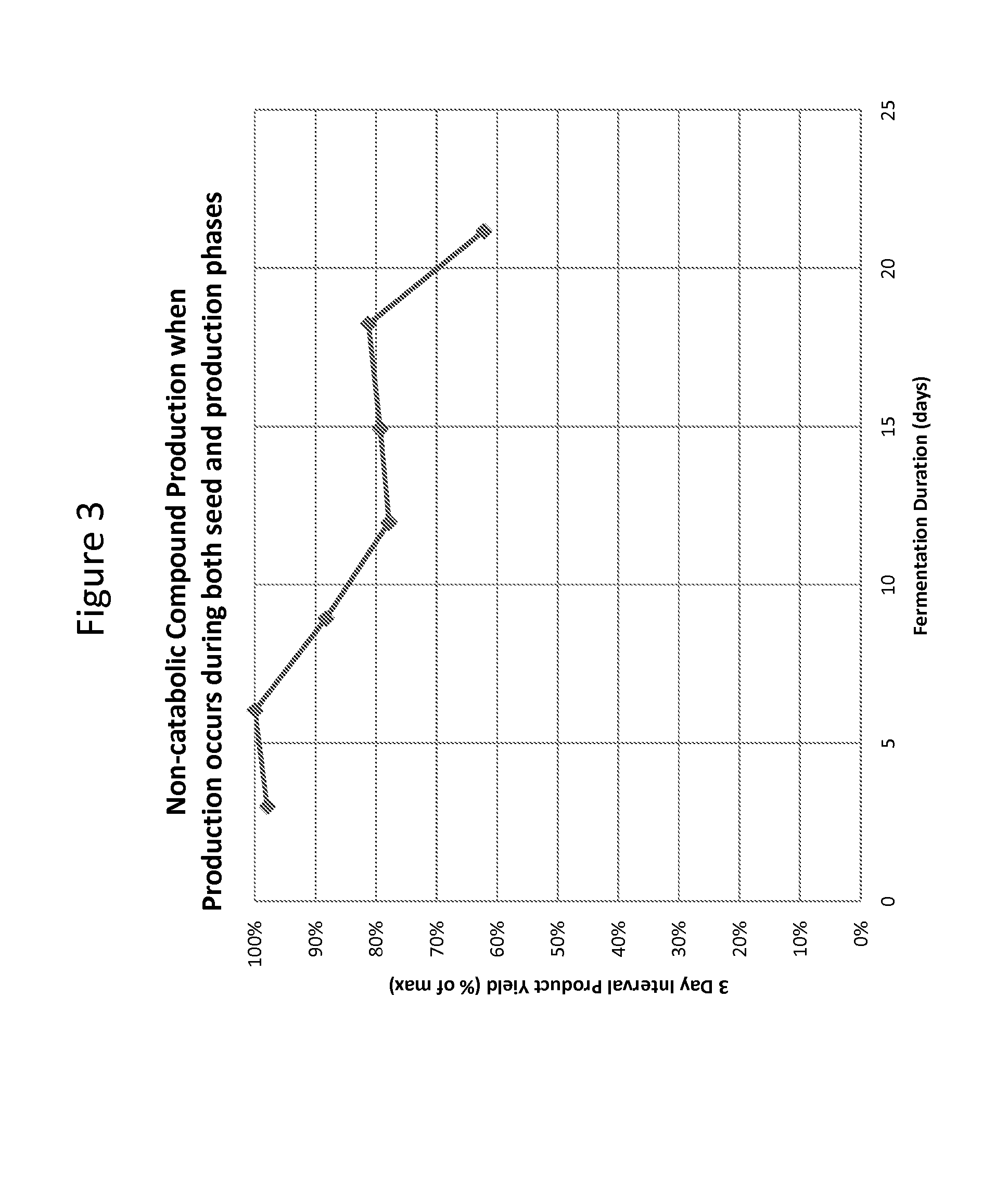

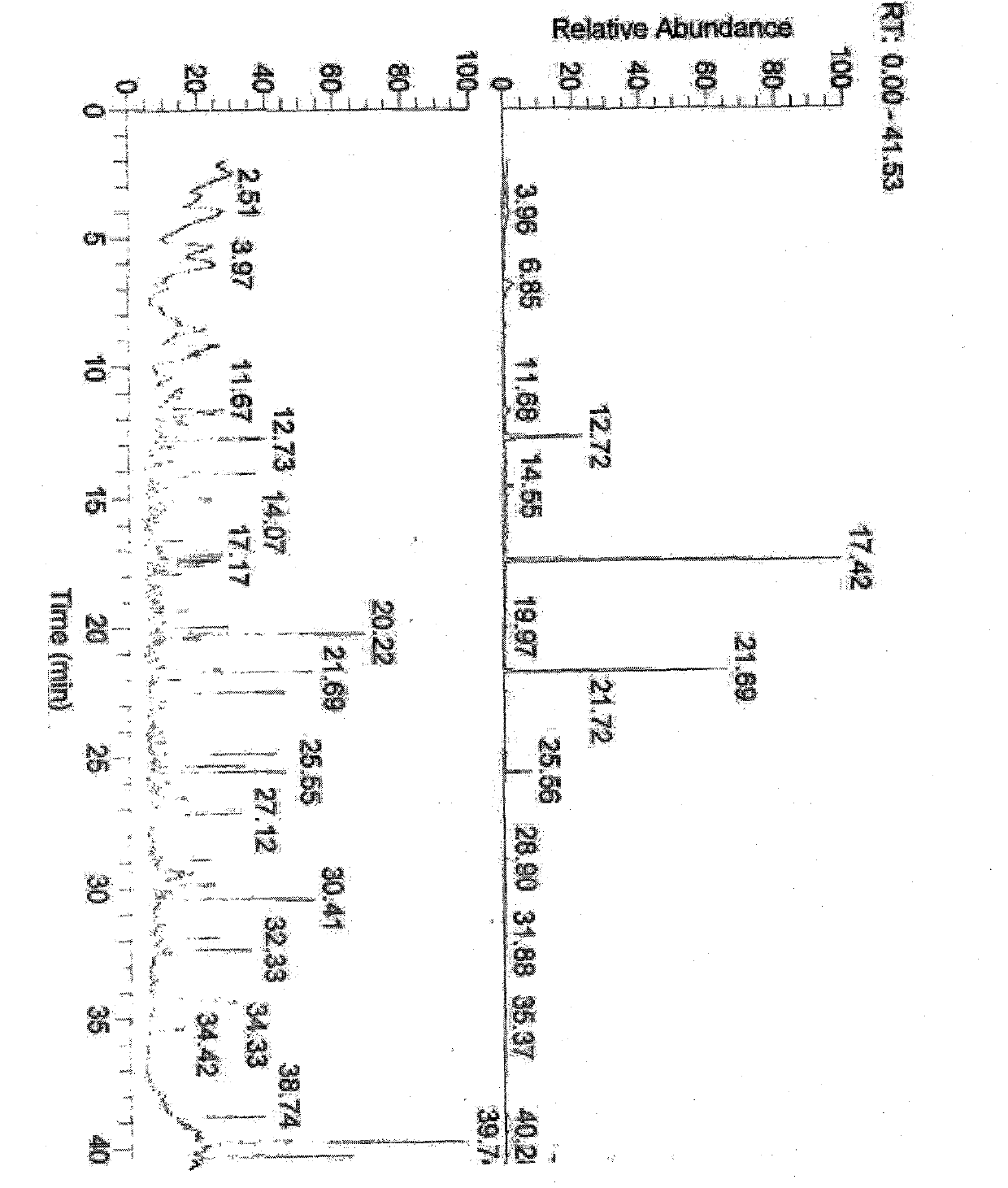

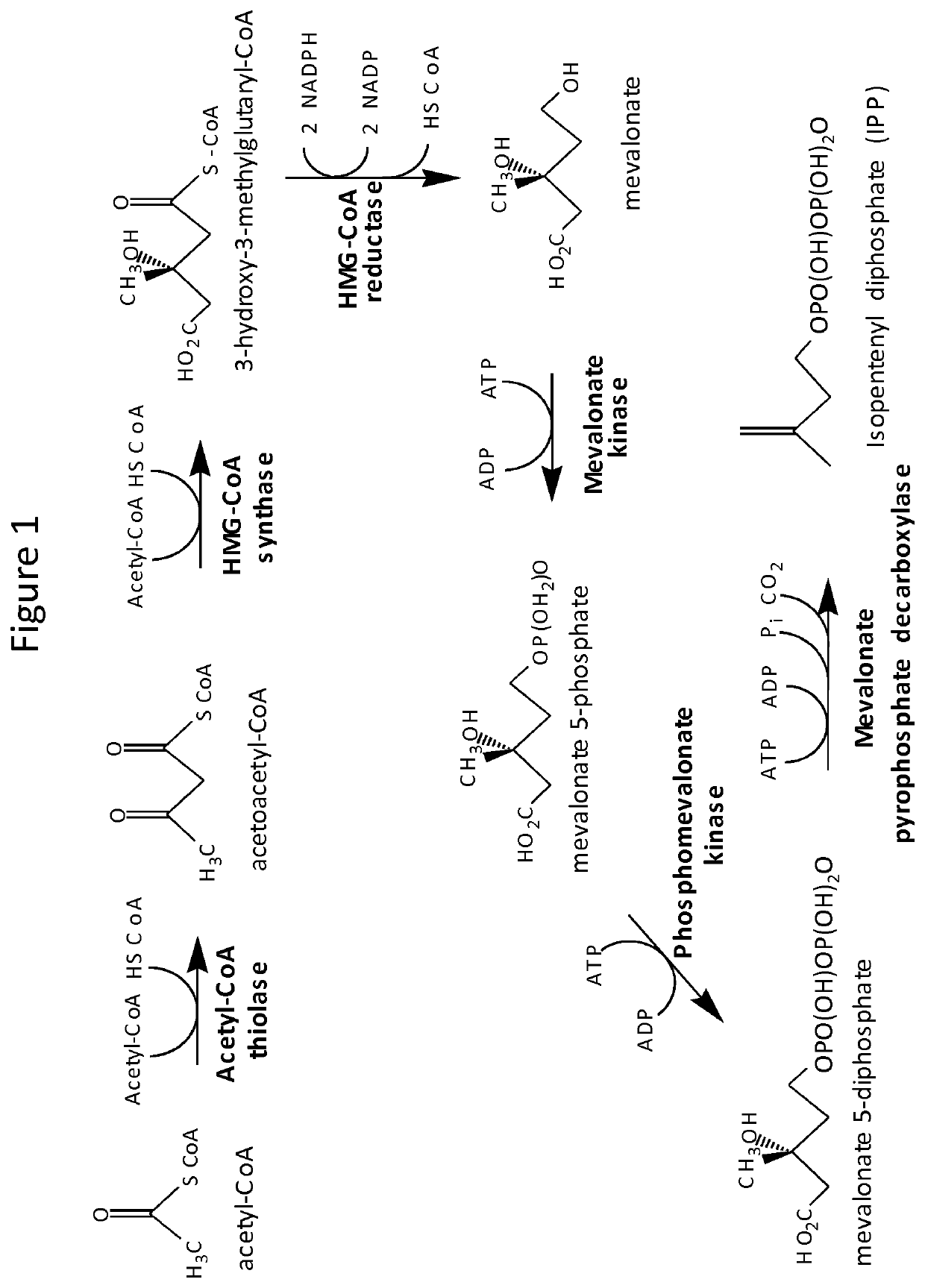

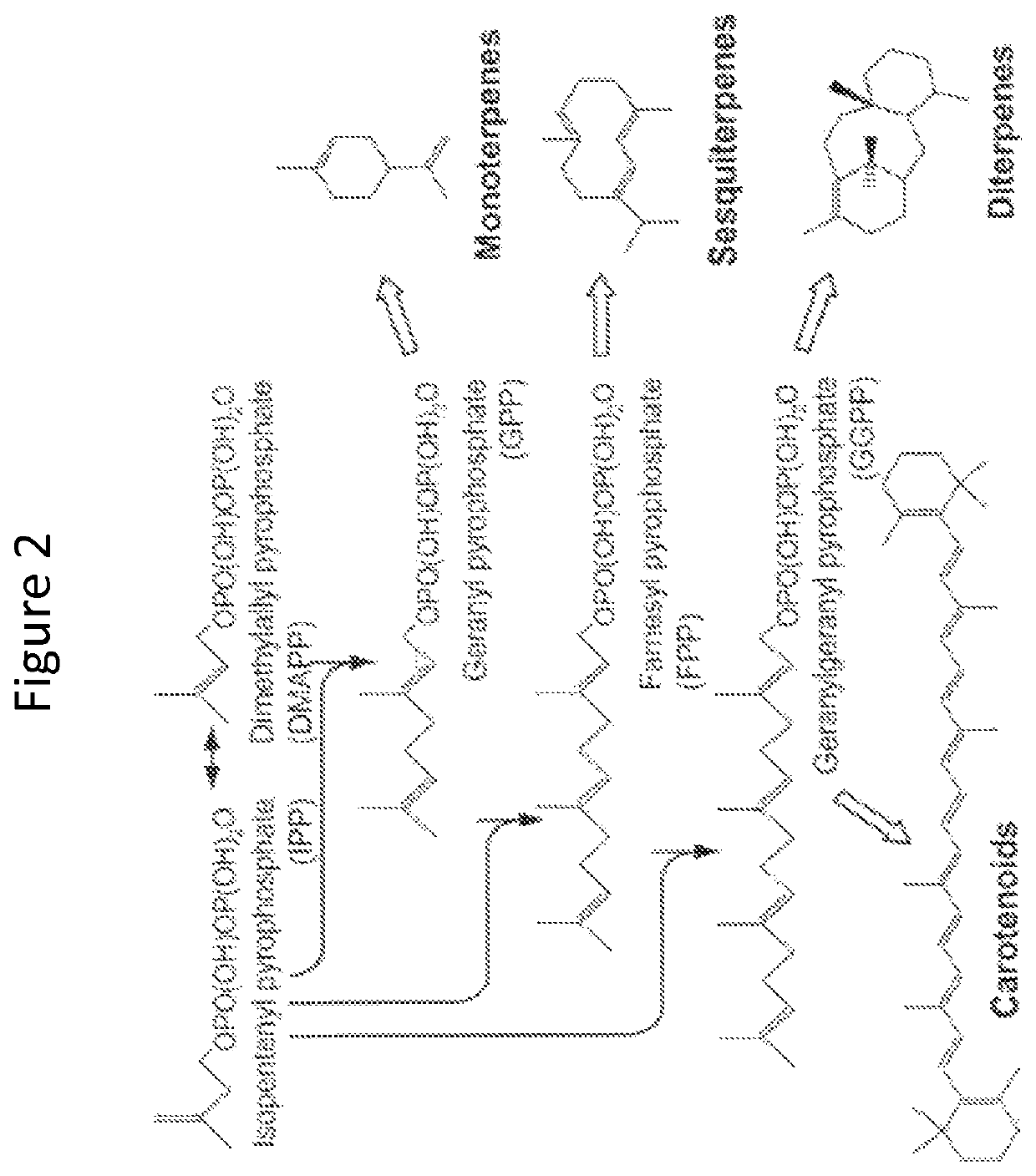

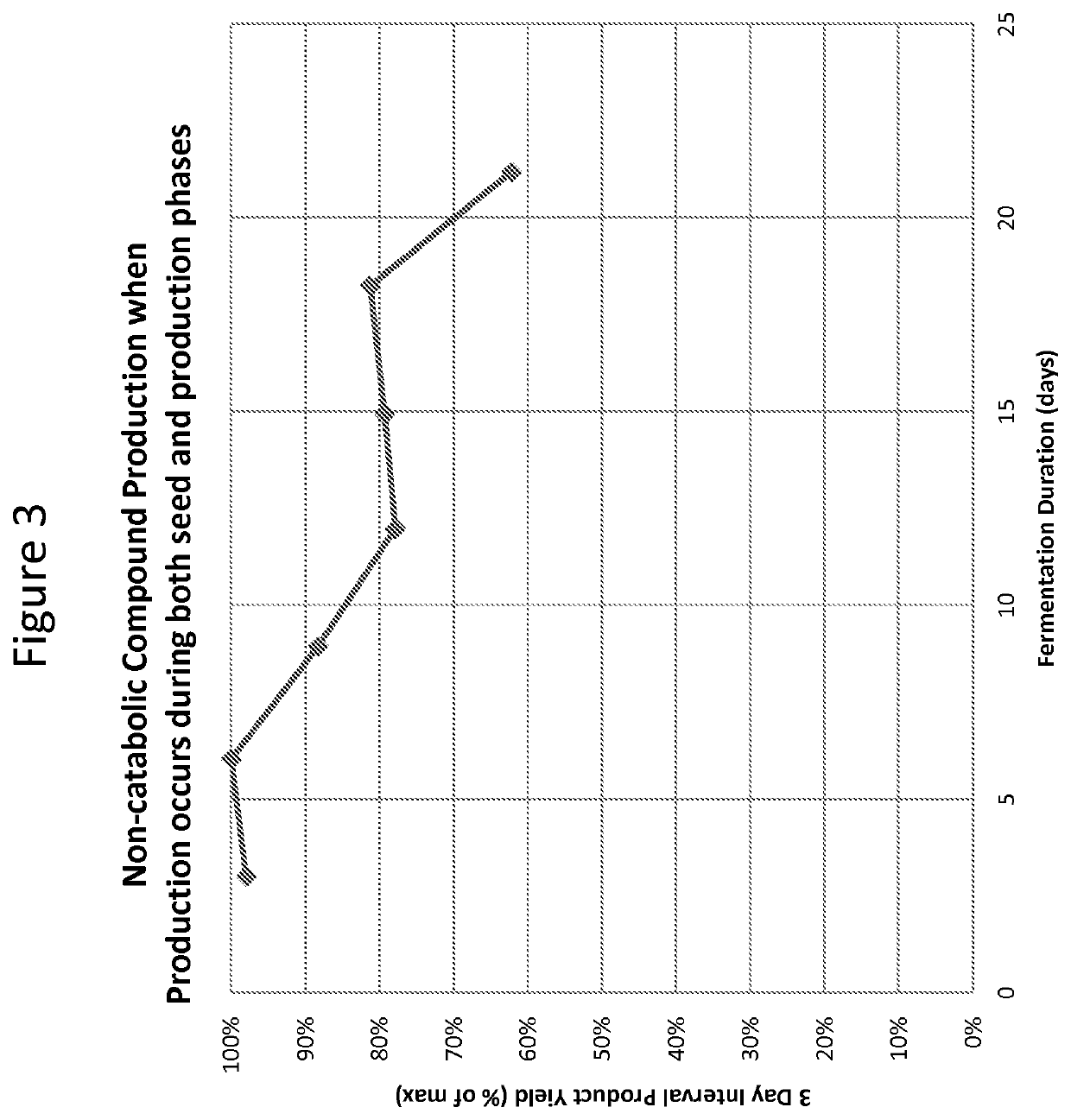

Methods for stabilizing production of acetyl-coenzyme a derived compounds

ActiveUS20160177341A1Increase probabilityLonger sustained non-catabolic compound productionFungiBacteriaMicroorganismHeterologous

The present disclosure relates to the use of a switch for the production of heterologous non-catabolic compounds in microbial host cells. In one aspect, provided herein are genetically modified microorganisms that produce non-catabolic compounds more stably when serially cultured under aerobic conditions followed by microaerobic conditions, and methods of producing non-catabolic compounds by culturing the genetically modified microbes under such culture conditions. In another aspect, provided herein are genetically modified microorganisms that produce non-catabolic compounds more stably when serially cultured in the presence of maltose followed by the reduction or absence of maltose, and methods of producing non-catabolic compounds by culturing the genetically modified microbes under such culture conditions.

Owner:AMYRIS INC +1

High tensile strength cold rolled steel sheet having excellent strain age hardening characteristics and the production thereof

InactiveUS20030145920A1Easy to shapeImproving size precisionFurnace typesHeat treatment furnacesSheet steelSolid solution

The present invention presents a high tensile strength cold rolled steel sheet having excellent formability, impact resistance and strain age hardening characteristics, and the production thereof. As a specific means, a slab having a composition which contains, by mass %, 0.15% or less of C, 0.02% or less of Al, and 0.0050 to 0.0250% of N at N / Al of 0.3 or higher, and has N in a solid solution state at 0.0010% or more, is first hot rolled at the finish rolling delivery-side temperature of 800° C. or above, and is subsequently coiled at the coiling temperature of 750° C. or below to prepare a hot rolled plate. Then, after cold rolling, the hot rolled plate is continuously cooled at a temperature from the recrystallization temperature to 900° C. at a holding time of 10 to 120 seconds, and is cooled by primary cooling in which the hot rolled plate is cooled to 500° C. or below at a cooling rate of 10 to 300° C. / s, and furthermore if necessary, by secondary cooling in which a residence time is 300 seconds or less in a temperature range of the primary cooling stopping temperature or higher and 350° C. or higher. Provided is a steel sheet containing a ferritic phase having an average crystal grain size of 10 mum or less at an area ratio of 50% or more, and if necessary, a martensitic phase at an area ratio of 3% or more as a second phase.

Owner:JFE STEEL CORP

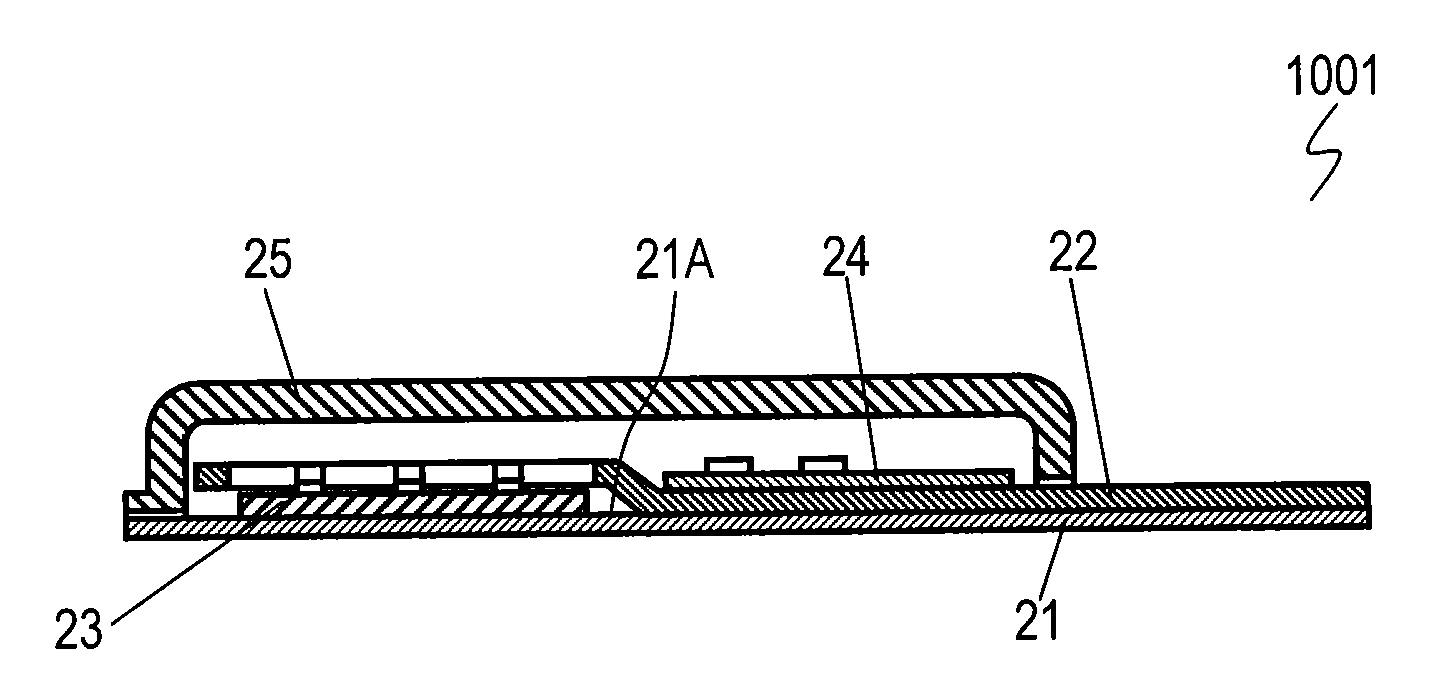

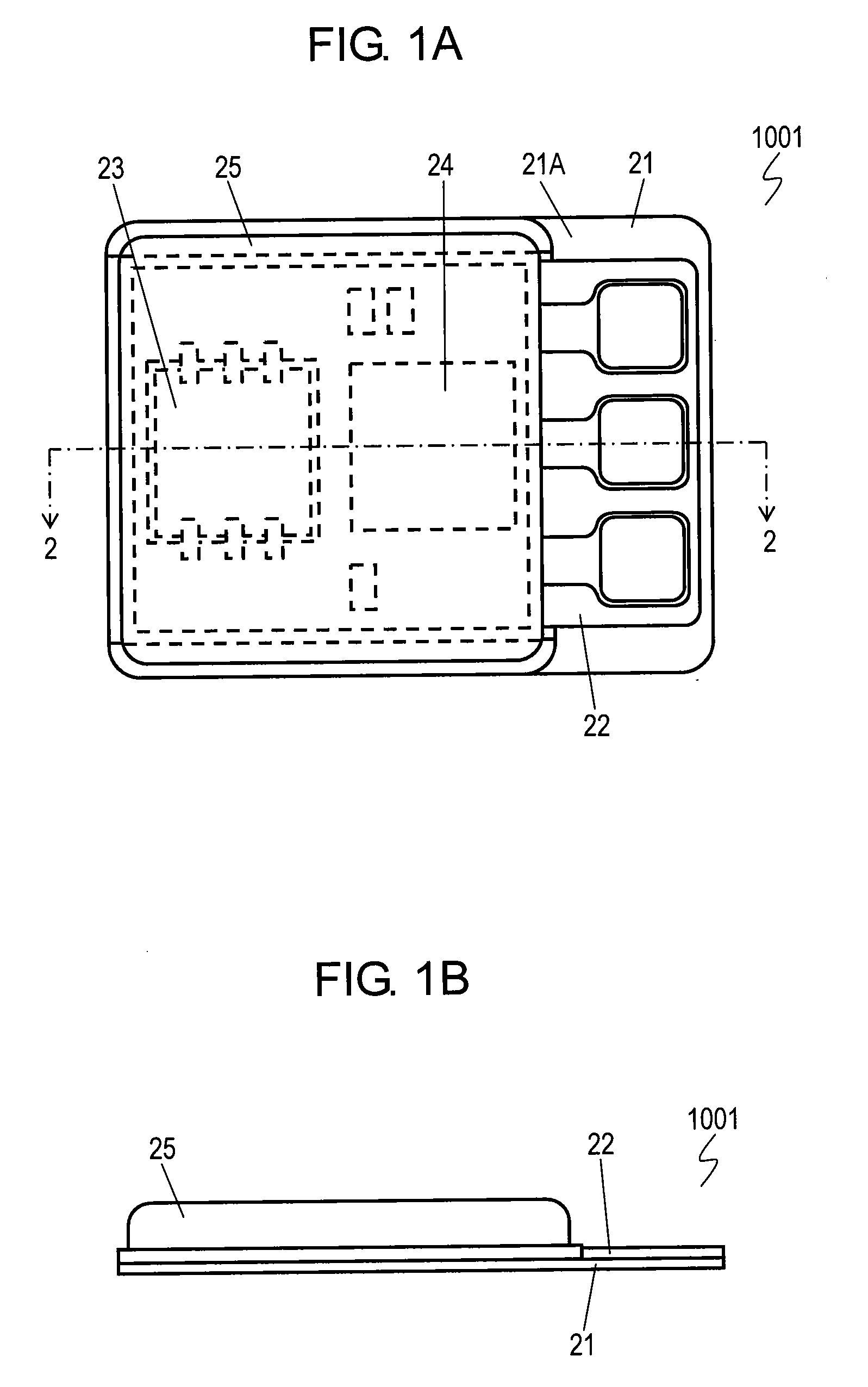

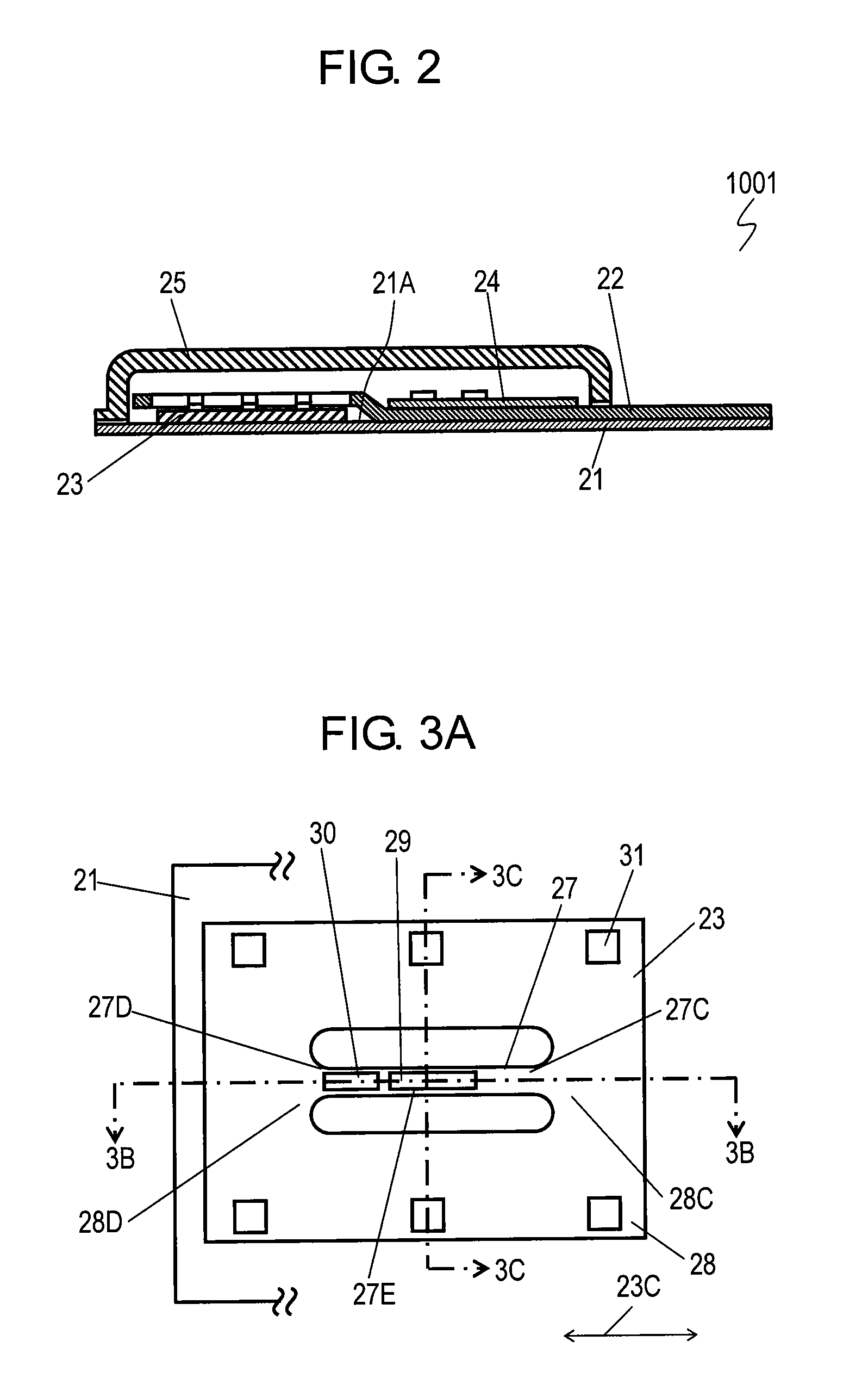

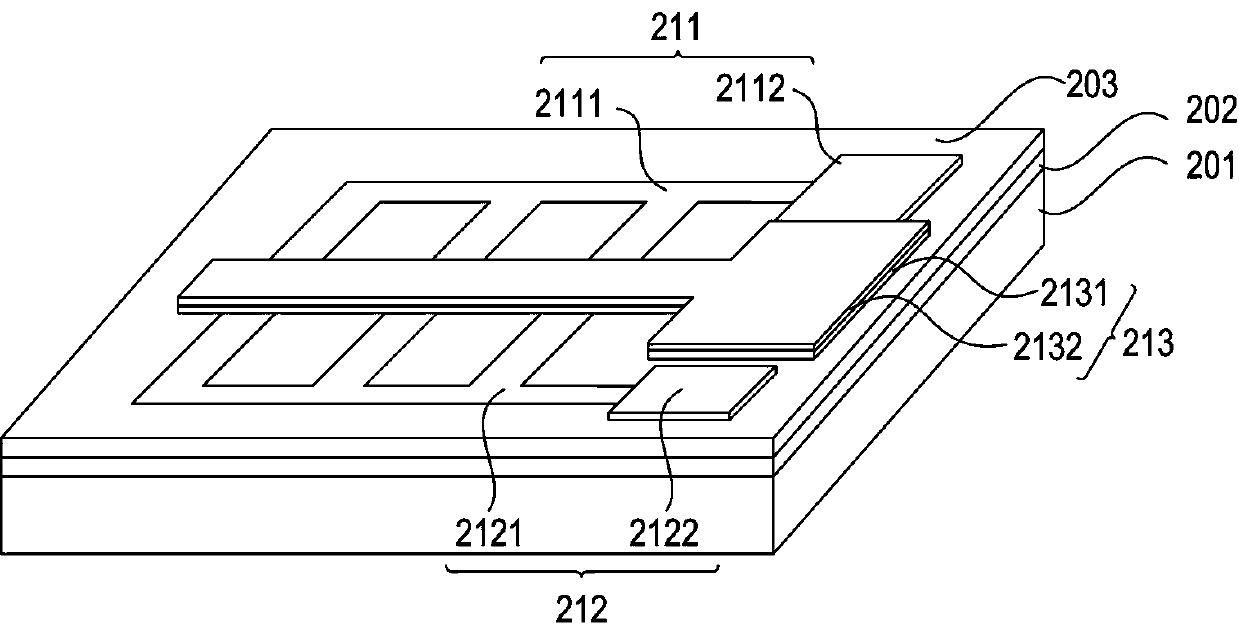

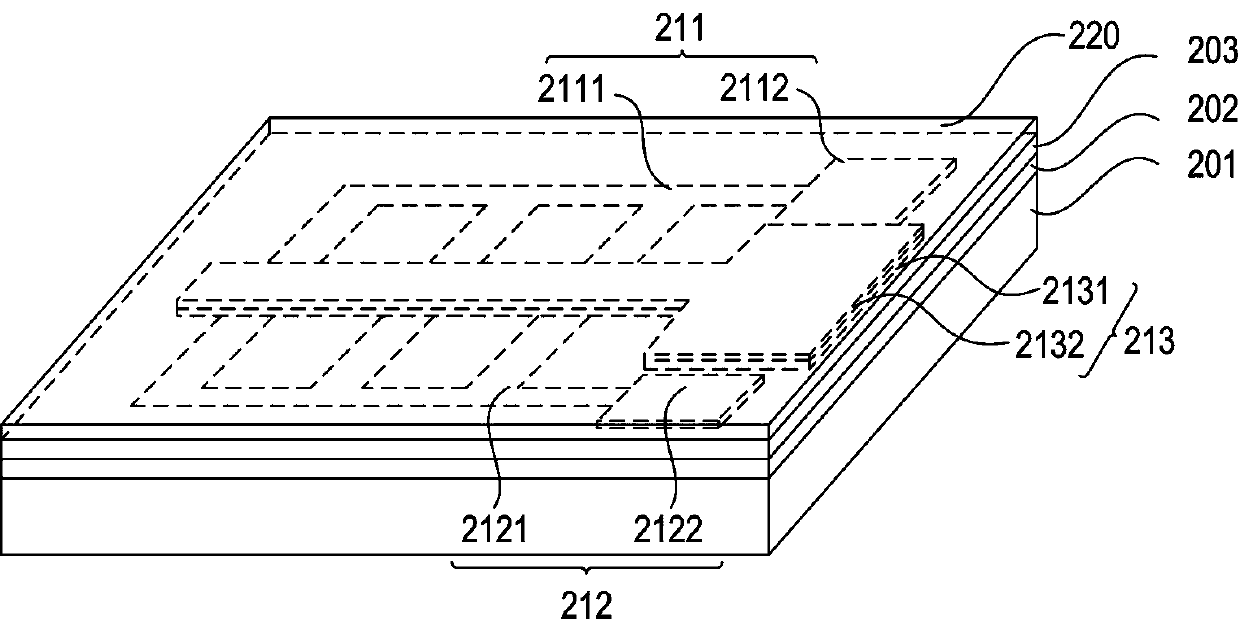

Physical quantity sensor

InactiveUS20120000288A1Strain stabilityStable tensionVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesAcousticsPhysical quantity

A physical quantity sensor includes a deformable body in which strain occurs in response to a stress applied thereto, a vibrator vibrating with a frequency according to the strain or with an amplitude according to the strain, and a processor processing a signal output from the vibrator. The vibrator is mounted to the deformable body such that the strain transmits to the vibrator. The processor is bonded to the deformable body such that the strain does not substantially transmit to the processor. This physical quantity sensor can stably detects strain and tension acting on an object.

Owner:PANASONIC CORP

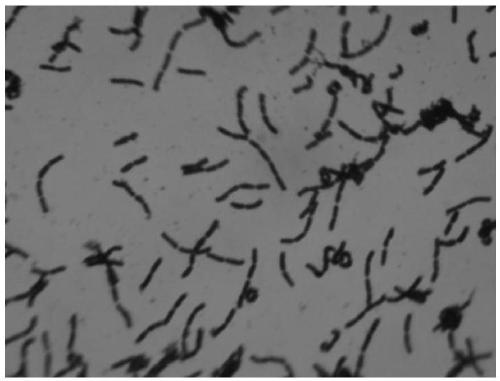

Lactobacillus rhamnosus culture medium and culture method

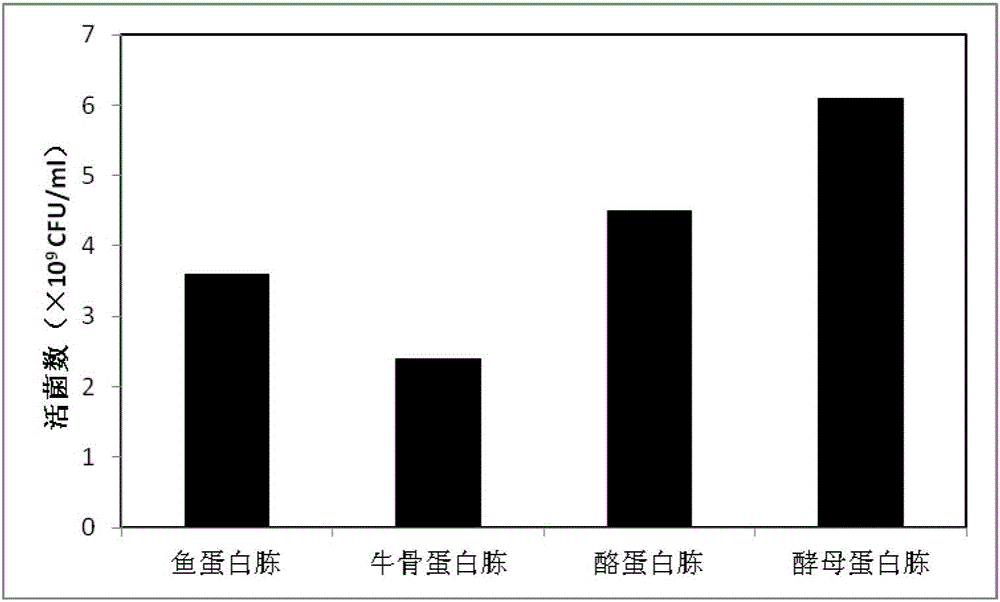

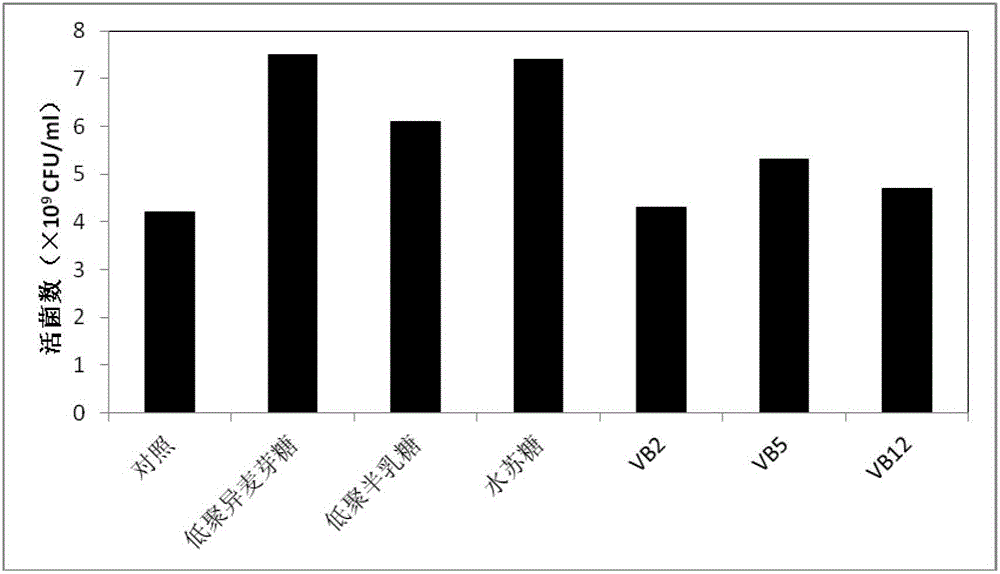

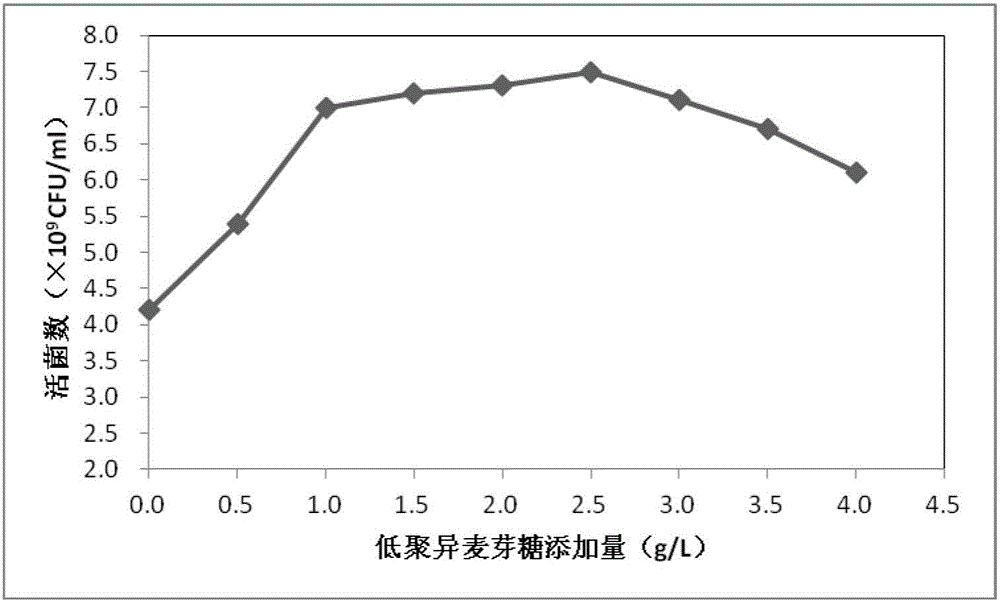

ActiveCN106244509ALow costSuitable for growthBacteriaMicroorganism based processesSodium acetateIsomaltooligosaccharide

The invention discloses a lactobacillus rhamnosus culture medium. The lactobacillus rhamnosus culture medium and culture method has a basic culture medium and an optimized culture medium, wherein the basic culture medium is prepared from the following components: yeast peptone, glucose, yeast extract, sodium acetate, magnesium sulfate, tween 80, isomaltooligosaccharide, potassium dihydrogen phosphate and the balance of sterile water, and the pH value is 6.20 to 6.80; and the optimized culture medium is prepared from the following components: yeast peptone, glucose, yeast extract, sodium acetate, magnesium sulfate, tween 80, isomaltooligosaccharide, potassium dihydrogen phosphate and the balance the sterile water, and the pH value is 6.20 to 6.80. The culture medium is suitable for proliferation culture of lactobacillus rhamnosus. By utilizing the method for culturing the lactobacillus rhamnosus by virtue of the culture medium, not only can the culture of the lactobacillus rhamnosus be effectively proliferated, but also the industrialized mass production can be facilitated.

Owner:江西仁仁健康微生态科技有限公司

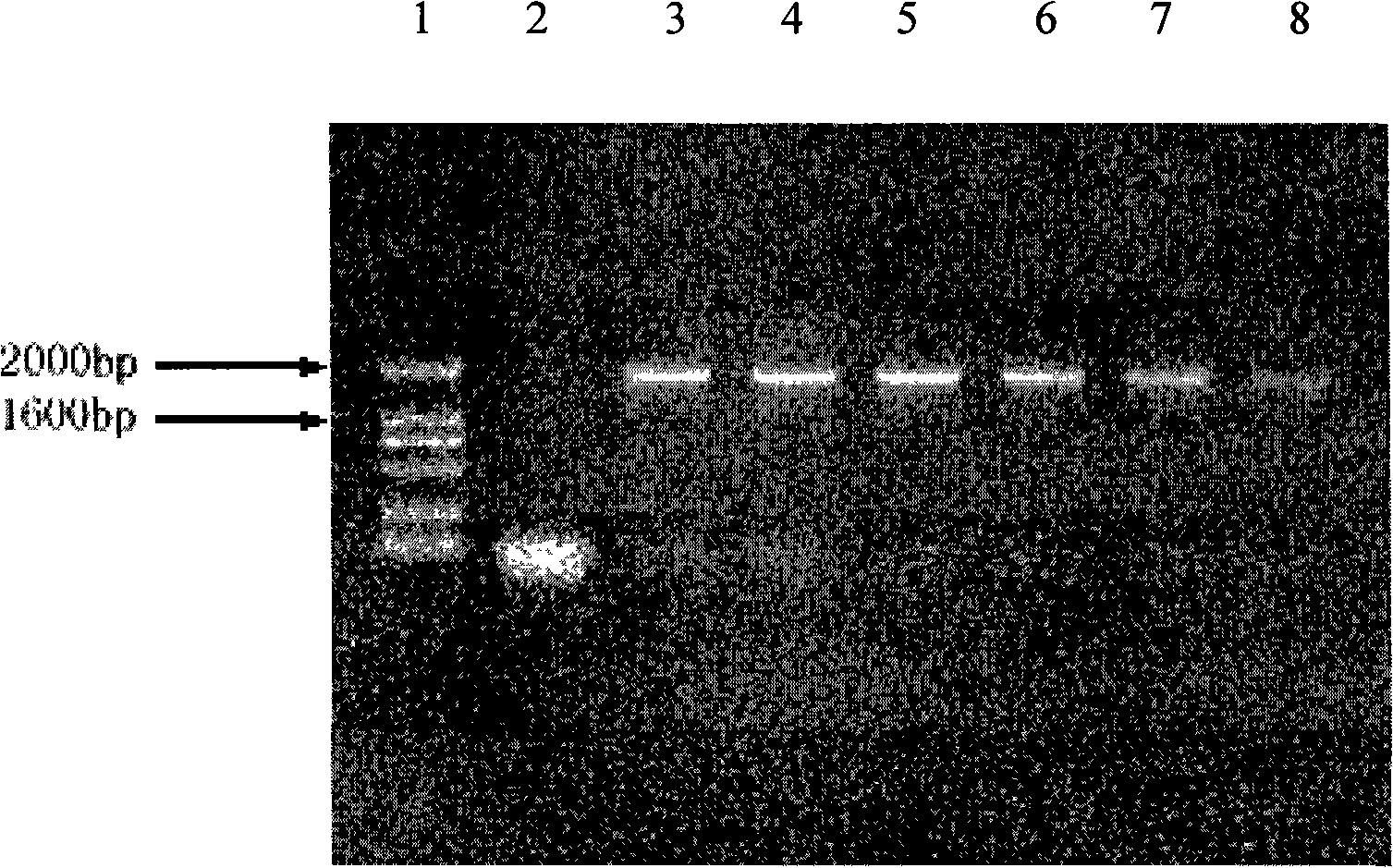

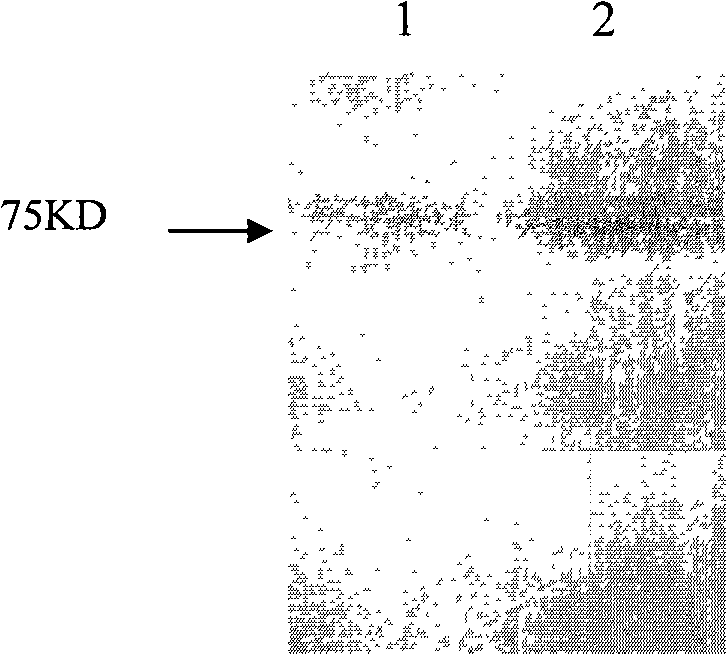

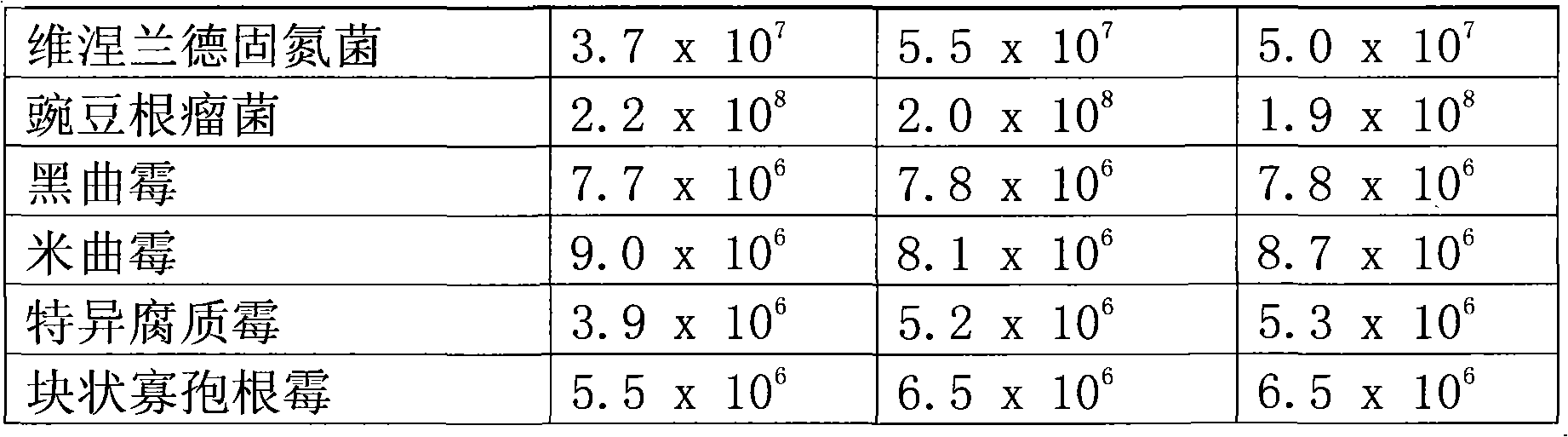

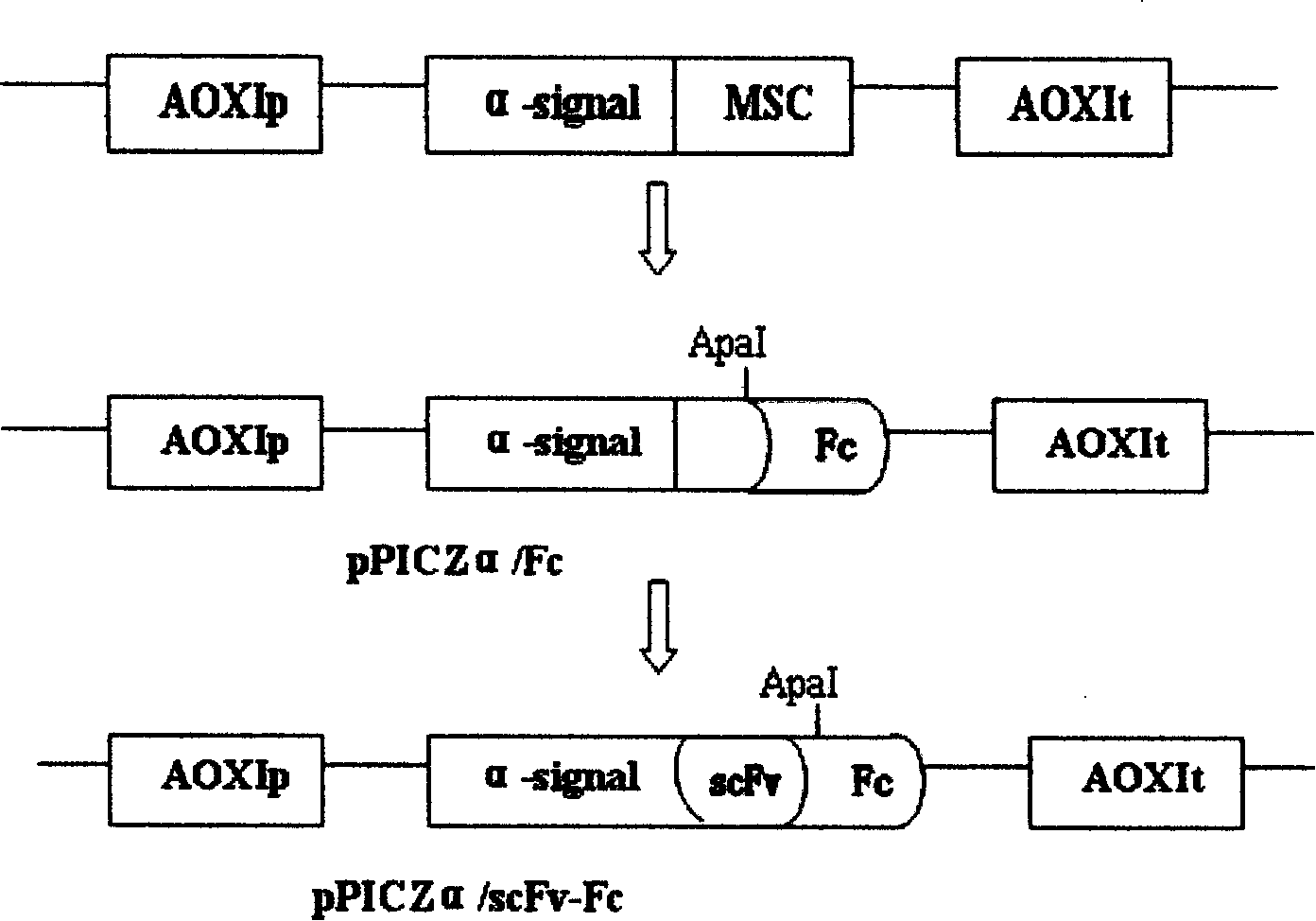

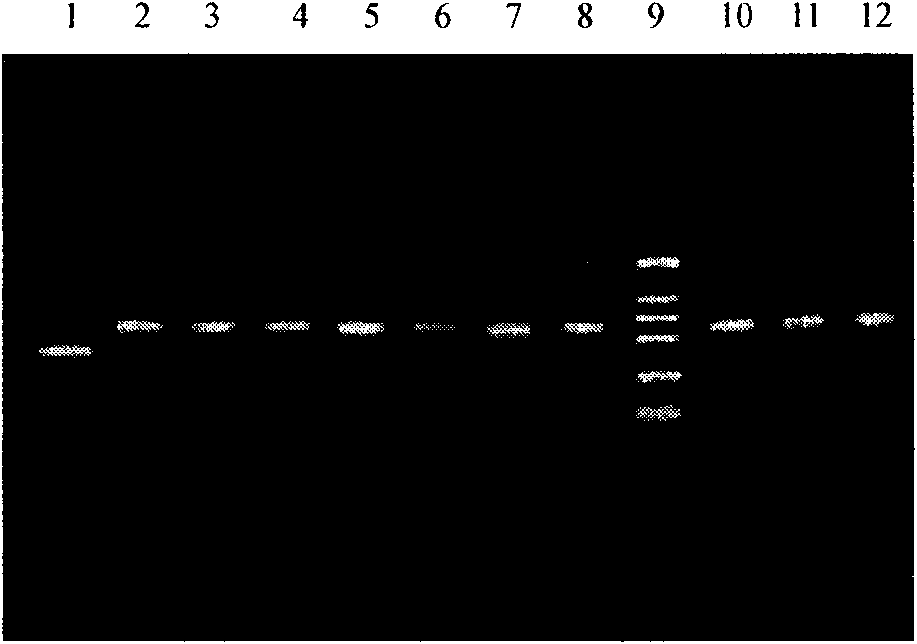

Method for producing recombinant human epidermal growth factor acceptor 2 cytoplasmic region with methylotrophy yeast

InactiveCN101492675AEfficient expressionOptimizing Dissolved Oxygen LevelsFungiMicroorganism based processesYeastFermentation

The invention relates to a method for producing, purifying and appraising protein, in particular to a method for expression of recombinant human her2 / neu ICD in Pasteur yeast as well as optimized large scale industrialized fermentation production and purification of the recombinant human her2 / neu ICD.

Owner:吉林圣元科技有限责任公司

High tensile strength cold rolled steel sheet having excellent strain age hardening characteristics and the production thereof

InactiveUS20030188811A1Strain stabilityTake advantage ofFurnace typesHeat treatment furnacesSheet steelSolid solution

The present invention presents a high tensile strength cold rolled steel sheet having excellent formability, impact resistance and strain age hardening characteristics, and the production thereof. As a specific means, a slab having a composition which contains, by mass %, 0.15% or less of C, 0.02% or less of Al, and 0.0050 to 0.0250% of N at N / Al of 0.3 or higher, and has N in a solid solution state at 0.0010% or more, is first hot rolled at the finish rolling delivery-side temperature of 800° C. or above, and is subsequently coiled at the coiling temperature of 750° C. or below to prepare a hot rolled plate. Then, after cold rolling, the hot rolled plate is continuously cooled at a temperature from the recrystallization temperature to 900° C. at a holding time of 10 to 120 seconds, and is cooled by primary cooling in which the hot rolled plate is cooled to 500° C. or below at a cooling rate of 10 to 300° C. / s, and furthermore if necessary, by secondary cooling in which a residence time is 300 seconds or less in a temperature range of the primary cooling stopping temperature or higher and 350° C. or higher. Provided is a steel sheet containing a ferritic phase having an average crystal grain size of 10 mum or less at an area ratio of 50% or more, and if necessary, a martensitic phase at an area ratio of 3% or more as a second phase.

Owner:JFE STEEL CORP

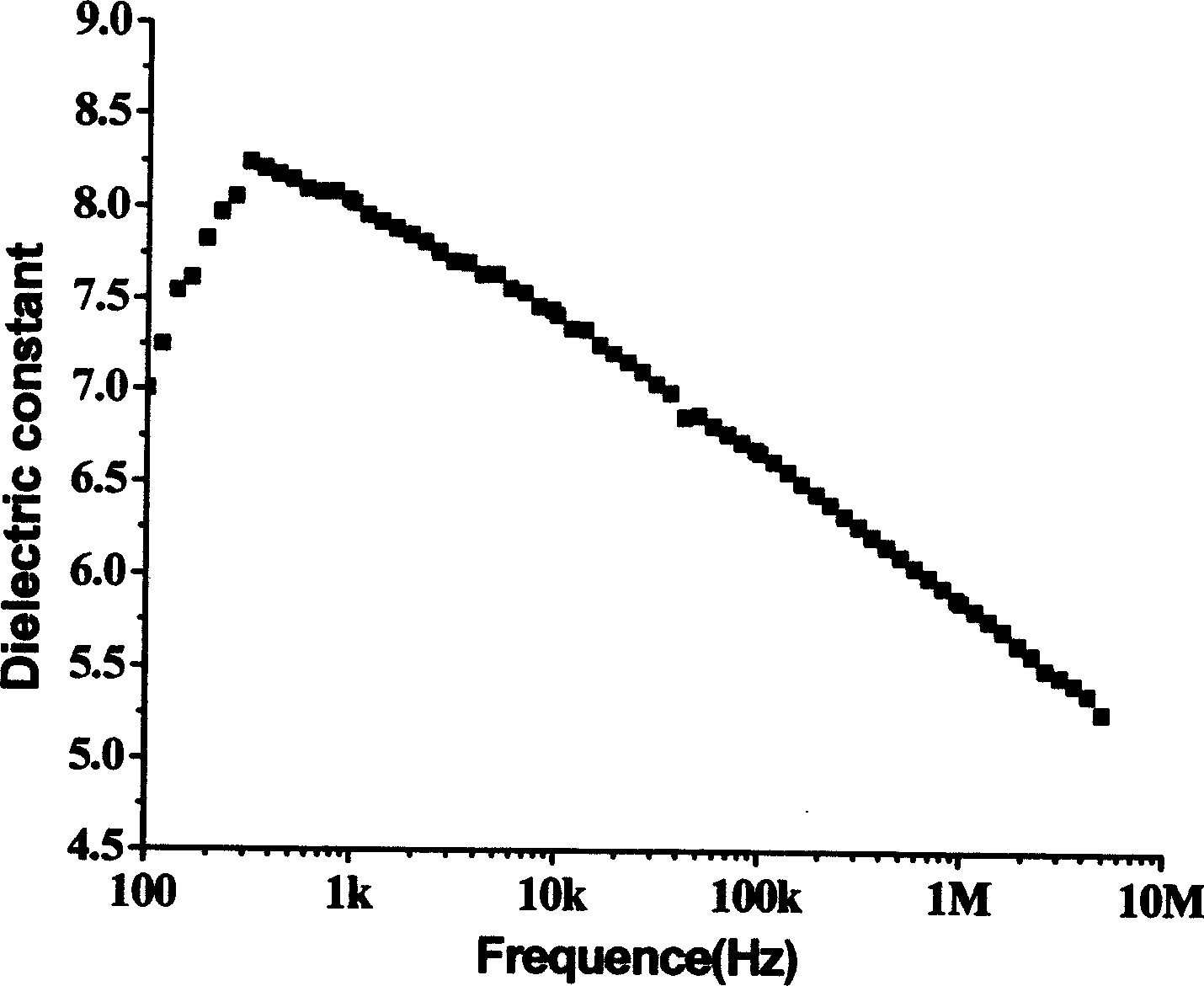

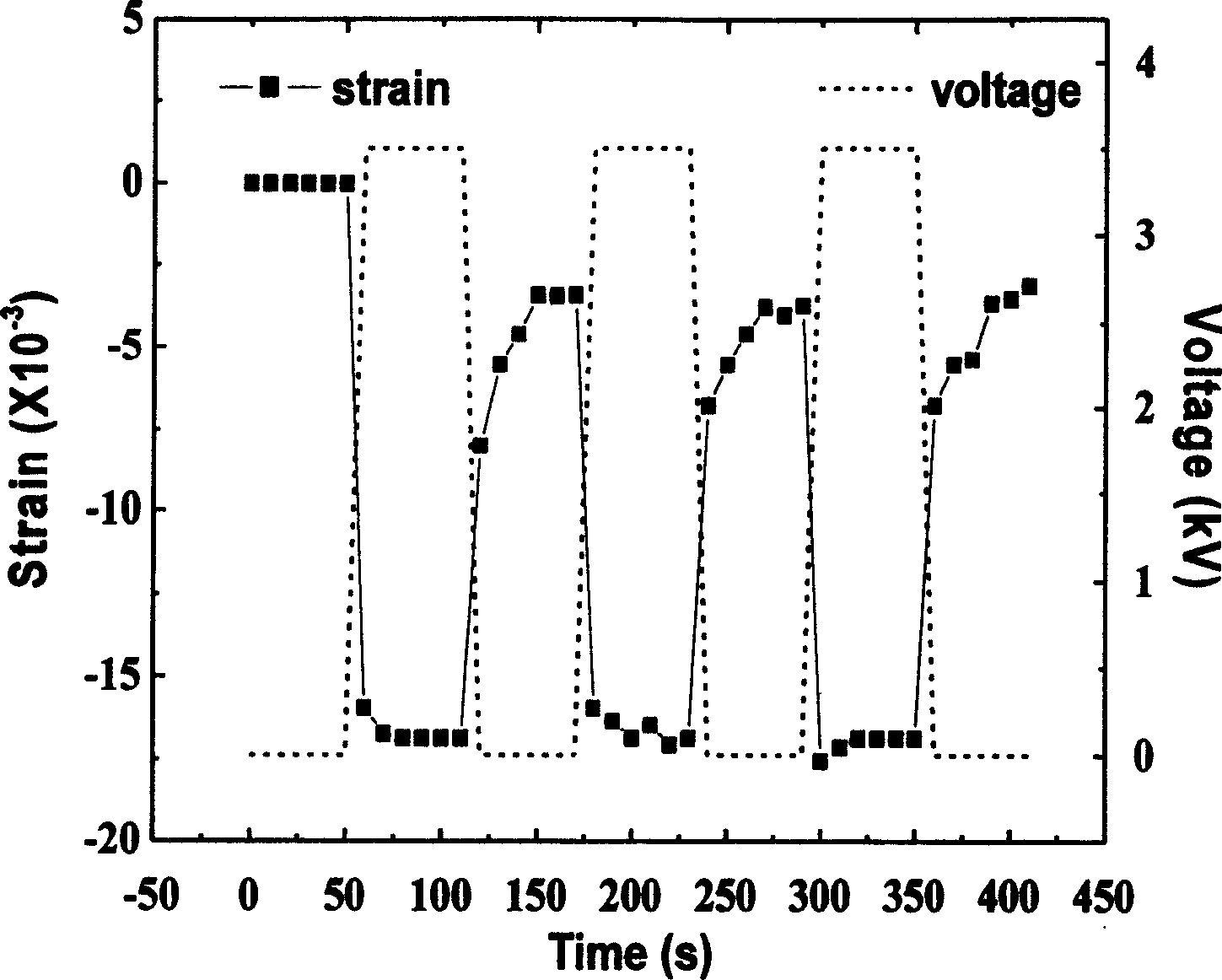

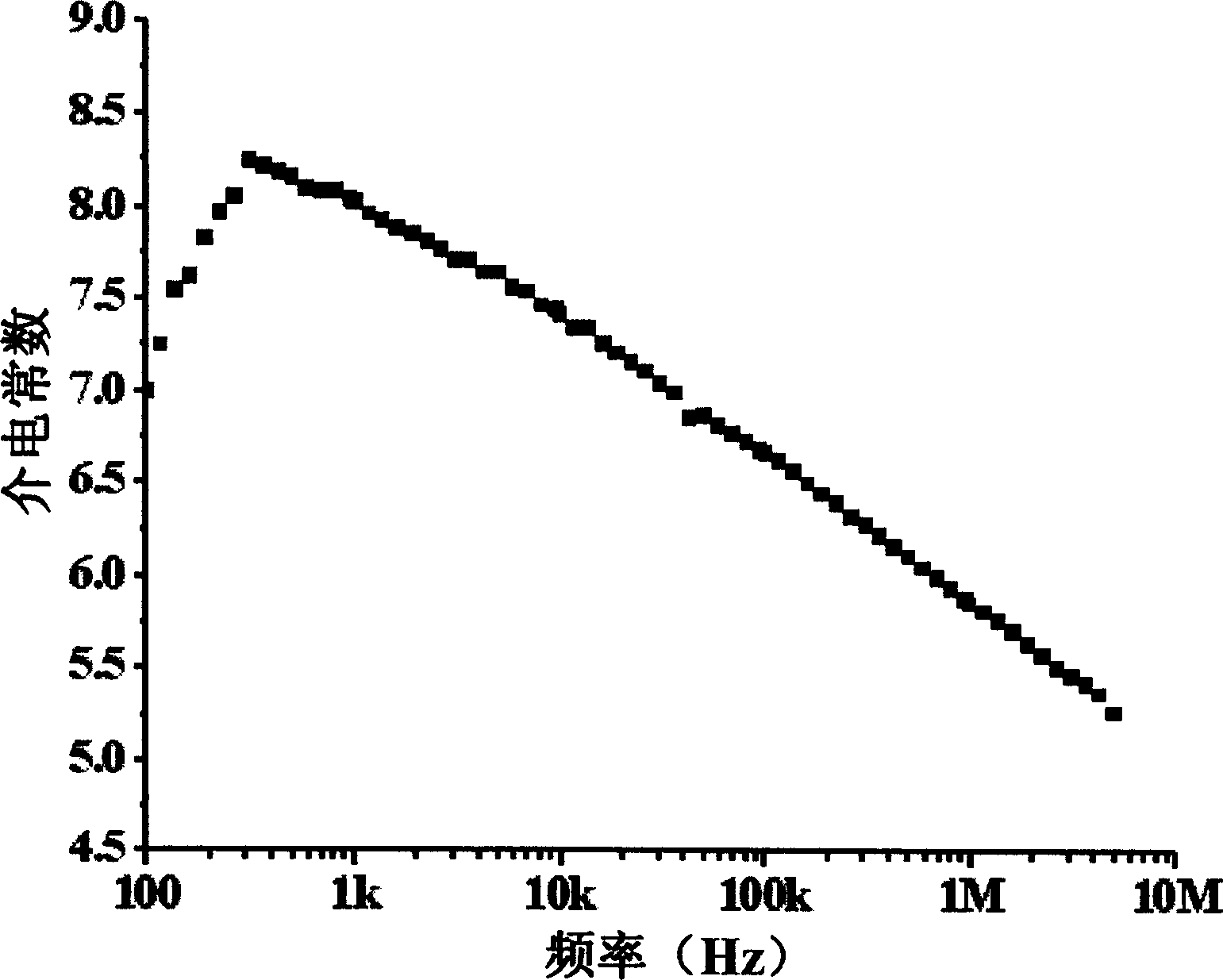

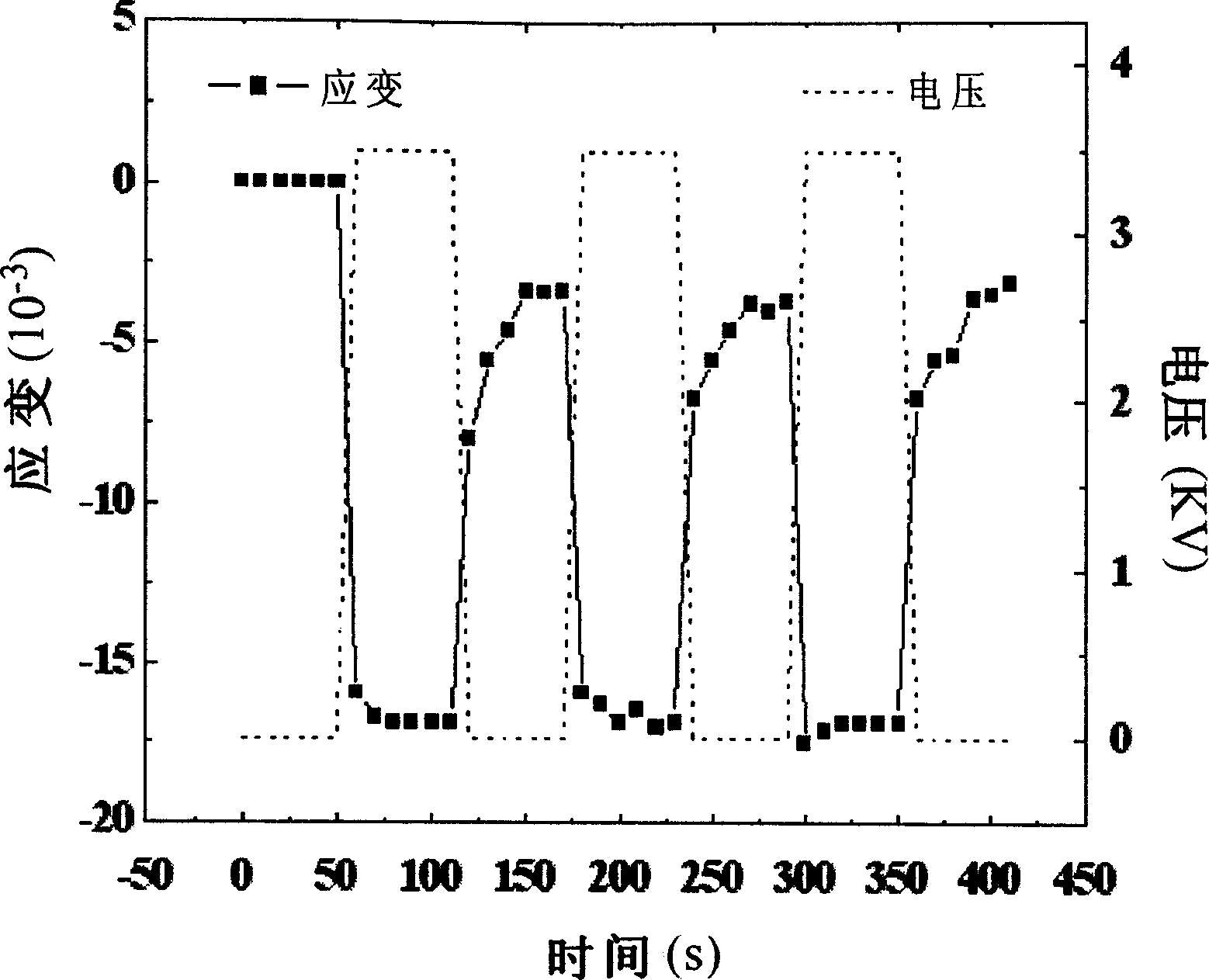

Process for synthesizing nano barium titanate/polyurethane elastic composite

InactiveCN1693363AExcellent dielectric propertiesImproved electrostrictive performancePolyurethane elastomerPolyester

A process for synthesizing the electrostrictive nano-barium carbonate / polyurethane elastomer compound includes such steps as proportionally mixing nano-barium carbonate, solvent and coupling agent, adding it to polyester polyol, adding isocyanate and cross-linking agent, polymerizing and high-temp solidifying.

Owner:SOUTHEAST UNIV

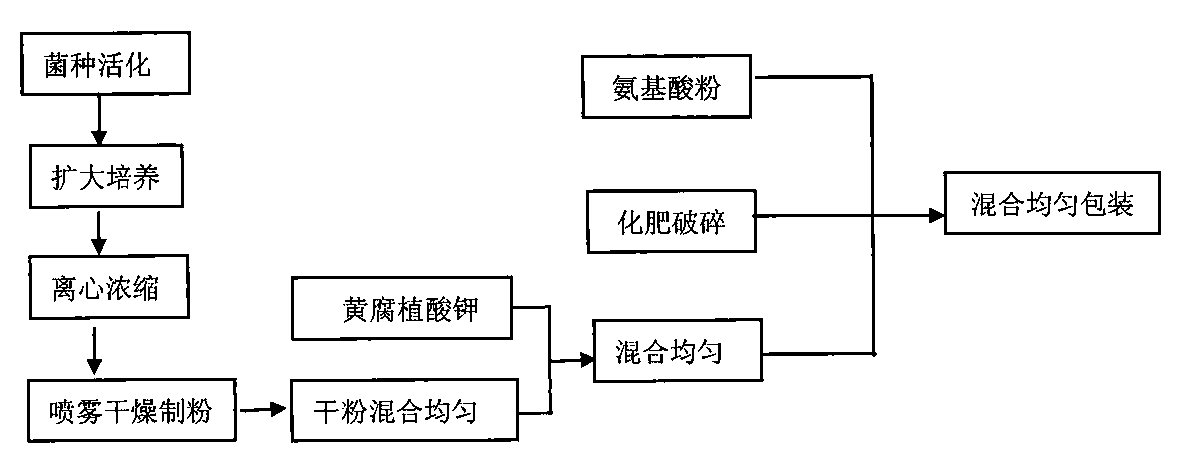

Fulvic acid fertilizer and preparation method thereof

The present invention provides a preparation method of a fulvic acid fertilizer, and the method utilizes of molasses alcohol fermentation waste as a raw material for production. In addition, the present invention also provides the fertilizer obtained by the production method and the fermenting agent used, etc.

Owner:叶长东

High tensile strength cold rolled steel sheet having excellent strain age hardening characteristics and the production thereof

InactiveUS6899771B2Take advantage ofStrain stabilityFurnace typesHeat treatment furnacesSheet steelSolid solution

The present invention presents a high tensile strength cold rolled steel sheet having excellent formability, impact resistance and strain age hardening characteristics, and the production thereof. As a specific means, a slab having a composition which contains, by mass %, 0.15% or less of C, 0.02% or less of Al, and 0.0050 to 0.0250% of N at N / Al of 0.3 or higher, and has N in a solid solution state at 0.0010% or more, is first hot rolled at the finish rolling delivery-side temperature of 800° C. or above, and is subsequently coiled at the coiling temperature of 750° C. or below to prepare a hot rolled plate. Then, after cold rolling, the hot rolled plate is continuously cooled at a temperature from the recrystallization temperature to 900° C. at a holding time of 10 to 120 seconds, and is cooled by primary cooling in which the hot rolled plate is cooled to 500° C. or below at a cooling rate of 10 to 300° C. / s, and furthermore if necessary, by secondary cooling in which a residence time is 300 seconds or less in a temperature range of the primary cooling stopping temperature or below and 350° C. or higher. Provided is a steel sheet containing a ferritic phase having an average crystal grain size of 10 μm or less at an area ratio of 50% or more, and if necessary, a martensitic phase at an area ratio of 3% or more as a second phase.

Owner:JFE STEEL CORP

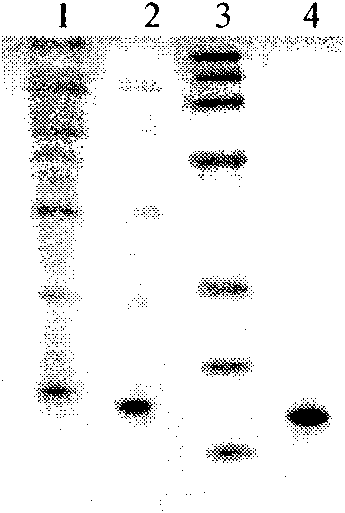

Recombination human rabies viruses resisting antibody

InactiveCN101235086ANo pollution problemEasy to purifyFungiImmunoglobulins against animals/humansHeavy chainNeutralizing antibody

The invention relates to a production method of recombination human antibody, in particular to a production method of recombination human anti rabies virus antibody, which is characterized in that the recombination antibody is neutralizing antibody specially combined with rabies virus, which is determined by the specific gene sequence in hypervariable region (CDRs) of antibody heavy chain and light chain variable region and can be expressed in procaryotic cell and eukaryotic cell. The CDR area, part or all gene of the antibody can generate the antibody in any expression system of procaryotic cell and eukaryotic cell, to prevent and treat rabies clinically.

Owner:吉林圣元科技有限责任公司

Microbial strain agent and organic fertilizers fermented by same

ActiveCN101643718BImprove adaptabilityImprove qualityBio-organic fraction processingFungiBiotechnologyRhizopus

The invention relates to a microbial inoculum for fermenting and producing organic fertilizers, comprising cellulomonas, bacillus, lactobacillus, methagen, thiobacillus, streptomyces, thermoactinomyces, thermomonospora, azotobacter, nitrosomonas, nitrobacter, rhizobium, aspergillus, yeast, penicillium, humicola, rhizopus and mycorrhizal fungi. In addition, the invention also relates to organic fertilizers fermented and produced by using the microbial inoculum and a method for fermentation and production.

Owner:宋彦耕

Microbial agent and soil modifying agent produced by fermentation thereof

ActiveCN101629156BImprove adaptabilityImprove fertilityFungiAgriculture tools and machinesBiotechnologyMicrobial agent

The invention relates to a microbial agent used for producing a soil modifying agent by fermentation, consisting of fiber monad, bacillus, lactobacillus, methanobacteria, thiobacillus, streptomycete, high-temperature actinomyces, high-temperature monad, azotobacteria, nitration monad, nitration bacilus, rhizobium, koji mold, leaven, blue mold, detritus mold, rhizopus as well as mycorrhizal fungi and substrate. In addition, the invention also relates to a soil modifying agent produced by the fermentation of the microbial agent, application thereof and the like.

Owner:宋彦耕

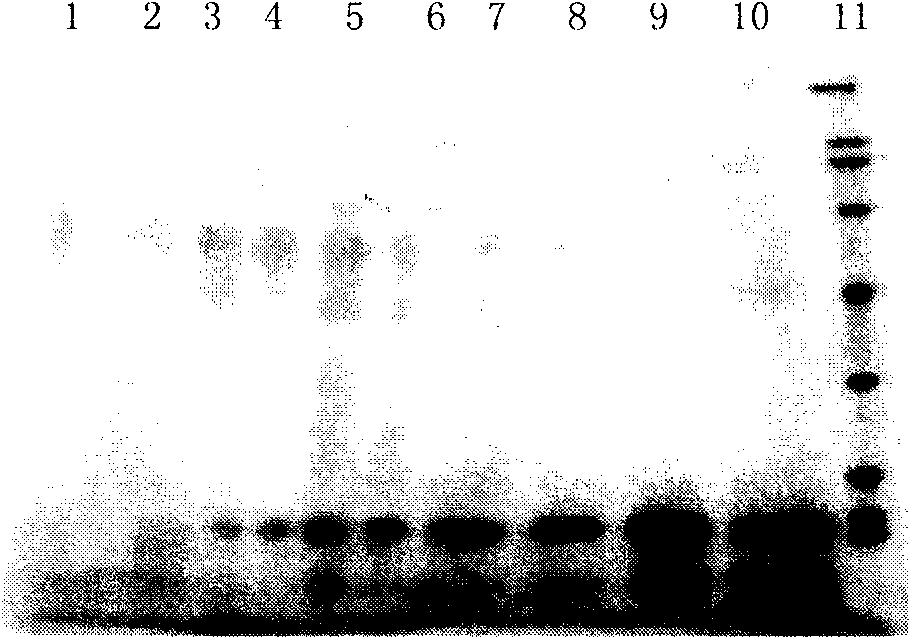

Pseudomonas fluorescens and application thereof

ActiveCN109022324APromote plant growthIncrease productionBacteriaContaminated soil reclamationChemistryPhosphate

The invention discloses Pseudomonas fluorescens RQ3-01 with an accession number of CGMCC No. 14471. In addition, the invention also discloses the application of the Pseudomonas fluorescens to degradation of poorly-soluble inorganic phosphorus. The Pseudomonas fluorescens of the invention is a dominant strain selected with the poorly-soluble inorganic phosphorus as a phosphorus source, and the strain converts the poorly-soluble inorganic phosphorus into bioavailable soluble phosphate during the growth and reproduction. Moreover, the Pseudomonas fluorescens of the invention also has the functions of degrading organic phosphorus and degrading potassium, can effectively increase the contents of available phosphorus and available potassium in soil, and has the functions of promoting plant growth and increasing yield.

Owner:XIAN UNVERSITY OF ARTS & SCI

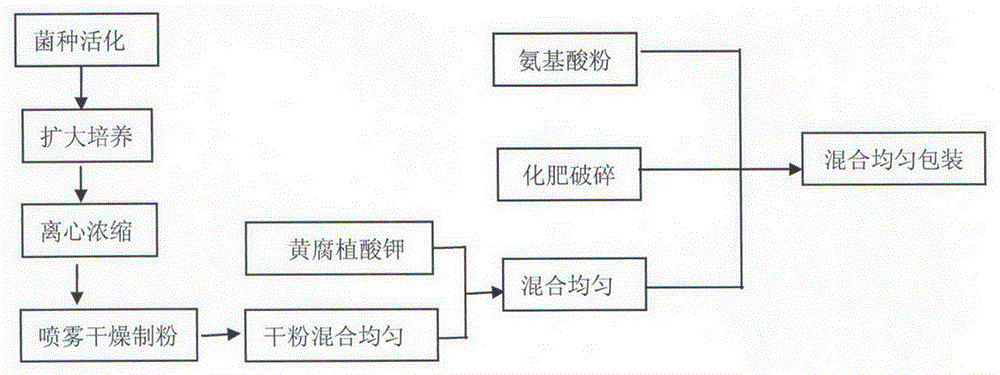

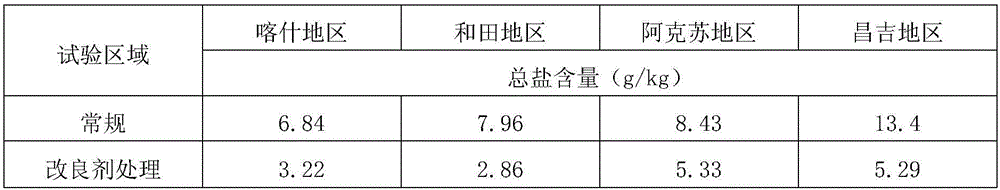

Bio-type drip irrigation saline-alkaline soil improver and preparation method thereof

ActiveCN106590669ANutritional diversityImprove stress resistanceAgriculture tools and machinesOrganic fertilisersSolubilityPhosphate

The invention discloses a bio-type drip irrigation saline-alkaline soil improver and a preparation method thereof. According to the present invention, the bio-type drip irrigation saline-alkaline soil improver is prepared from amino acids, potassium fulvate, urea, monoammonium phosphate, potassium nitrate and dry powder fungicide, has good water solubility, can be used through the drip tube system, can rapidly reduce the salt content and the pH value of soil, further has effects of saline-alkaline land improving, biological activity, crop growth promoting, crop yield increasing and crop quality improving, and can effectively improve the soil fertility and increase the crop yield after the long-term use of the bio-type drip irrigation saline-alkaline soil improver, wherein the strain of the used dry powder fungicide is stable, and the spore has strong tolerance and strong adaptability.

Owner:XINJIANG AGRI UNIV

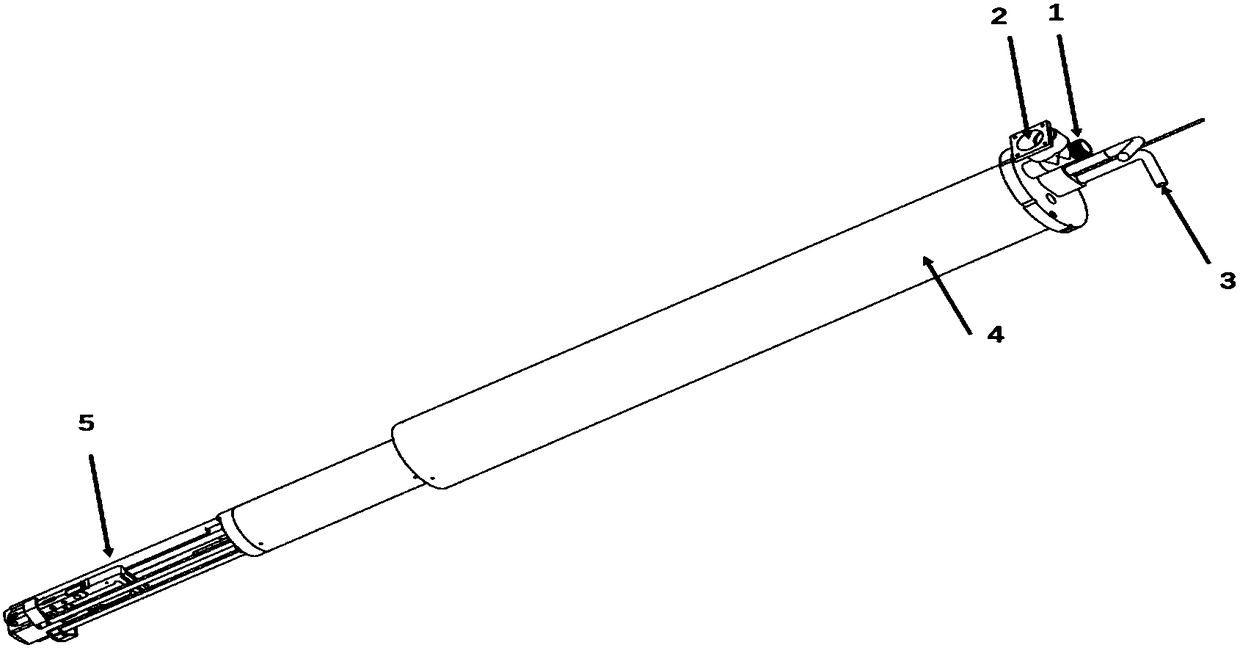

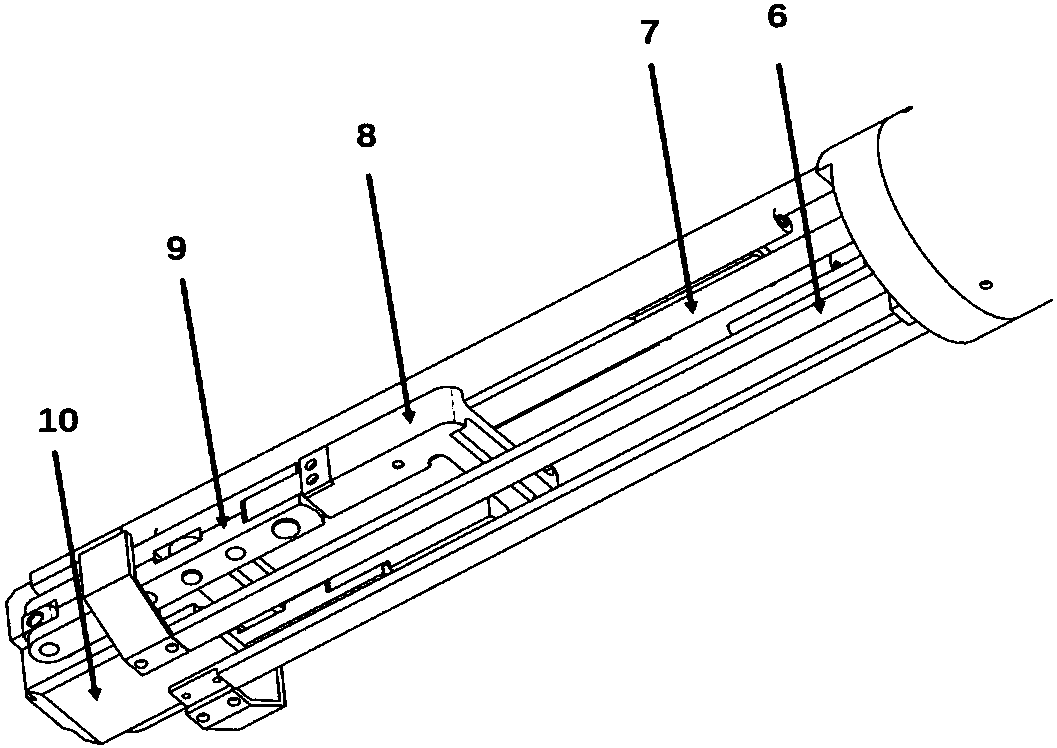

Superconducting line axial strain critical performance testing device

InactiveCN108106935AWon't hurtNovel design of strain loading structureMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesImage resolutionEngineering

The invention discloses a superconducting line axial strain critical performance testing device which comprises a drive rod, two current leads and a lower-end measuring module; the lower-end measuringmodule comprises a U-shaped spring mounted at the end part of the drive rod and is mounted at the lower end of the drive rod, levers are respectively connected with the lower end parts on the two sides of the U-shaped spring, the lower end parts of the levers are connected with the driving end of a worm-and-gear device, a to-be-tested superconducting line is fixed on the upper end plane of the U-shaped spring in a tin welding manner, the two ends of the to-be-tested superconducting line pass by the U-shaped spring and are connected with the lower end parts of the two current leads, and a measuring lead interface is formed in the upper end part of the drive rod. The superconducting line axial strain critical performance testing device disclosed by the invention has the advantages that positive and negative axial strain can be simply and effectively applied to a superconducting line sample, the strain change resolution is high, and in the critical current testing process, the strain isstale; the design of a sample strain loading structure is novel, the contact is reliable at a low temperature, large current can be introduced, the measuring precision is high, the operation is simpleand easy during the sample replacement, and the superconducting line cannot be damaged.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Novel prebiotics

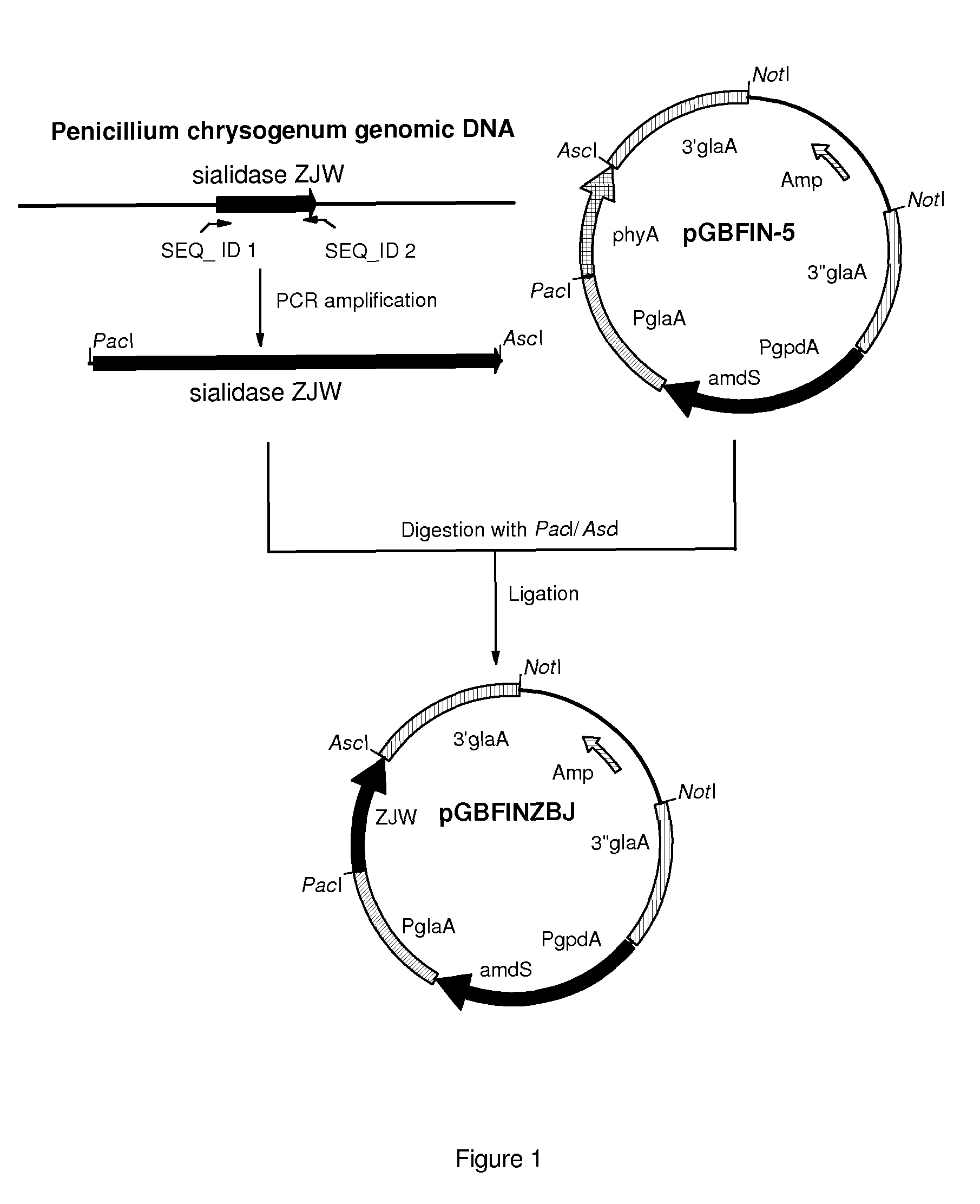

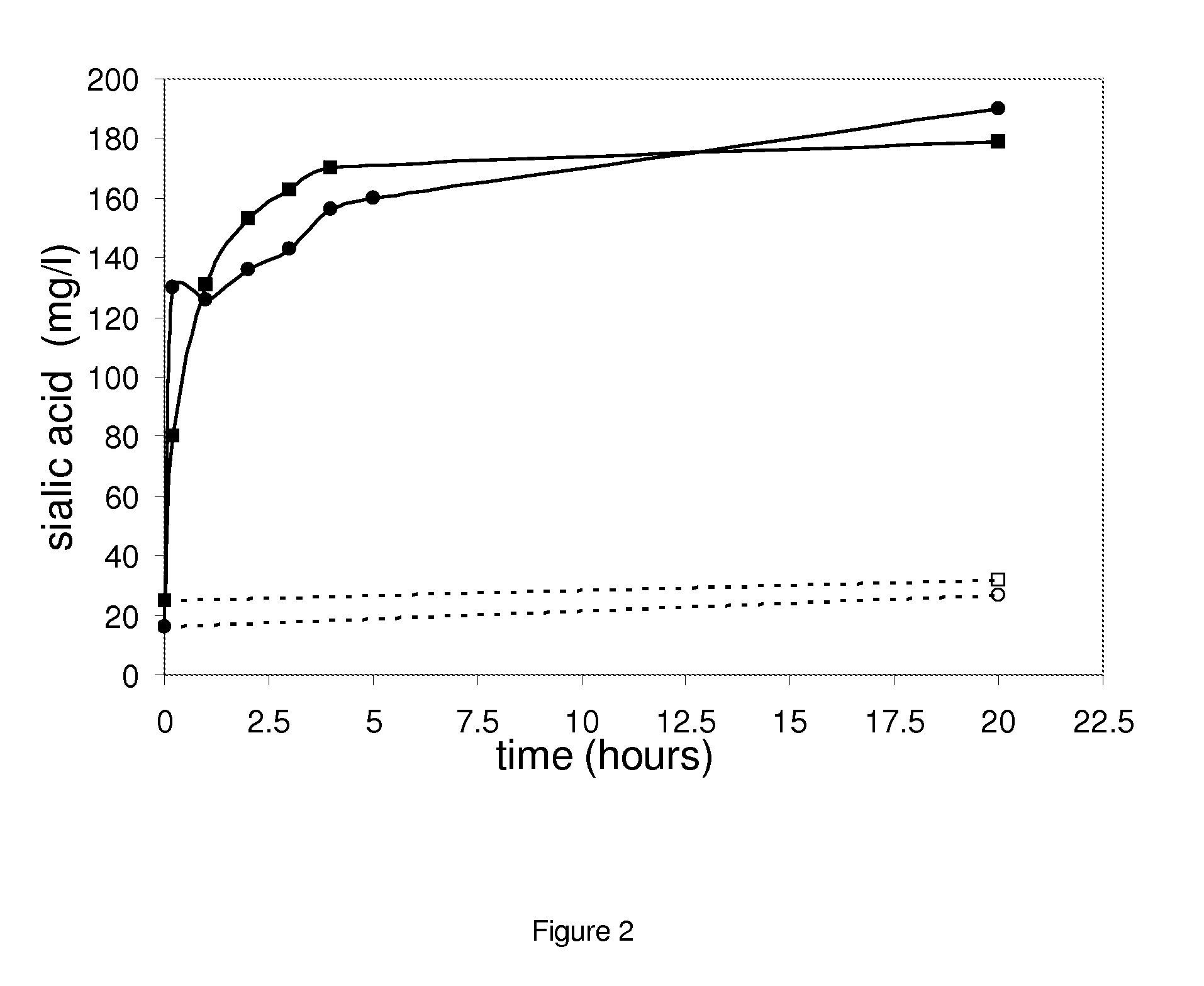

InactiveUS20100196539A1Low costCost effective productionMilk preparationSugar derivativesSialic acidOligosaccharide

The present invention relates to a composition which comprises: an oligosaccharide which is free of sialyloligosaccharide, and free sialic acid.

Owner:DSM IP ASSETS BV

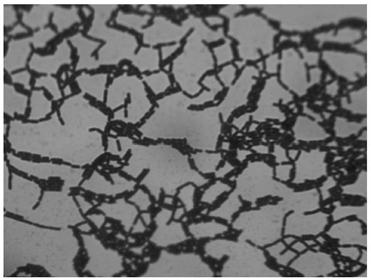

Bacillus subtilis

ActiveCN104195078AEcological securitySolubilize phosphorusBacteriaMicroorganism based processesPhosphateEcological safety

The invention discloses a Bacillus subtilis ZK1-18 of which the collection number is CGMCC No.9402. The Bacillus subtilis ZK1-18 strain is derived from soil, and has the advantages of high ecological safety, no corrosion and no harm to animals and plants. The strain is a dominant strain screened on the basis of the organic phosphorus source, and can change the properties of the organic phosphorus in the growth and reproduction process so as to change the organic phosphorus components, thereby performing the phosphate-solubilizing function. The strain provides an efficient and stable strain and base data for subsequent development of biological organic fertilizers capable of degrading organic phosphorus in soil.

Owner:北京中晟丰和微生物技术有限公司

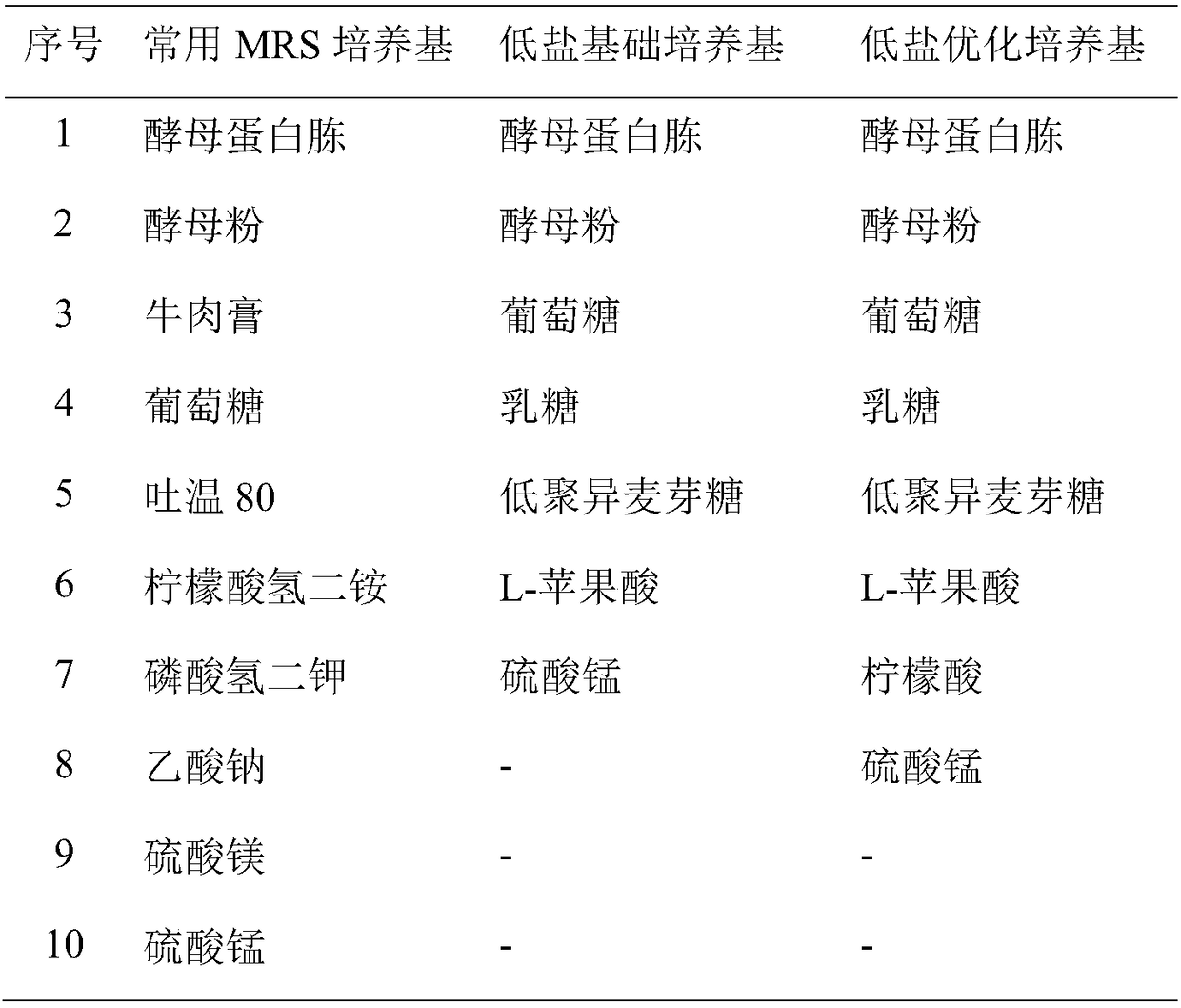

A low-salt culture medium for Lactobacillus rhamnosus and a culture method thereof

ActiveCN109234215ALow Inorganic Salt ContentStrain stabilityBacteriaMicroorganism based processesFermentation brothYeast

The invention discloses a low-salt culture medium of Lactobacillus rhamnosus comprising a basic culture medium and an optimized culture medium, wherein that basic culture medium comprises yeast peptone, yeast powder, glucose, lactose, isomaltooligosaccharide, L-Malic acid, manganese sulfate, the balance of sterile water, pH 6.50-7.00. The optimized medium consistes of yeast peptone, yeast powder,glucose, lactose, isomaltooligosaccharide, L-Malic acid, citric acid, manganese sulfate, the balance of sterile water, pH 6.50-7.00. The culture medium is suitable for the propagation of Lactobacillusrhamnosus, and the number of viable bacteria in fermentation broth could reach more than 109 CFU / ml.

Owner:江西仁仁健康产业有限公司

A kind of biological drip irrigation saline-alkali soil improver and preparation method

ActiveCN106590669BNutritional diversityImprove stress resistanceAgriculture tools and machinesOrganic fertilisersSolubilityAlkali soil

The invention discloses a bio-type drip irrigation saline-alkaline soil improver and a preparation method thereof. According to the present invention, the bio-type drip irrigation saline-alkaline soil improver is prepared from amino acids, potassium fulvate, urea, monoammonium phosphate, potassium nitrate and dry powder fungicide, has good water solubility, can be used through the drip tube system, can rapidly reduce the salt content and the pH value of soil, further has effects of saline-alkaline land improving, biological activity, crop growth promoting, crop yield increasing and crop quality improving, and can effectively improve the soil fertility and increase the crop yield after the long-term use of the bio-type drip irrigation saline-alkaline soil improver, wherein the strain of the used dry powder fungicide is stable, and the spore has strong tolerance and strong adaptability.

Owner:XINJIANG AGRI UNIV

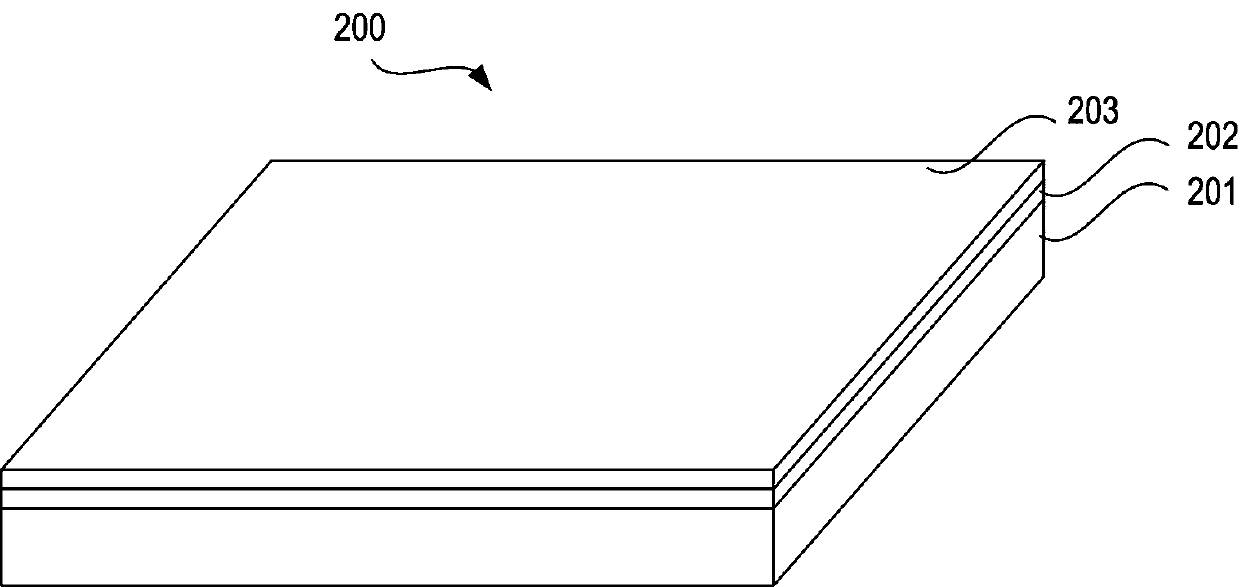

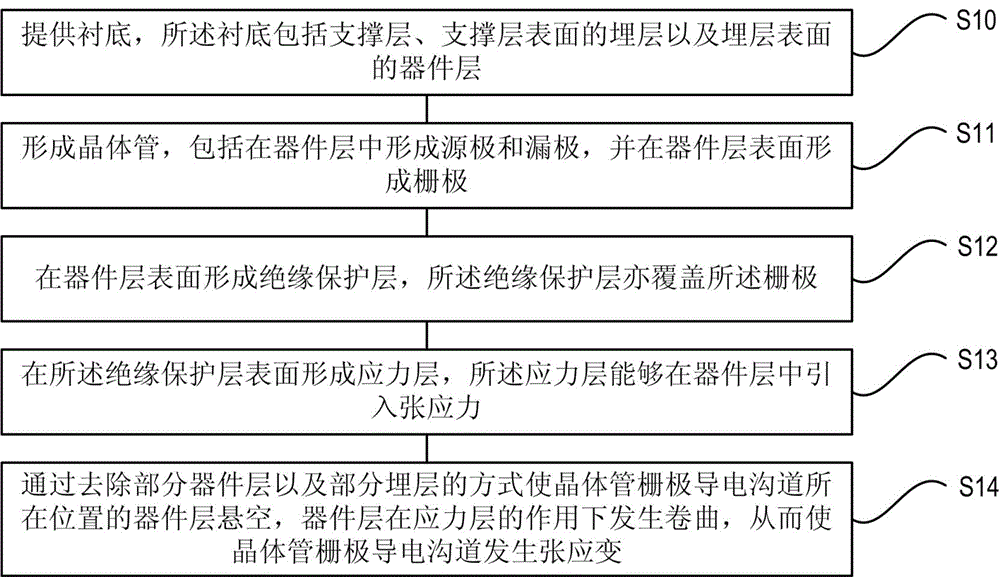

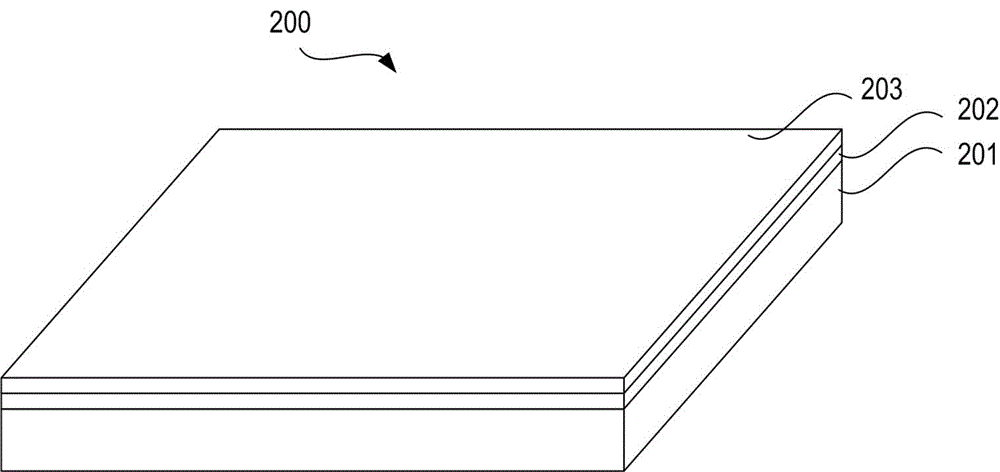

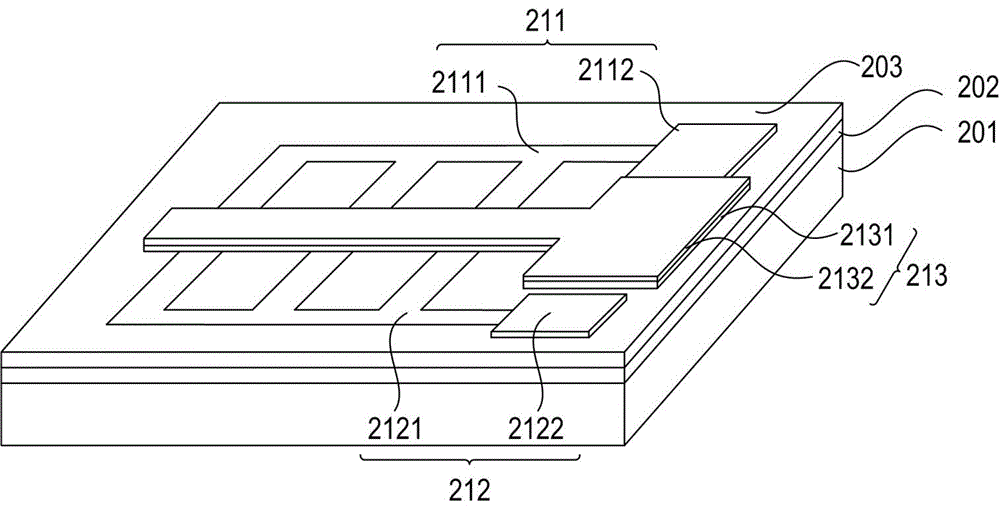

Preparation method of transistor with stressed channel and transistor with stressed channel

ActiveCN103745928AStrain stableStrain stabilityTransistorSemiconductor/solid-state device manufacturingTensile strainConducting channel

The invention provides a preparation method of a transistor with a stressed channel and the transistor with the stressed channel. The method comprises the following steps: providing a substrate which comprises a device layer; forming a transistor, including a source electrode and a drain electrode formed in the device layer and a grid electrode formed on the surface of the device layer; forming an insulation protective layer on the surface of the device layer; forming a stress layer on the surface of the insulation protective layer; suspending the device layer where there is a conducting channel of the grid electrode of the transistor such that the device layer is curled under the action of the stress layer, thus leading to tensile strain of the conducting channel of the grid electrode of the transistor. The invention has advantages as follows: the device layer where there is the grid electrode is curled freely and the device layer undergoes strain under the action of the tensile strain; and as the strain is introduced by physical deformation, strain is stable and is not easy to disappear.

Owner:SHANGHAI SIMGUI TECH

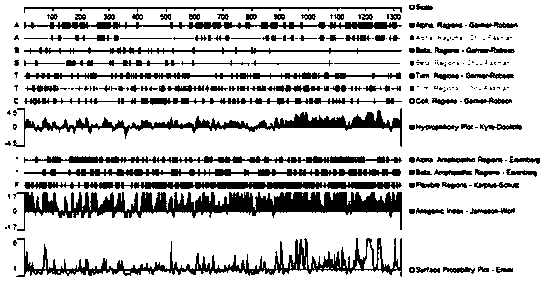

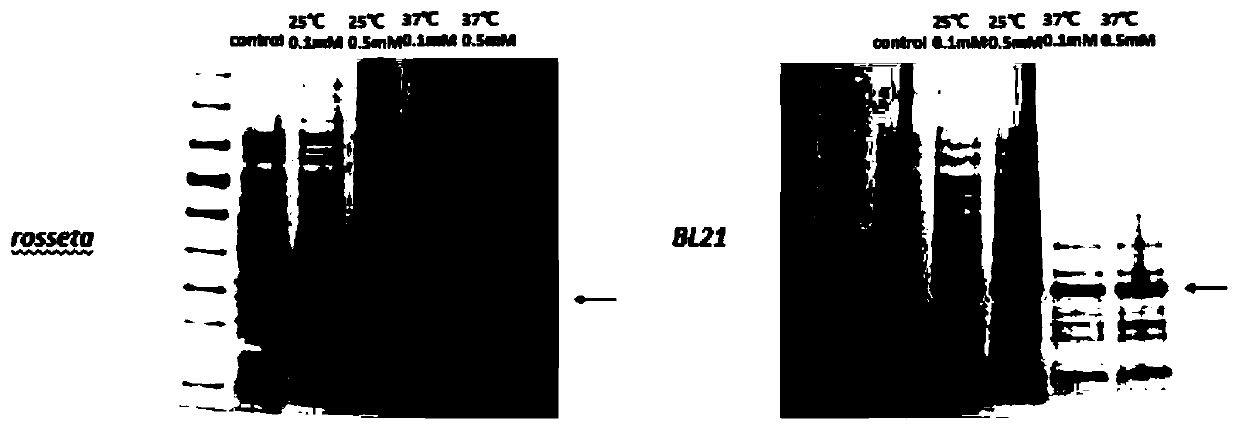

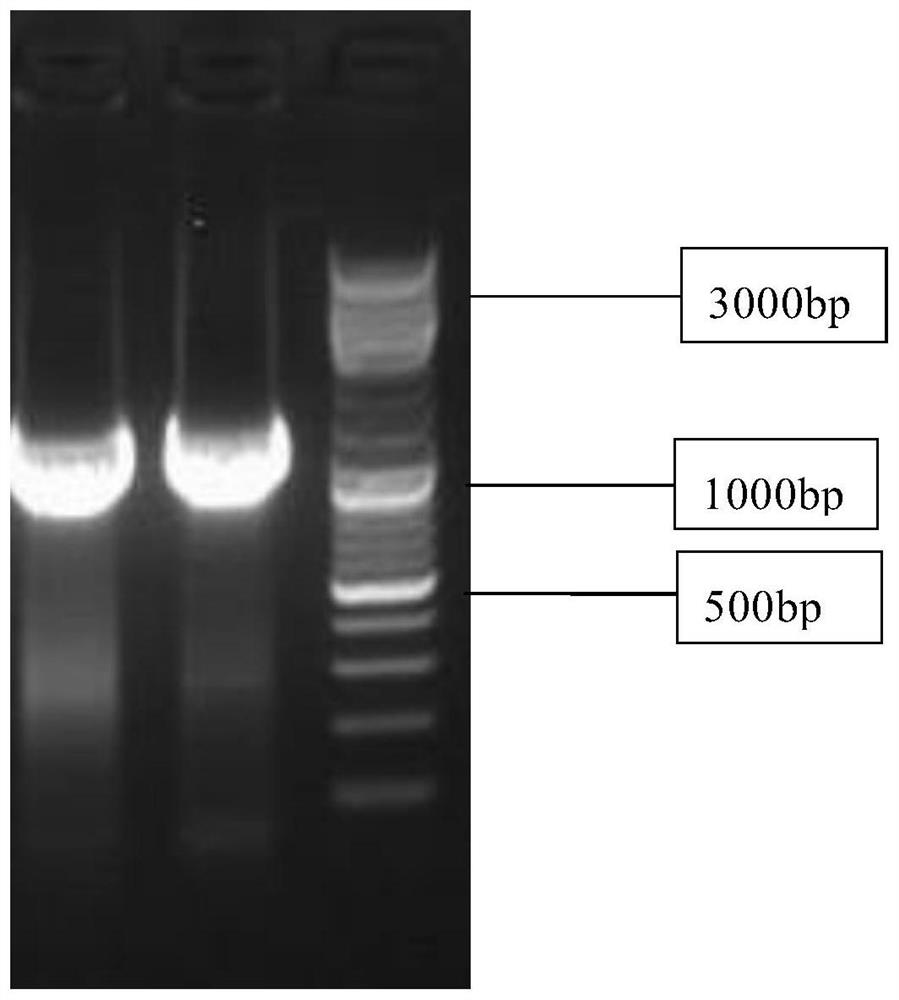

Preparation method and application of polyclonal antibody for specifically recognizing protein USP42

InactiveCN110526980AExpress guaranteeHigh expression yieldBiological material analysisVector-based foreign material introductionRestriction Enzyme Cut SiteEpitope

The invention relates to the technical field of bioscience and detection reagents. The invention specifically discloses a preparation method and application of a polyclonal antibody for specifically recognizing protein USP42. The method comprises the following steps: (1), protein USP42 antigenic epitope analysis: selecting a target fragment as recombinant expression of protein USP42 through the antigenic epitope analysis, wherein the gene sequence of the target fragment is shown as SEQ ID N0.1 in a sequence table; and respectively introducing BamH1 and Not I restriction enzyme cutting sites into an upstream primer and a downstream primer. According to the invention, the preparation of the polyclonal antibody of USP42 is realized.

Owner:NANJING MEDICAL UNIV

Methods for stabilizing production of acetyl-coenzyme a derived compounds

ActiveUS10563229B2Increase probabilityIncreasing overall yield and productivityFungiBacteriaHeterologousCoenzyme A biosynthesis

The present disclosure relates to the use of a switch for the production of heterologous non-catabolic compounds in microbial host cells. In one aspect, provided herein are genetically modified microorganisms that produce non-catabolic compounds more stably when serially cultured under aerobic conditions followed by microaerobic conditions, and methods of producing non-catabolic compounds by culturing the genetically modified microbes under such culture conditions. In another aspect, provided herein are genetically modified microorganisms that produce non-catabolic compounds more stably when serially cultured in the presence of maltose followed by the reduction or absence of maltose, and methods of producing non-catabolic compounds by culturing the genetically modified microbes under such culture conditions.

Owner:AMYRIS INC +1

Preparation of new apolipoprotein A-II

InactiveCN101928723AEfficient expressionOptimizing Fermentation pHApolipeptidesMicroorganism based processesHuman apolipoproteinHigh density

The invention relates to a recombinant protein and a production, purification and identification method thereof, in particular to a recombinant human apolipoprotein A-II (rhApoA-II) expressed in saccharomyces pastorianus, and the optimized method for high-density fermentation, production and purification of the recombinant human apolipoprotein A-II.

Owner:吉林圣元科技有限责任公司

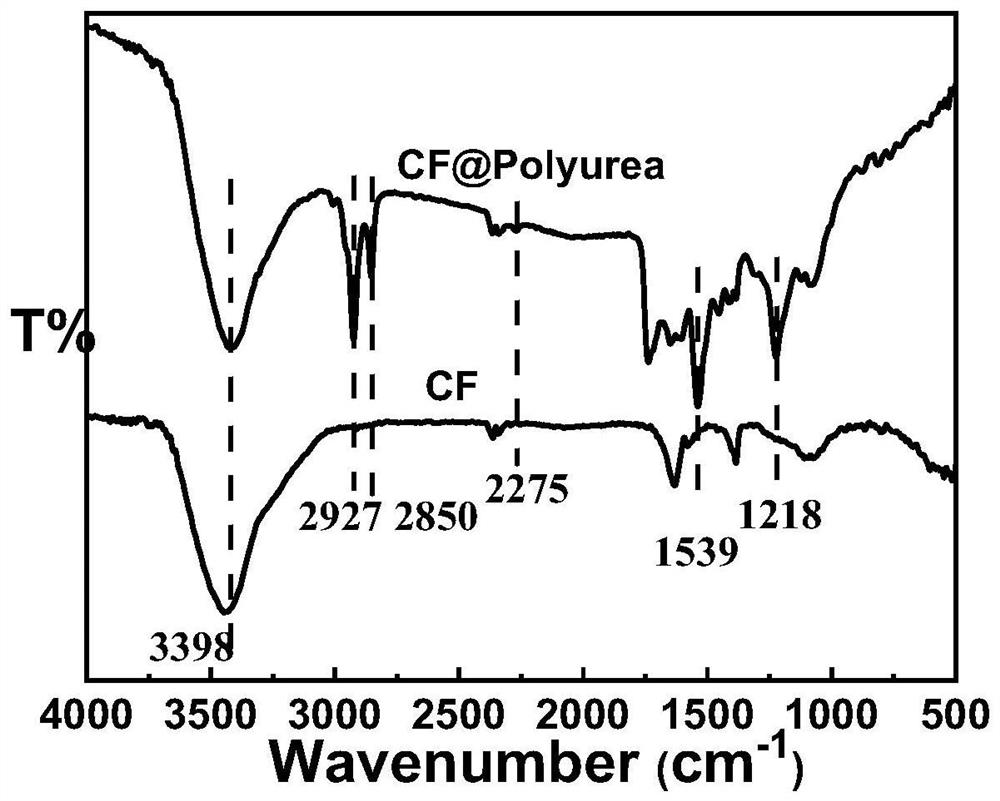

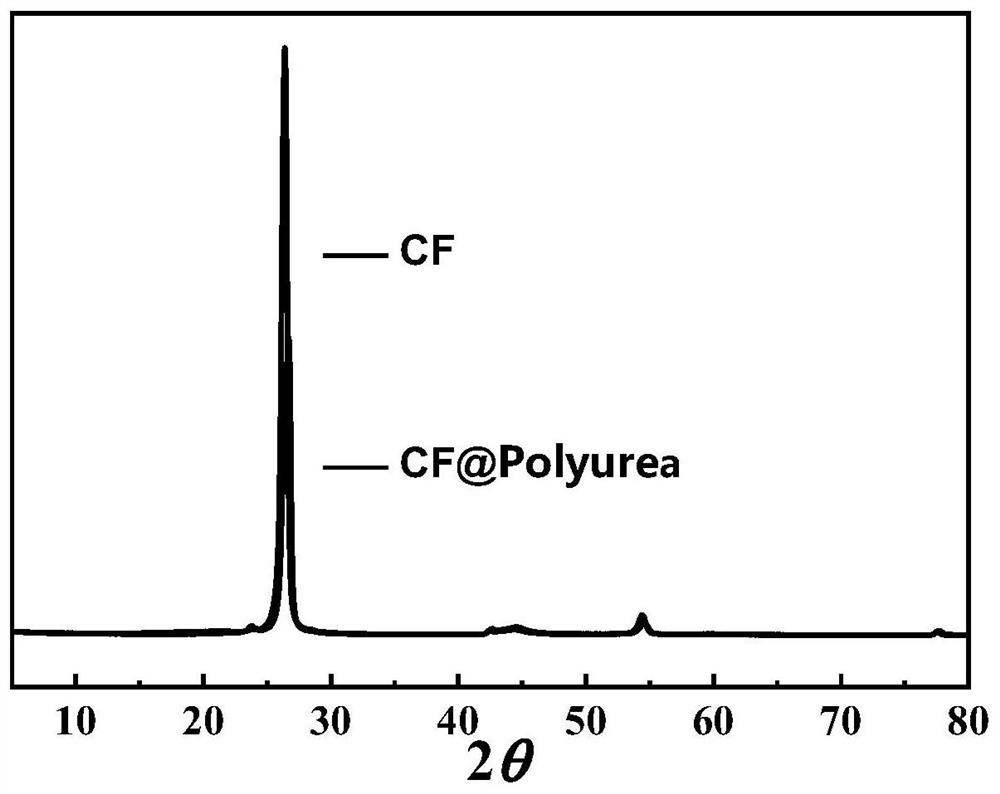

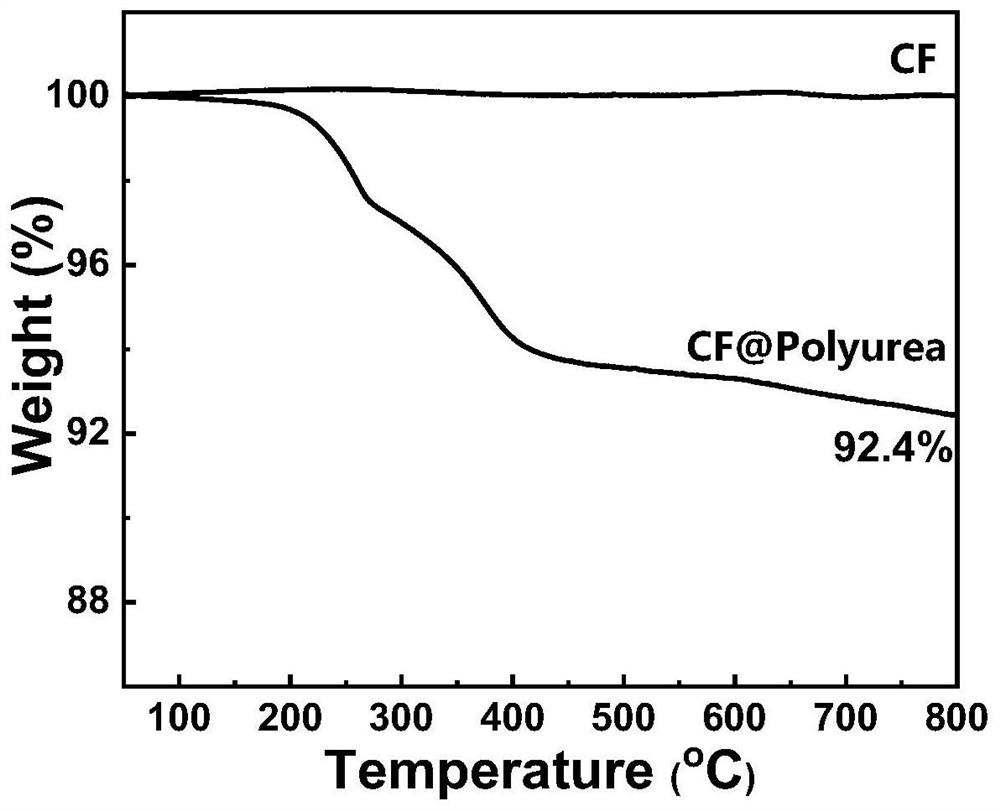

Carbon fiber-based intelligent fabric and preparation method thereof

ActiveCN112609474AGood compatibilityImprove the interface binding forceTextile/flexible product manufactureElectrical/magnetic solid deformation measurementFiberPolymer science

The invention provides a carbon fiber-based intelligent fabric. The carbon fiber-based intelligent fabric comprises a fabric layer and a strain functional layer, the strain functional layer is prepared from functional slurry with conductivity, and the functional slurry comprises a resin-coated carbon fiber material and an interface bonding material. According to the carbon fiber-based intelligent fabric, the resin-coated carbon fiber is adopted as a conductive material, the compatibility between the resin-coated carbon fiber and the interface bonding material is enhanced, so that the interface bonding force between the prepared strain functional layer and the fabric is remarkably improved, then the sensitivity of a strain sensor prepared on the basis of the carbon fiber-based intelligent fabric is greatly improved, and the requirements of practical application are met.

Owner:WUHAN TEXTILE UNIV

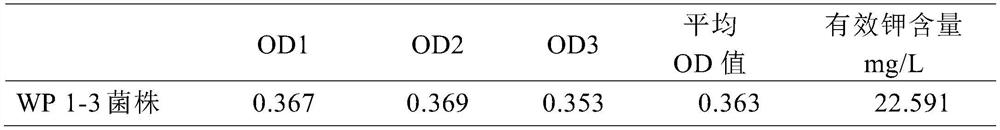

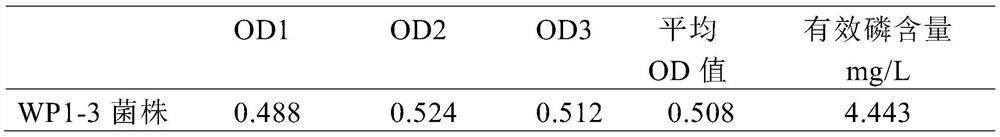

A kind of rhizobia and its application

ActiveCN109097305BEcological securityExpand sourceAgriculture tools and machinesBacteriaGrowth plantSoil science

The invention discloses a rhizobium bacterium Rhizobium sp. WP 1‑3, and the preservation number is CGMCC No. 14472. In addition, the invention also discloses the application of the rhizobia in decomposing soil potassium and insoluble phosphorus in soil. The rhizobia of the present invention is a dominant bacterial strain screened out with potassium feldspar as a potassium source. During the process of growth and reproduction, the bacterial strain can convert the insoluble potassium element in the aluminosilicate in the soil into a soluble component. Decomposition of insoluble phosphorus to increase the source of phosphorus in the soil. In addition, the strain also has the function of nitrogen fixation, and provides nitrogen needed for plant growth and metabolism.

Owner:XIAN UNVERSITY OF ARTS & SCI

Process for synthesizing nano barium titanate/polyurethane elastic composite

InactiveCN1269903CExcellent dielectric propertiesImproved electrostrictive performancePolyurethane elastomerPolyester

A process for synthesizing the electrostrictive nano-barium carbonate / polyurethane elastomer compound includes such steps as proportionally mixing nano-barium carbonate, solvent and coupling agent, adding it to polyester polyol, adding isocyanate and cross-linking agent, polymerizing and high-temp solidifying.

Owner:SOUTHEAST UNIV

A kind of Pseudomonas fluorescens and its application

ActiveCN109022324BEcological securityPromote growthBacteriaContaminated soil reclamationBiotechnologyGrowth plant

The invention discloses Pseudomonas fluorescens RQ3‑01, the preservation number of which is CGMCC No. 14471. In addition, the invention also discloses the application of the Pseudomonas fluorescens in degrading insoluble inorganic phosphorus. The Pseudomonas fluorescens of the present invention is a dominant bacterial strain screened out with insoluble inorganic phosphorus as a phosphorus source, and the bacterial strain converts insoluble inorganic phosphorus into bioavailable soluble phosphate during the growth and reproduction process; in addition, The Pseudomonas fluorescens of the invention also has the function of degrading organic phosphorus and potassium, can effectively increase the content of available phosphorus and available potassium in soil, and has the functions of promoting plant growth and increasing yield.

Owner:XIAN UNVERSITY OF ARTS & SCI

Transistor fabrication method with strained channel and transistor with strained channel

ActiveCN103745928BStrain stabilityTransistorSemiconductor/solid-state device manufacturingTensile strainConducting channel

The invention provides a preparation method of a transistor with a stressed channel and the transistor with the stressed channel. The method comprises the following steps: providing a substrate which comprises a device layer; forming a transistor, including a source electrode and a drain electrode formed in the device layer and a grid electrode formed on the surface of the device layer; forming an insulation protective layer on the surface of the device layer; forming a stress layer on the surface of the insulation protective layer; suspending the device layer where there is a conducting channel of the grid electrode of the transistor such that the device layer is curled under the action of the stress layer, thus leading to tensile strain of the conducting channel of the grid electrode of the transistor. The invention has advantages as follows: the device layer where there is the grid electrode is curled freely and the device layer undergoes strain under the action of the tensile strain; and as the strain is introduced by physical deformation, strain is stable and is not easy to disappear.

Owner:SHANGHAI SIMGUI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com