Process for synthesizing nano barium titanate/polyurethane elastic composite

A polyurethane elastomer and composite material technology, which is applied in the synthesis field of nano-barium titanate/polyurethane elastomer composite materials, can solve the problems of poor electromechanical activity and low dielectric constant, and achieve shortened response time, excellent dielectric properties, Effects of less demanding temperature and pressure conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

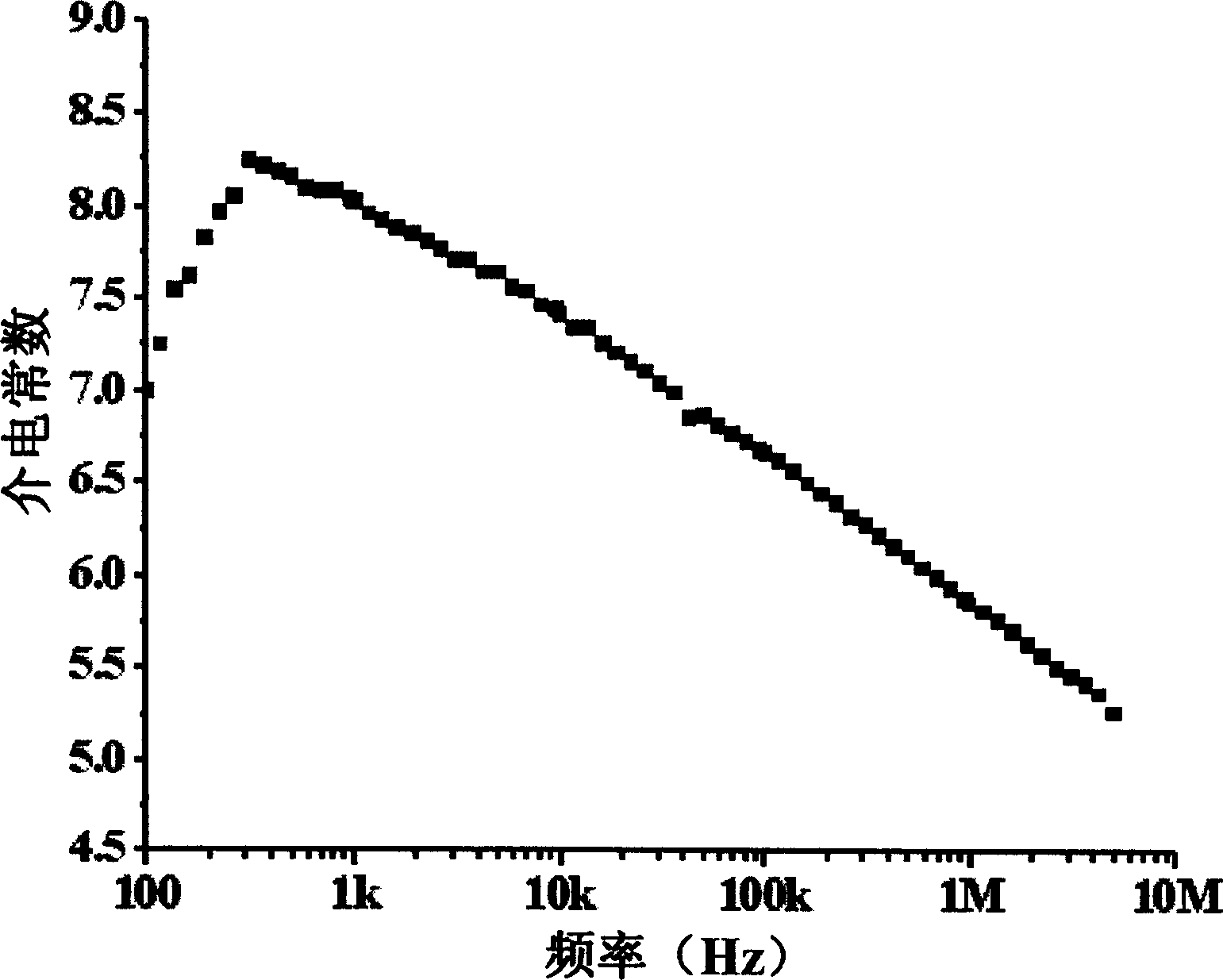

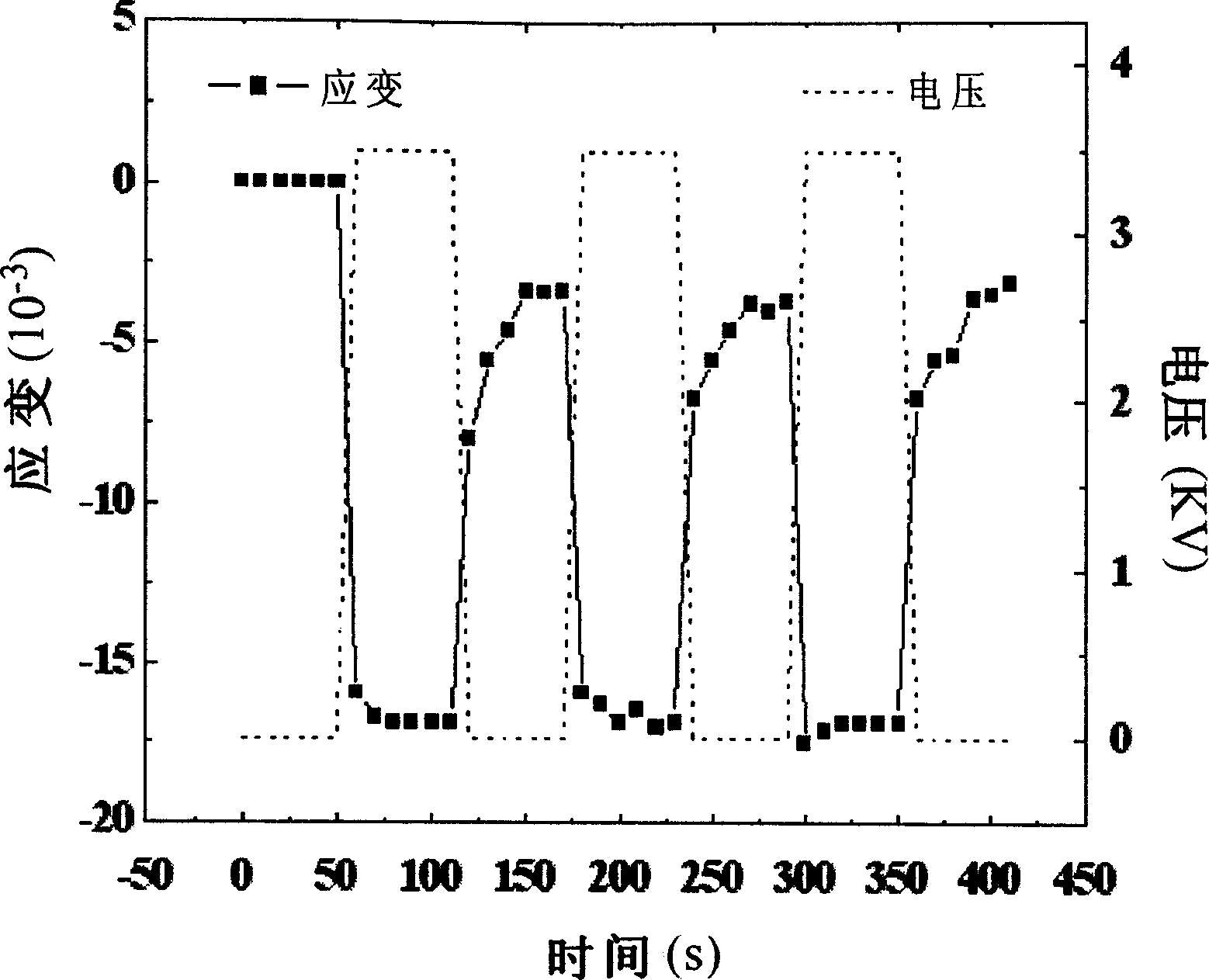

[0019] Add nanoscale barium titanate powder to N, N-dimethylacetamide solution containing coupling agent (coupling dose is 1.6% of the weight of barium titanate powder) to form 10% (wt / wt) After stirring for 4 hours at room temperature, take out 1ml and add it to 6.2g poly(hexanediol-neopentyl glycol) adipate polyol (hydroxyl value 74), stir vigorously, and heat to 160°C for pumping Vacuum to remove the solvent in the system. Keep the vacuum and lower the temperature to 75°C, add 0.2728g of 1,1,1-trimethylolpropane and 0.046ml of 1,4-butanediol (80% cross-linking agent ratio), and continue to fully stir. Then add 1.17ml of toluene diisocyanate, stir all the materials quickly and fully, pour them into the mold, cure in an oven at 110°C for 10 hours, and slowly cool down to room temperature to obtain nano barium titanate / polyurethane elastomer composite material. from figure 1 It can be seen that the relationship between the dielectric constant and the frequency of the obtaine...

Embodiment 2

[0021] The polyhexamethylene adipate neopentyl glycol ester polyol in Example 1 was changed to polybutylene adipate neopentyl glycol ester polyol with the same relative molecular weight, and other conditions remained unchanged. The obtained material has a maximum dielectric constant of 8.1 and a maximum strain of -0.021 (5000V applied voltage).

Embodiment 3

[0023] The addition amount of the nano-barium titanate powder suspension in Example 1 was further increased to 1.5 ml, and the other conditions remained unchanged. The maximum dielectric constant is 8.6 and the maximum strain is -0.0152 (5000V applied voltage).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com