Industrial production method of alkylbenzene sulfonyl chloride

A technology for the production of alkylbenzenesulfonyl chloride and its production method, which is applied in the fields of sulfonic acid preparation and organic chemistry, and can solve problems such as difficult separation of materials and waste acid, poor safety of production equipment, lack of competitiveness in production, etc., and achieve good intrinsic safety , production cost reduction, and the effect of reducing the amount of hazardous chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

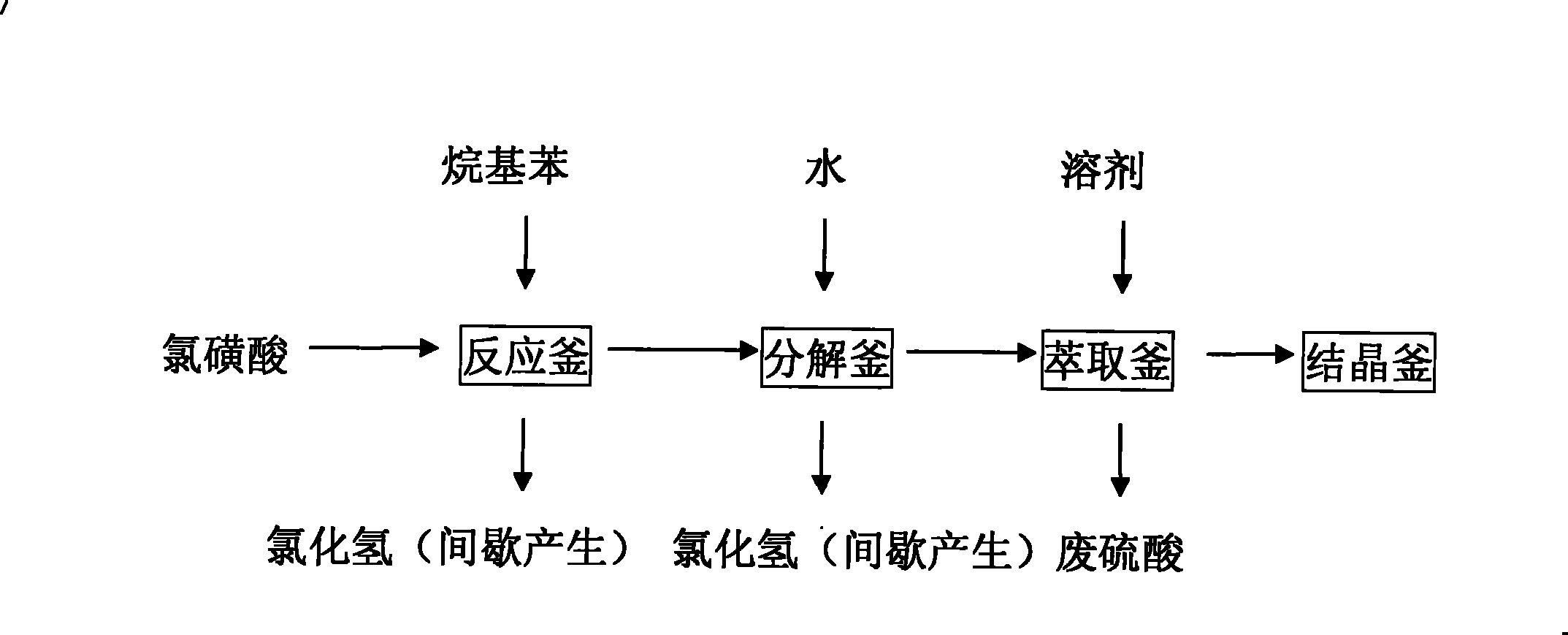

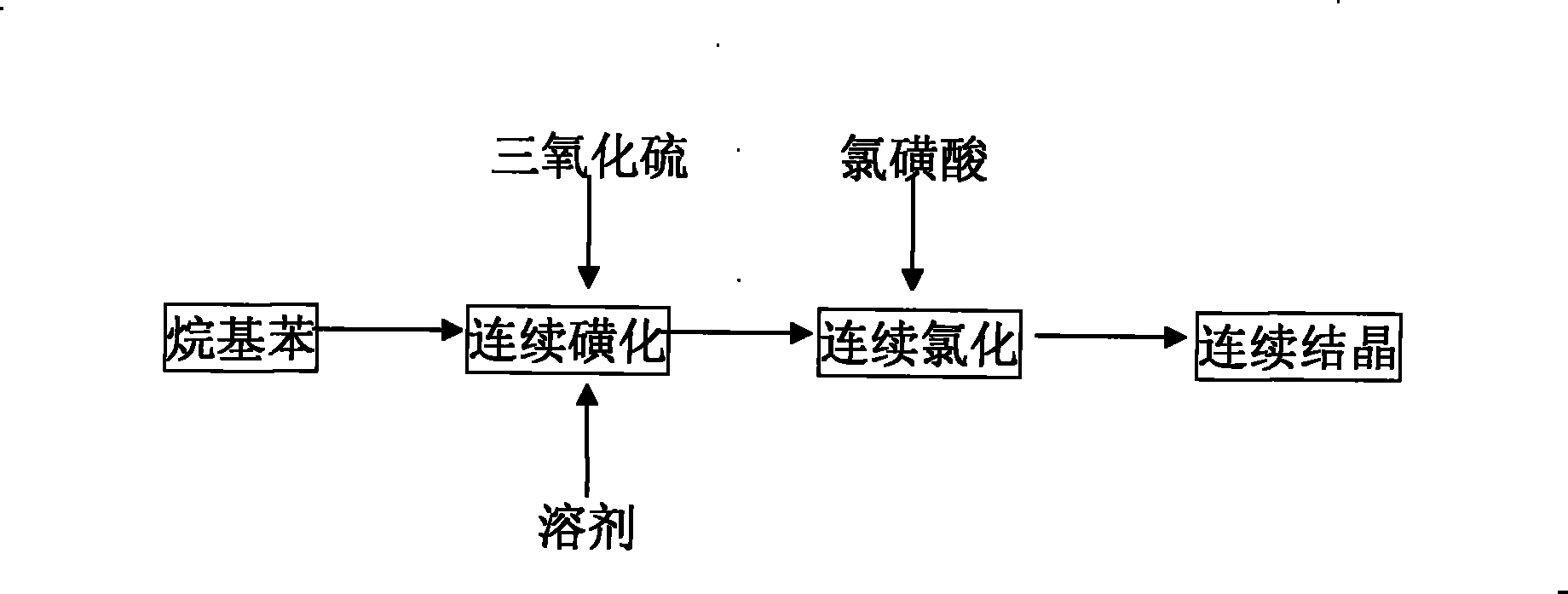

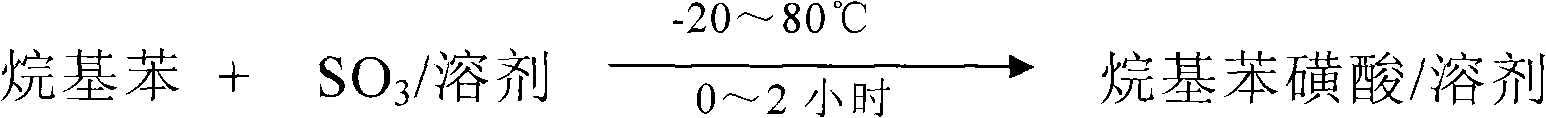

Method used

Image

Examples

Embodiment 1

[0026] Through the metering pump, the benzene (liquid paraffin) solution with a flow rate of 39 kg / h and a concentration of 20% is cooled and the liquid sulfur trioxide (liquid paraffin) solution with a flow rate of 16 kg / h and a concentration of 50% through pre-cooling is injected simultaneously with stirring In a 500ml four-neck flask continuous sulfonation pipeline reactor with a device, a thermometer and a feeding port, the reaction is controlled at a temperature of 50-60°C. The reacted feed liquid enters the continuous chlorination pipeline reactor together with the chlorosulfonic acid with a flow rate of 11.6kg / h. The reaction temperature is controlled at 60-70°C. After the reaction, it enters the continuous precipitation system. The benzenesulfonyl chloride product is 16.4kg / h, the product purity is 97%, and the yield is 90.1%.

Embodiment 2

[0028] Add 920kg of toluene and 500kg of chloroform into a 3000L reaction kettle with a stirrer, a thermometer and a feeding port, start stirring, and add 1600kg of liquid sulfur trioxide / chloroform solution dropwise at a temperature of 60-70°C (wherein the concentration of sulfur trioxide is 50% ), after dripping and keeping warm for 1 hour, then add 1160kg chlorosulfonic acid at 60-70°C, and after dropping, heat up to 70-80°C and keep warm for 1 hour. Cool to 20°C, add a small amount of water to wash, separate the layers, and desolventize the solvent layer to obtain 1860 kg of toluenesulfonyl chloride product with a purity of 95% and a yield of 92.8%.

Embodiment 3

[0030] Add 10 grams of liquid paraffin in a 500 ml four-necked flask with a stirrer, a thermometer and a feed port, start stirring, then dropwise add 0.1 mol of benzene and 0.05 mol of liquid sulfur trioxide (wherein containing 10 grams of liquid paraffin), controlled at React at a temperature of -20-0°C, keep the temperature for 2 hours after dropping, then add 0.35mol chlorosulfonic acid at -20°C, raise the temperature to 60-70°C and keep warm for 2 hours after dropping. Cool to 20°C, add a small amount of water to wash, separate layers, and desolventize the solvent layer to obtain 16.4 g of benzenesulfonyl chloride product with a purity of 97% and a yield of 90.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com