Petroleum hydrocarbon adsorption desulfurization method

A technology for adsorption desulfurization and petroleum hydrocarbons, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., can solve the problems of increasing energy consumption and wasting hydrogen, and achieve the effects of energy saving, wear reduction and continuous reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

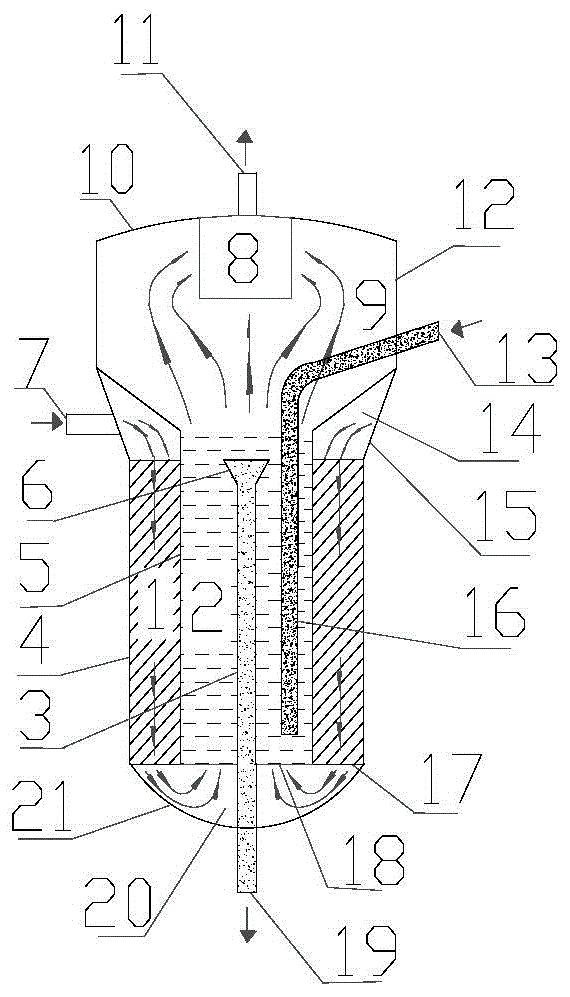

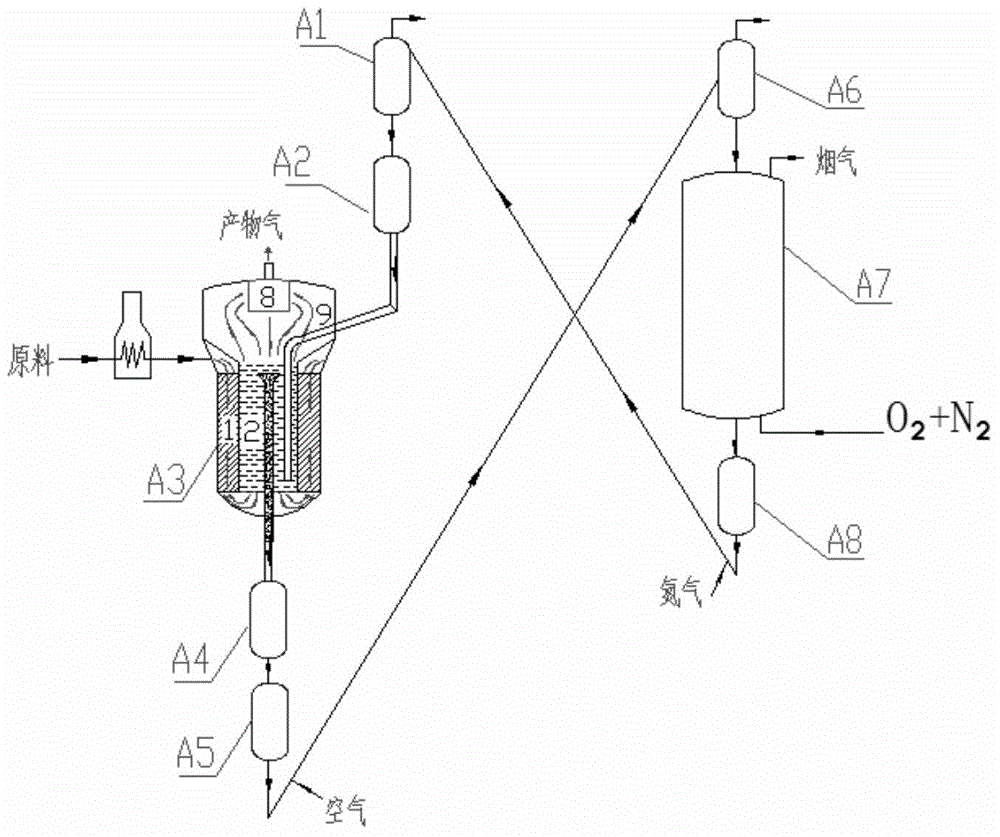

[0065] use as image 3 The reaction device shown, wherein the fixed-fluidized bed reactor structure is as attached figure 1 shown. In the fixed-fluidized bed reactor, the fixed bed layer is filled with hydrodesulfurization catalyst RSDS-21, and the fluidized bed layer uses desulfurization adsorbent Cat-1. The catalytic cracking gasoline raw material is added to the fixed bed layer through the fluid feed port for reaction, and the operating conditions of the fixed-fluidized bed reactor: the pressure is 5.0MPa, and the hydrogen-to-oil ratio is 0.4Nm 3 / m 3 , the reaction temperature is 420°C, and the reaction weight hourly space velocity is 4h -1 . The superficial gas velocity of the fluidized bed is 0.3m / s, the residence time of the desulfurization adsorbent in the fluidized bed is 30 minutes, and the temperature of the adsorbent regenerator is 550°C. Product properties and hydrogen consumption are shown in Table 4.

Embodiment 2

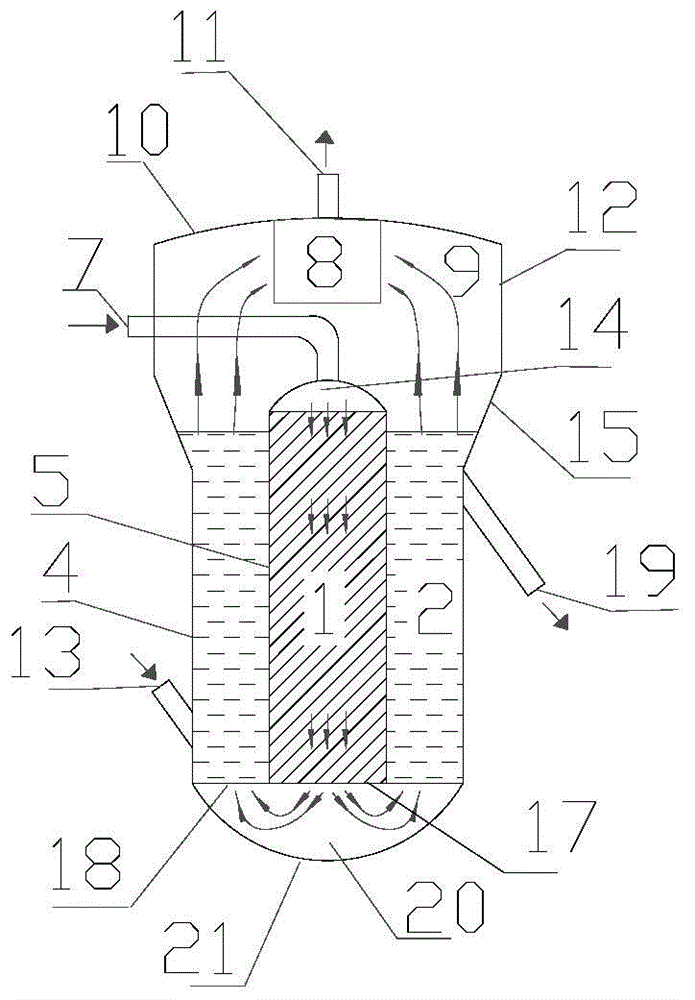

[0067] use as image 3 The reaction device shown, wherein the fixed-fluidized bed reactor structure is as attached figure 2 shown. In the fixed-fluidized bed reactor, the fixed bed layer is filled with hydrodesulfurization catalyst RSDS-21, and the fluidized bed layer uses desulfurization adsorbent Cat-2. The catalytic cracking gasoline raw material is added to the fixed bed layer through the fluid feed port for reaction. The operating conditions of the fixed-fluidized bed reactor: the pressure is 3MPa, and the hydrogen-to-oil ratio is 0.5Nm 3 / m 3 , the reaction temperature is 440°C, and the reaction weight hourly space velocity is 5h -1 , the superficial gas velocity of the fluidized bed is 0.1m / s, the residence time of the desulfurization adsorbent in the fluidized bed is 10 minutes, and the regeneration temperature of the adsorbent is 550°C. Product properties and hydrogen consumption are shown in Table 4.

Embodiment 3

[0069] use as image 3 The reaction device shown, wherein the fixed-fluidized bed reactor structure is as attached figure 2 shown. In the fixed-fluidized bed reactor, the fixed bed layer is filled with hydrodesulfurization catalyst RSDS-21, and the fluidized bed layer uses desulfurization adsorbent Cat-3. The catalytic cracking gasoline raw material is added into the fixed bed layer through the fluid feed port for reaction. The operating conditions of the fixed-fluidized bed reactor: the pressure is 4MPa, and the hydrogen-to-oil ratio is 0.2Nm 3 / m 3 , the reaction temperature is 350°C, and the reaction weight hourly space velocity is 3h -1 , the superficial gas velocity of the fluidized bed is 0.6m / s, the residence time of the desulfurization adsorbent in the fluidized bed is 30 minutes, and the regeneration temperature of the adsorbent is 550°C. Product properties and hydrogen consumption are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com