Methane-reforming and hydrogen-production method

A technology for reforming hydrogen and methane production, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as wasting energy and increasing reduction processes, reducing wear and tear, continuous reaction, and simplifying device construction and operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 illustrates the effect of adopting the method for producing hydrogen by steam reforming of methane provided by the present invention.

[0049] Preparation of reforming catalyst: Use alumina as a carrier, impregnate with nickel nitrate solution, then dry, then contact with aluminum colloidal solution containing nitric acid to form a paste, extrude into strips, and then dry at 120°C for 180 minutes, The dried catalyst was calcined at 500° C. for 4 hours to obtain a catalyst whose nickel content was 10 wt%.

[0050] CO 2 Preparation of adsorbent: Add a certain amount of nano-scale calcium carbonate to alumina hydrosol with a solid content of 10%, add a small amount of water and stir evenly, add nano-scale calcium carbonate, mix well, spray dry, and calcinate to obtain an average particle size of 70 microns CO 2 Adsorbent, its CaO composition is 50%, the rest is alumina.

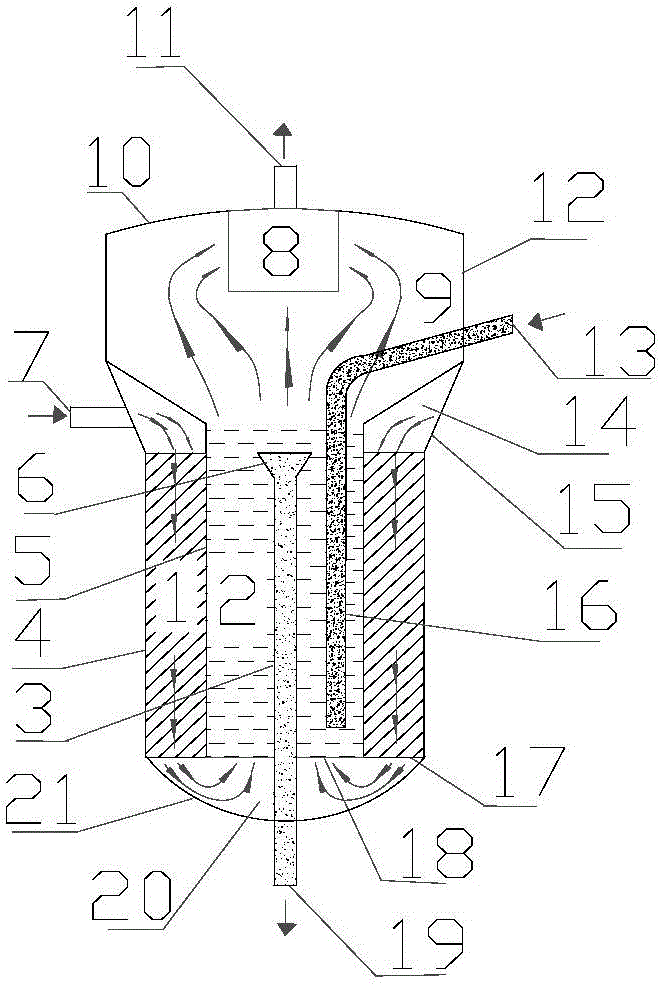

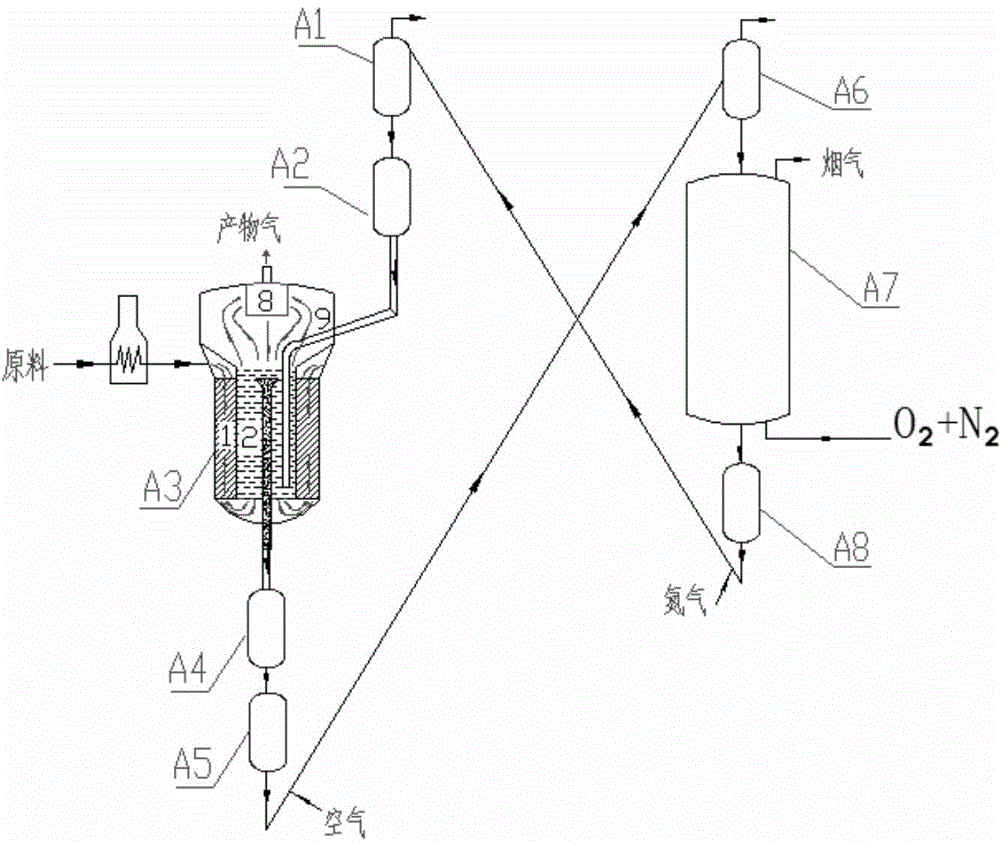

[0051] The methane hydrogen production reaction unit adopts image 3In the reaction rege...

Embodiment 2

[0056] The methane hydrogen production reaction unit adopts the attached image 3 The device proposed by the present invention shown, the reactor adopts the attached figure 1 In the reactor type shown, the regenerator adopts a conventional moving bed reactor. The catalyst is a methane reforming hydrogen generator, and its preparation is the same as in Example 1. The main active ingredient is Ni with a content of 15 wt%, and the carrier is alumina. The catalyst is placed in a fixed bed inside the reactor. CO 2 The preparation of the adsorbent is the same as in Example 1, the main active ingredient is calcium oxide with a content of 40 wt%, and the carrier is silicon oxide. After the adsorbent is treated in the regenerator, it is transported to the moving bed in the reactor. Methane and steam are introduced into the reactor for reforming reaction, and the deactivated adsorbent is removed from the reactor and entered into the regenerator for regeneration and recycling.

[00...

Embodiment 3

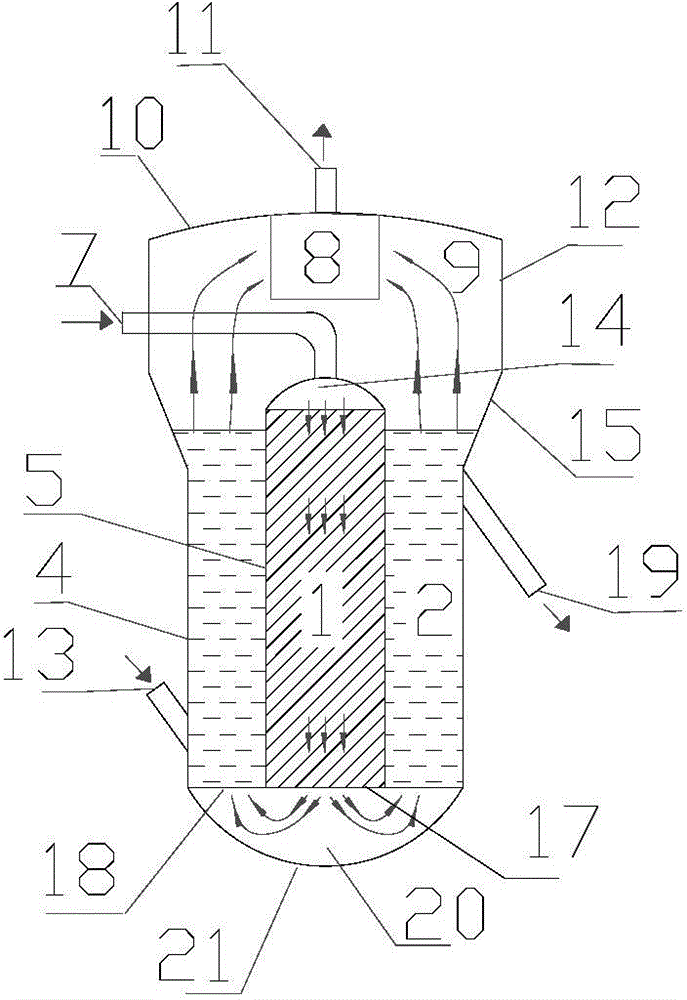

[0059] The methane hydrogen production reaction unit adopts image 3 The device proposed by the present invention shown, the reactor adopts figure 2 In the reactor type shown, the regenerator adopts a conventional moving bed reactor. The catalyst is a methane reforming hydrogen production agent, the main active component is Ni, and the carrier is alumina. The catalyst is placed in a fixed bed inside the reactor. CO 2 The preparation of the adsorbent is the same as in Example 1, the main active ingredient is calcium oxide with a content of 70 wt%, and the carrier is silicon oxide. After the adsorbent is treated in the regenerator, it is transported to the moving bed in the reactor. Methane and steam are introduced into the reactor for reforming reaction, and the deactivated adsorbent is removed from the reactor and entered into the regenerator for regeneration and recycling.

[0060] Hydrogen production conditions: fixed bed: water vapor to methane molar ratio 6, space ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com