Anaerobic organism fluidized bed mixed carrier for treating industrial waste water and application of anaerobic organism fluidized bed mixed carrier

A mixed carrier, anaerobic biological technology, used in anaerobic digestion treatment, special compound water treatment, biological water/sewage treatment, etc. It can improve the effective utilization rate, reduce energy consumption and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

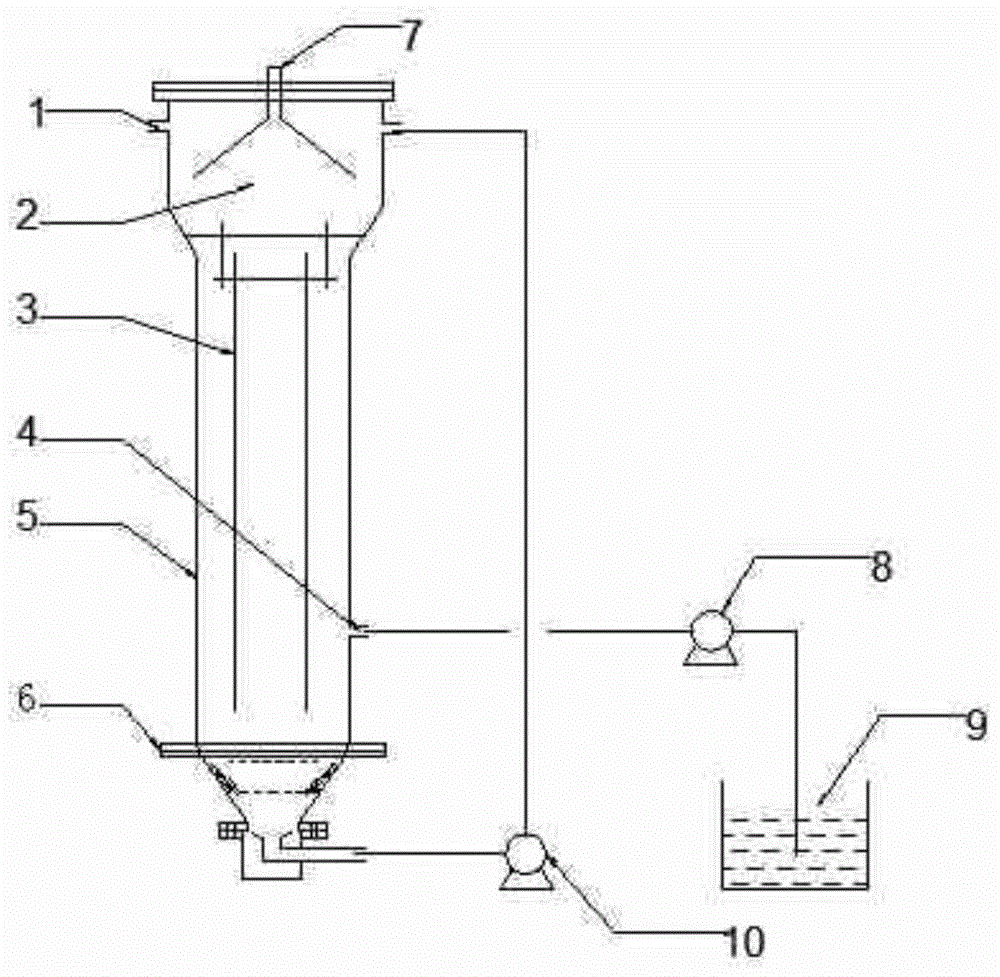

Method used

Image

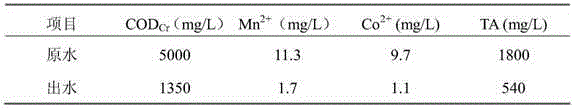

Examples

Embodiment 1

[0025] Prepare the mixed carrier as follows:

[0026] A. Activated carbon modification:

[0027] 1) Use coconut shell activated carbon and wood activated carbon with a particle size of 0.7mm and a specific gravity of 1.1g / mL as raw materials, with a volume ratio of 1:1, boil with distilled water, wash and dry, and mix the activated carbon with nitric acid and sulfuric acid at 312°C Activation in solution for 3h, surface modification and pore expansion reaction.

[0028] B. Diatomite modification:

[0029] 1) Use diatomite with a particle size of 0.9mm as raw material, wash and air-dry the diatomite, then put the diatomite into 2mol / L potassium hydroxide solution, stir and soak for 6.5h at 82°C, and put After soaking, the diatomaceous earth is washed and air-dried;

[0030] 2) Put the diatomite obtained in 1) into a sulfuric acid solution with pH=2, stir and soak for 2 hours, wash and air-dry the soaked diatomite;

[0031] 3) Calcining the diatomite obtained in 2) at a temp...

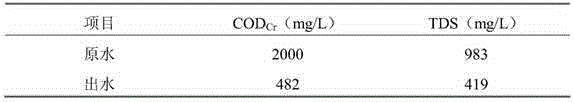

Embodiment 2

[0040] A. Activated carbon modification:

[0041] 1) Use coconut shell activated carbon, wood activated carbon, and fruit shell activated carbon with a particle size of 1.0mm and a specific gravity of 1.2g / mL as raw materials. The volume ratio is 1:2:1. , Nitric acid and sulfuric acid mixed solution for activation for 4h to carry out surface modification and pore expansion reaction.

[0042] B. Diatomite modification:

[0043] 1) Use diatomite with a particle size of 1.0mm as the raw material, wash and air-dry the diatomite, then put the diatomite into a mixed solution of 3mol / L sodium hydroxide and potassium hydroxide, at 82°C Stir and soak for 7 hours, wash and air-dry the soaked diatomaceous earth;

[0044] 2) Put the diatomite obtained in 1) in a sulfuric acid solution with pH=4, stir and soak for 2.5 hours, wash and air-dry the soaked diatomite;

[0045] 3) Calcining the diatomite obtained in 2) at a temperature of 500° C. for 1.6 h, cooling the calcined diatomite with...

Embodiment 3

[0055] A. Activated carbon modification:

[0056] 1) Use coconut shell activated carbon, wood activated carbon, fruit shell activated carbon, and rubber-plastic activated carbon with a particle size of 1.9mm and a specific gravity of 1.3g / mL as raw materials, with a volume ratio of 3:1:1:1, boil with distilled water, wash and dry After drying, activated carbon was activated in nitric acid solution at 345°C for 3.5h to carry out surface modification and pore expansion reactions.

[0057] B. Diatomite modification:

[0058] 1) Use diatomite with a particle size of 1.6mm as raw material, wash and air-dry the diatomite, then put the diatomite into a 5mol / L sodium hydroxide solution, stir and soak it at 84°C for 7.5h, and put After soaking, the diatomaceous earth is washed and air-dried;

[0059] 2) Put the diatomite obtained in 1) into a mixed solution of sulfuric acid and nitric acid at pH=3, stir and soak for 3 hours, wash and air-dry the soaked diatomite;

[0060] 3) Calcini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com