Abrasion-resistant and anticorrosion pipe or pipe fitting with double ceramic lining layers and preparation method of abrasion-resistant and anticorrosion pipe or pipe fitting

A technology of ceramic lining and ceramic layer, applied in the direction of pipes/pipe joints/fittings, pipeline protection, pipeline anticorrosion/rust protection, etc., can solve the problems of low reliability and short service life, and achieve long service life and reduce production. cost, the effect of avoiding small peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

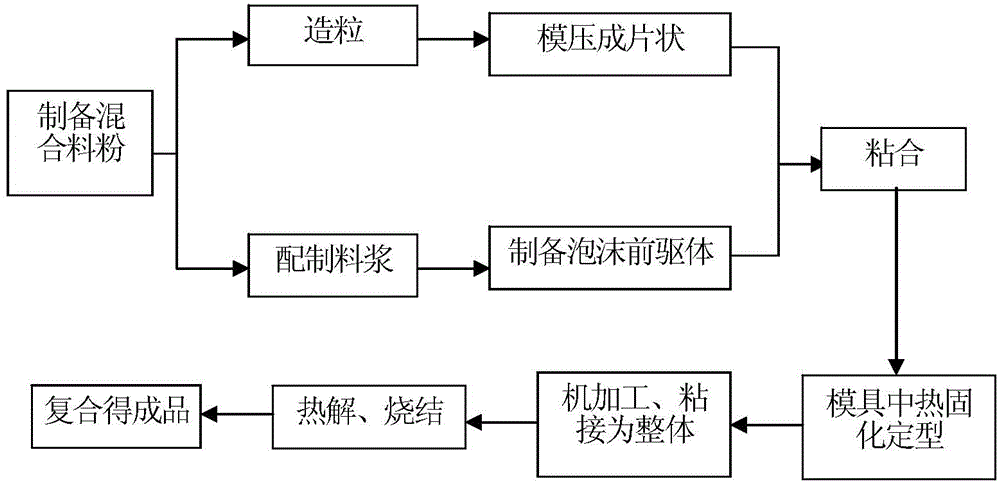

[0046] In this embodiment, the method for preparing a wear-resistant and corrosion-resistant pipe or pipe fitting with dual ceramic linings includes the following steps:

[0047] (1) The mass ratio of furfurone resin: silicon carbide particles (average diameter 10μm): p-toluenesulfonic acid = 100: 120: 5 to mix the above raw materials, ball mill for 1 hour to obtain the powder, the materials in the powder are evenly mixed , There is no obvious reunion phenomenon;

[0048] (2) Prepare a liquid slurry with the powder obtained in (1) at a mass ratio of powder: alcohol=100:200, and then fully soak the foam with a thickness of 5mm in the slurry and squeeze out the excess slurry. Air dry at 120°C. After air drying, the sample is immersed in the slurry again, and the excess slurry between the holes is blown off, and then air dried at a high temperature of 120°C. Repeat the above steps 5 times to obtain the required foam ceramic layer precursor;

[0049] (3) Prepare the material powder ob...

Embodiment 2

[0055] In this embodiment, the method for preparing a wear-resistant and corrosion-resistant pipe or pipe fitting with dual ceramic linings includes the following steps:

[0056] (1) Mix the above-mentioned raw materials at a mass ratio of epoxy resin: alumina particles: citric acid = 100:50:5, and ball mill for 2 hours to obtain a slurry; the particle size of the alumina particles is 2 microns;

[0057] (2) Prepare a liquid slurry with the powder obtained in (1) at a mass ratio of powder: alcohol=100:200, and then fully soak the foam with a thickness of 5mm in the slurry and squeeze out the excess slurry. Air dry at 120°C. After air drying, the sample is immersed in the slurry again, and the excess slurry between the holes is blown off, and then air dried at a high temperature of 120°C. Repeat the above steps 5 times to obtain the required foam ceramic layer precursor;

[0058] (3) Prepare the material powder obtained in (1) with a mass ratio of material powder: alcohol=100:20, mi...

Embodiment 3

[0064] In this embodiment, the method for preparing a wear-resistant and corrosion-resistant pipe or pipe fitting with dual ceramic linings includes the following steps:

[0065] (1) Mix the above-mentioned raw materials with a mass ratio of phenolic resin: silicon carbide particles: p-toluenesulfonic acid = 100:50:5, and ball mill for 2 hours to obtain slurry; the silicon carbide particles have a particle size of 2 microns.

[0066] (2) Prepare a liquid slurry with the powder obtained in (1) at a mass ratio of powder: alcohol=100:200, and then fully soak the foam with a thickness of 5mm in the slurry and squeeze out the excess slurry. Air dry at 120°C. After air drying, the sample is immersed in the slurry again, and the excess slurry between the holes is blown off, and then air dried at a high temperature of 120°C. Repeat the above steps 5 times to obtain the required foam ceramic layer precursor;

[0067] (3) Prepare the material powder obtained in (1) with a mass ratio of mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com