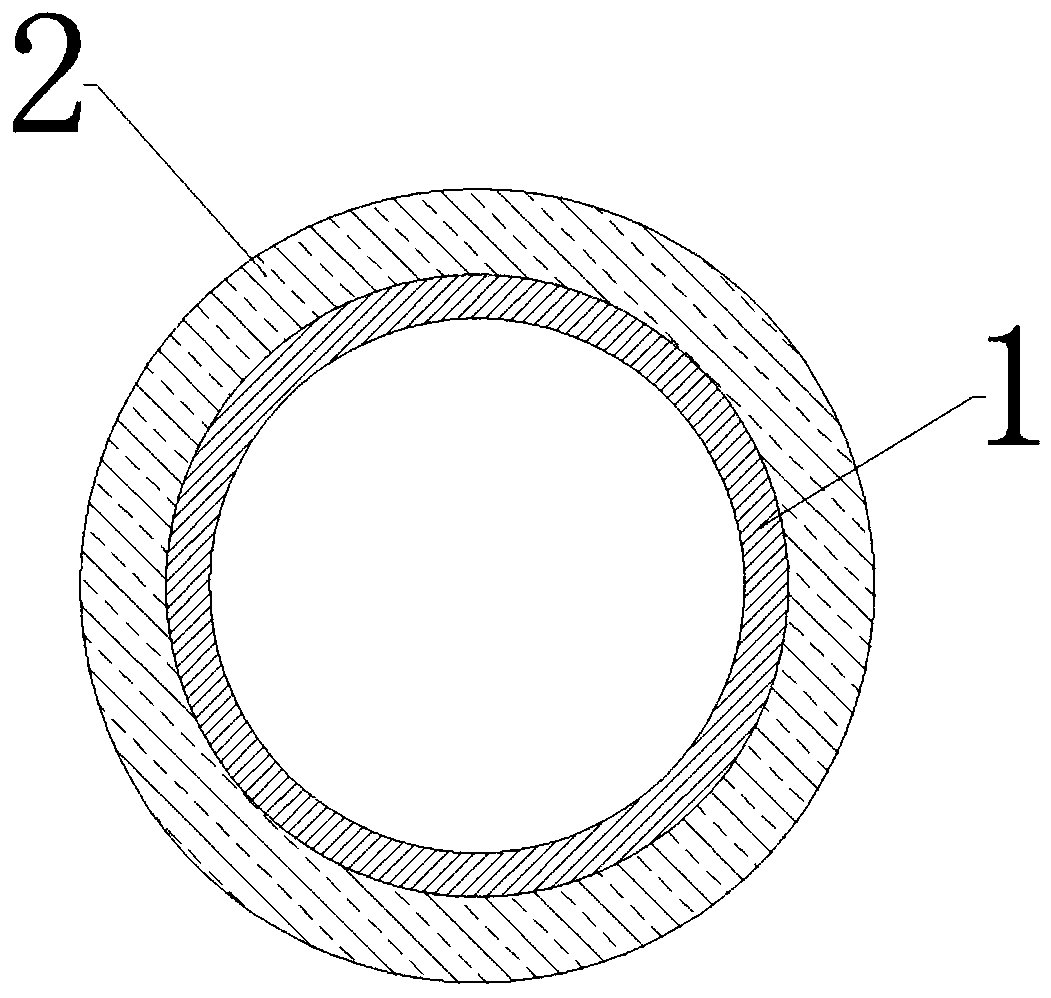

Light magnetic ball and preparation method thereof

A magnetic ball, lightweight technology, applied in the field of magnetic therapy, can solve the problems of heaviness, high density, affecting sleep quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of lightweight magnetic balls, comprising:

[0037] S10, preparing ceramic hollow spheres.

[0038] Firstly, ceramic slurry is prepared, and then the ceramic slurry is evenly coated on the surface of polystyrene spheres layer by layer, and then sintered and cooled to obtain the ceramic hollow spheres.

[0039] The preparation method for preparing the ceramic slurry is as follows: first, fully mix 65-85 parts of zircon, 40-60 parts of calcined kaolin, and 10-15 parts of attapulgite to make ceramic powder; then press 50-60 parts of ceramic powder % (mass ratio, unless otherwise specified, the following percentages are all mass ratios), the ratio of 40% to 50% of the powder solvent is mixed, ground for a certain period of time, and the ceramic slurry is obtained. The powder solvent includes a first dispersant, a thickener, a binder and water, and the mass proportions of each component are: 0.1-0.3% of the first disp...

Embodiment 1

[0057] The preparation method of the present embodiment ceramic hollow sphere comprises:

[0058] Fully mix 65 parts of zircon, 40 parts of calcined kaolin and 10 parts of attapulgite to prepare ceramic powder.

[0059] The powder solvent is configured according to the following component ratios: 0.1% sodium polyacrylate, 0.05% sodium carboxymethylcellulose, 1.0% dextrin, and 98.85% water.

[0060] Mix according to the ratio of 50% of ceramic powder and 50% of powder solvent, put into planetary ball mill and grind for 6 hours to prepare ceramic slurry.

[0061] Put the steam-expanded polystyrene sphere into the drum, set the rotating speed at 8 rpm, raise the temperature inside the drum to 35° C., and then add the ceramic slurry. During the rotation of the drum, the ceramic slurry is uniformly coated on the surface of the polystyrene sphere, and when the polystyrene sphere coated with the ceramic slurry reaches a specified size, the polystyrene sphere is dried.

[0062] Send...

Embodiment 2

[0065] The preparation method of the present embodiment ceramic hollow sphere comprises:

[0066] Fully mix 75 parts of zircon, 55 parts of calcined kaolin and 12 parts of attapulgite to prepare ceramic powder.

[0067] The powder solvent is configured according to the following component proportions: 0.3% of methacrylic acid amine, 0.15% of hydroxypropyl cellulose sodium, 1.0% of polyvinyl alcohol, and 98.55% of water.

[0068] Mix according to the ratio of 60% of ceramic powder and 40% of powder solvent, put into a planetary ball mill and grind for 6 hours to prepare ceramic slurry.

[0069] Stir and mix the steam-expanded polystyrene spheres and the ceramic slurry with a high-speed mixer, and filter out the polystyrene spheres whose surfaces are covered with the ceramic slurry for every 1 hour of stirring, and dry them. Repeat this 3 times.

[0070] Send the dried spheres to a high-temperature sintering furnace for sintering, raise the temperature to 700-800°C at a rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com