Thin film resistor and manufacturing method thereof

A technology of thin film resistors and resistive layers, applied in thin film resistors, resistor manufacturing, resistors, etc., can solve problems such as increasing manufacturing costs and reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

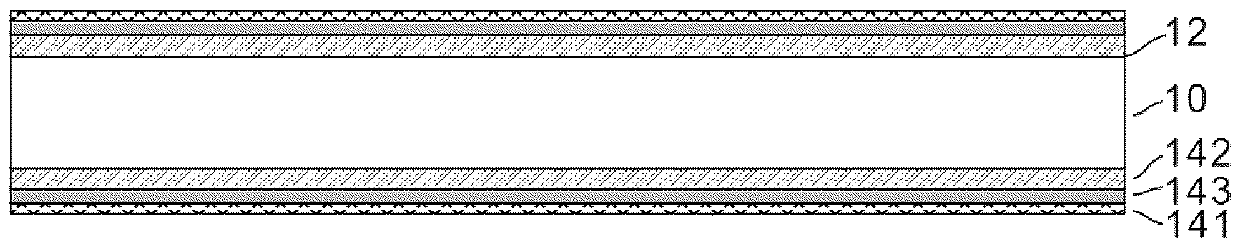

[0080] This embodiment relates to a metal thin film resistor.

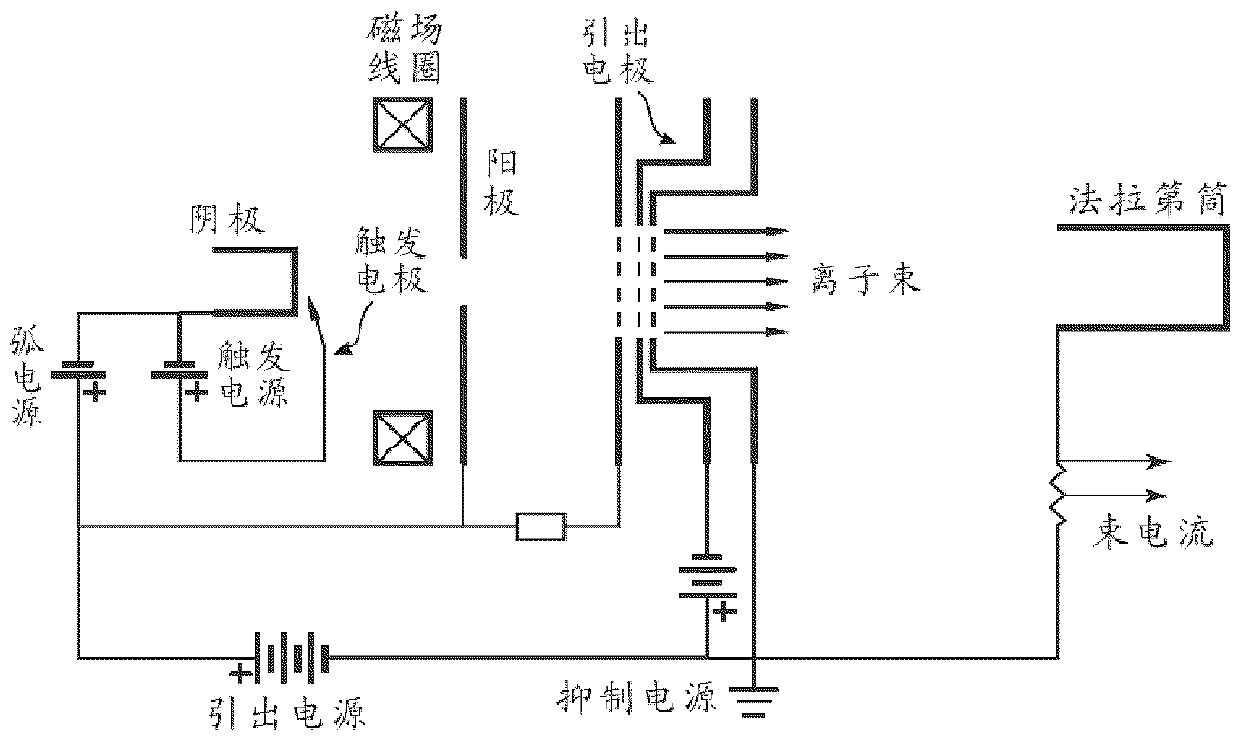

[0081] First, glass with a thickness of 500 μm is selected as the substrate. Then, a resistance layer is formed on the surface of the glass substrate by adopting a treatment method of ion implantation followed by plasma deposition.

[0082] In the ion implantation process, one of Ti, Ta, Cr, Ni, Al, Cu, Ag, Au, V, Zr, Mo, Nb, In, Sn, Tb, Be, Ca, Mg is selected as the target material; Preferably, Ni or Cr can be selected as the vacuum cathode arc target material. Control the process temperature of ion implantation to 600°C, vacuumize to 2×10 -1 up to 5×10 -5 Pa, and adjust the energy of the implanted ions to 50-100keV, and the implanted dose is 1.0×10 17 to 5.0×10 17 ion / cm 2 , so that the lower surface of the ion implantation layer is located at a depth of 5-50 nm below the surface of the substrate.

[0083] In the plasma deposition process, one of Ti, Ta, Cr, Ni, Al, Cu, Ag, Au, V, Zr, Mo, Nb, In, Sn, Tb, ...

Embodiment 2

[0085] This embodiment relates to an alloy thin film resistor.

[0086] First, a silicon plate with a thickness of 80 μm is selected as the substrate. Then, a resistance layer is formed on the surface of the silicon plate by using a treatment method of ion implantation followed by plasma deposition. In the process of ion implantation and plasma deposition, the composition of the alloy target material used is shown in Table 1 below, where the values represent mass percentages.

[0087] components

Ni

Cr

Al

Ti

Cu

be

Ta

Au

Alloy combination 1

50

50

Alloy combination 2

40

40

20

Alloy combination 3

47

47

6

Alloy Set 4

75

15

10

Alloy combination 5

50

50

Alloy combination 6

30

20

15

10

25

Alloy combination 7

40

40

...

Embodiment 3

[0091] This embodiment relates to an alloy thin film resistor.

[0092] First, silicon dioxide with a thickness of 100 μm is selected as the substrate. Then, a resistance layer is formed on the surface of the silicon dioxide substrate by using a treatment method of ion implantation followed by plasma deposition.

[0093] In the process of ion implantation, different proportions of Ni-Cr alloys are selected and mixed with Ta, Al or Mo as the vacuum cathode arc target. Preferably, a Ni-Cr-dopant series alloy with a mass ratio of 40:40:20 or 35:55:10 is selected as the vacuum cathode arc target material, and the process temperature of ion implantation is controlled to be 600°C, and the vacuum is evacuated to 2 ×10 -1 up to 5×10 -5 Pa, and the energy of implanted ions is adjusted to 50 to 100keV, and the implanted dose is 1.0×10 17 to 5.0×10 17 ion / cm 2 , so that the lower surface of the ion implantation layer is located at a depth of 5-50 nm below the surface of the substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com