Method and system for processing glass door panels

A processing method and technology of door panels, applied in the installation of window glass, door leaf, window/door, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The embodiment of the present invention provides a glass door panel processing method and system, and provides a frameless stainless steel glass door panel manufacturing process, solving the stainless steel frameless glass door panel processing and 45° angle splicing manufacturing process.

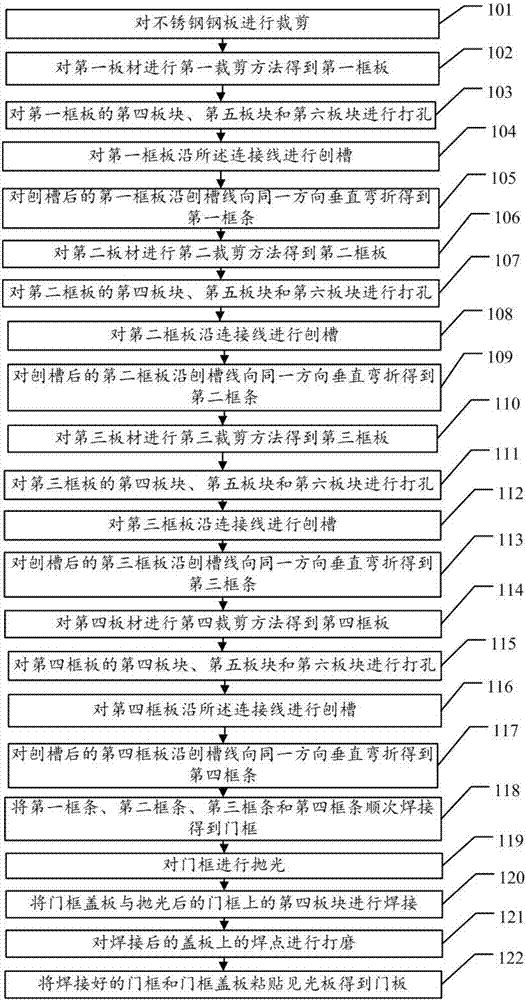

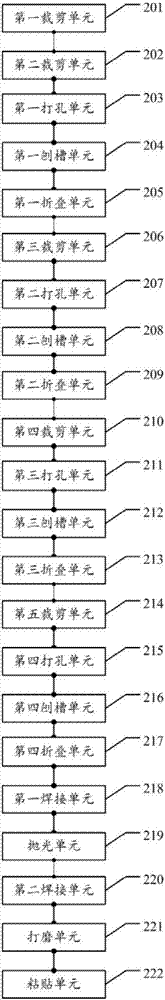

[0101] see figure 1 , an embodiment of a glass door panel processing method provided by the present invention, comprising:

[0102] A method for processing a glass door panel provided by the invention comprises:

[0103] A method for processing a glass door panel, comprising:

[0104] 101. Cutting the stainless steel plate to obtain the first plate, the second plate, the third plate and the fourth plate;

[0105] In this embodiment, the large stainless steel plate is cut into the first plate, the second plate, the third plate and the fourth plate to be processed;

[0106] 102. Performing the first cutting method on the first plate to obtain the first frame plate, the first frame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com