An air flotation device for optical device coupling and using method

An optical device and air flotation technology, which is applied in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems of relative position change and affecting the performance of optical devices, so as to avoid the existence of angle and ensure the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] like Figure 1-4 As shown, an air flotation device for optical device coupling includes a support table 1, a ball seat 2, a floating ball 3, a compressed air joint 8 and a vacuum joint 9, the support table 1 is a cylindrical support table, and the support table 1 There is an installation cavity inside the ball seat 2, the ball seat 2 is a cylindrical structure, and the inner side wall of the ball seat 2 is provided with an annular groove 24, and the side wall of the ball seat 2 is symmetrically opened with a first gas path 5 and a second gas path 6. Both the first air passage 5 and the second air passage 6 communicate with the annular groove 24, the floating ball 3 is movably embedded inside the upper end of the ball seat 2, and the top of the floating ball 3 extends to the outside of the upper end of the ball seat 2 , the top of the floating ball 3 is provided with a horizontal plane, and the top of the floating ball 3 is provided with a station slot 4, the side of the...

Embodiment 2

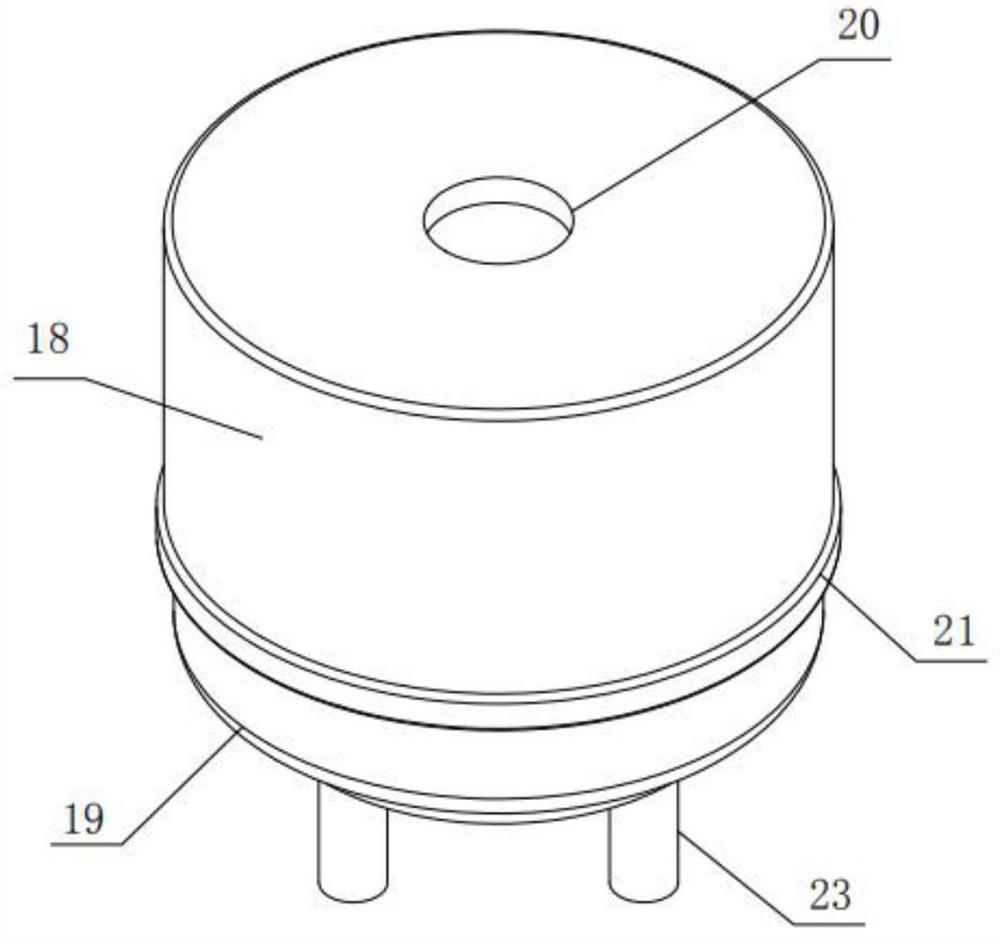

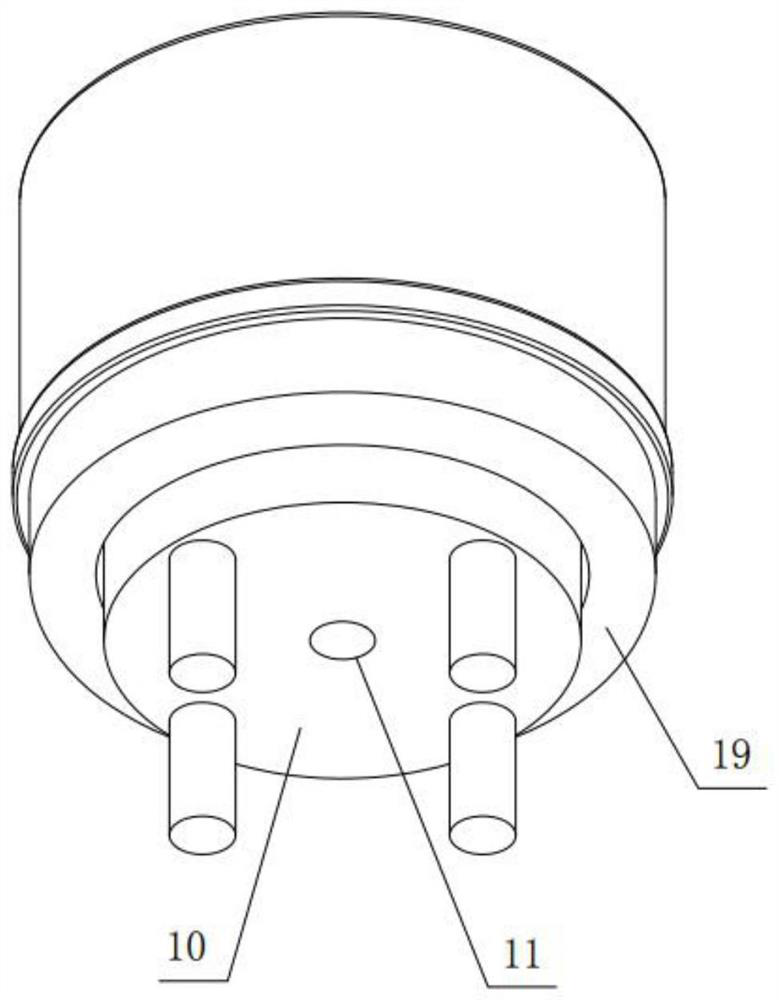

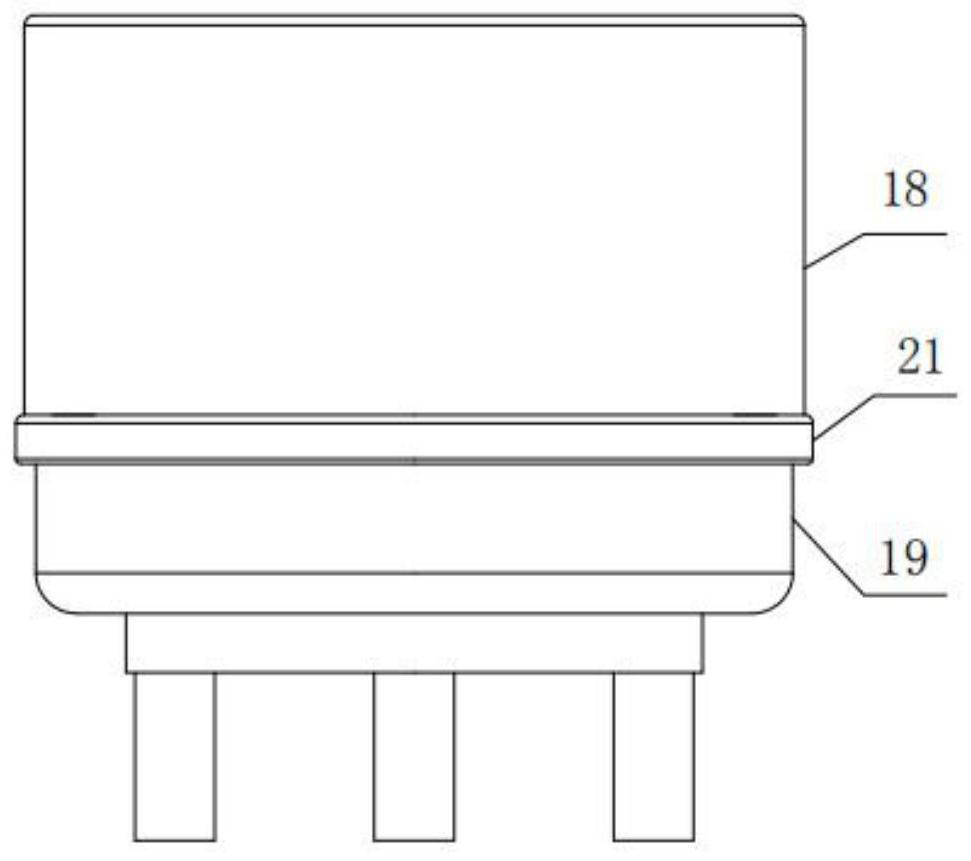

[0038] like Figure 1-7 As shown, the difference between this embodiment and Embodiment 1 is that the air flotation device used for optical device coupling also includes a dust-proof assembly, and the dust-proof assembly includes a dust-proof cover 18 and a dust-proof cloth bag 19, and the dust-proof cover 18 is fixed It is installed on the top of the floating ball 3, and the upper surface of the dust cover 18 is a horizontal plane. The center of the dust cover 18 is provided with a through hole 20 that is matched with the station slot 4, and the dust cover 18 has a direction toward the support table. 1. The side wall provided, the edge of the side wall of the dust cover 18 is integrally provided with an annular slide rail 22, the through hole 20 is completely overlapped with the station slot 4, the dust cloth bag 19 is a ring structure, and the outer ring of the dust cloth bag 19 is An annular slider 21 is fixedly installed on the edge, and an annular fitting seat 7 is fixedl...

Embodiment 3

[0044] like Figure 1-9 As shown, the difference between this embodiment and Embodiment 2 is that at least three installation grooves 13 are evenly opened on the inner side wall of the ball seat 2 (theoretically, the three installation grooves 13 are sufficient to ensure the stability of the floating ball 3). The bottoms of the mounting grooves 13 are fixedly mounted on the first spring seats 14 , the upper parts of the first spring seats 14 are fixedly mounted with springs 15 , and the upper ends of the springs 15 are fixedly mounted with the second spring seats 16 . The upper part of the 16 is rotated and embedded with a universal ball 17. The spherical surface of the universal ball 17 is in conflict with the spherical surface of the floating ball 3. The spring 15 can be used to lift the floating ball 3 to offset the gravity of the floating ball 3, so that the floating ball 3 is more stable. Easy to float. In addition, under the action of the universal ball 17 , the frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com