Packaging tape installer

An installer and tape technology, applied in the directions of transportation and packaging, sending objects, thin material handling, etc., can solve the problems of poor tape guiding effect and tape bonding, and achieve the effect of avoiding tape displacement and high pasting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

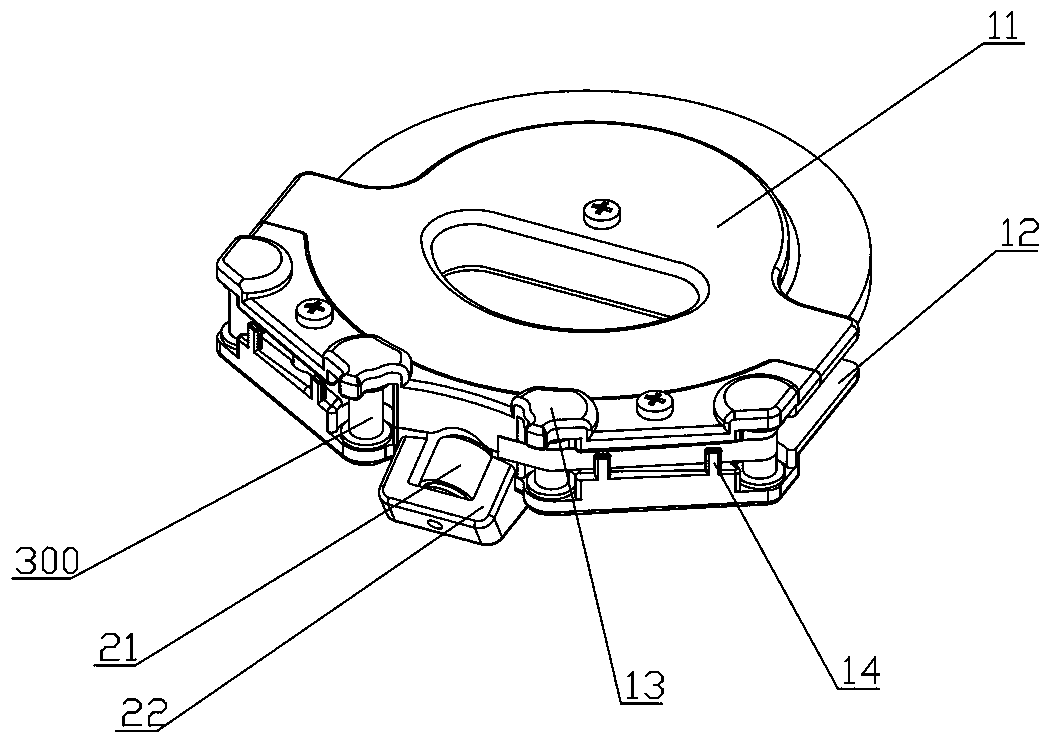

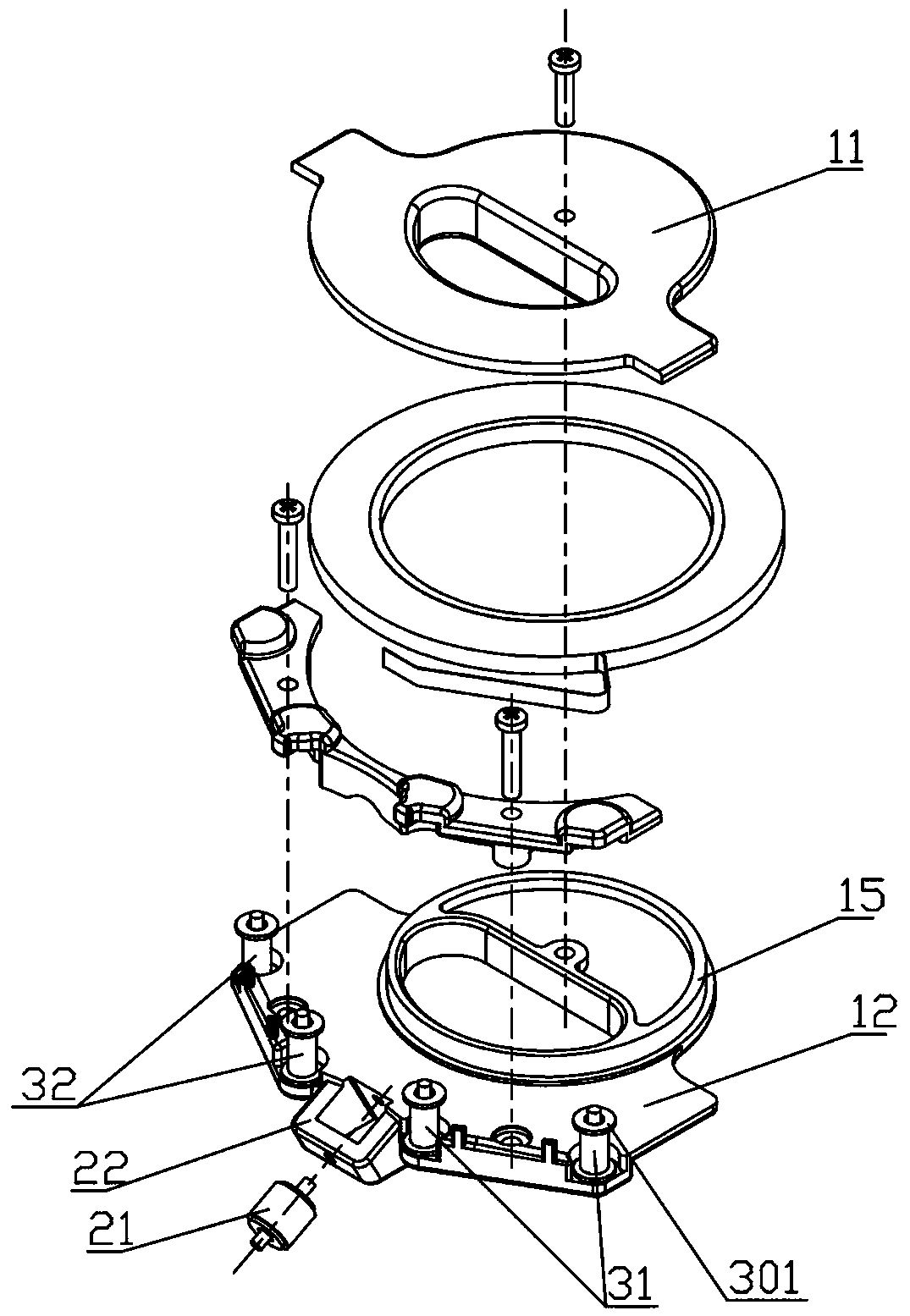

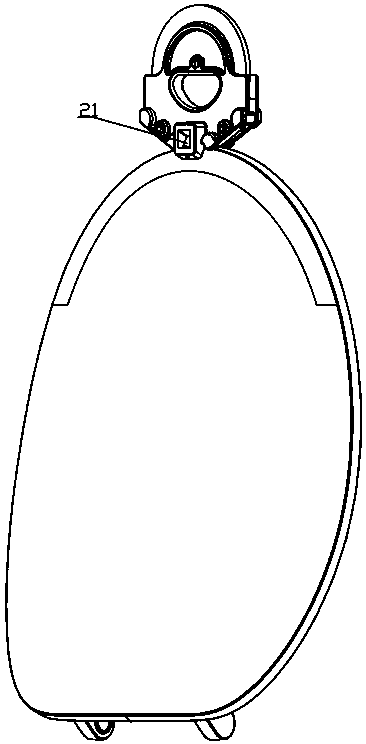

[0024] Such as figure 1 , 2 As shown, a tape installer includes a main body, the main body includes a base 12 and an upper cover 11, and a convex portion 15 is provided on the base 12, the convex portion 15 matches the core of the tape roll, and the convex portion 15 has a circular structure. Its shape is the same as the core shape of the tape roll, its diameter is smaller than the diameter of the core, and the height of the protrusion is larger than the thickness of the tape roll. There is a screw hole in the middle of the protrusion, and the screw passes through the upper cover 11 and the middle of the protrusion. The screw holes are connected, the upper cover 11 and the base 12 are combined, and an accommodating cavity for accommodating the tape roll is formed between the upper cover 11 and the middle part, and the protrusion is arranged in the accommodating cavity.

[0025] One side of the main body is provided with an outlet communicating with the accommodating cavity, ...

Embodiment 2

[0031]This embodiment is similar to Embodiment 1, except that in this embodiment, positioning ribs 14 are provided on the outside of the opening. Specifically, the positioning ribs 14 are set flush with the side of the base 12. Placed on the inside of the positioning rib 14, the setting of the positioning rib 14 can ensure that when the device is not in use, the tape head is restricted by the positioning rib 14 so that it will not be warped outwards, and because the sticking surface of the adhesive tape is set outwards, Under the isolation of the positioning rib 14, even if it is not applicable, the adhesive tape will only be pasted to the inner side of the positioning rib 14, and will not be pasted to other places, so it is more convenient to use.

[0032] In addition, in this embodiment, limit baffles 301 are provided on both sides of the rotating wheel 300 . The position of the adhesive tape can be limited by the limit baffle 301, so as to prevent the adhesive tape from shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com