Automatic film pasting device

A film applicator, automatic technology, applied in packaging and other directions, can solve the problems of air bubbles, sticking impurities, film waste and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

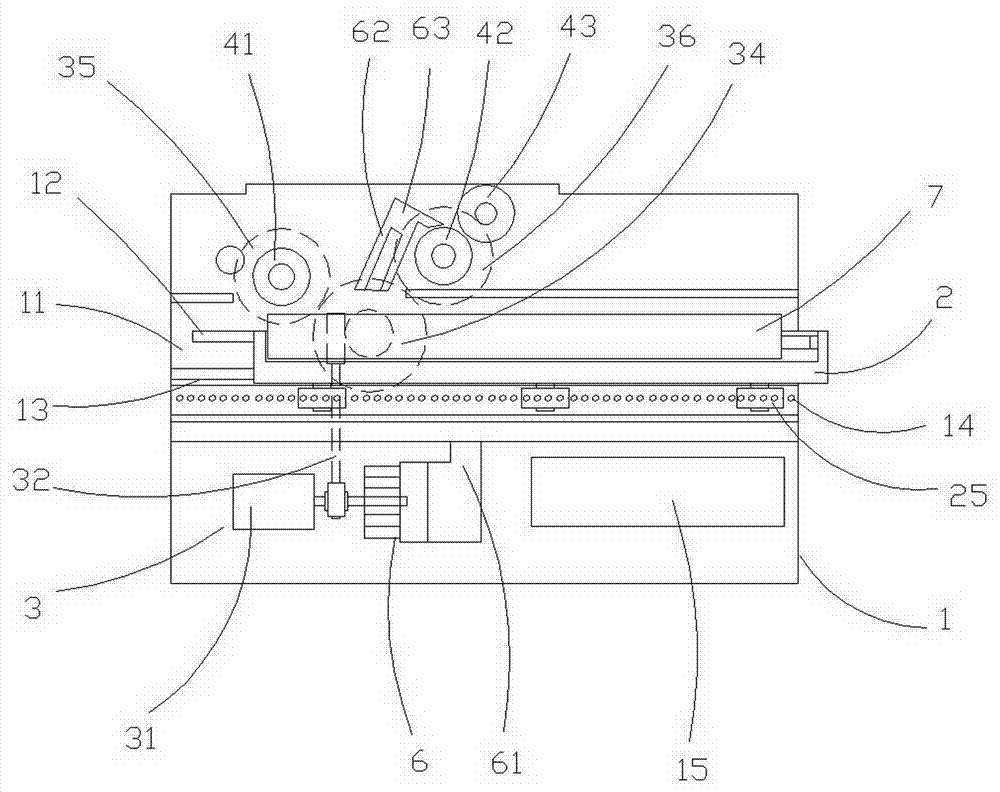

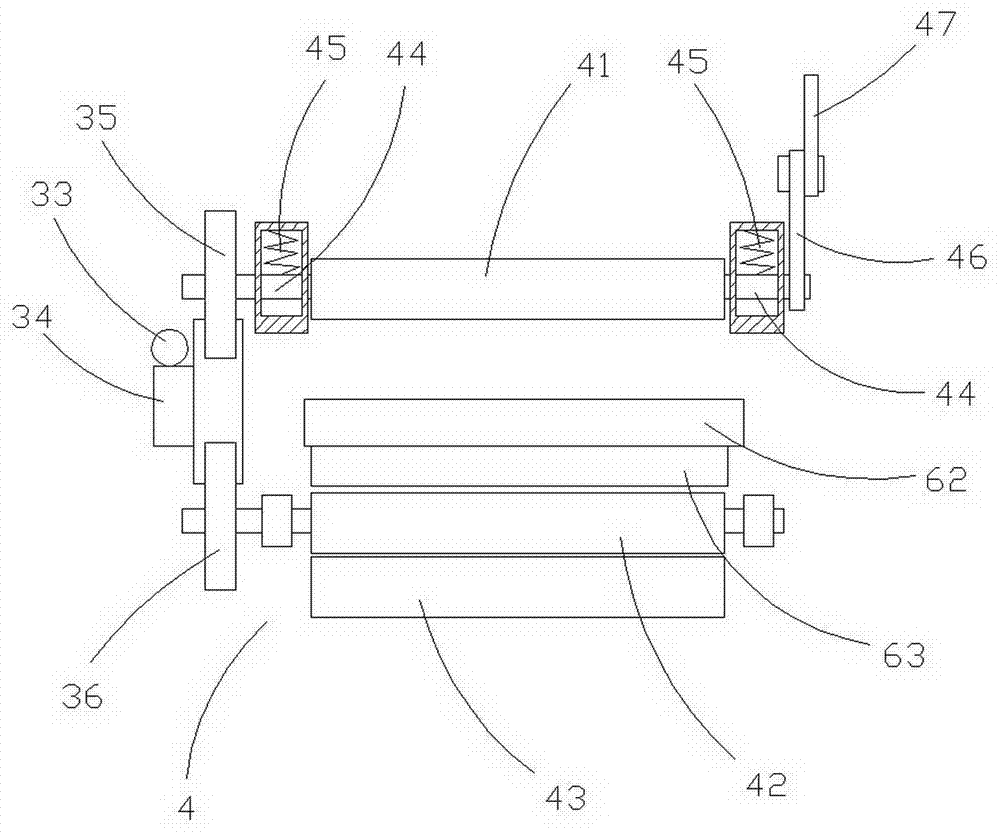

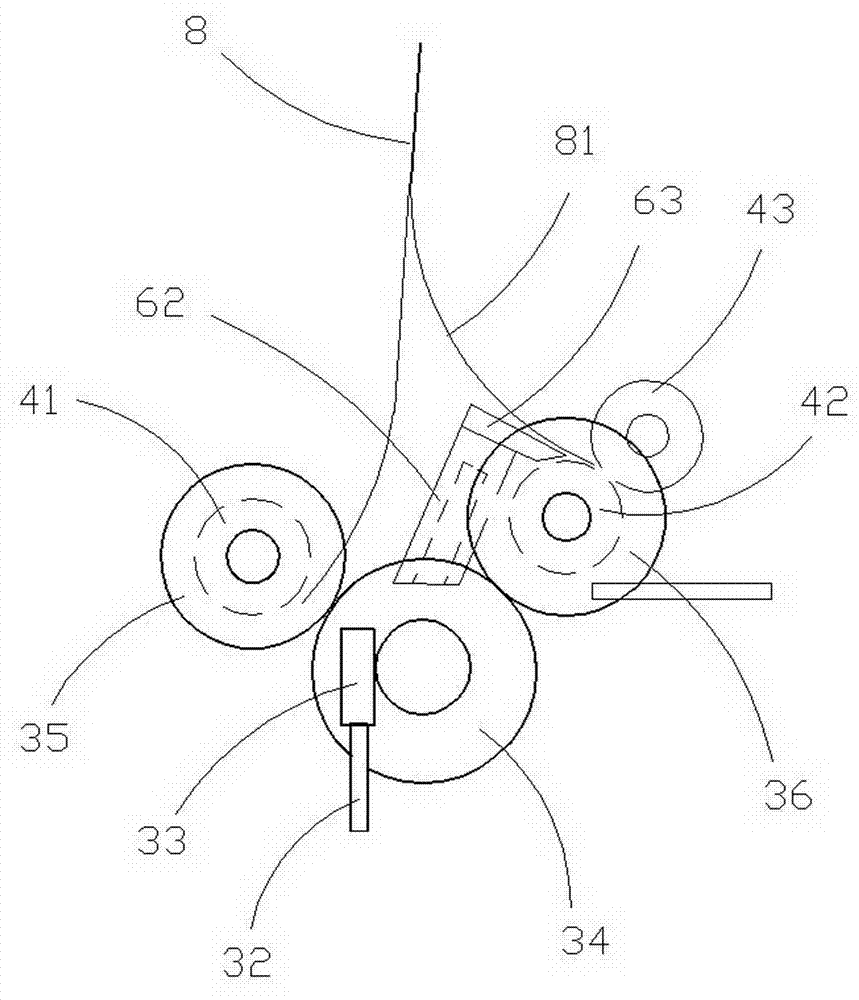

[0025] Such as figure 1 , 2 As shown in , 3 and 4, an automatic film applicator includes an outer shell 1, an accommodating tray 2, a transmission device 3, and a film sticking mechanism 4. The outer shell is provided with a through chamber 11, and the accommodating device placed in the chamber The disk 2, the corresponding upper clamping column 23 and the lower clamping column 24 on its two sides and the arranged rollers 25 slide with the upper slideway 12 and the sliding slideway 13 on the two side walls of the chamber 11 and the evenly arranged protrusions 14. Cooperate, be provided with transmission device 3 below chamber 11, the motor 31 of transmission device connects driving wheel 34 through the pinion 33 on the rotating shaft 32, the first driven wheel 35 on the film pressing shaft 41 of driving wheel 34 and film sticking mechanism 4 and The second driven wheel 36 on the film-exiting shaft 42 is meshed, the motor is connected to the dust collector 6, and the air duct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com