Flatly pasted floor covering film

A technology for flooring and lamination, applied in the field of decorative materials, can solve problems such as affecting the effect and appearance of the post, tripping over bubbles, and being difficult to remove, etc., and achieves the effect of easy and smooth pasting, and saving the time of pasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

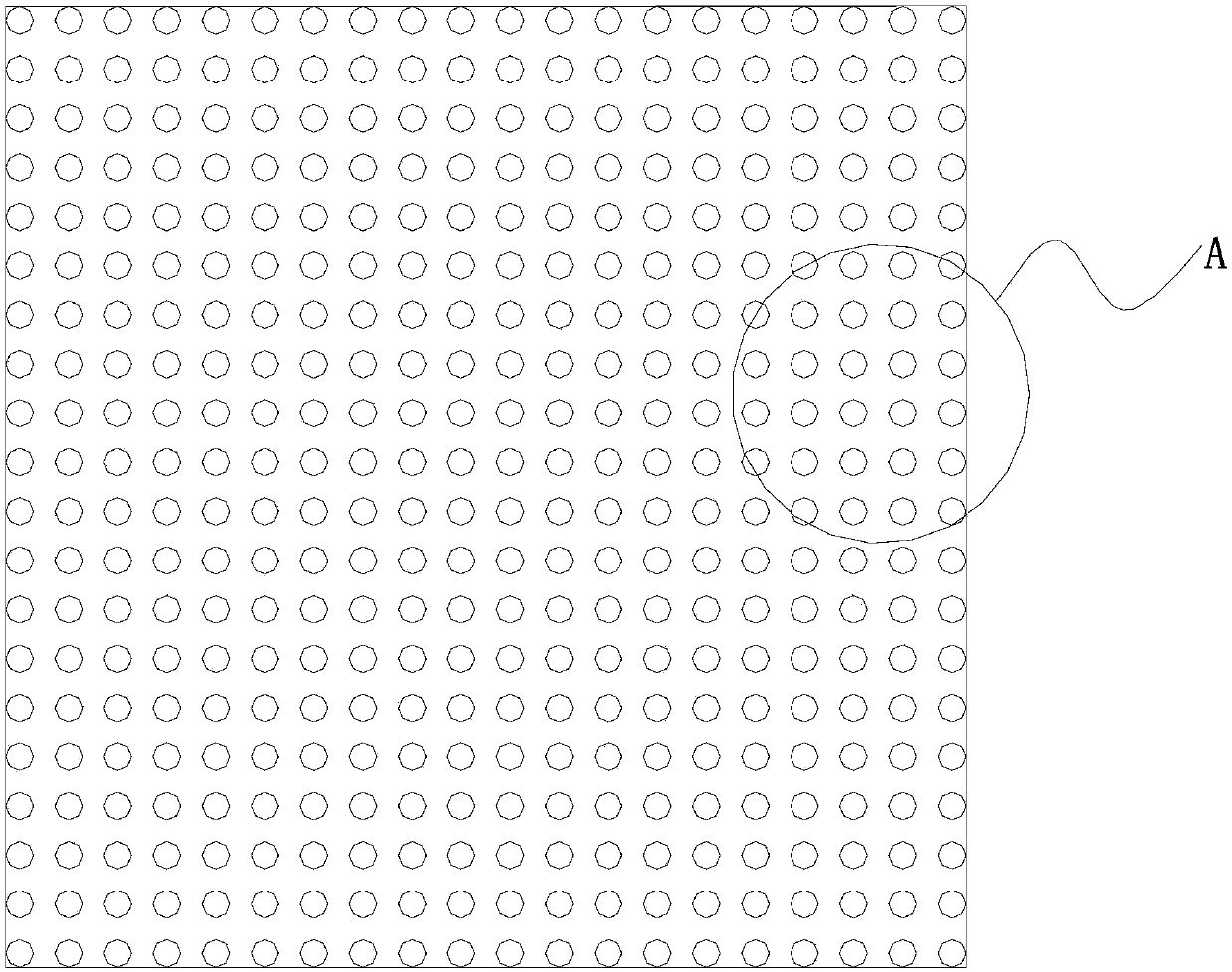

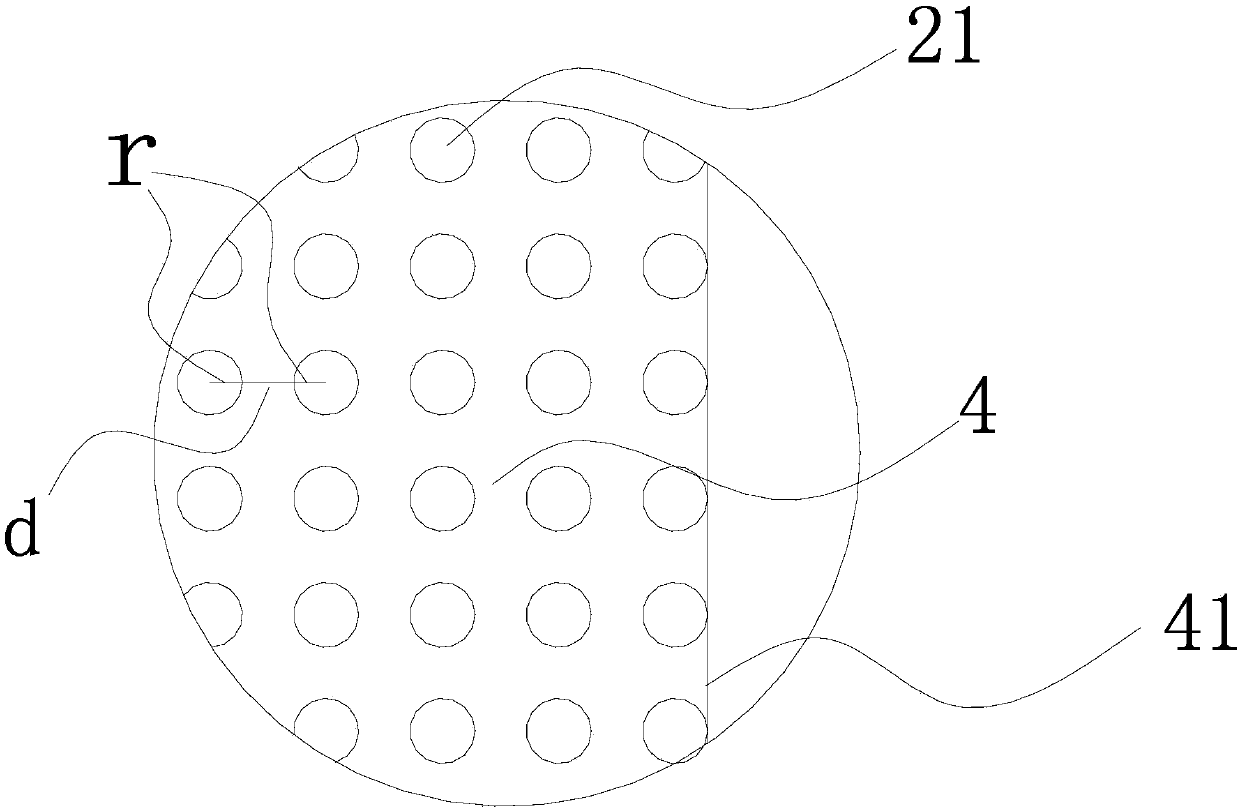

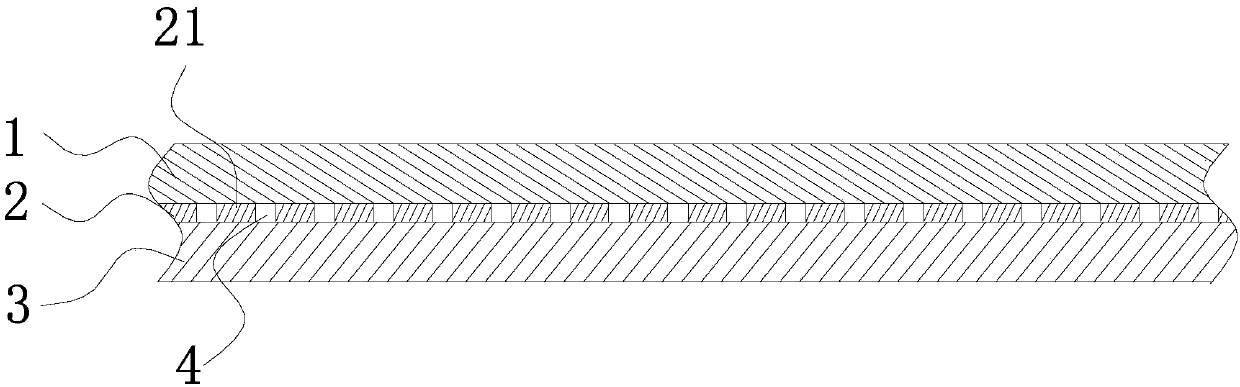

[0022] Such as Figure 1 to Figure 3 Shown is a kind of pasted flat floor covering film of the present invention, comprises surface layer 1, adhesive layer 2 and bottom layer 3, and described adhesive layer 2 is arranged by the viscose glue distributed between surface layer 1 and bottom layer 2 21 are formed, and gaps are left between the viscose 21 . The floor covering film is torn off from the bottom layer 2 and pasted on the attached body. Since there is a gap between the adhesives 21, the gas can be easily squeezed out from the gap, so that the floor covering film is pasted flat and avoids the sticking process during the pasting process. Scratch the film in order to drive away the air bubbles.

[0023] Depend on figure 2 It can be seen that there is an air channel 4 between the glue 21 , and the air channel 4 forms an air outlet 41 at the edge of one side of the floor coating. Gas can be discharged from the gas outlet 41 through the gas channel 4 to further eliminate a...

Embodiment 2

[0027] Such as Figure 3 to Figure 5 It is shown as a kind of pasted flat floor covering film of the present invention, comprising surface layer 1, adhesive layer 2 and bottom layer 3, and described adhesive layer 2 is arranged between surface layer 1 and bottom layer 2 by the adhesive Glues 21 are formed with gaps between them. An air channel 4 is left between the adhesives 21, and the air channel 4 forms an air outlet at the edge of one side of the floor coating. The viscose 21 is distributed between the surface layer and the bottom layer in dot-like intervals, and the dot-like glue 21 is rectangular. The rest of the structure of this implementation is similar to that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0029] Such as image 3 , Figure 6 , Figure 7 It is shown as a kind of pasted flat floor covering film of the present invention, comprising surface layer 1, adhesive layer 2 and bottom layer 3, and described adhesive layer 2 is arranged between surface layer 1 and bottom layer 2 by the adhesive Glues 21 are formed with gaps between them. An air channel 4 is left between the adhesives 21, and the air channel 4 forms an air outlet 41 at the edge of the floor coating. The viscose 21 is distributed between the surface layer 1 and the bottom layer 3 in strips at intervals, and the strips of viscose are linear. The rest of the structure of this implementation is similar to that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com