Patents

Literature

68results about How to "Uniform coating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

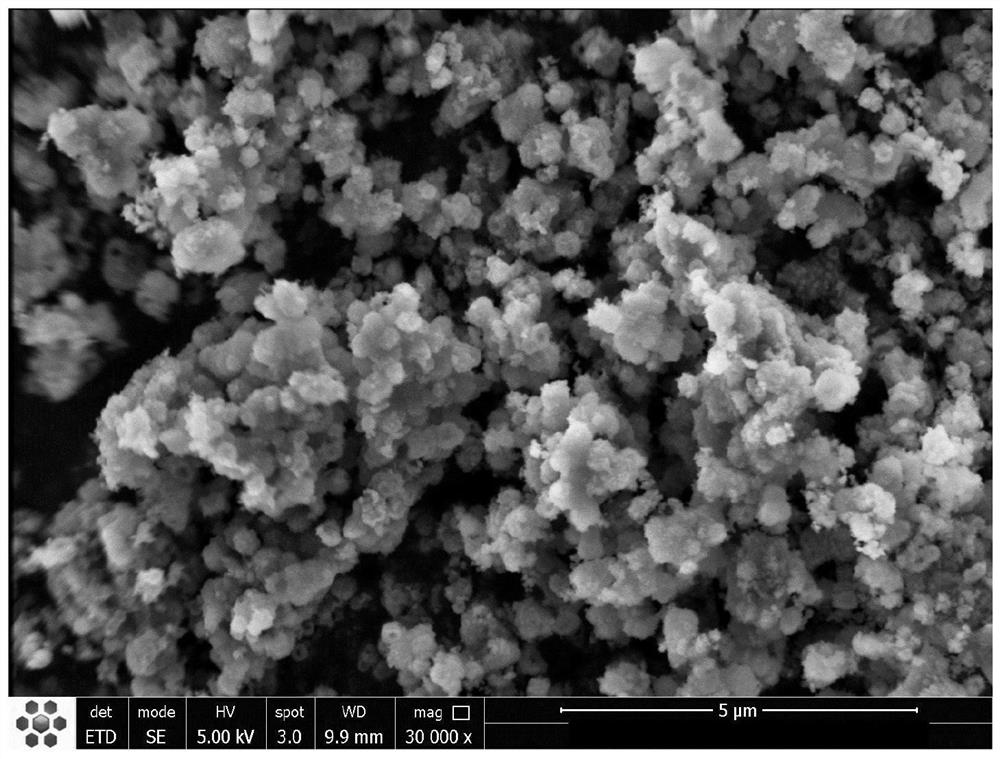

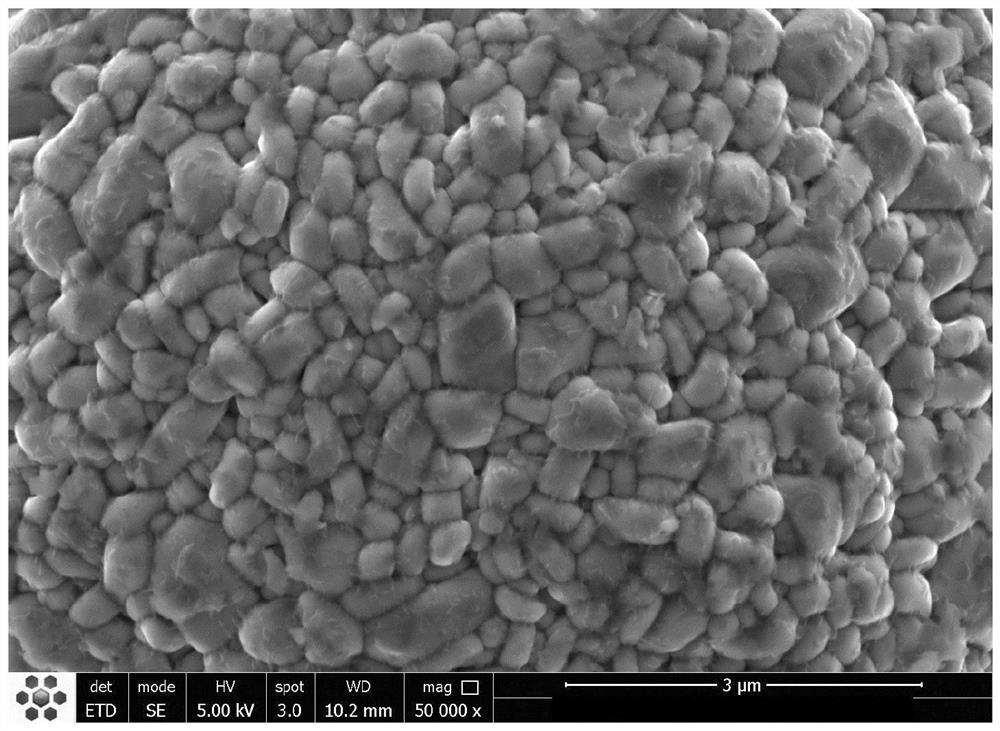

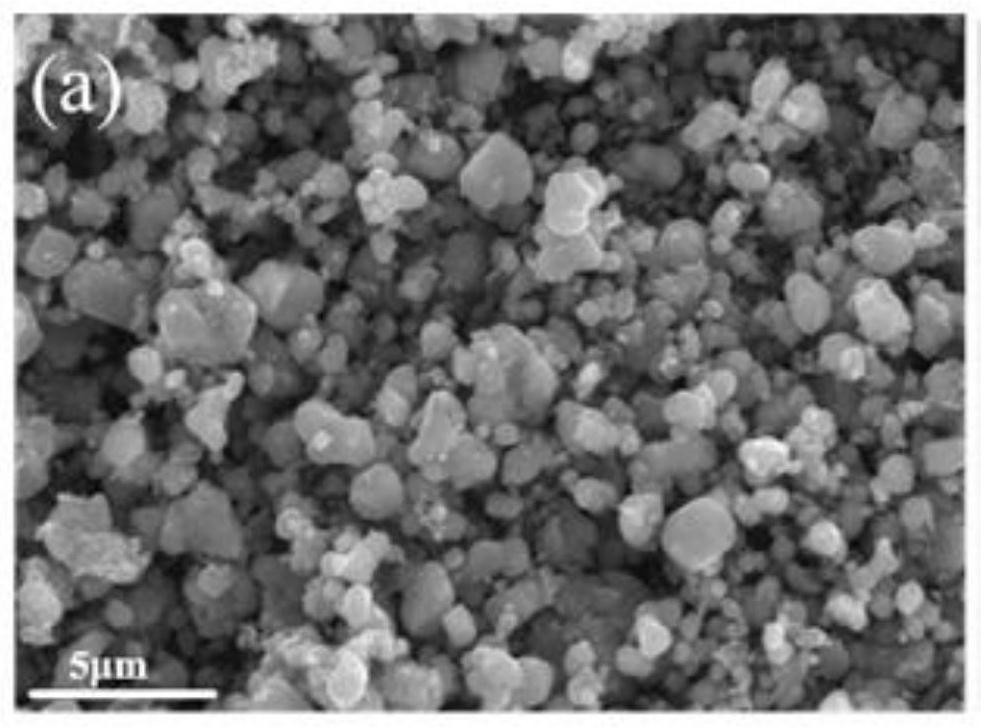

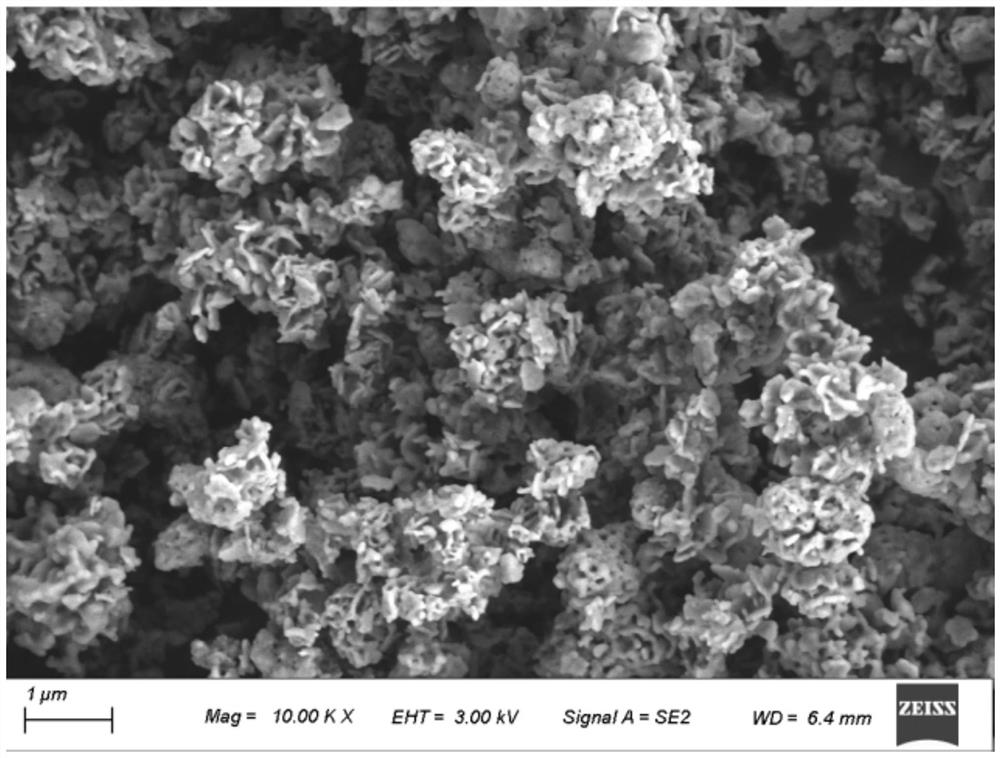

SiOx based composite negative electrode material, preparation method and battery

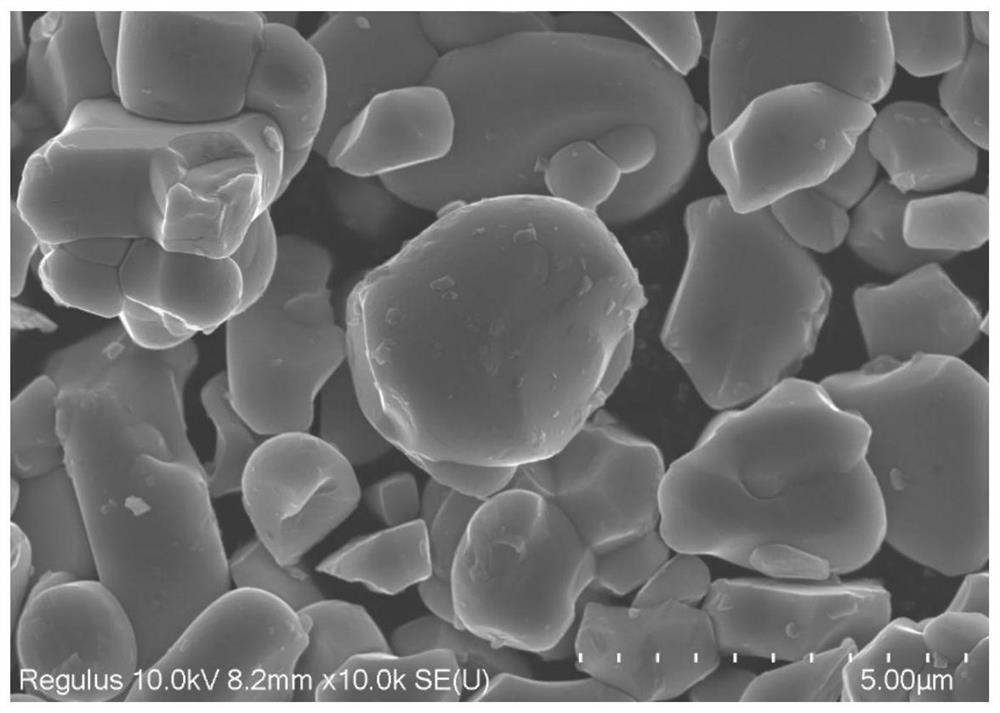

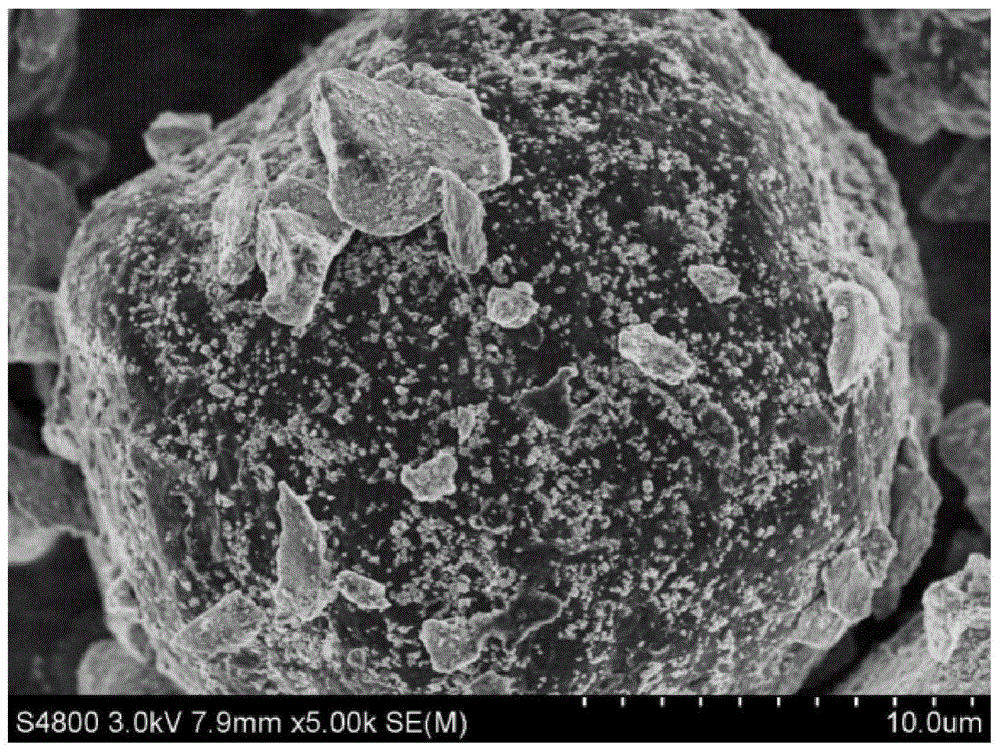

ActiveCN103647056AGood dispersionQuick blend effectCell electrodesLi-accumulatorsCarbon coatingSilicon oxide

The invention relates to a high-capacity SiOx based composite negative electrode material, a preparation method and a battery, wherein the negative electrode material comprises a silicon oxide material, a carbon material and an amorphous carbon coating layer; the silicon oxide material is silicon oxide or silicon oxide material modified in a carbon coating manner; surfaces of carbon material particles are coated with the silicon oxide material. A preparation method of the high-capacity SiOx based composite negative electrode material comprises the steps of performing physical processing or carbon coating modification on a silicon oxide raw material, thus obtaining a micron-sized silicon oxide material; and then mechanically fusing, coating with a solid phase and sintering at a high temperature to obtain the high-capacity negative electrode material. Through the high-capacity SiOx based composite negative electrode material, the effect of uniform dispersing and coating of the micron-sized silicon oxide particles on the surfaces of the carbon material particles can be achieved by virtue of the combination of mechanical fusion and solid-phase coating processes. The silicon oxide particles are well dispersed on the surface of the carbon material particle; the strength of bonding between the silicon oxide particles and the carbon material particles is high; the recycling performance of the material can be greatly improved; and meanwhile, the high-capacity SiOx based composite negative electrode material is high in first efficiency (breaking through the theoretical efficiency of SiOx), low in expansion rate, long in service life, environmental-friendly, pollution-free and low in cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Preparation method of modified ultrafine bentonite, prepared modified ultrafine bentonite and application thereof

ActiveCN102660159AUniform coatingImprove anti-aging propertiesPigment physical treatmentPigment treatment with non-polymer organic compoundsChemistryBoric acid

The invention discloses a preparation method of modified ultrafine bentonite, prepared modified ultrafine bentonite and application thereof. The preparation method comprises the following steps: (1), drying and crushing crude bentonite; performing multi-stage water washing, and removing sander; purifying the bentonite till the montmorillonite content is above 95wt%; adding water, and regulating PH to 7 plus or minus 1; stirring and reacting for 1-12 hours; purifying the bentonite secondarily till the montmorillonite content is above 98wt%; and pulverizing to obtain 3000-5000-mesh ultrafine bentonite powder; and (2), at a temperature of 100-150 DEG C, pressurizing, and performing surface activation modification by using a boric acid ester modifier to obtain the modified ultrafine bentonite product. The problems of the compatibility and the dispersibility of the ultrafine bentonite and a polymer material are solved; and when the prepared modified ultrafine bentonite can be applied to processing of a rubber or plastic product, the prepared modified ultrafine bentonite can be used as a reinforcing agent and the service life of the produced rubber or plastic product can be prolonged by more than 30%.

Owner:SHANDONG HUAWEI BENTONITE

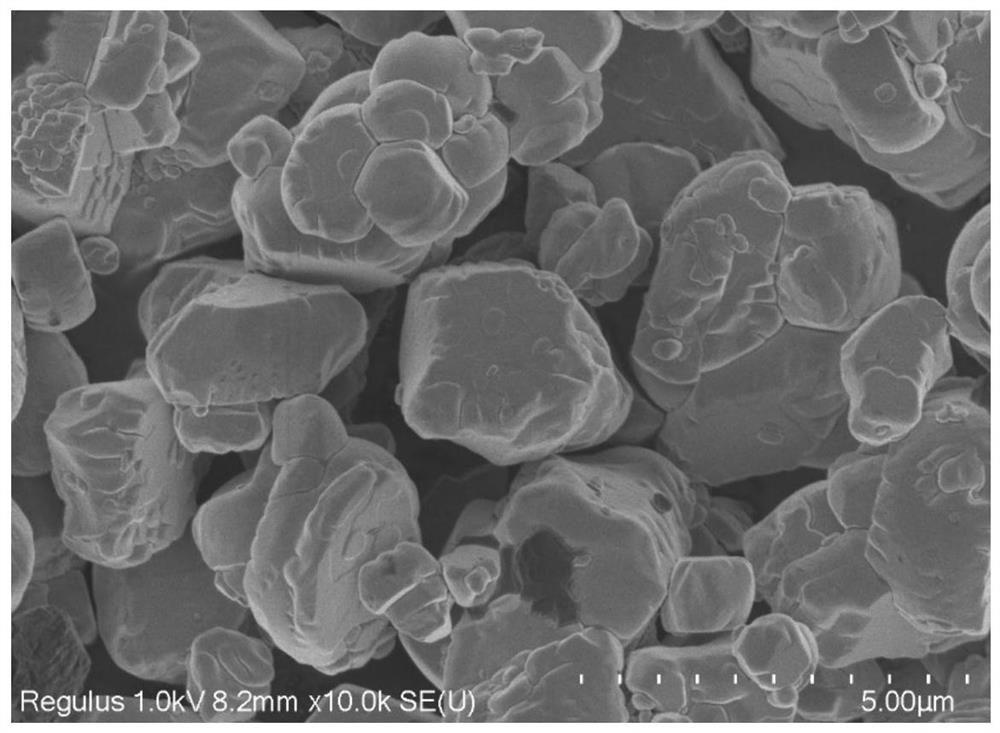

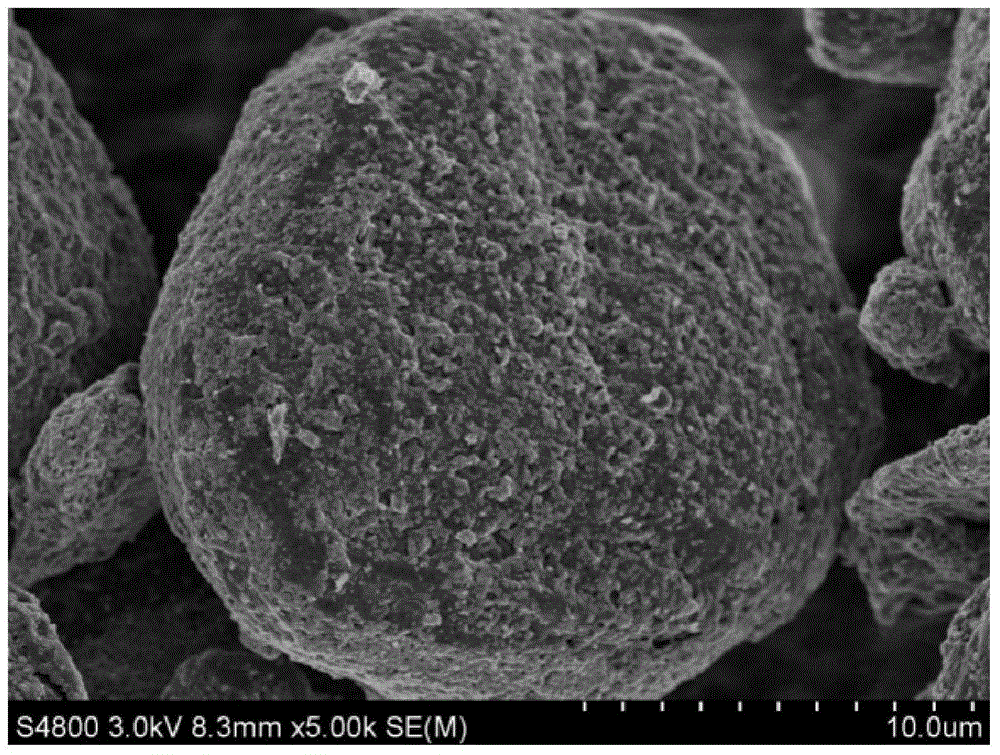

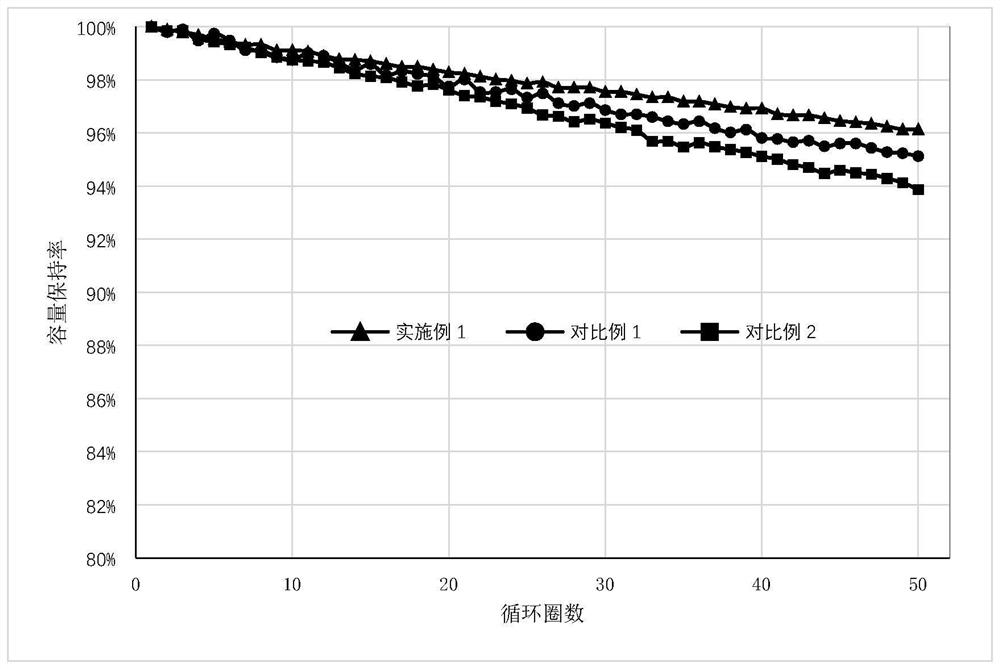

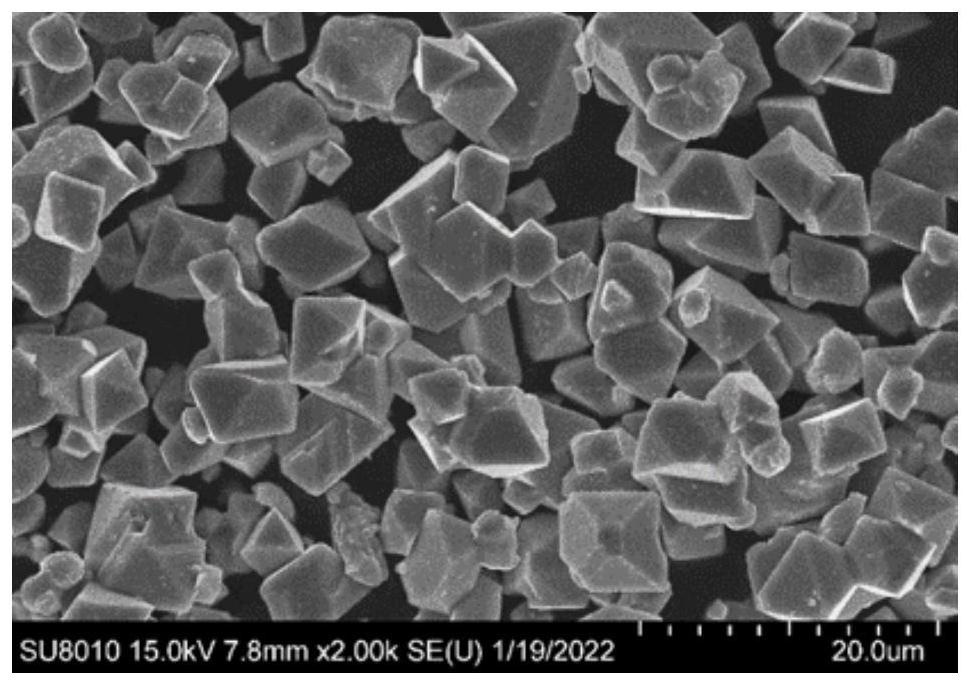

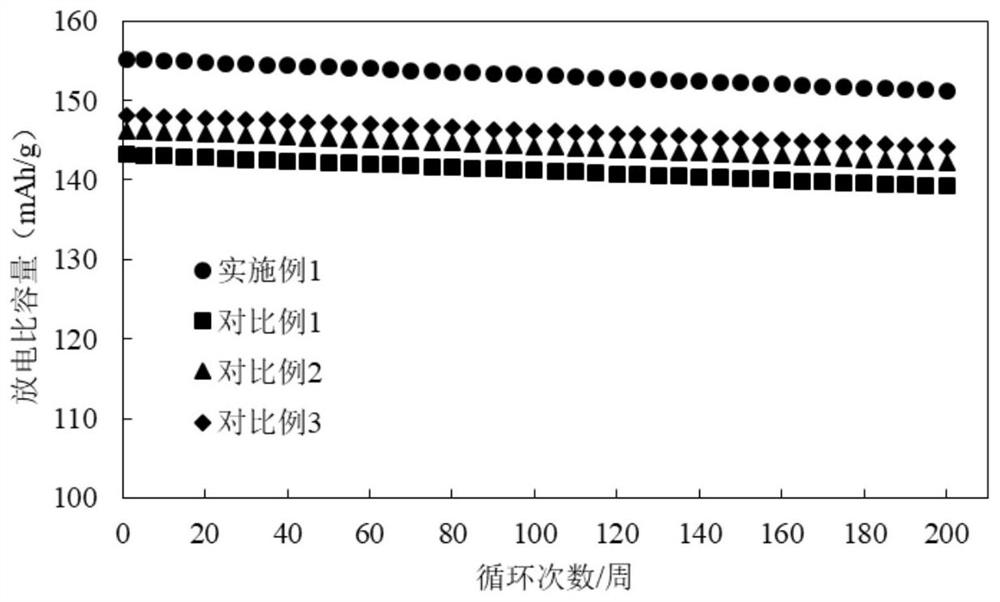

Positive electrode material, preparation method thereof and lithium ion battery

ActiveCN112750999ALow costUniform coating effectMaterial nanotechnologyPolycrystalline material growthPhysical chemistryManganese

The invention relates to the technical field of lithium ion batteries, and discloses a positive electrode material, a preparation method thereof and a lithium ion battery. The positive electrode material comprises a high-nickel cobalt-free multi-element positive electrode material intermediate and a cobalt-containing compound coating the outer surface of the high-nickel cobalt-free multi-element positive electrode material intermediate, and the total mole number of nickel and manganese in the high-nickel cobalt-free multi-element positive electrode material intermediate is taken as a reference, the content of the cobalt-containing compound in terms of cobalt element is 0.5-5 mol%. The positive electrode material is stable in structure, high in energy density, good in rate capability, high in capacity retention ratio, simple in preparation method and low in cost.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

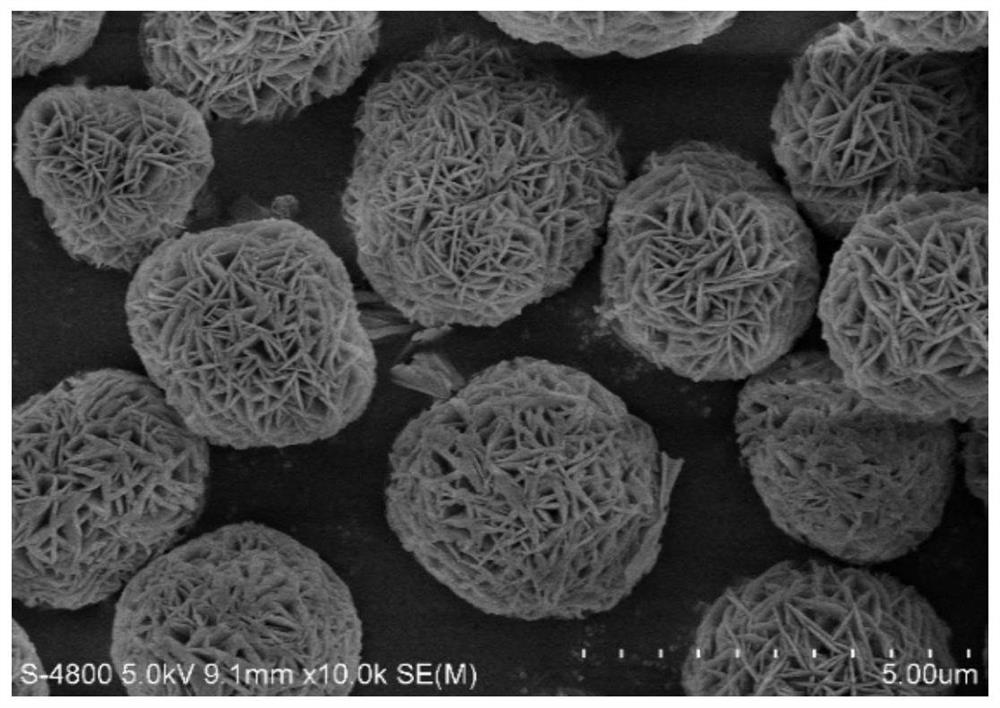

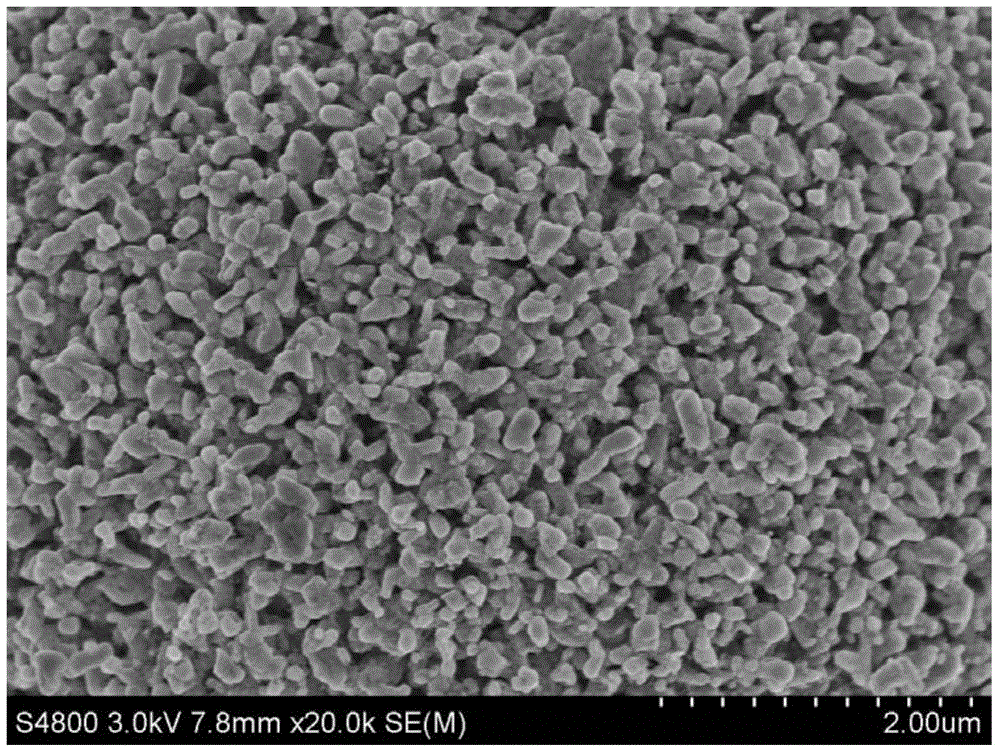

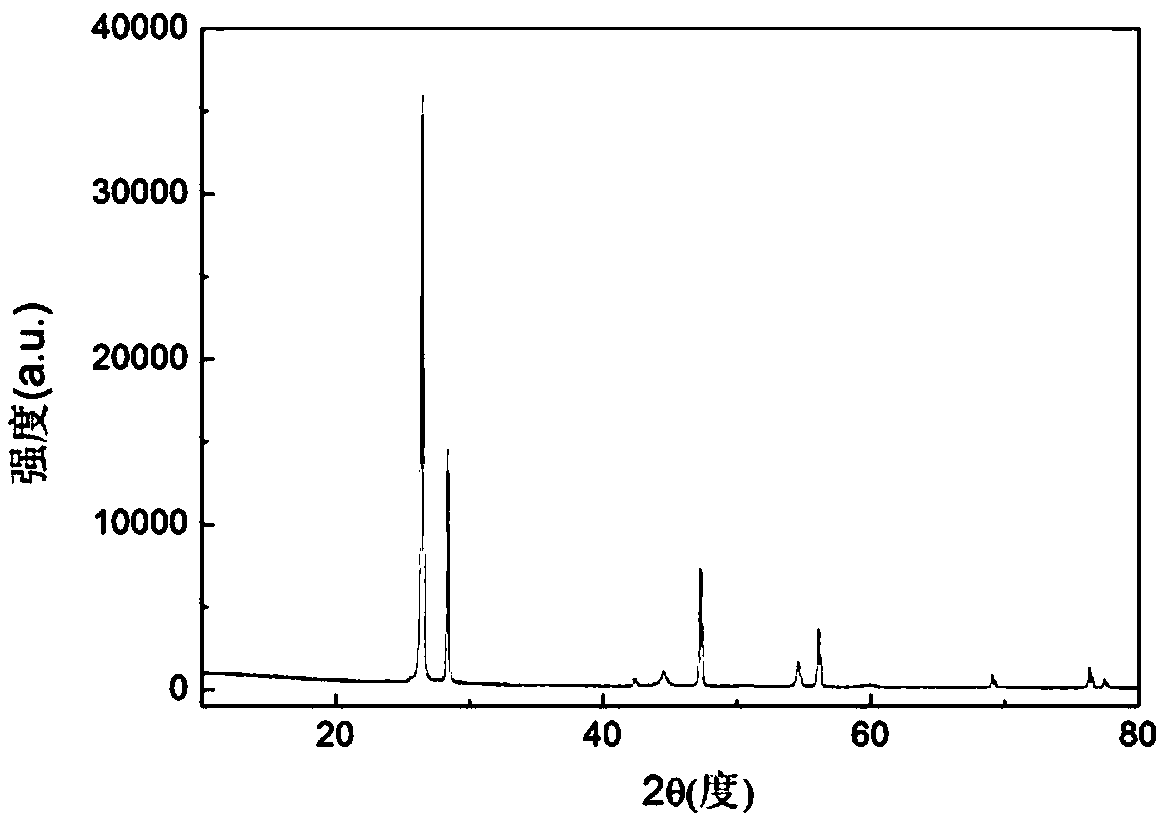

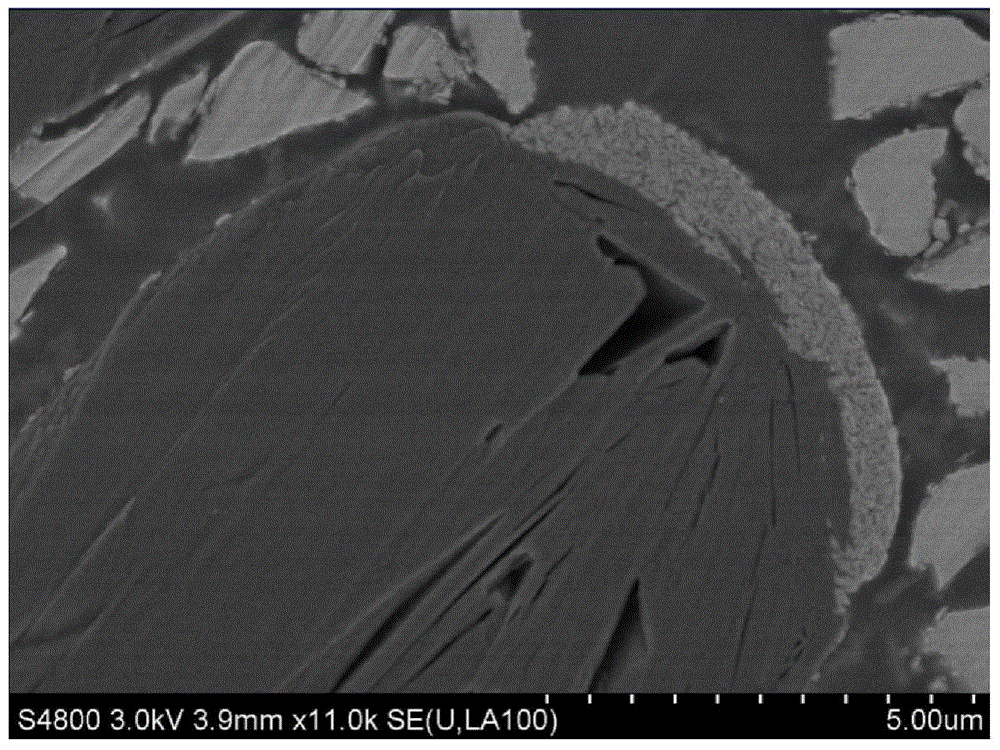

Lithium iron phosphate/carbon nanocomposite and preparation method thereof

ActiveCN103606676AImprove conductivityControl shapeCell electrodesSecondary cellsLithium iron phosphatePhosphoric acid

The invention relates to a preparation method of a lithium iron phosphate / carbon nanocomposite, which comprises the steps of preparing nanoscale iron phosphate; uniformly mixing the nanoscale iron phosphate with a lithium source, and introducing CO2 gas or adding soluble carbonate for a deposition reaction to obtain a nanoscale lithium iron phosphate precursor; performing chemical vapor deposition (CVD) coating on the lithium iron phosphate precursor to obtain a carbon-coated lithium iron phosphate material. According to the method provided by the invention, lithium is uniformly deposited on the surface of iron phosphate, and molecular-level uniform and consistent mixing can be realized; compared with a process of preparing lithium iron phosphate directly by a hydrothermal process, the reaction time is short, the energy consumption is low, and the process and appearance are easier to control; finally, carbon reduction and coating are performed by a CVD process, the coating effect is more uniform than that of the traditional carbon coating process, and the electric conductivity of lithium iron phosphate is improved perfectly.

Owner:江苏贝特瑞纳米科技有限公司

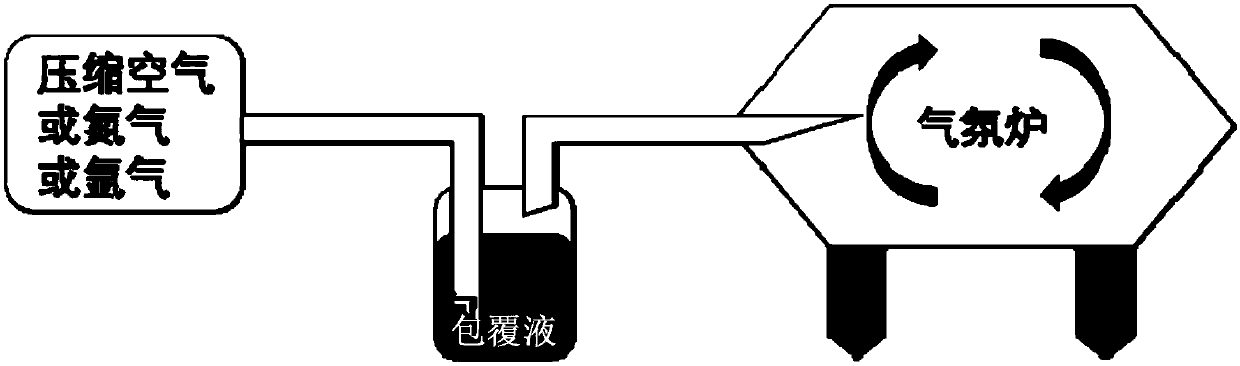

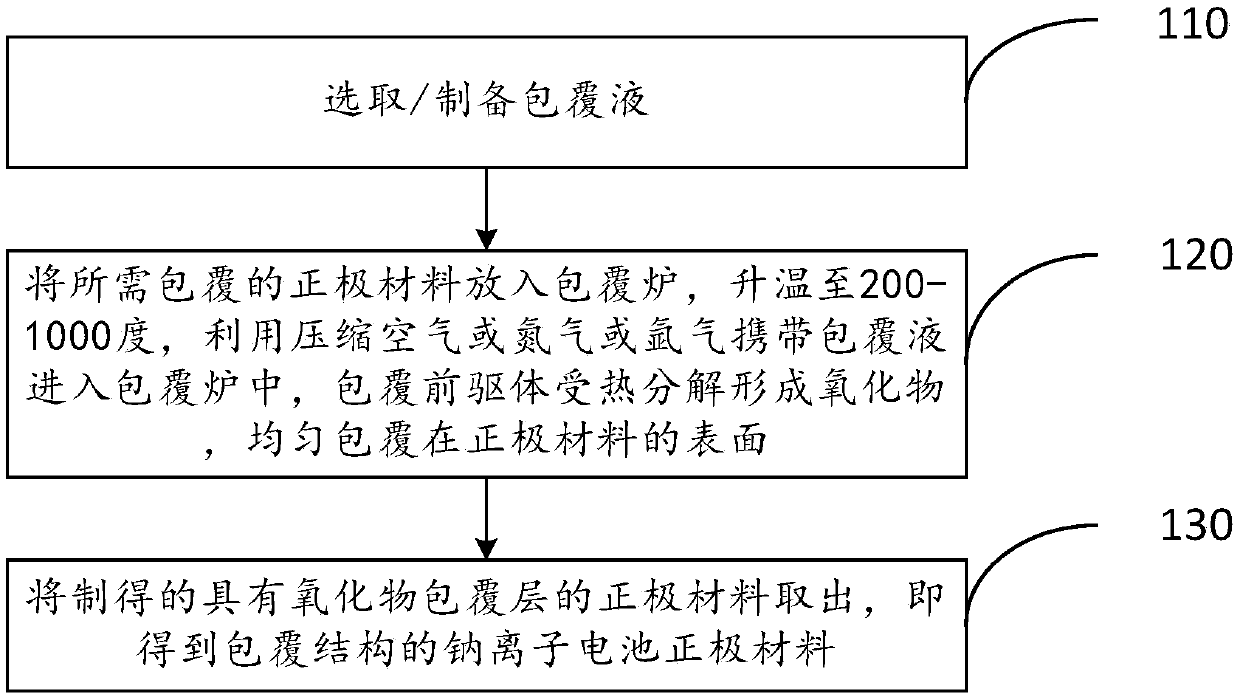

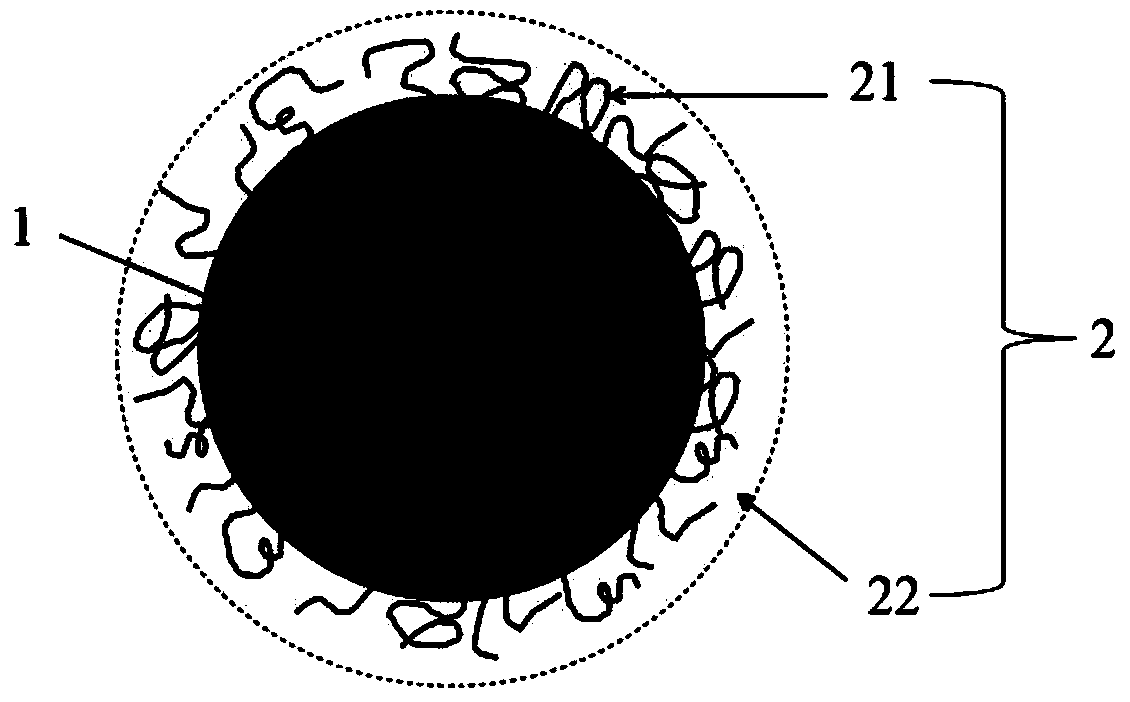

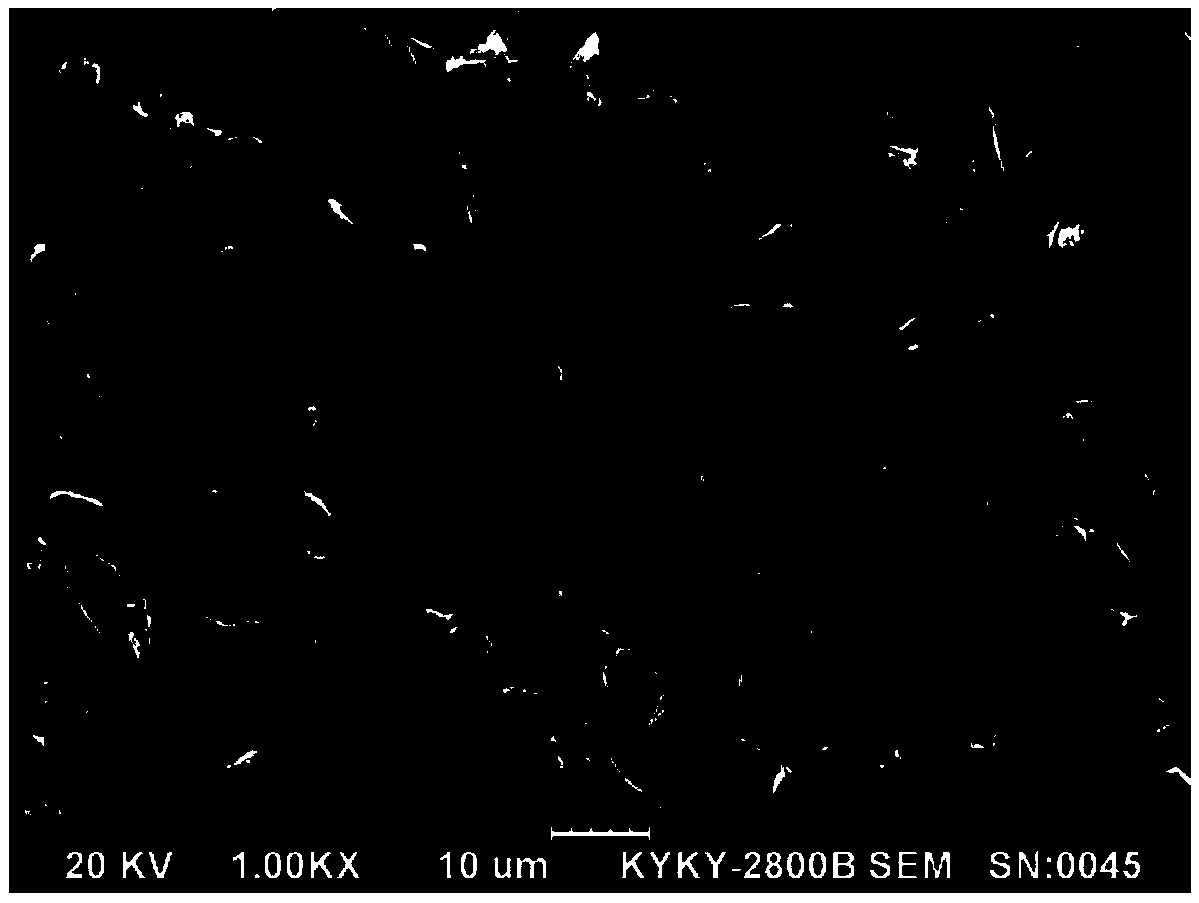

Coating-structure sodium-ion battery anode material as well as preparation method and application thereof

ActiveCN109524649AImprove cycle stabilitySimple interfaceCell electrodesSecondary cellsNitrogenSodium-ion battery

The invention discloses a coating-structure sodium-ion battery anode material as well as a reparation method and application thereof. The method comprises the following steps: selecting / preparing coating liquid, wherein the coating liquid contains coated precursor formed by metal salt and / or hydrate of the metal salt; putting a to-be-coated anode material into a coating furnace, heating to 200-1000 DEG C, introducing the coating liquid into the coating furnace through compressed air or nitrogen or argon, heating to decompose the coated precursor into oxide uniformly coating the surface of theanode material; and taking out the prepared anode material with an oxide coating layer, so as to obtain the coating-structure sodium-ion battery anode material.

Owner:BEIJING HINA BATTERY TECH CO LTD

Core-shell structure multi-component composite material, preparation method thereof and a lithium ion battery comprising the multi-component composite material

InactiveCN108832092AImprove low temperature charge and discharge performanceImprove high temperature storage performanceCell electrodesSecondary cellsCarbon layerCarbonization

The invention discloses a core-shell structure multi-component composite material, a preparation method thereof and a lithium ion battery comprising the multi-component composite material. The multi-component composite material comprises a graphite core and an outer shell coating the surface of the core, and the outer shell comprises a chain-shaped hard carbon layer and a soft carbon layer from the inside to the outside. The method comprises the following steps: 1) mixing an amorphous carbon precursor, a solvent and a surfactant to obtain a liquid phase first precursor; 2) mixing the core material graphite and the chain polymer material, and carrying out surface modification treatment to obtain a second precursor; 3) adopting a second precursor and the first precursor of the liquid phase to prepare a composite third precursor through coating treatment, and carry out carbonization to obtain a core-shell structure multi-component composite material. The method of the invention is simple,the process is short, the cost is low, the environment is friendly and pollution-free, and the obtained multi-component composite material has the characteristics of high compaction density, high first reversible capacity and first coulomb efficiency, and excellent processing performance and low temperature performance.

Owner:BTR NEW MATERIAL GRP CO LTD

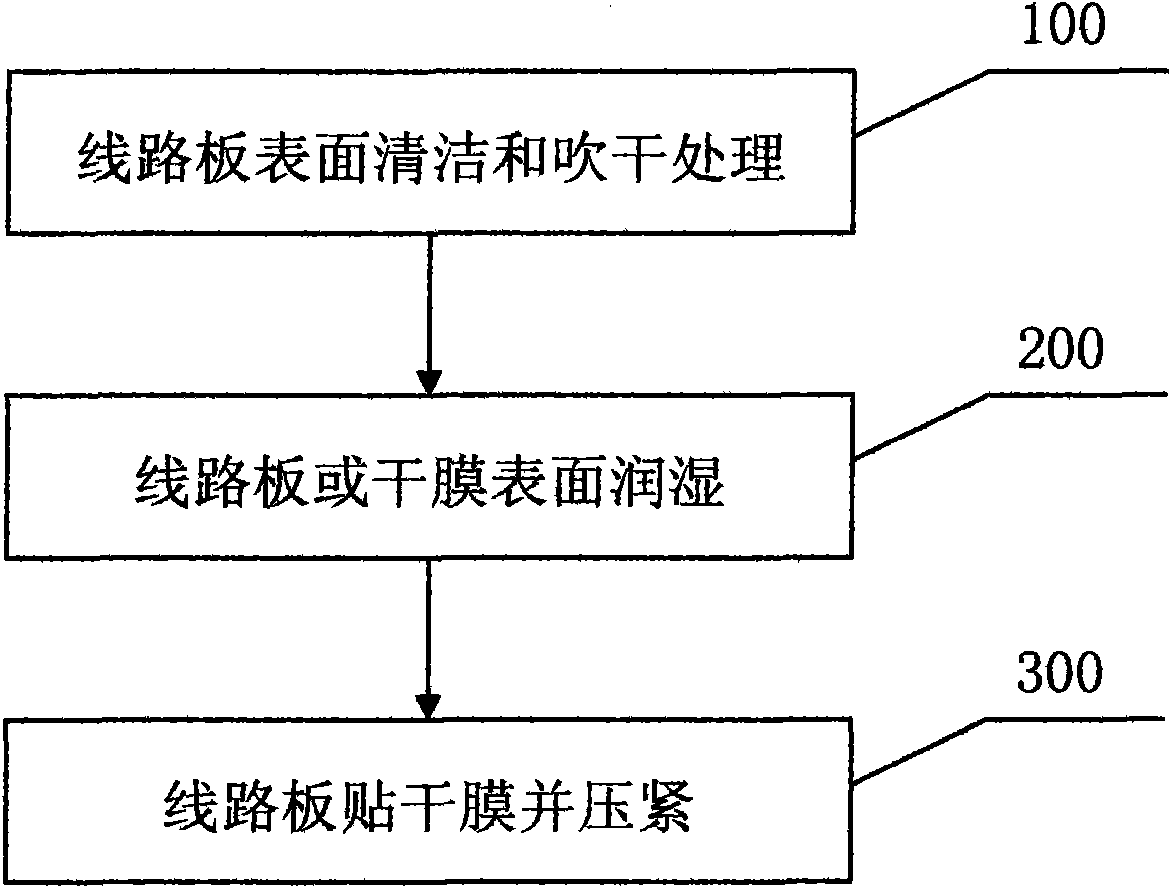

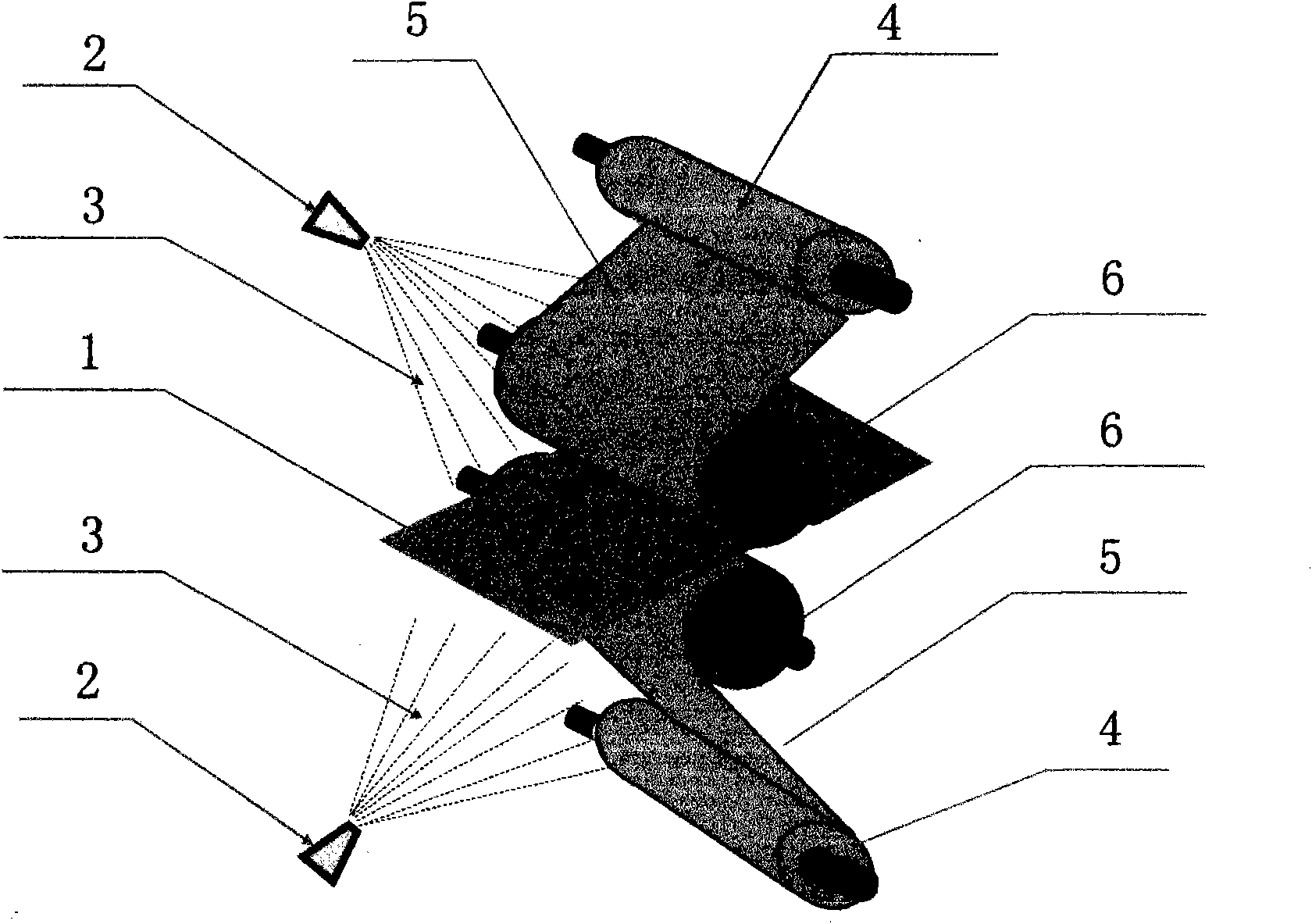

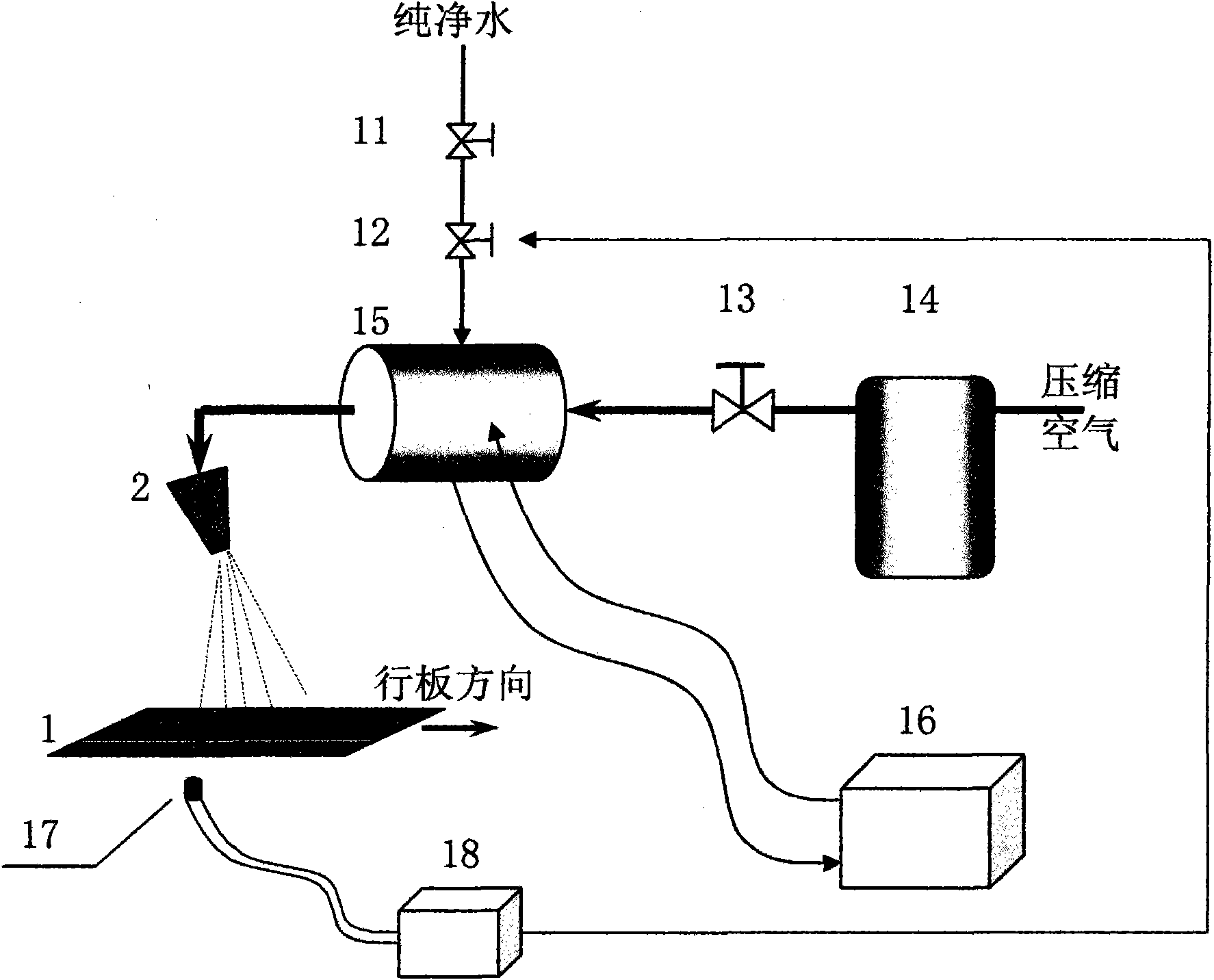

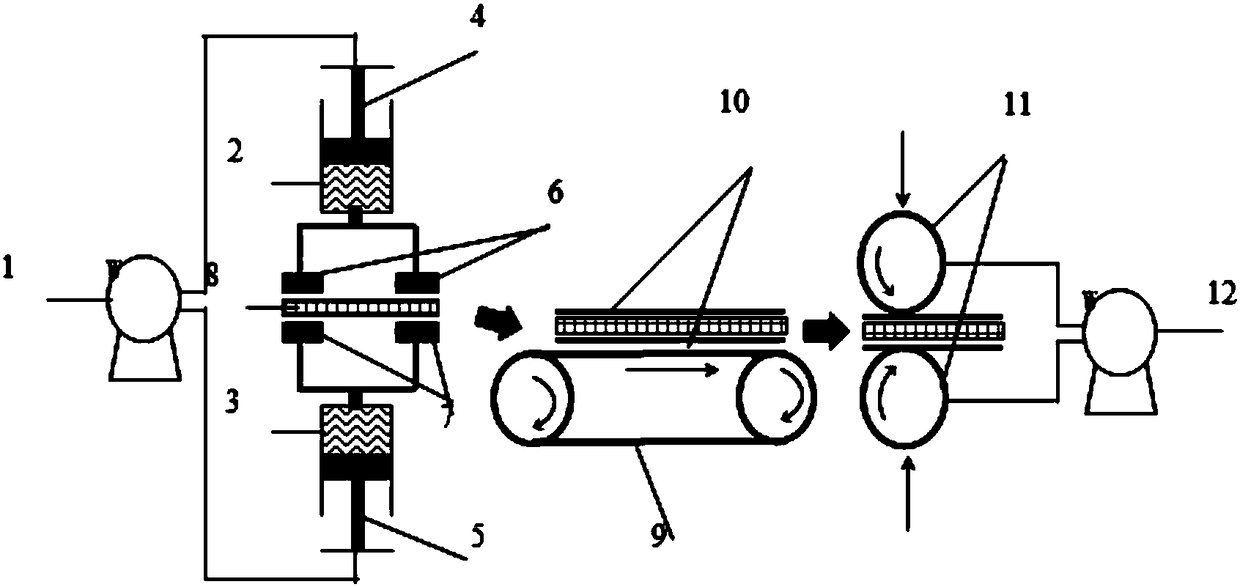

Circuit board wet-lamination method and device

InactiveCN101961942AImprove bindingGood filling fruitLamination ancillary operationsLaminationSpray nozzleEngineering

The invention relates to a circuit board wet-lamination method and a circuit board wet-lamination device. The method comprises the following steps of: cleaning and blow-drying the surface of a circuit board, wetting the surface of the circuit board with water in a way of spraying water mist onto the surface of the circuit board or the surface of a dry film or the surfaces of both the circuit board and the dry film, laminating the dry film onto the surface of the circuit board, and then applying temperature and pressure to tightly attach the dry film onto the surface of the circuit board. A spray type water coating device required by the method consists of a water mist generation device, a nozzle and spray direction regulation device, a sensing device and an outer cover. Compared with a conventional direct dry-film lamination method, the method can effectively increase the yield rate and improve the quality of the circuit board.

Owner:代芳

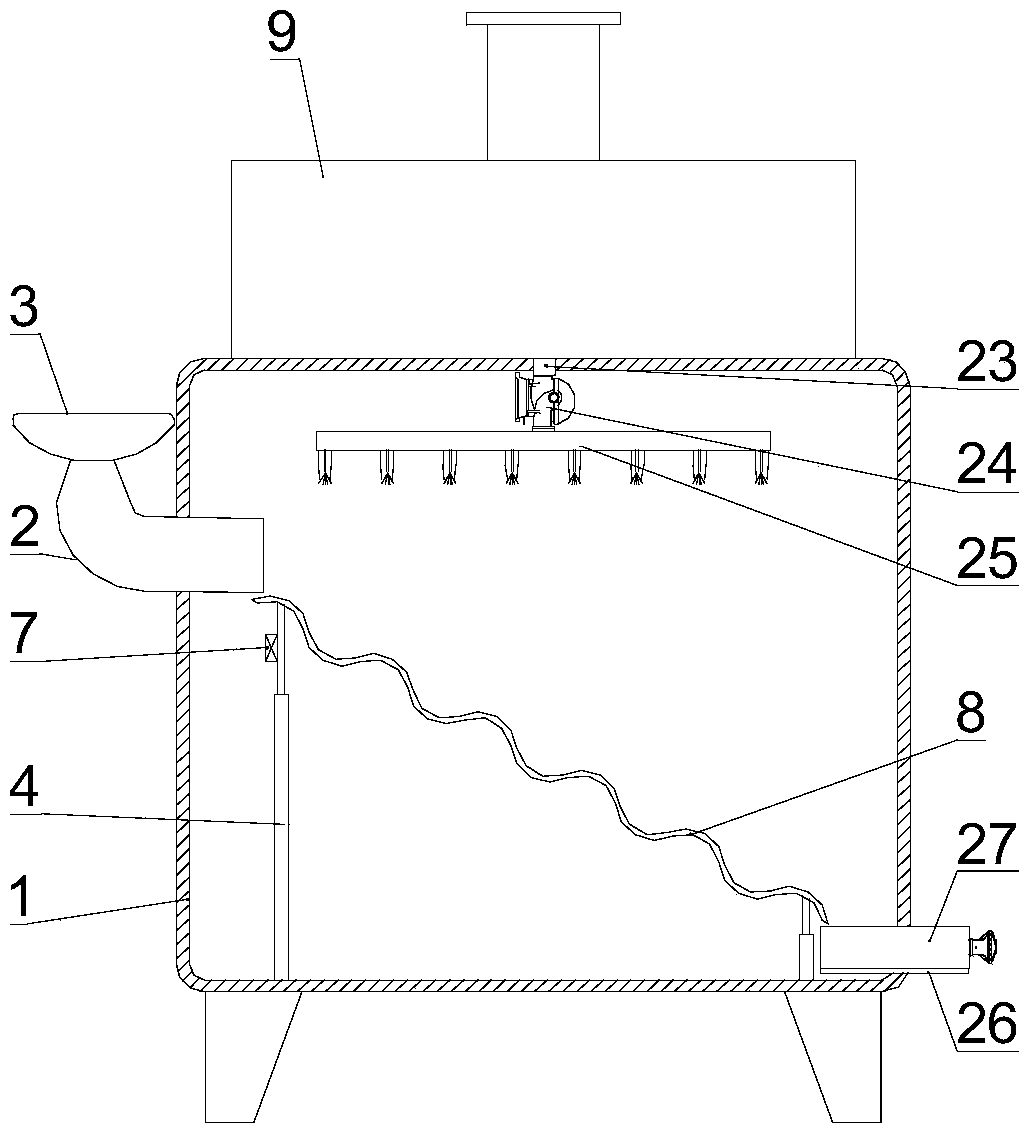

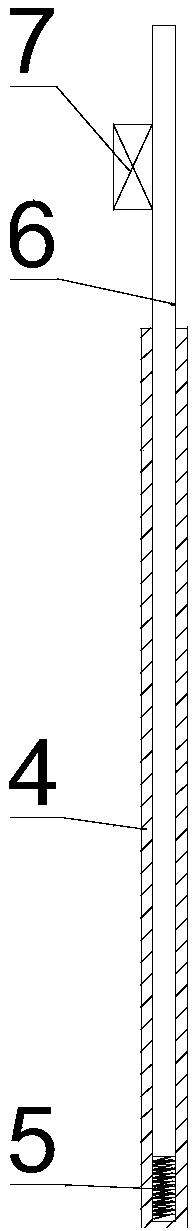

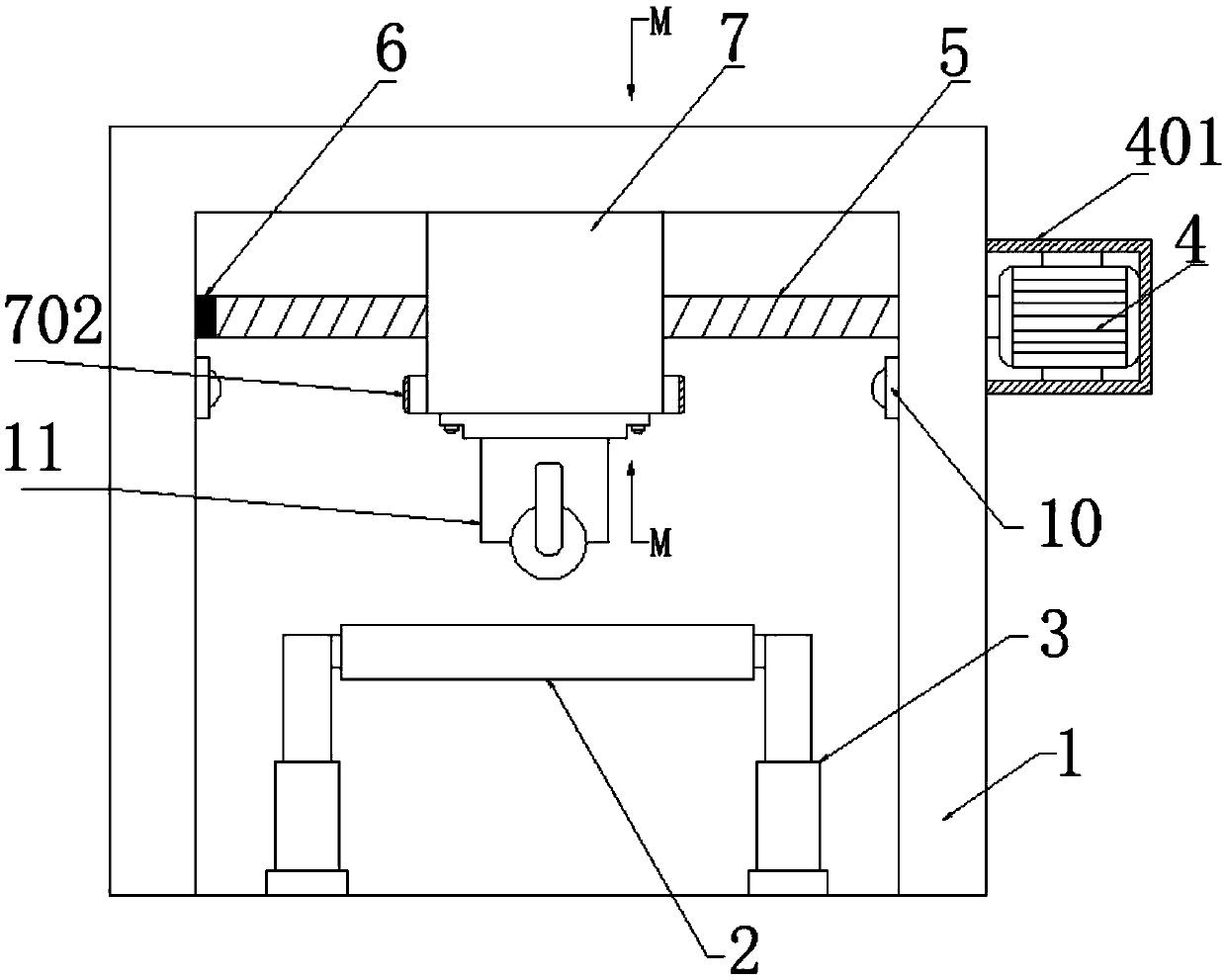

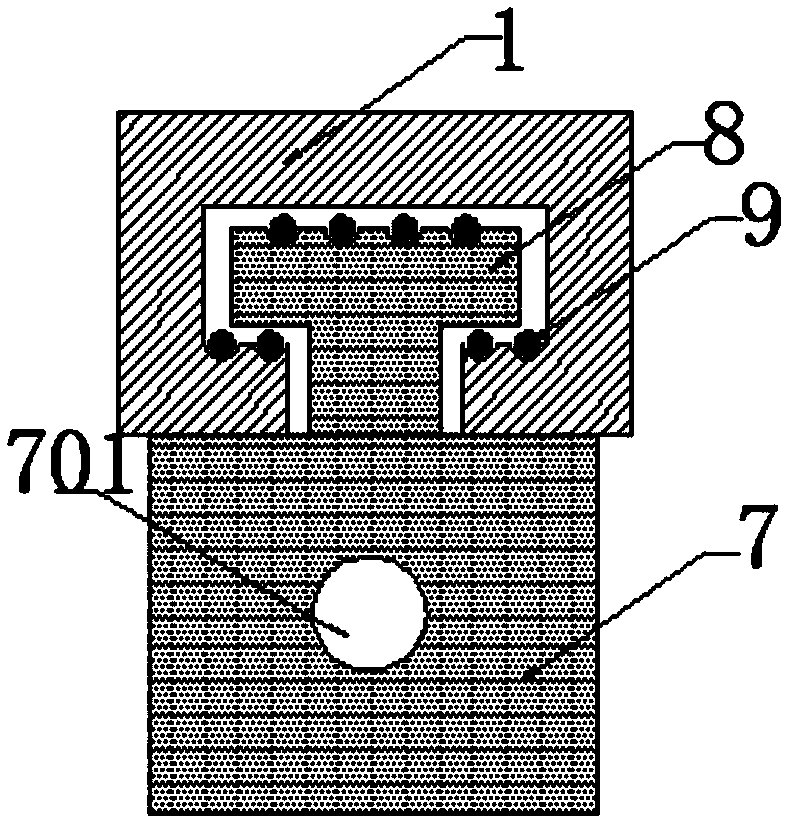

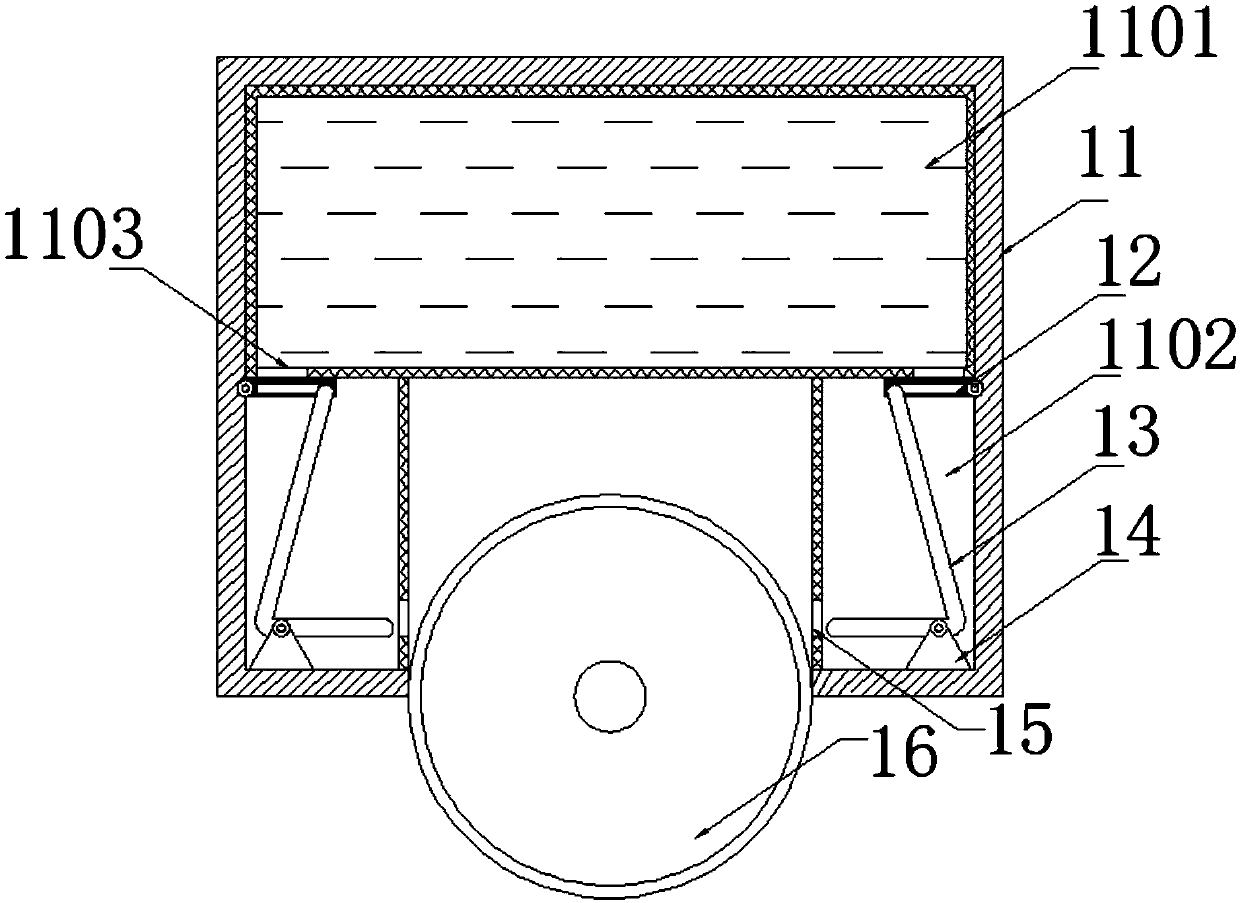

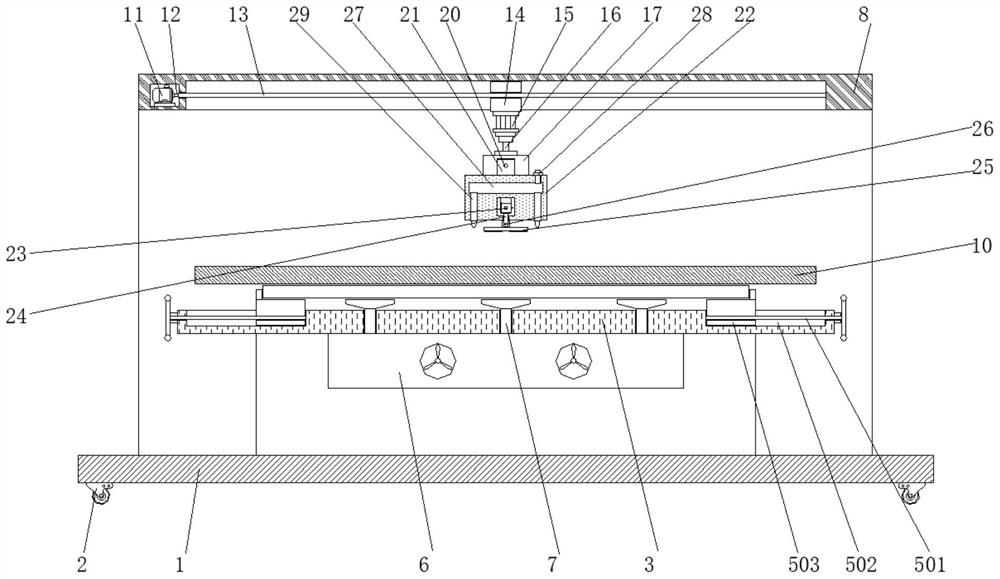

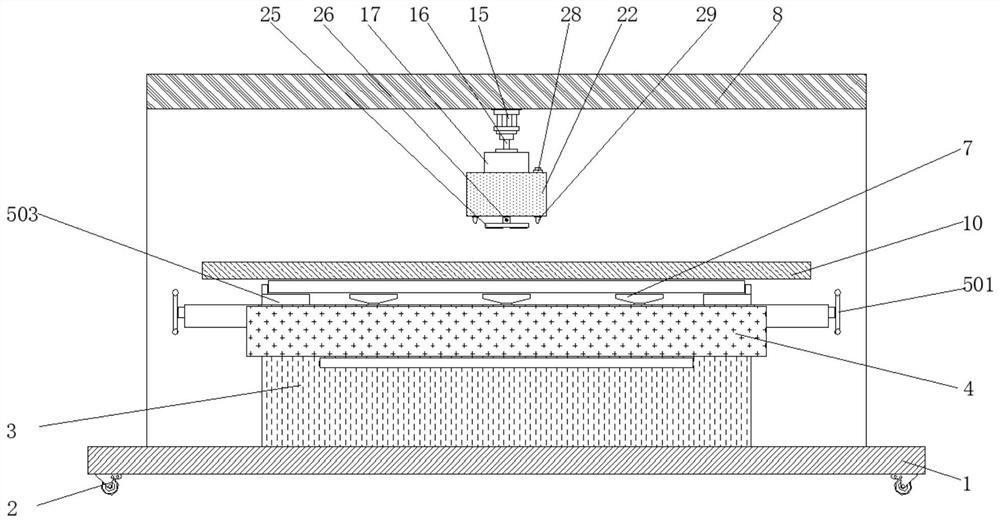

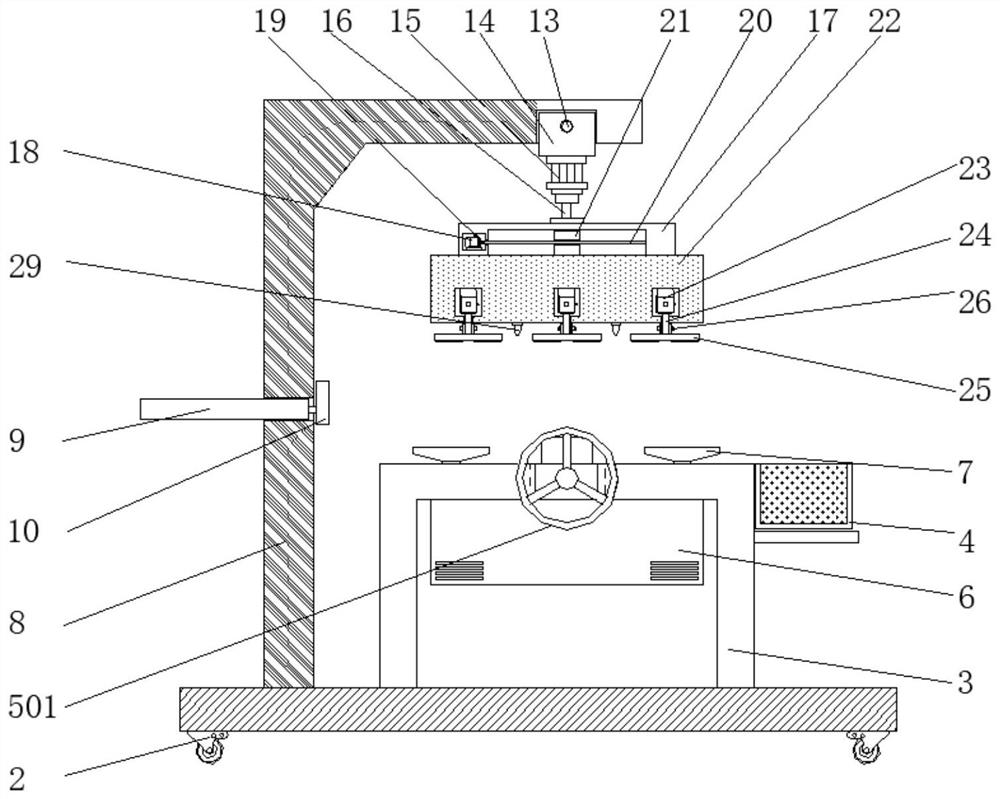

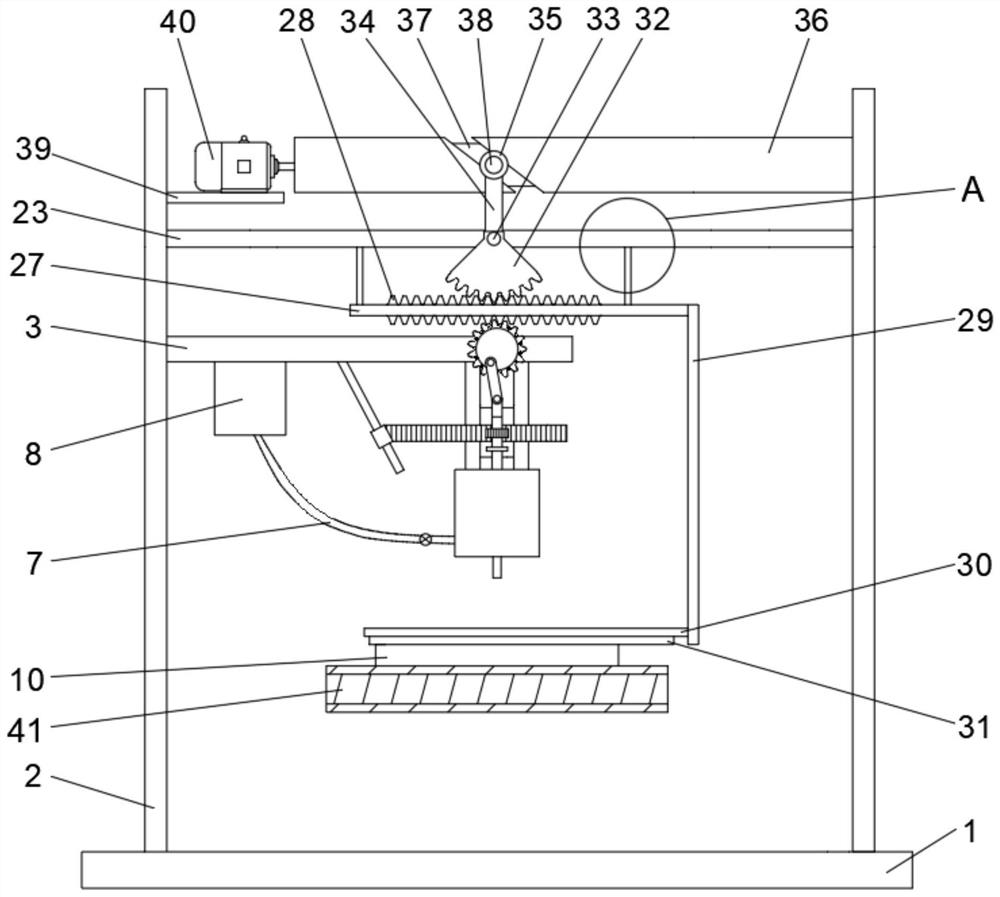

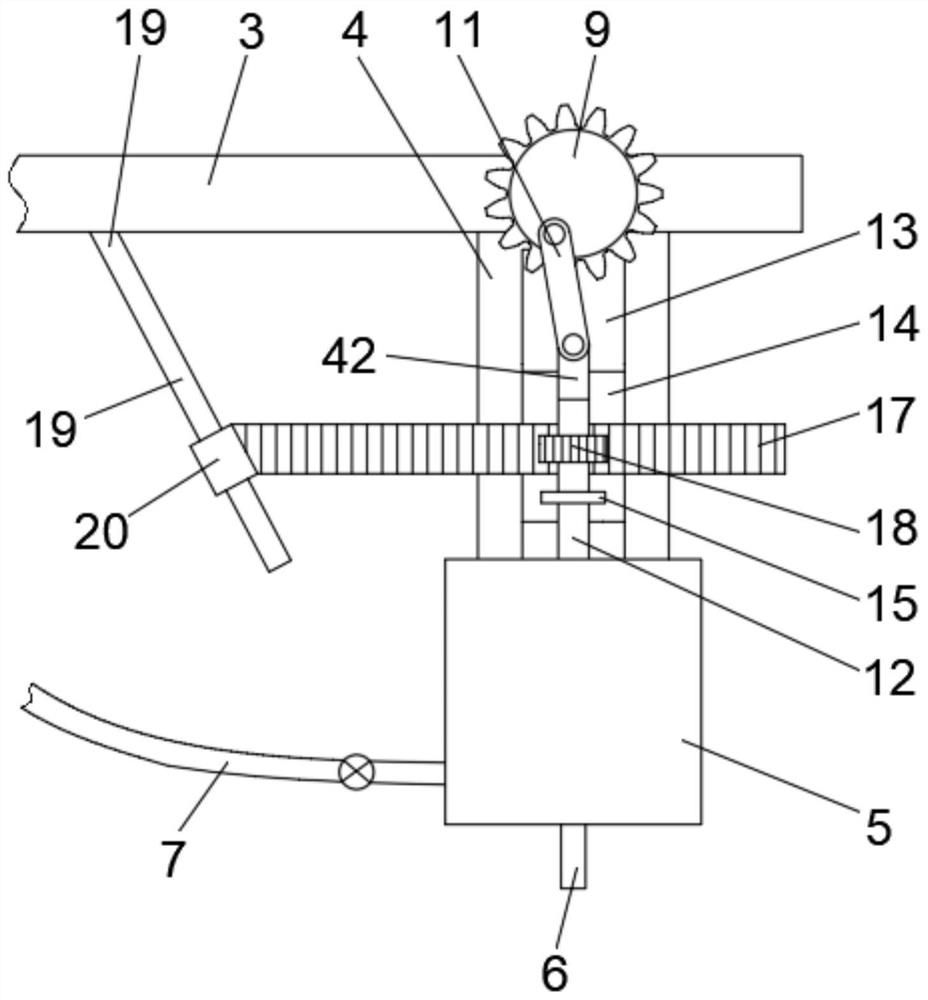

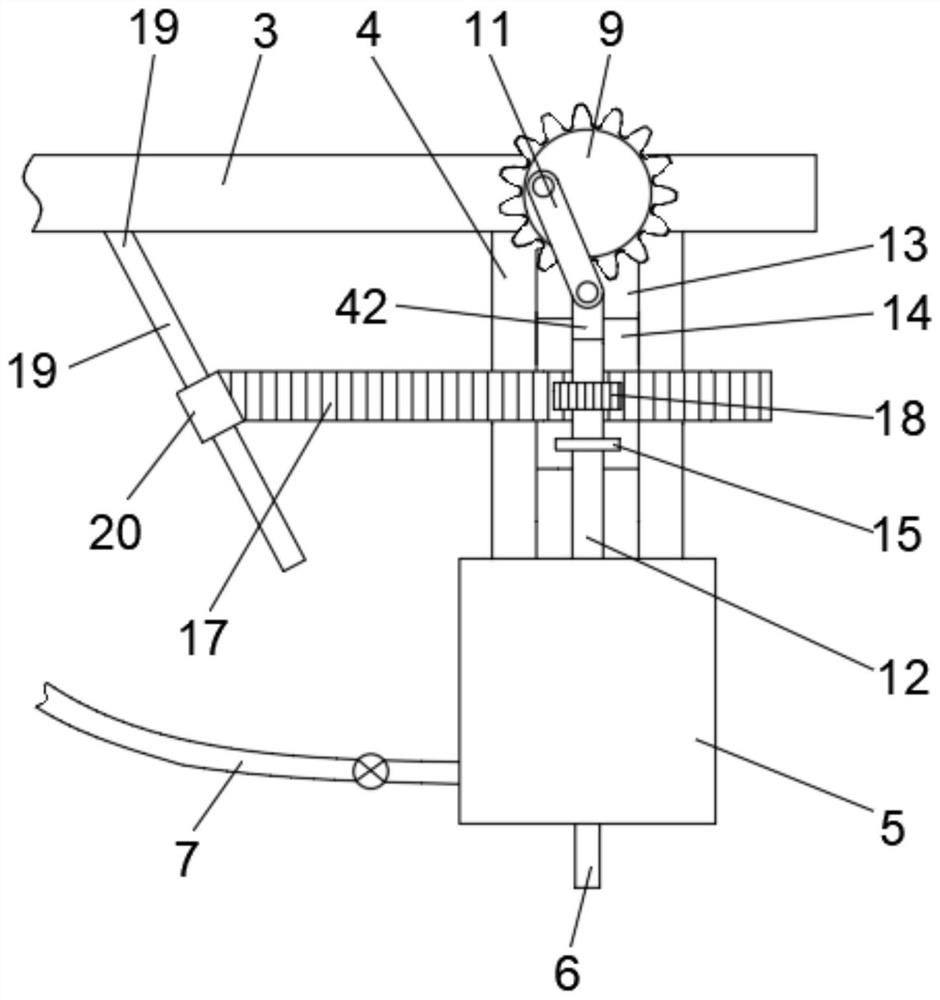

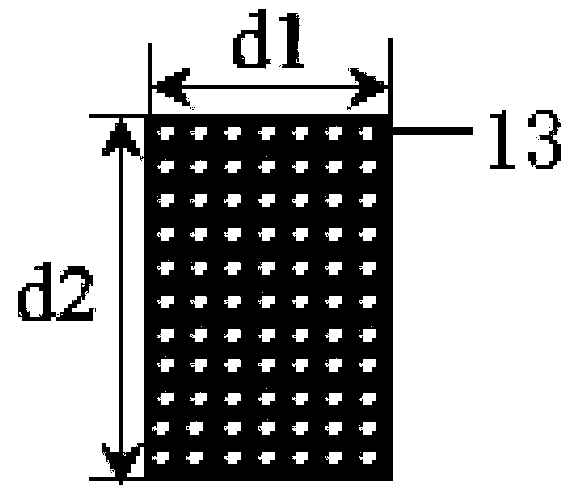

Coating machine for traditional Chinese medicine processing

InactiveCN108464936AUniform coating effectAvoid accumulationPharmaceutical product form changeCoatingsSlide plateSlurry

The invention discloses a coating machine for traditional Chinese medicine processing, and relates to the technical field of pharmaceutical processing. The coating machine comprises a coating box which is internally provided with a material sliding plate in a slope shape, the left portion of the material sliding plate is high, and the left portion of the material sliding plate is low, a first elastic expansion and contraction device and a second elastic expansion and contraction device which are consistent in structure are fixedly installed in the lower side of the coating box, the upper active ends of the first expansion and contraction device and the second expansion and contraction device are fixedly connected with the material sliding plate separately, and a slurry box is fixedly connected to the upper surface of the coating box; tablets roll on the material sliding plate, and make contact with slurry sprayed out of a sprayer, the coating effect of the tablets is uniform, and the product quality is improved; by means of the action of a vibration motor, the phenomenon that the tablets are accumulated on the material sliding plate is avoided; due to the fact that a rotating shaftrotates, the swinging range of a second stirring paddle is extended; by means of the action of an elastic rope, a first stirring paddle moves in the same way, the mixed area is enlarged, the slurry is homogenized, and the uniformity of the sprayed slurry is improved.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

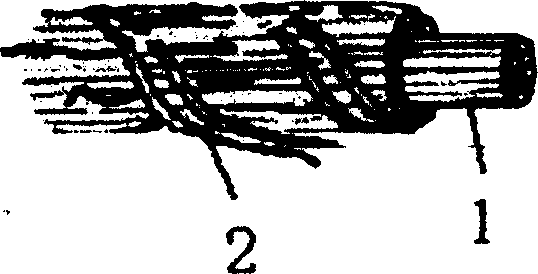

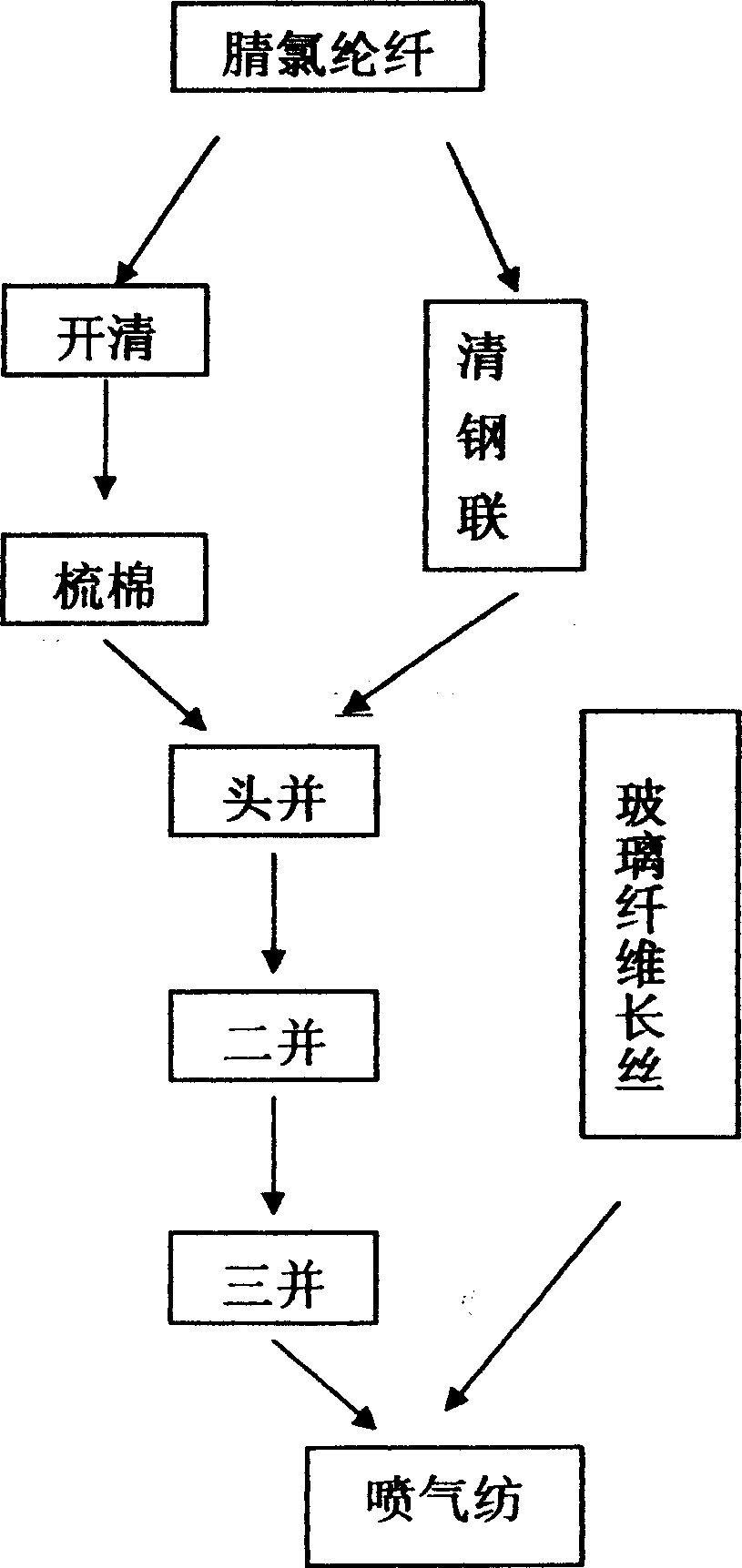

Vinyl chloride acrylonitrile copolymer fibre and glass fibre coading core yarn and jet spinning processing method thereof

InactiveCN1861862AShort and sparse hairinessCoated evenlyContinuous wound-up machinesOpen-end spinning machinesYarnFiber

There is a Vinyl chloride-acrylonitrile copolymer fiber and fiber-glass coving yarn and its jet spinning preparation method. The characteristic of it is that the continuous fiber-glass yarn is the core line of the coving yarn, Vinyl chloride-acrylonitrile copolymer fiber homogeneously covered and twisted around the continuous fiber-glass yarn. This Vinyl chloride-acrylonitrile copolymer fiber and fiber-glass coving yarn is made by jet spinning preparation method. The technology processes are as fellows: the chloride-acrylonitrile copolymer fiber is through cleaning, scotching or firstly, secondly and thirdly drawing process, it is lonely made the strip of 2g / m-4g / m. Then the strip of Vinyl chloride-acrylonitrile copolymer fiber and the continuous glass-fiber yarn feed into the discharge nozzle of the jet spinning machine at the same time, the Vinyl chloride-acrylonitrile copolymer fiber and fibre-glass coving yarn can be coiled out from the second nozzle. Jet spinning preparation method is a new preparation method, and the feather of covering yarn formed by this method is short and rare. It has the ability to resist the forming of hair and hair bulb, and the outer fibre covers uniformly.

Owner:SHANGHAI NO 17 COTTON TEXTILE MILL

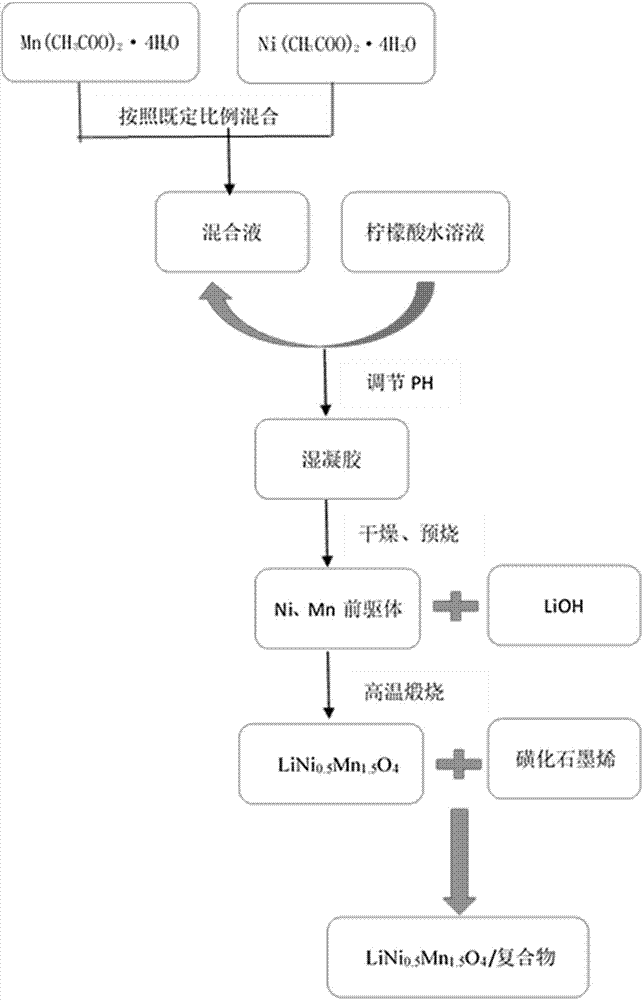

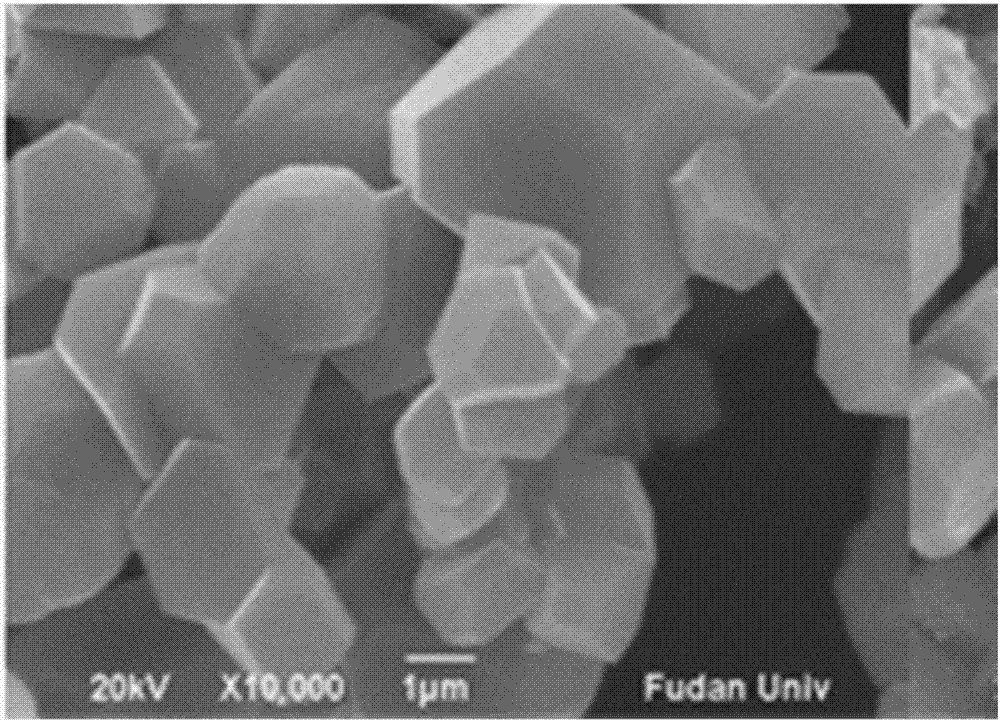

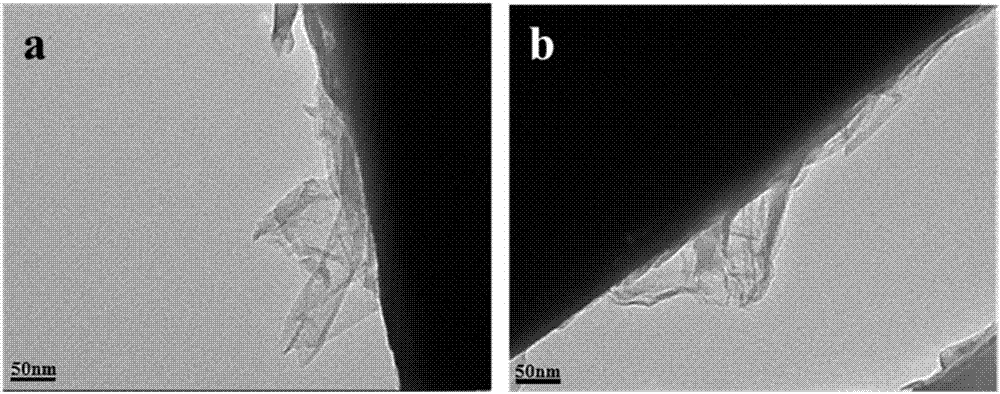

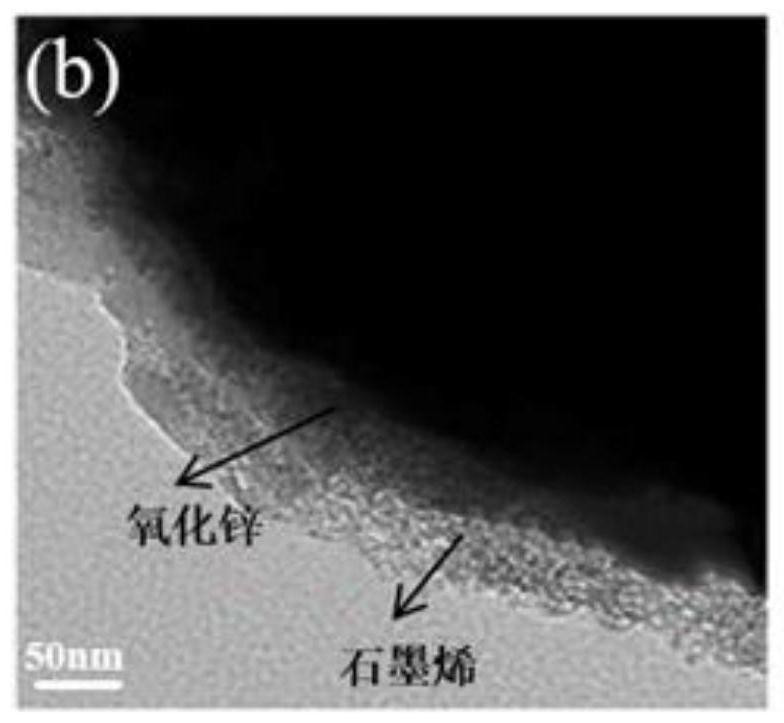

Sulfonated graphene and lithium nickel manganese oxide composite material and preparation method and application thereof

InactiveCN106941173AHigh chemical homogeneityAchieve hybridCell electrodesSecondary cellsOxygenManganese oxide

The invention discloses a sulfonated graphene and lithium nickel manganese oxide composite material and a preparation method and application thereof. The mass ratio of lithium nickel manganese oxide to sulfonated graphene in the composite material is (10-30):1. Sulfonated graphene coats the surface of lithium nickel manganese oxide, which has the molecular formula of LiNi<x>Mn<2-x>O4, wherein 0.3<x<0.7. The preparation method comprises the following steps: (1) preparing a nickel manganese oxide precursor through a sol-gel method; (2) mixing the nickel manganese oxide precursor with a soluble lithium source substance and performing calcination in an oxygen-containing atmosphere to obtain lithium nickel manganese oxide; and (3) mixing lithium nickel manganese oxide with a sulfonated graphene aqueous solution and performing drying. The prepared lithium nickel manganese oxide is excellent in crystallinity and integrated in crystal structure. Through surface modification of sulfonated graphene, a uniform coating effect is achieved, and the poor electronic conductivity of lithium nickel manganese oxide is overcome, so that the electrochemical performance of the composite material is improved.

Owner:SHANGHAI ELECTRICGROUP CORP

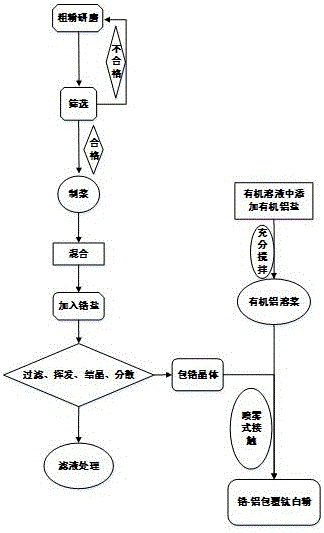

Preparation method of novel zirconium-aluminum coated titanium dioxide

ActiveCN105860591AGuaranteed chemical stabilityGuaranteed weather resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsOrganic filmOrganic solvent

The invention discloses a preparation method of novel zirconium-aluminum coated titanium dioxide. The preparation method includes the steps that rutile type titanium dioxide screened to meet the particle size requirement is dissolved in an organic solvent for slurrying, organic zirconium salt is added into slurry for coating, zirconium salt obtained after coating is filtered, dried and dispersed, and filter liquor is cooled, filtered and volatilized and then is recycled; organic aluminum salt is dissolved in an organic solvent to prepare organic aluminum sol, zirconium-coated crystals and organic aluminum sol are in contact in a spraying mode, and zirconium-coated crystals obtained after contact are dried and dispersed again. According to the preparation method, reaction conditions are mostly mild, many washing procedures are omitted, the process is simplified, and modified titanium dioxide which is more uniform in coating effect and has both an inorganic film and an organic film can be obtained at a low cost through the coating method; meanwhile, by treating waste liquor and recycling the treated organic solvents, the cost can be further reduced, and secondary pollution to the environment can be prevented.

Owner:中钛集团焦作市裕盛钛业有限公司

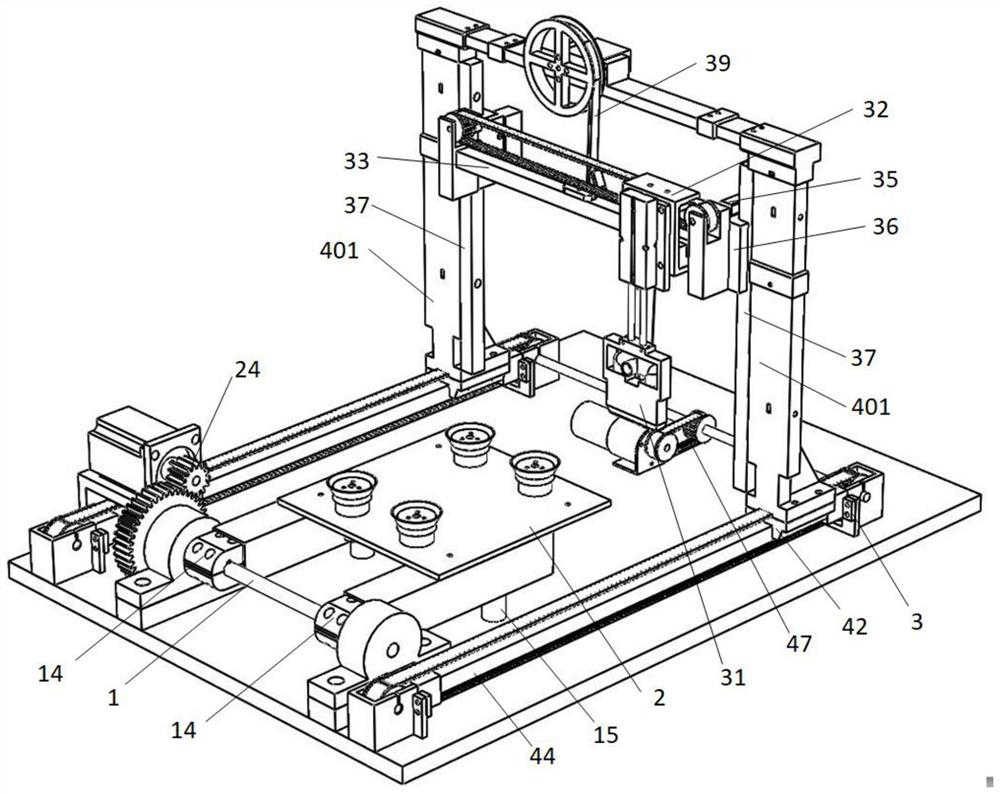

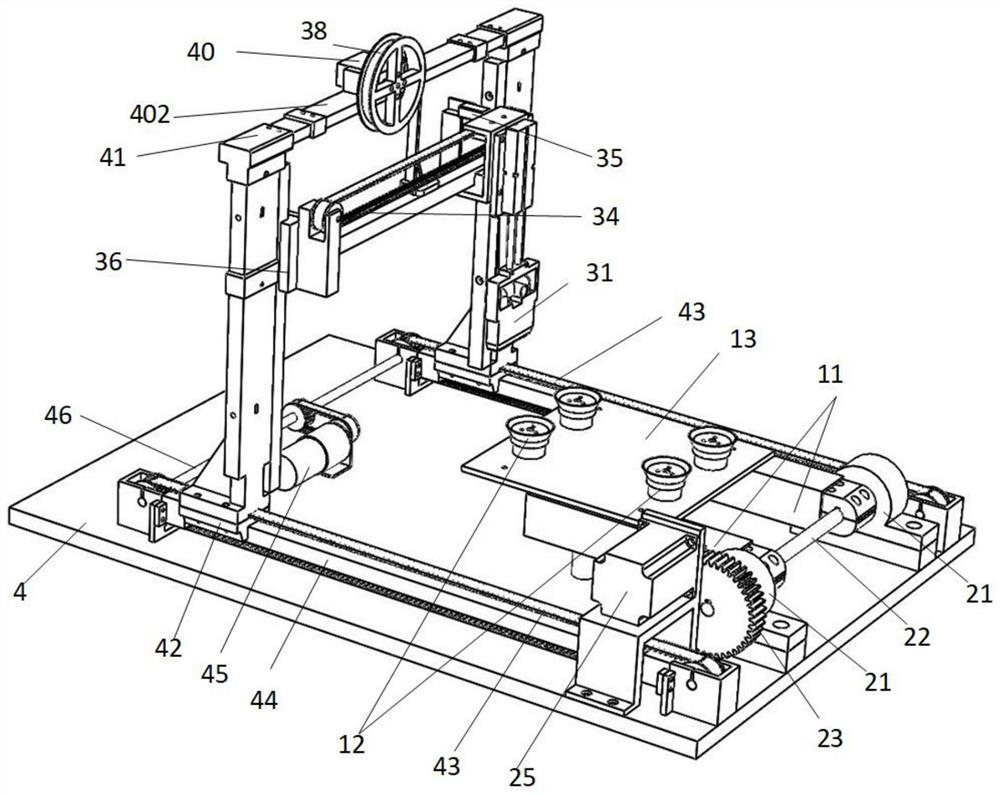

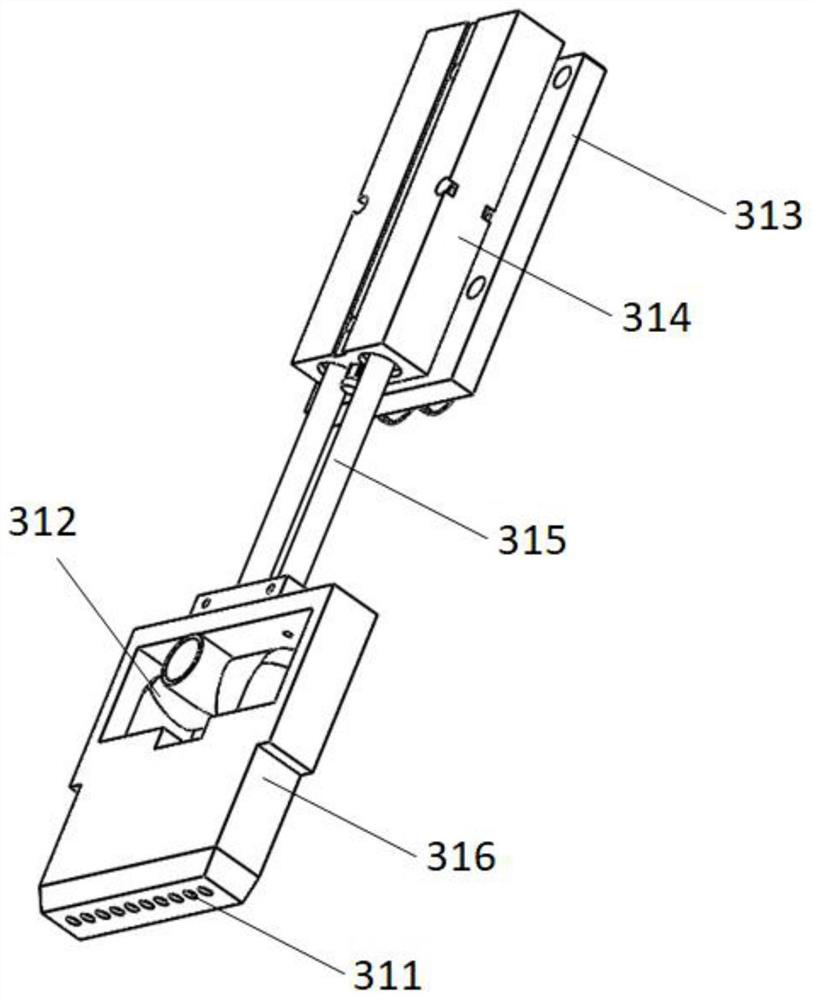

Automatic gluing device for ceramic tiles

InactiveCN113775150AApply glue evenlyReduce labor intensityLiquid surface applicatorsBuilding constructionsBuilding renovationMechanical engineering

The invention discloses an automatic gluing device for ceramic tiles, and belongs to the technical field of building decoration. The automatic gluing device comprises a picking part, an overturning part, a gluing part and a platform. Adsorption and overturning of the ceramic tiles are achieved by utilizing a simple mechanical principle, the workload of manual carrying is omitted, automatic gluing is conducted in cooperation with the gluing part, glue outlet holes arranged in a line can effectively and uniformly coat the ceramic tiles in all directions, so that the coating effect is more uniform, and the ceramic tile glue can be attached to the surfaces of the ceramic tiles as much as possible; and by using the device, ceramic tile gluing can be quickly, accurately, economically and cleanly completed, the construction efficiency and the construction quality are greatly improved, the labor intensity of workers is reduced, and the construction cost is reduced.

Owner:SANJIANG UNIVERSITY

Method for coating surface of lithium-ion ternary positive electrode material with oxide

The invention discloses a method for coating the surface of a lithium-ion ternary positive electrode material with an oxide. The method comprises the steps of firstly dispersing lithium-ion ternary positive electrode material powder into a certain amount of deionized water; dispersing the powder evenly, adding a certain amount of organic acid or salt and an insoluble metal salt to the powder and reacting for a certain period of time; and drying the treated ternary positive electrode material and carrying out thermal treatment at certain temperature for a certain period of time to obtain an oxide-coated lithium-ion ternary positive electrode material. According to the method disclosed by the invention, a whole-wet method is adopted and the lithium-ion ternary positive electrode material iscoated with liquid, so that the process of coating modification is short, the used raw materials are common, the cost is low, the ternary positive electrode material can be greatly and efficiently modified, the coating degree is uniform and the effect is good.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

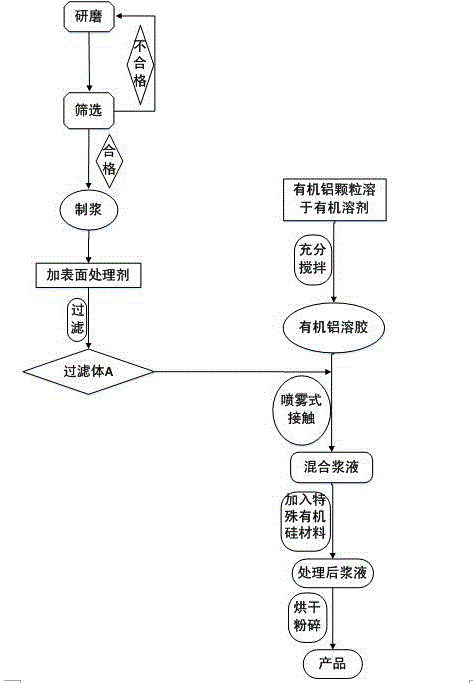

Special cladding titanium dioxide for ink and preparation method of titanium dioxide

ActiveCN105860648AGood dispersionImprove stabilityInksPigment treatment with organosilicon compoundsOrganic solventTitanium

The invention provides special cladding titanium dioxide for ink and a preparation method of the titanium dioxide. The preparation method includes adding organic solute into rutile titanium dioxide yet to be treated by surface treatment after screening to make pulp, adding surfactant into the titanium dioxide pulp, filtering the treated titanium dioxide and performing atomizing mixed cladding of organic alumina sol, adding special organosilicone of proper viscosity into the cladded titanium dioxide pulp for organic surface treatment, drying the cladded titanium dioxide pulp after surface treatment to obtain cladding crystal, and crushing the cladded crystal to obtain the product eventually. Reaction is mostly performed in the mild condition, the process is simple and the cladding titanium dioxide having more uniform cladding effect and high dispersion and stability in the organic solvent can be obtained. In addition, the titanium dioxide is good in luster, and weather-proof, and excellent in binding force, dispersion, wettability and mobility, so that cladded titanium dioxide can be used for producing high-end ink.

Owner:中钛集团焦作市裕盛钛业有限公司

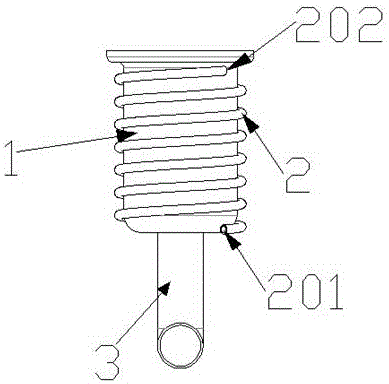

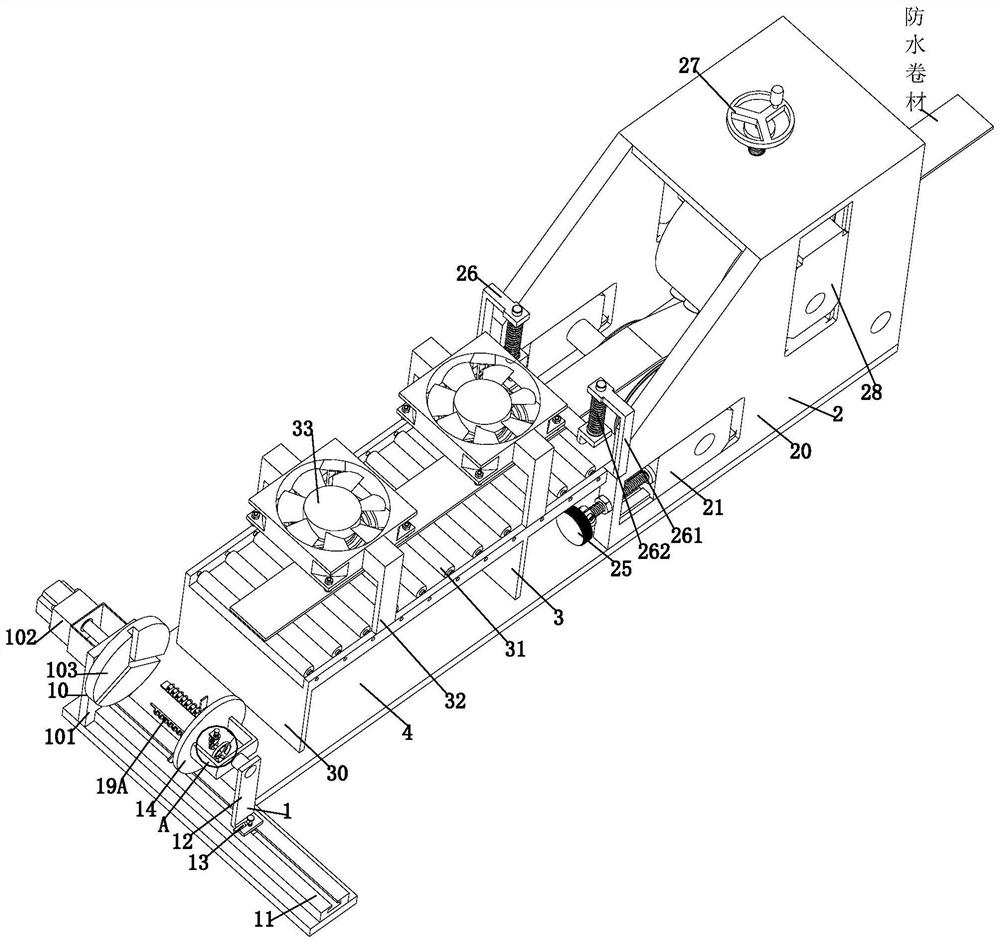

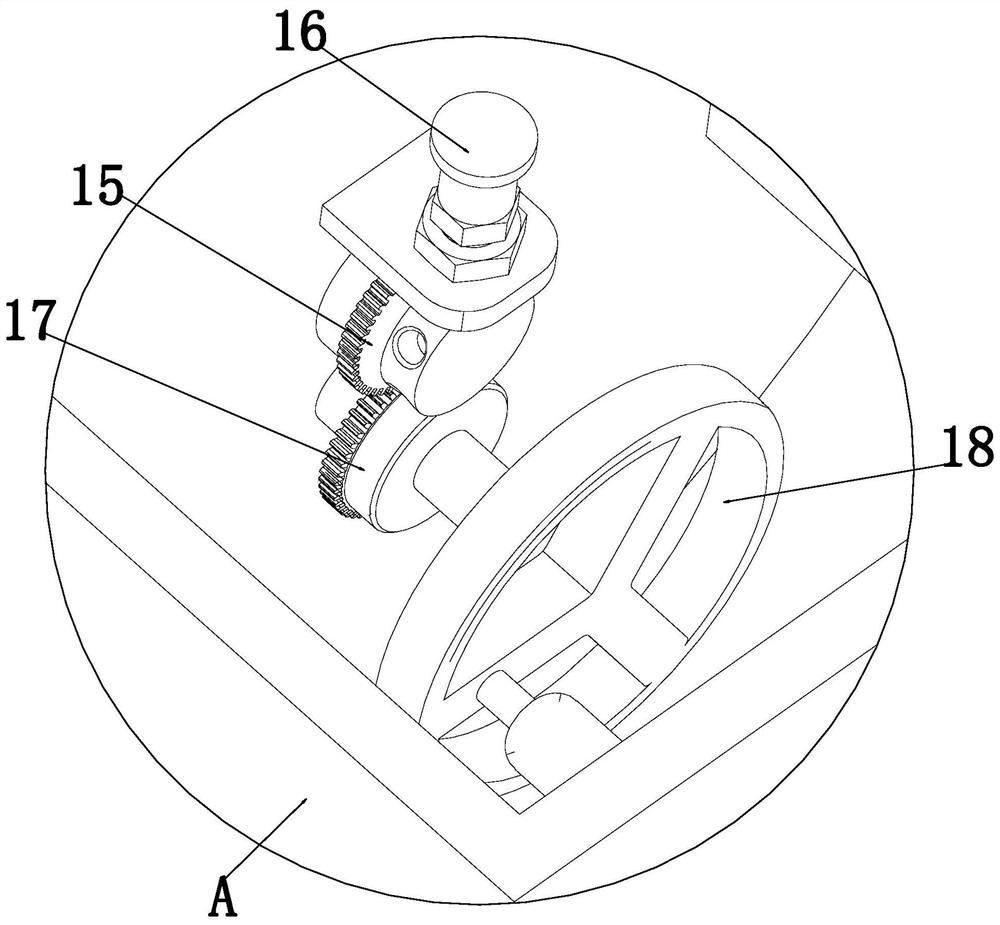

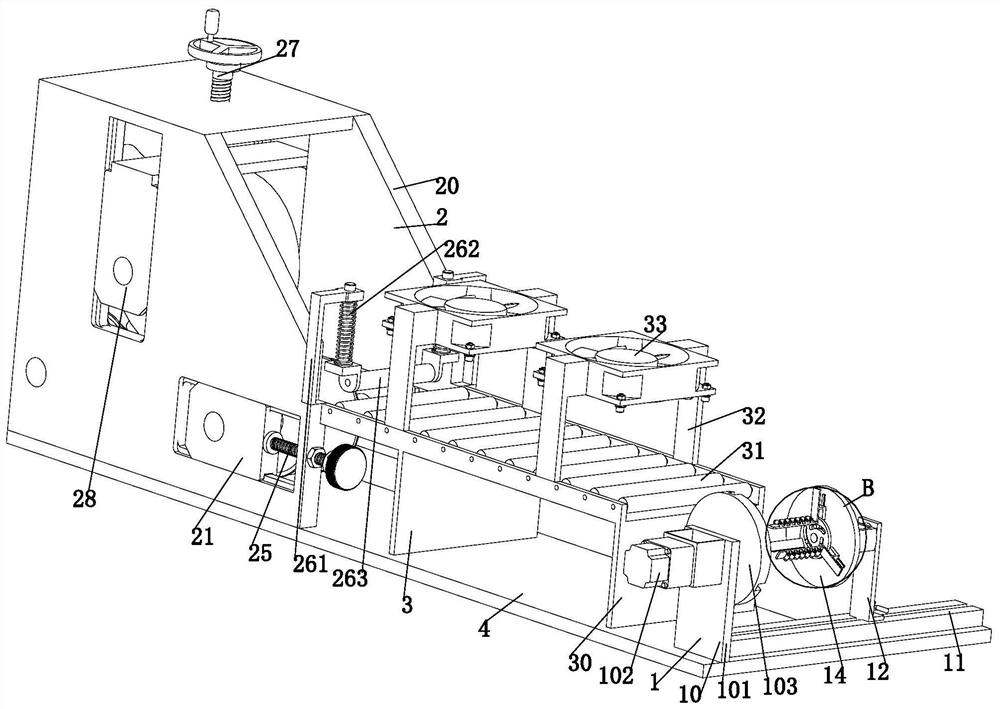

Coating device and method for waterproof roll coating

ActiveCN112295853AIncrease contact areaIncrease the coating area of the base surfacePretreated surfacesCoatingsComposite materialEngineering

The invention provides a coating device and method for a waterproof roll coating. The coating device comprises a winding mechanism, a roll coating mechanism, a drying mechanism and a bottom plate. Thewinding mechanism is mounted on the end face of the front portion of the bottom plate. The roll coating mechanism is mounted on the end face of the rear portion of the bottom plate. The drying mechanism is arranged between the roll coating mechanism and the winding mechanism and mounted on the bottom plate. The problems that in order to require uniform coating at present, a spray head large-areaspraying processing mode is adopted, so that an anti-corrosion coating material becomes highly-dispersed spray bodies, the spray bodies are prone to being exposed and dispersed in air, volatilized solvents are often pungent in taste, the processing environment is severe, the physical health of workers is threatened if the processing mode goes on like this, waste of coatings is prone to being caused by spraying, and economic losses are generated are solved; and in addition, natural airing needs to be conducted after spraying, so that the processing time is prolonged, an aired waterproof roll needs to be manually wound and collected, and the labor intensity of workers is increased.

Owner:WEIFANG HUAGUANG WATERPROOF MATERIALS

a kind of sio x Matrix composite negative electrode material, preparation method and battery

ActiveCN103647056BImprove cycle performanceUniform dispersionCell electrodesLi-accumulatorsCarbon coatingSilicon oxide

The invention relates to a high-capacity SiOx based composite negative electrode material, a preparation method and a battery, wherein the negative electrode material comprises a silicon oxide material, a carbon material and an amorphous carbon coating layer; the silicon oxide material is silicon oxide or silicon oxide material modified in a carbon coating manner; surfaces of carbon material particles are coated with the silicon oxide material. A preparation method of the high-capacity SiOx based composite negative electrode material comprises the steps of performing physical processing or carbon coating modification on a silicon oxide raw material, thus obtaining a micron-sized silicon oxide material; and then mechanically fusing, coating with a solid phase and sintering at a high temperature to obtain the high-capacity negative electrode material. Through the high-capacity SiOx based composite negative electrode material, the effect of uniform dispersing and coating of the micron-sized silicon oxide particles on the surfaces of the carbon material particles can be achieved by virtue of the combination of mechanical fusion and solid-phase coating processes. The silicon oxide particles are well dispersed on the surface of the carbon material particle; the strength of bonding between the silicon oxide particles and the carbon material particles is high; the recycling performance of the material can be greatly improved; and meanwhile, the high-capacity SiOx based composite negative electrode material is high in first efficiency (breaking through the theoretical efficiency of SiOx), low in expansion rate, long in service life, environmental-friendly, pollution-free and low in cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Automatic clothing material surface glue coating device

ActiveCN111068973AApply evenlyRealize automatic gluing functionLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention discloses an automatic clothing material surface glue coating device. The automatic clothing material surface glue coating device comprises a supporting frame and a fixed block. Conveying rolls are arranged at the lower end of the supporting frame. A motor is arranged on the outer side of one end of the supporting frame. The supporting frame is transversely provided with a rotary shaft. The fixed block is in threaded connection with the rotary shaft. The upper end of the fixed block is fixedly connected with a T-shaped sliding block. The upper end of the supporting frame is provided with a sliding groove. The T-shaped sliding block is slidably connected with the sliding groove at the upper end of the supporting frame. The two sides of the supporting frame are fixedly providedwith limiting switches. The lower end of the fixed block is fixedly connected with a glue coating device body. The glue coating device body is internally provided with a glue storage cavity and a glue coating cavity. Glue discharge ports are formed at the joint between the glue storage cavity and the glue coating cavity. A partition board is arranged at the lower end of each glue discharge port.One end of each partition board is hinged to the sidewall of the glue coating cavity. Each partition board is internally provided with a sliding groove. An L-shaped connecting rod is slidably connected to the interior of each sliding groove. Supporting bases are arranged at the lower end of the glue coating cavity. The lower ends of the L-shaped connecting rods are rotatably connected with the corresponding supporting bases. A glue coating roller is rotatably arranged at the lower end of the glue coating device body. The automatic clothing material surface glue coating device is reasonable instructure, high in automation degree, uniform in glue coating and high in practicality.

Owner:上海寓尚电子商务有限公司

Boron-doped lithium phosphate coated lithium ion battery positive electrode material and preparation method thereof

ActiveCN112599736AIncrease capacityImproved magnification performanceSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention discloses a boron-doped lithium phosphate coated lithium ion battery positive electrode material, which takes a layered structure oxide with high nickel content as a matrix, and the outer surface of the matrix is coated with a boron-doped Li3PO4 coating layer. The preparation method comprises the following steps: (1), adding a lithium source, a phosphorus source and a boron source into a high-pressure reaction kettle for hydrothermal reaction, and after the reaction is finished, performing cooling, washing, filtering and drying to obtain a coating agent; and (2), weighing a basematerial and the coating agent according to a stoichiometric ratio, uniformly performing mixing, and performing sintering to obtain the boron-doped lithium phosphate coated lithium ion battery positive electrode material. By introducing a proper amount of boron into the lithium phosphate coating layer of the lithium ion battery positive electrode material, the lithium ion conduction capability ofthe lithium ion battery positive electrode material is effectively improved, so that the positive electrode material coated with the coating layer shows relatively good capacity and rate capability and has a relatively low DCIR growth rate.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

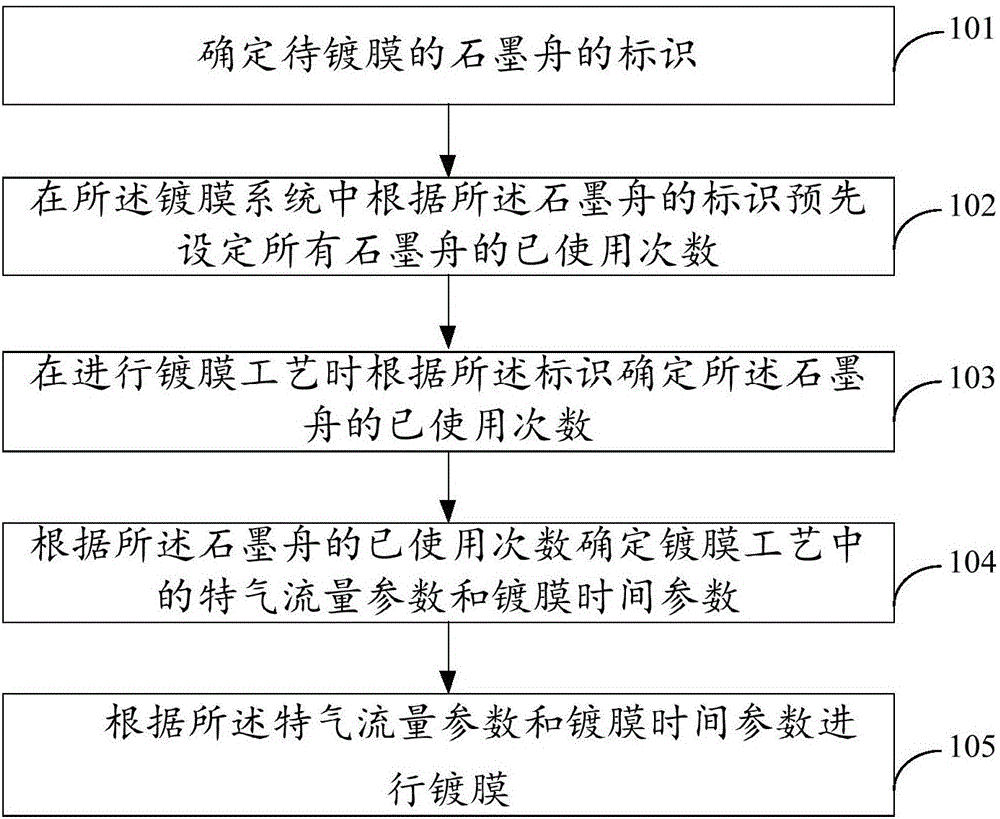

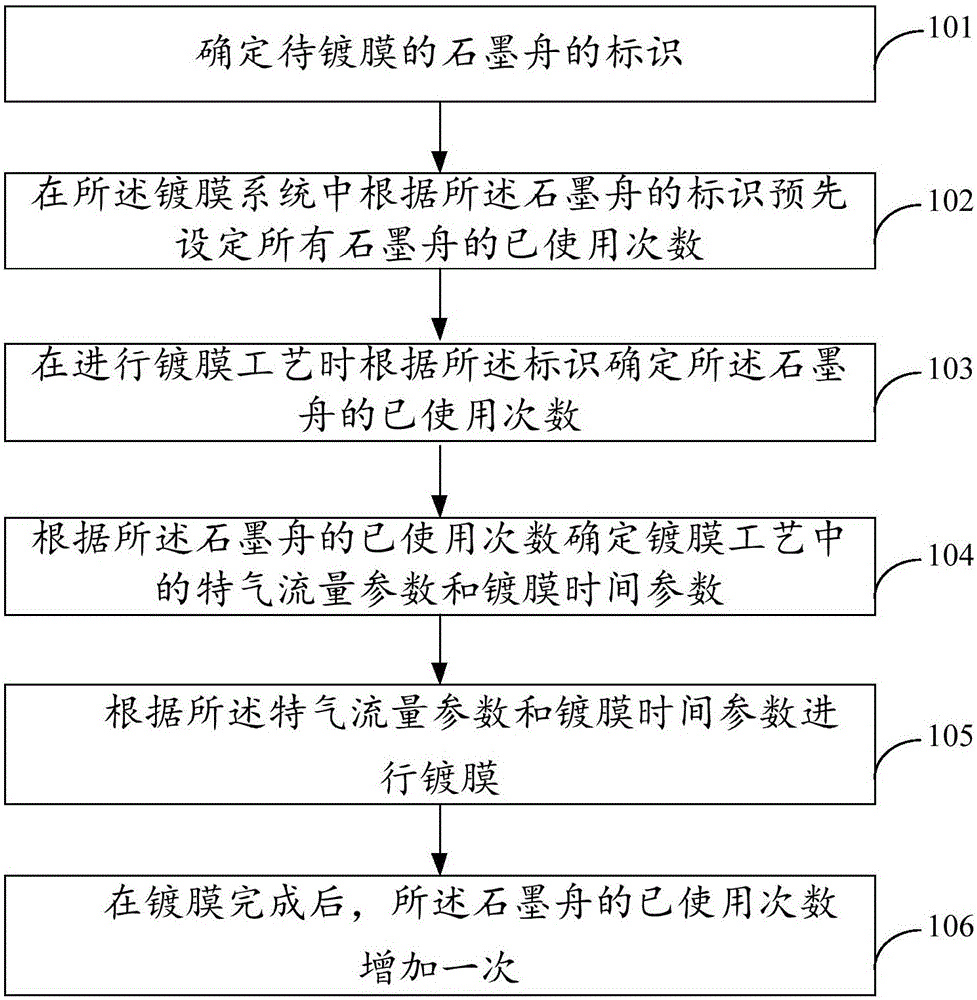

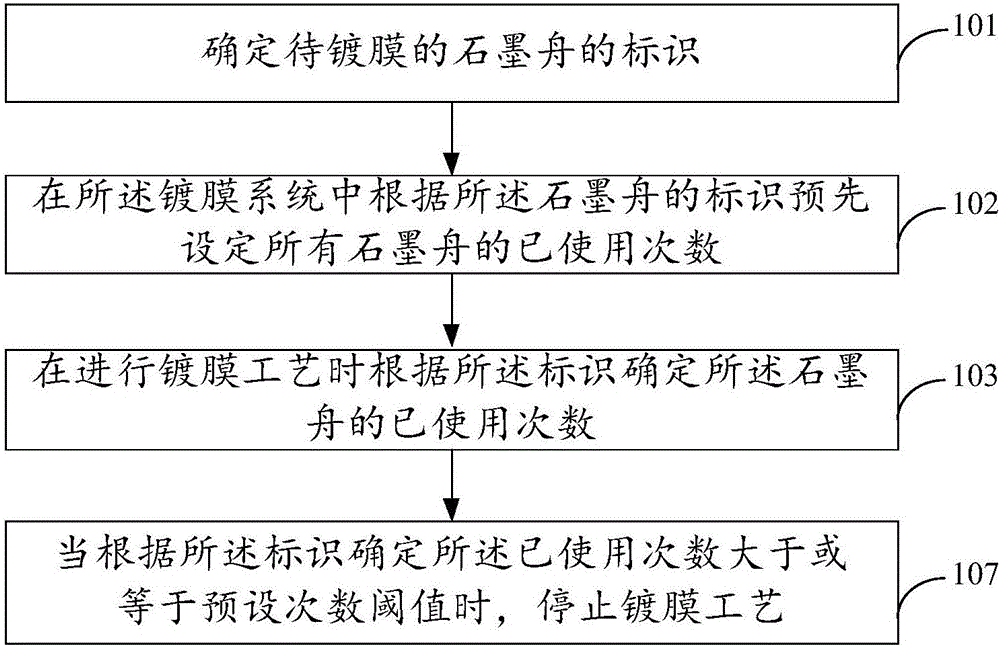

Technological treatment method and device

InactiveCN106245006AWill not affect the coating effectCoating effect is consistentChemical vapor deposition coatingGraphiteSilicon chip

The invention provides a technological treatment method and device applicable to a film plating system using graphite boat for film plating on silicon chips. The method includes: determining the marks of graphite boats needing film plating; in the film plating system, presetting the used number of times of all graphite boats according to the marks of the graphite boats; determining the used number of times of the graphite boats according to the marks; determining the special gas flow parameters and film plating time parameters in the film plating process according to the used number of times of the graphite boats; and conducting film plating according to the special gas flow parameters and film plating time parameters. When the graphite boats are employed to perform film plating operation on silicon chips, the special gas flow parameters and film plating time parameters can be determined according to the used number of times of the graphite boats, the graphite boats with different used numbers of times adopt different special gas flows and film plating time. Even if the surface smoothness of graphite boat sheets in the graphite boats is reduced, the film plating effect of the silicon chips is not affected, the film formed on the silicon chip has consistent thickness and consistent refractivity, and the silicon chip film coating effect is more unified.

Owner:JIANGXI RISUN SOLAR ENERGY CO LTD

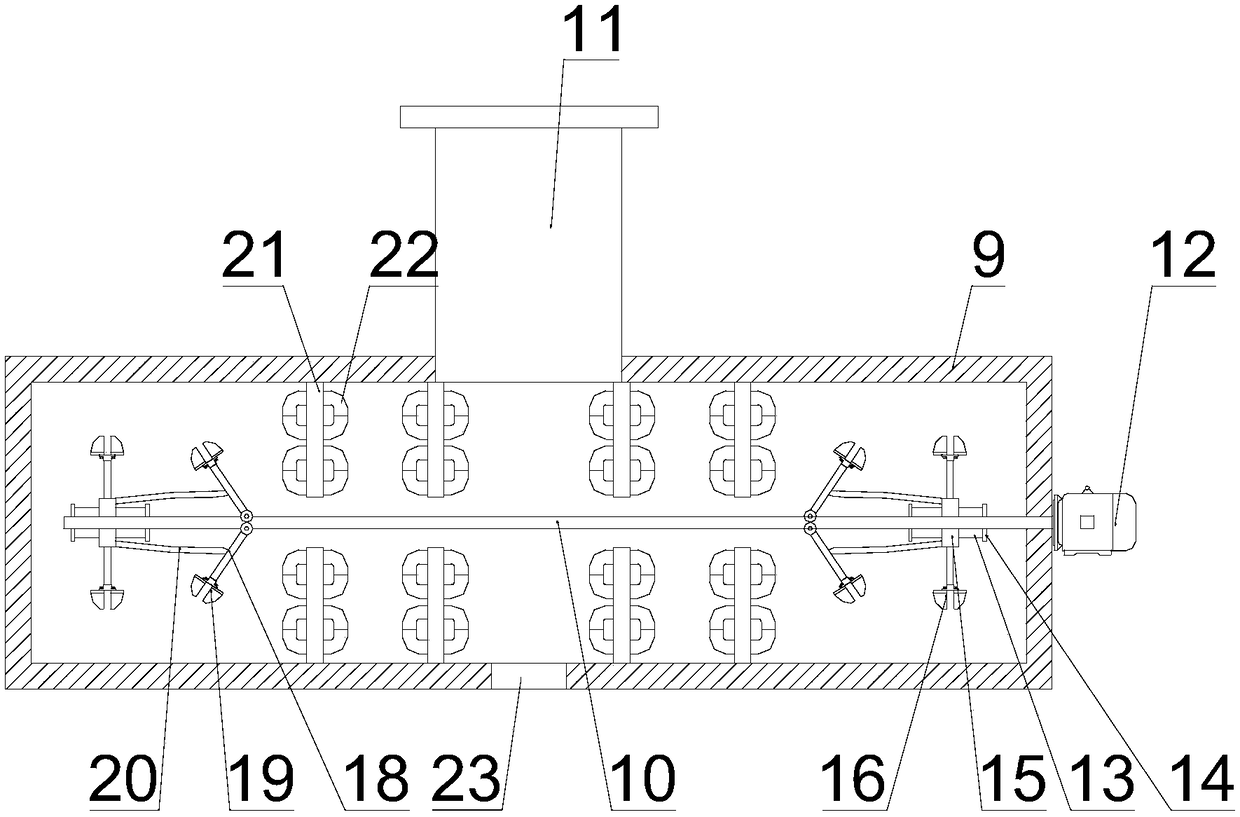

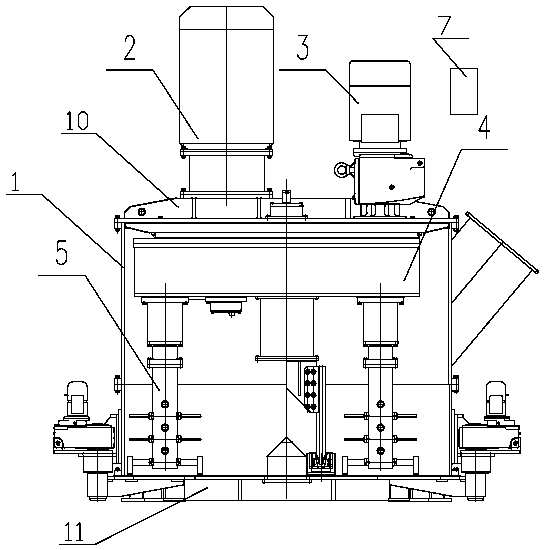

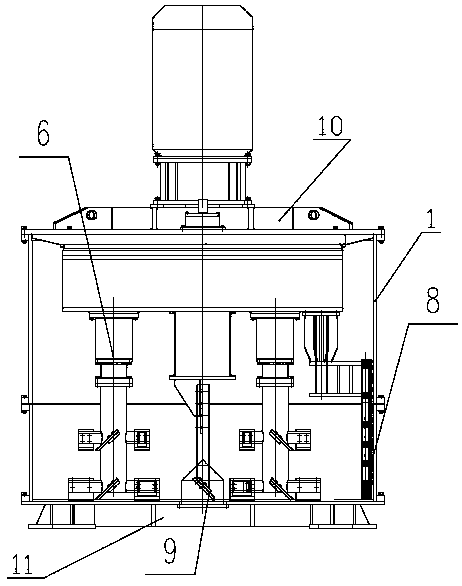

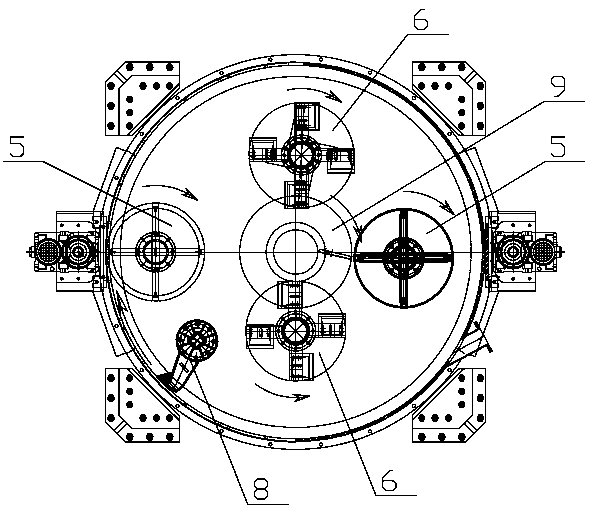

Multi-rotor frequency-changing sand mixer and sand mixing method

ActiveCN103949580AStir track overlap increasedHigh overlapMould handling/dressing devicesFrequency changerThermodynamics

Owner:常州市通力机电设备制造有限公司

Lithium nickel manganese oxide positive electrode material as well as preparation method and application thereof

PendingCN114843501AImprove cycle performanceImprove thermal stabilityCell electrodesElectrolytic agentLithium

The invention discloses a lithium nickel manganese oxide positive electrode material and a preparation method and application thereof, the molecular formula of the lithium nickel manganese oxide positive electrode material is Li alpha Ni beta Mn 2-beta M gamma O 4-delta / N, alpha is more than or equal to 0.95 and less than or equal to 1.1, beta is more than or equal to 0.4 and less than or equal to 0.6, gamma is more than or equal to 0.0005 and less than or equal to 0.02, and delta is more than or equal to 0 and less than or equal to 0.2; m is a single crystal dispersed element, and M is at least one of V, Nb, Ta, Mo or W; n is a coating layer, and the coating layer comprises a P compound and / or an Al compound; and the coating amount of N is 500 to 10000 ppm. The preparation method comprises the following steps: firstly, adding a small amount of single-crystal dispersed elements (V, Nb, Ta, Mo or W) to prepare a high-voltage nickel-manganese material with good single-crystal dispersity, so that the high-voltage nickel-manganese material has a smaller specific surface area; furthermore, the lithium nickel manganese oxide positive electrode material with high single crystal dispersity is uniformly coated with the P compound and / or the Al compound, so that oxygenolysis caused by direct contact between the positive electrode material and an electrolyte is avoided, the stability of the material is improved, and the cycle performance of the battery is improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

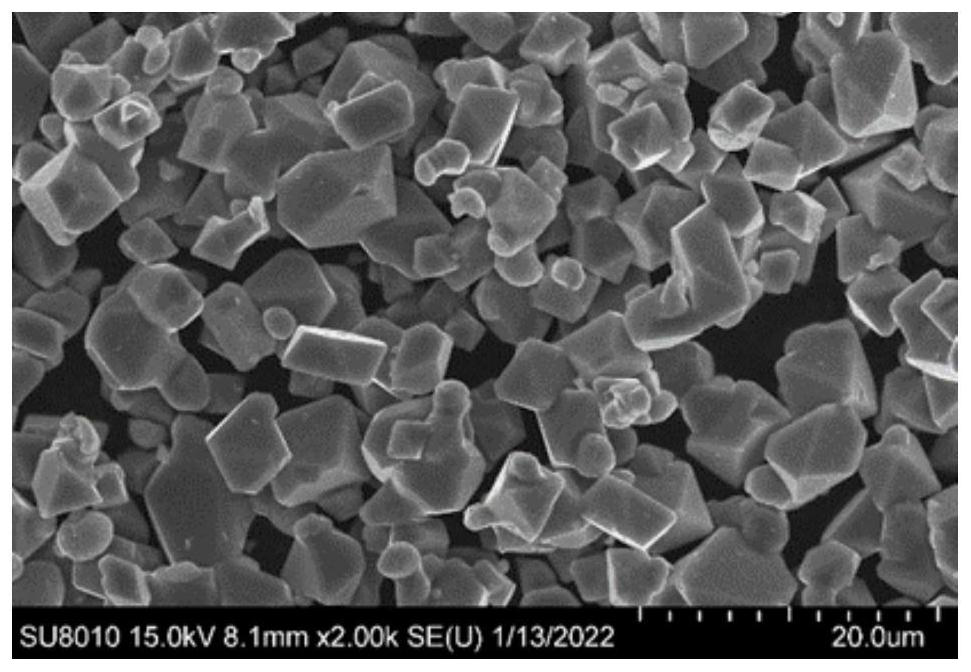

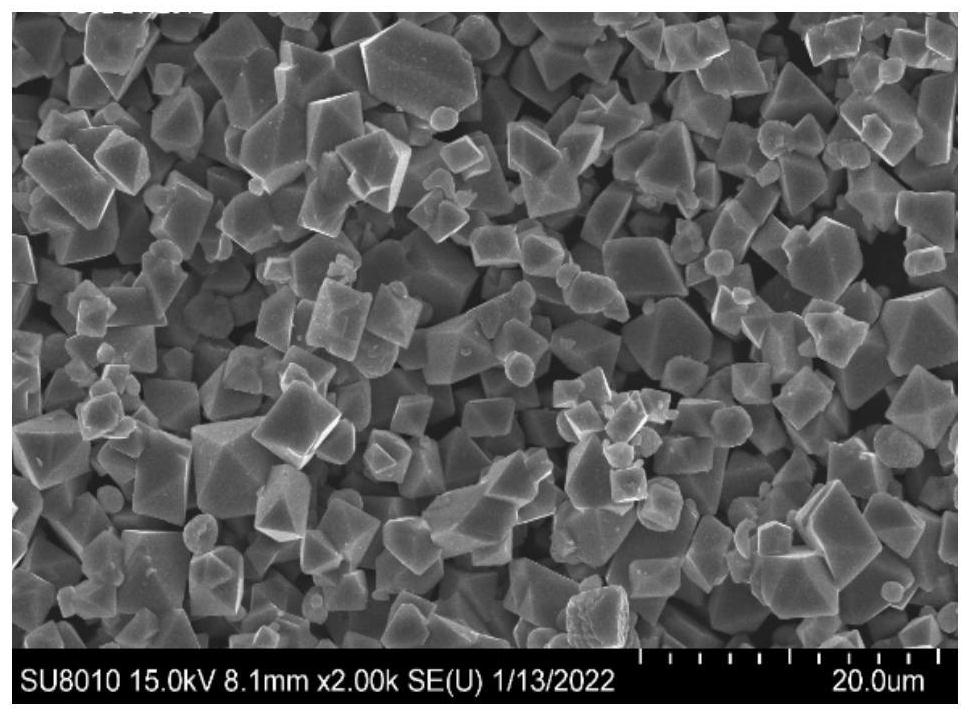

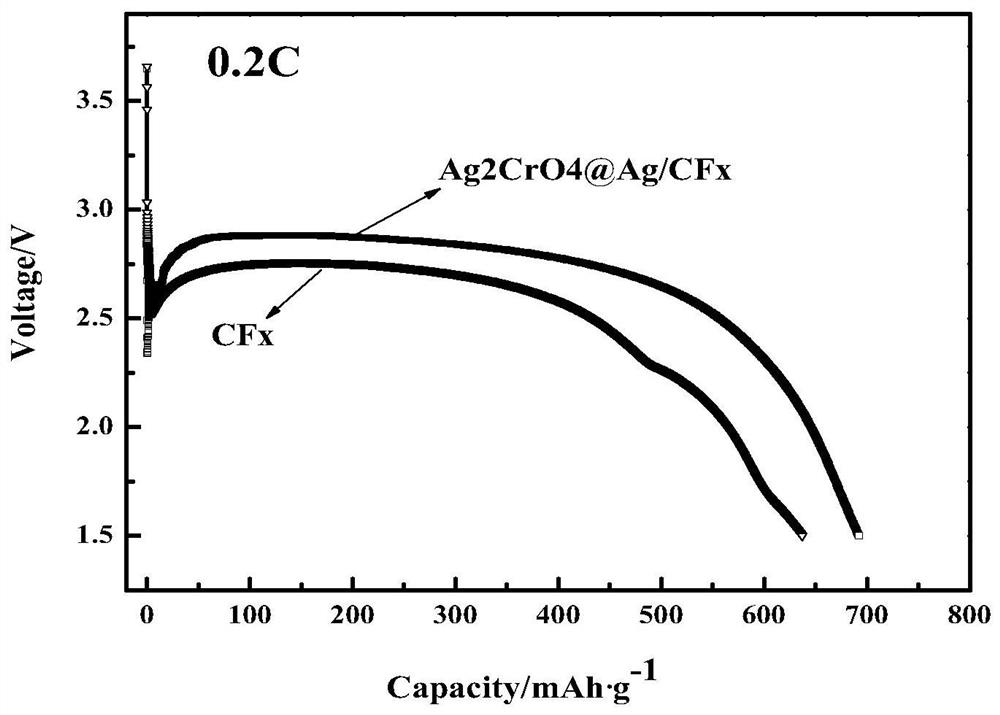

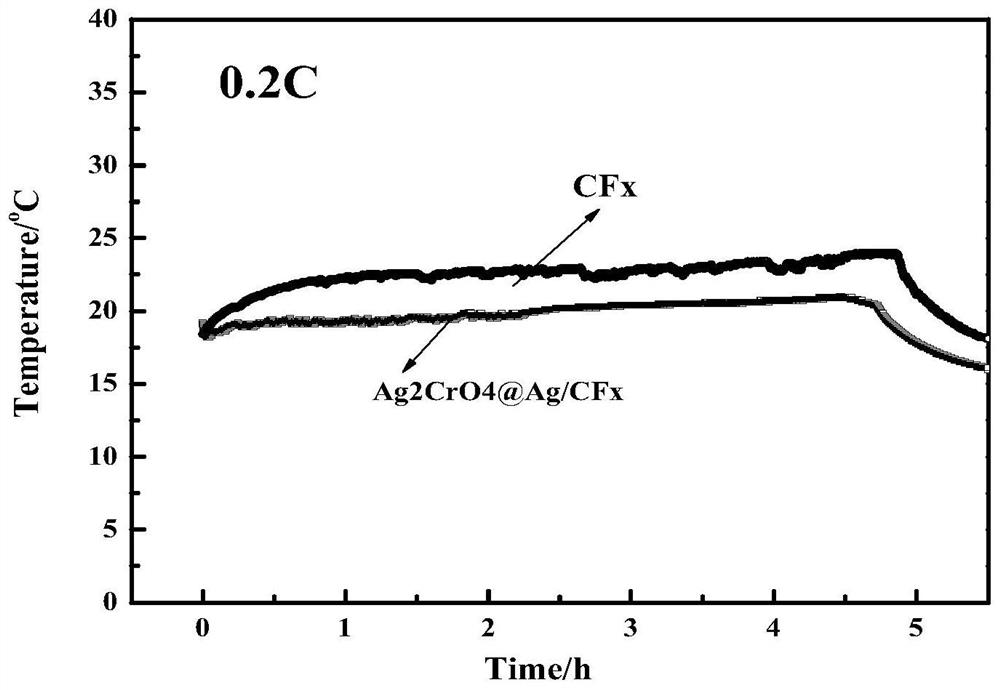

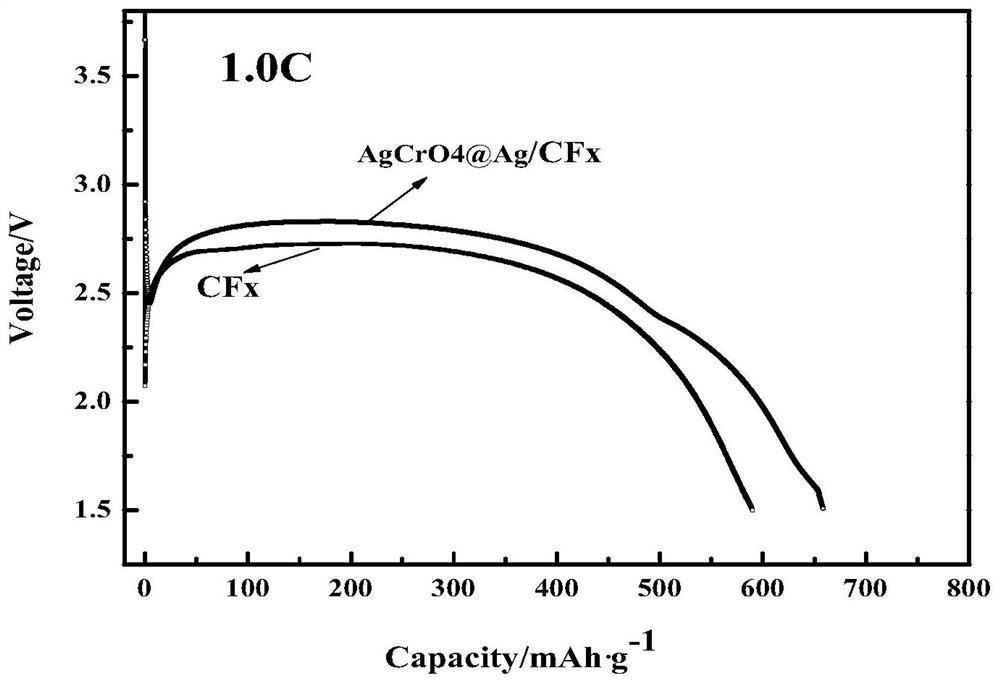

Preparation method of Ag2CrO4@Ag modified carbon fluoride positive electrode material

ActiveCN113363495AMake up for the voltage lag problemGood high current discharge performanceNon-aqueous electrolyte cellsPositive electrodesModified carbonElectrical battery

The invention relates to the technical field of carbon fluoride positive electrode material modification, in particular to a preparation method of an Ag2CrO4@Ag modified carbon fluoride positive electrode material, which comprises the following steps of: (1) preparing a potassium chromate solution; (2) preparing a carbon fluoride dispersion liquid; (3) preparing a mixed solution: well stirring the potassium chromate solution and the carbon fluoride dispersion liquid to obtain the mixed solution; (4) preparing a silver nitrate solution; (5) preparing mixed slurry: slowly adding the silver nitrate solution into the mixed solution, continuing reaction after the silver nitrate solution is completely added to obtain a mixed reaction solution, and performing high-energy ball milling to obtain the mixed slurry; (6) drying and sieving the mixed slurry to obtain mixed powder; and (7) calcining: calcining the mixed powder. The problem of voltage lag at the initial discharge stage of the carbon fluoride battery is effectively solved, the rate capability and platform voltage are improved, the temperature rise in the discharge process of the lithium carbon fluoride battery is reduced, and the preparation method is simple and low in cost.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD +1

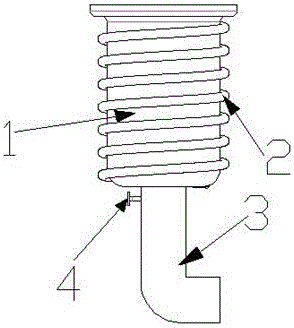

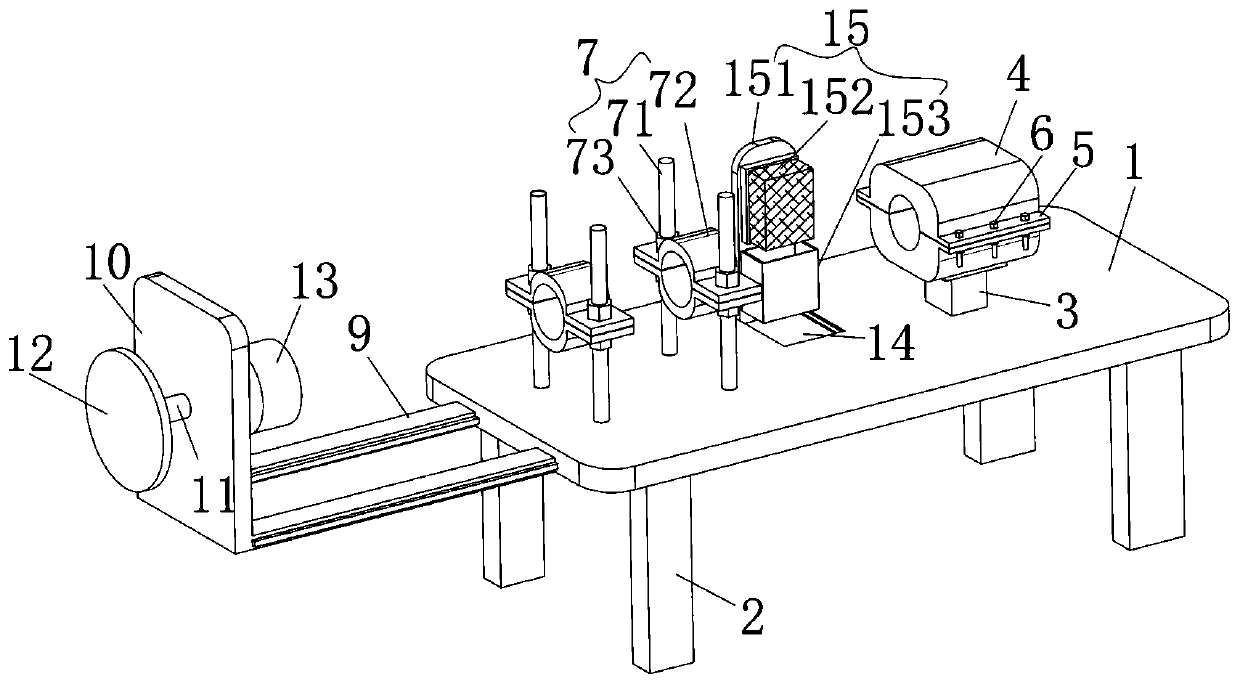

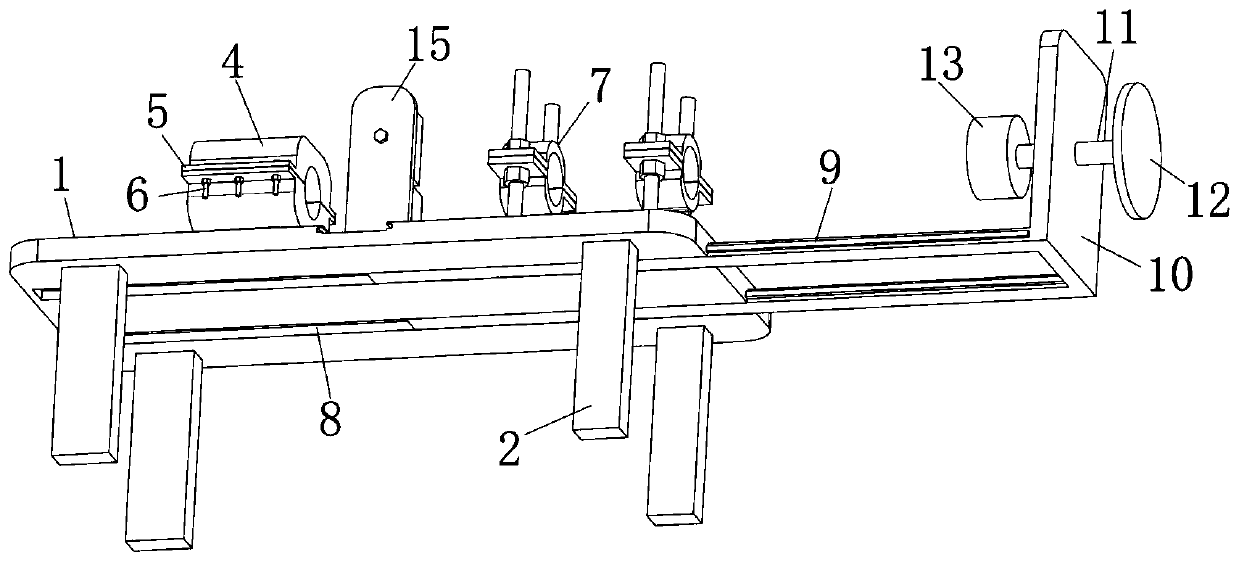

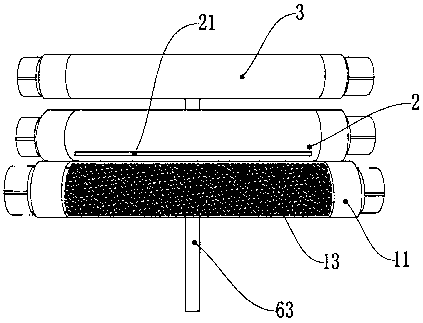

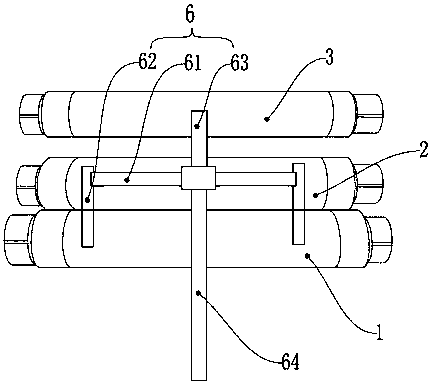

Installation device for PVC water pipe connector

The invention relates to the technical field of water pipe installation, in particular to an installation device for a PVC water pipe connector. Connecting plates are fixedly arranged on the two sides, in the width direction, of each connector clamping plate, wherein the two connecting plates are symmetrically arranged, and every two corresponding connecting plates are fixedly connected under cooperation of multiple fixing bolts and nuts. Multiple water pipe clamping mechanisms coaxially arranged with the connector clamping plates are fixedly installed on the other side of the upper surface ofa worktable, a side plate is telescopically arranged on the surface of the tail end of one side, in the length direction, of the worktable, and the side plate and a water pipe clamping mechanism arecorrespondingly arranged. Threaded pillars are arranged on the side plate in a threaded penetrating manner, and the threaded pillars and the water pipe clamping mechanism are coaxially arranged. A sleeve is fixedly installed at the tail end of the inner side of each threaded pillar, and a rotating disc is fixedly installed at the tail end of the outer side of each threaded pillar. A second slidinggroove is formed in the position, between the water pipe clamping mechanism and the connector clamping plates, on the upper surface of the worktable in the length direction, and a glue spraying mechanism is installed in the second sliding groove in a sliding manner. The installation device has the beneficial effects that time and labor are saved, and installation is convenient.

Owner:郑丽芳

Convenient and fast antithetical couplet pasting device

The invention discloses a convenient and fast antithetical couplet pasting device. The device comprises, from bottom to top in sequence, a glue distributing roller, an antithetical couplet winding roller and a pressure roller which are arranged and connected transversely. The glue distributing roller comprises a glue distributing barrel, a baffle and a bristlebrush roller body; glue inlets are formed in the two ends of the glue distributing barrel correspondingly; the baffle is mounted in the glue distributing barrel and partitions the glue distributing barrel into a front glue outlet cavity and a rear glue inlet cavity; a glue applying port is formed in the front glue outlet cavity; the rear glue inlet cavity communicates with the corresponding glue inlet; the front glue outlet cavity communicates with the rear glue inlet cavity through through holes which are uniformly distributed and formed in the surface of the baffle; the bristlebrush roller body is mounted in the front glue outlet cavity and right faces the glue applying port; an antithetical couplet outlet is formed in the front end of the side surface of the antithetical couplet winding roller; and the glue distributing roller, the antithetical couplet winding roller and the pressure roller roll synchronously from top to bottom. The convenient and fast antithetical couplet pasting device has the advantages that glue applying is uniform and stable, and sticking is fast and flat.

Owner:佛山市禅城区下朗小学

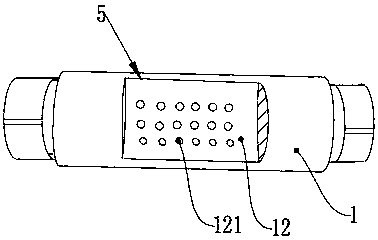

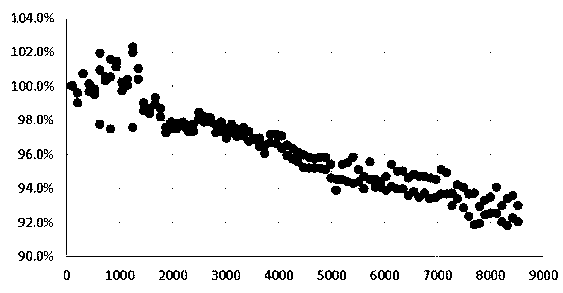

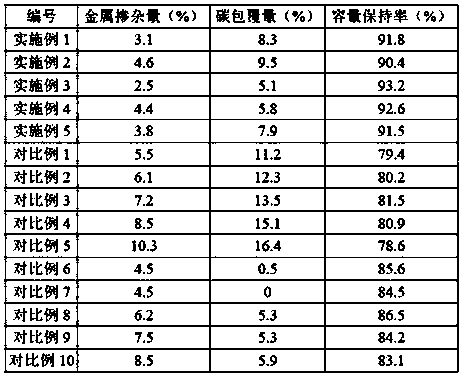

Carbon coated metal doped lithium titanate composite material as well as preparation and application thereof

PendingCN109671944AUniform coating effectEasy to prepareNegative electrodesSecondary cellsCyclic stabilityLithium electrode

The invention discloses a carbon coated metal doped lithium titanate composite material as well as preparation and application thereof. According to the carbon coated metal doped lithium titanate composite material disclosed by the invention, the gas generation problem of a lithium titanate material is improved by an appropriate metal doping amount and an appropriate carbon coating amount, so thatthe electronic conductivity of the lithium titanate material is enhanced, and the advantage that the lithium titanate material has long service life is brought into full play. The invention further provides a lithium ion battery. The carbon coated metal doped lithium titanate composite material is utilized as a negative electrode material of the lithium ion battery. The lithium ion battery has good cyclic stability, and the capacity retention ratio of the lithium ion battery can be kept at 90% or more after 8000-week charge-discharge cycles under the 3 C rate.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Solar photovoltaic glass plate coating device

The invention discloses a solar photovoltaic glass plate coating device which comprises a base, clamping and fixing mechanisms, a first motor, an electric liquid inlet valve and an electric spray valve, self-locking rollers are fixed to the left side and the right side of the lower end face of the base, the clamping and fixing mechanisms are arranged on the left side and the right side of the top of a bearing table, and a suction cup is fixed to the upper side of a suction pump. A bearing frame is arranged on the outer side of the bearing table, a first sliding block is slidably connected to the inner top of the bearing frame, a second sliding block is slidably connected to the interior of a sliding rail, the electric liquid inlet valve penetrates through the top of a bearing plate and communicates with a liquid passing channel, and the liquid passing channel is formed in the bearing plate. The electric spray valve penetrates through the bottom of the bearing plate to communicate with the liquid passing channel, and the electric spray valve is located on the outer side of a rotary disc. According to the solar photovoltaic glass plate coating device, in the process that the electric spray valve is used for spraying coating liquid, the rotating disc rotates, the coating liquid can be evenly dispersed conveniently, and the coating effect is more comprehensive and even.

Owner:徐州中辉光伏科技有限公司

Preparation method of lithium iron phosphate positive electrode material, positive electrode material and battery

ActiveCN112340721ALow costImproved magnification performanceZinc oxides/hydroxidesFinal product manufactureElectrical batteryZinc metal

The invention provides a preparation method of a lithium iron phosphate positive electrode material, the positive electrode material and a battery. The preparation method is a method for preparing thelithium iron phosphate positive electrode material with a nanometer zinc oxide coating layer and a graphene coating layer by comprehensively utilizing blast furnace ash. The preparation method specifically comprises the following steps: carrying out flotation on the blast furnace ash to obtain concentrates and tailings; performing active treatment on the concentrate to obtain active carbon powder; treating the tailings to obtain zinc metal steam and an iron-containing raw material; preparing carbon doped lithium iron phosphate; introducing hot air and the zinc metal steam at a high temperature for zinc oxide vapor deposition coating; and with zinc oxide as a substrate, cracking active carbon powder into carbon atoms at a high temperature, wherein the carbon atoms are adsorbed on the surface of zinc oxide to form a graphene coating layer. According to the method, zinc, carbon and iron contained in the blast furnace ash can be recycled to prepare the lithium iron phosphate positive electrode material; compared with a traditional preparation method using analytically pure raw materials, the production cost of the method of the invention can be greatly reduced; and meanwhile, the prepared material has double coating layers, namely the zinc oxide coating layer and the graphene coating layer, so coating is more uniform, and the electrochemical performance of the material is more excellent.

Owner:湖南桑瑞新材料有限公司

Laminated glass coating equipment

InactiveCN112337694AAchieve the effect of automatic coatingUniform coverageSpraying apparatusMechanical engineeringGlass sheet

The invention discloses laminated glass coating equipment, and relates to the technical field of glass coating equipment. The laminated glass coating equipment comprises an operation base and a conveying belt, the upper surface of the operation base is fixedly connected with two supporting frames, the opposite sides of the two supporting frames are jointly and fixedly connected with a first supporting plate, and the bottom face of the first supporting plate is fixedly connected with a first fixed plate. According to the laminated glass coating equipment, through mutual cooperation between thestructures, the effects that glass plates are automatically coated in batches, the labor intensity of operators is greatly reduced, the good coating effect is guaranteed, a glue solution is stirred inthe coating process, and the glue solution is prevented from being coagulated in advance are achieved; and the problems that traditional coating equipment is inconvenient to use, it cannot be guaranteed that a glue solution is evenly smeared on the surface of a glass plate, consequently, the quality of a finished product is poor, the glue solution used for coating is prone to being coagulated during storage, and consequently an operator needs to frequently clean a containing and transferring container are solved.

Owner:滁州蓝天特种玻璃有限公司

Preparation method of anhydrous iron phosphate and preparation method of lithium iron phosphate carbon composite material

PendingCN114772571AUniform shapeNot easy to mergeCell electrodesPhosphorus compoundsCarbon compositesCarbon coating

The invention discloses a preparation method of anhydrous iron phosphate and a preparation method of a lithium iron phosphate carbon composite material, a green vanadium product is purified from titanium dioxide to synthesize an iron phosphate product, and APP is utilized to replace DAP or MAP, so that on one hand, the cost can be reduced to a certain extent, and on the other hand, the pollution can be reduced. In addition, a two-step aging mode or a multi-step aging mode is controlled, and the dehydration temperature and time are adjusted, so that primary particles of iron phosphate can be controlled at a relatively small level of about 100nm, and meanwhile, a relatively normal Fe / P ratio is obtained. The lithium iron phosphate carbon composite material is prepared by adopting the anhydrous iron phosphate, and composite carbon source and composite carbon coating is performed by a rheological phase method, so that the sintering temperature can be reduced, the sanding and sintering time can be shortened, the coating uniformity can be improved, and meanwhile, the electrical property, especially the rate capability, of lithium iron phosphate can be enhanced.

Owner:WANXIANG 123 CO LTD

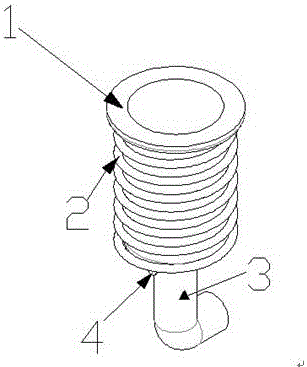

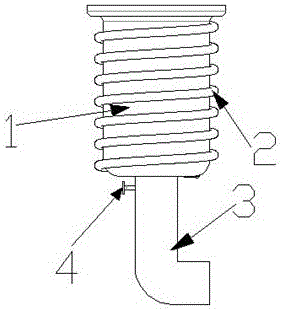

Textile stretch performance test pretreatment device and pretreatment method

PendingCN108535109AStretch CharacterizationAccurate experimental test dataMaterial strength using tensile/compressive forcesYarnPretreatment method

The invention discloses a textile stretch performance test pretreatment device and a pretreatment method. The pretreatment device comprises a first glue storage groove, a second glue storage groove, afirst glue pushing device, a second glue pushing device, a first glue coating device and a second glue coating device, wherein the first glue pushing device moves in the extending direction of the first glue storage groove; the second glue pushing device moves in the extending direction of the second glue storage groove; the first glue coating device is communicated with the first glue storage groove; the second glue coating device is communicated with the second glue storage groove; the first glue coating device comprises a first left glue coating device and a first right glue coating device; the shape of the first left glue coating device and the shape of the first right glue coating device are respectively rectangular shapes; four adjacent vertexes between the first left glue coating device and the second right glue coating device form a rectangular shape; the second glue coating device uses the textile as the symmetrical surface to realize the mirror image symmetry with the firstglue coating device. The problems of carrying yarn pulling, structure disengagement and looseness, yarn slip motion and the like generated in the stretch performance test of great-load machine weavingstructural textile can be solved. The accurate experiment test data can be provided; the stretch performance of the great-load machine weaving structure textile can be expressed.

Owner:SUZHOU XINNAN TEXTILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com