Coating-structure sodium-ion battery anode material as well as preparation method and application thereof

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of process difficulty, increased material cost, difficulty in comprehensive coating, uneven coating, etc., and achieve improved cycle stability , good coating effect and simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

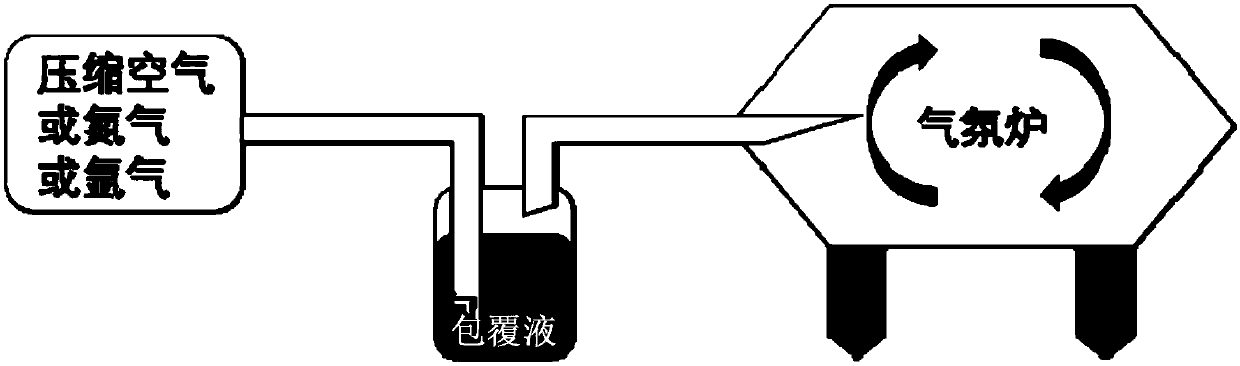

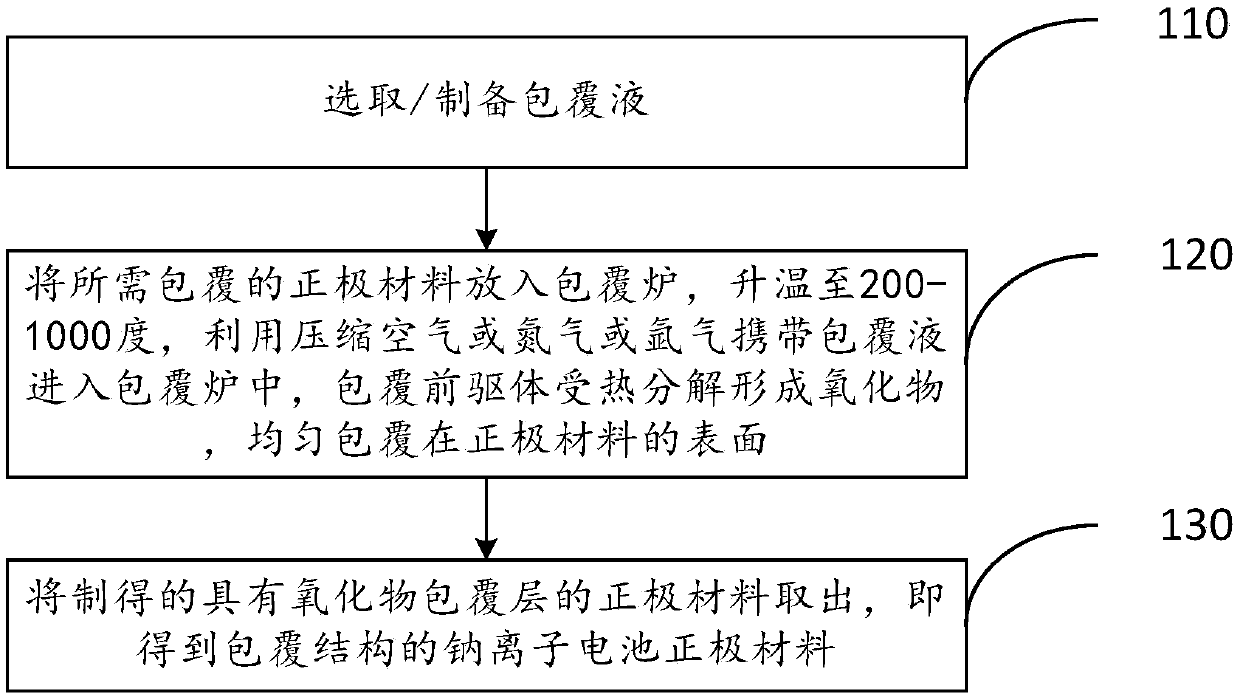

[0047] The above materials can be obtained through the following figure 1 In the method shown, the gas is passed into the coating liquid, and the coating liquid is carried into the atmosphere furnace, so that the coating precursor is thermally decomposed, and the positive electrode material is coated. Its specific preparation method can be as follows figure 2 As shown in the flow chart shown, it specifically includes the following steps:

[0048] Step 110, selecting / preparing a coating solution;

[0049] Specifically, the coating solution includes a coating precursor composed of metal salts and / or hydrates thereof, wherein the metal salts and / or hydrates thereof are preferably nitric acid of Al, Mg, Ti, Zn, Zr, Nb or La One or more of salts and their hydrates, sulfates and their hydrates, and organic salts;

[0050] In this step, the liquid-coated precursor can be directly used as the coating liquid, or the solid raw material of the precursor can be dissolved in a correspo...

Embodiment 2

[0060] First, choose the positive electrode material as Na 0.9 Cu 0.22 Fe 0.30 mn 0.48 o 2 , which is recorded as raw material 1, and its particle size D50 is 10 μm. The coating liquid is composed of aluminum nitrate and water, the concentration is 50g aluminum nitrate / 100g water, the gas is selected as compressed air, and the furnace is selected as rotary furnace.

[0061] Then, 100kg of positive electrode material was weighed and placed in a rotary furnace, and the rotation was turned on to increase its contact area. Turn on the heating to make the temperature in the furnace reach 700 degrees Celsius. Turn on the compressed air, which carries the coating liquid into the furnace body, and the coating liquid contacts the material and decomposes into Al at high temperature 2 o 3 , evenly covering the surface of the material. The 700-degree heat preservation time is set to 8 hours, and the ventilation is stopped after the time is up. Turn on the cooling system, the furn...

Embodiment 3

[0066] First, choose the positive electrode material as Na 1.0 Ni 0.22 Cu 0.11 Fe 0.33 mn 0.33 o 2 , which is recorded as raw material 2, and its particle size D50 is 10 μm. The coating liquid is tetrabutyl titanate, the gas is nitrogen, and the furnace is a rotary furnace.

[0067] Then, 100kg of positive electrode material was weighed and placed in a rotary furnace, and the rotation was turned on to increase its contact area. Turn on the heating to make the temperature in the furnace reach 900 degrees Celsius. Turn on the compressed air, which carries the coating liquid into the furnace body, and the coating liquid contacts the material and decomposes into TiO at high temperature 2 , evenly covering the surface of the material. The 900-degree heat preservation time is set to 4 hours, and the ventilation is stopped after the time is up. Turn on the cooling system, the furnace body cools down rapidly, and TiO can be obtained after taking it out 2 Coated Na 1.0 Ni 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com