Sulfonated graphene and lithium nickel manganese oxide composite material and preparation method and application thereof

A technology of sulfonated graphene and lithium nickel manganese oxide, which is applied in the field of sulfonated graphene/lithium nickel manganese oxide composite materials and its preparation, can solve the problems of poor material structure stability, poor cycle stability, and low specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

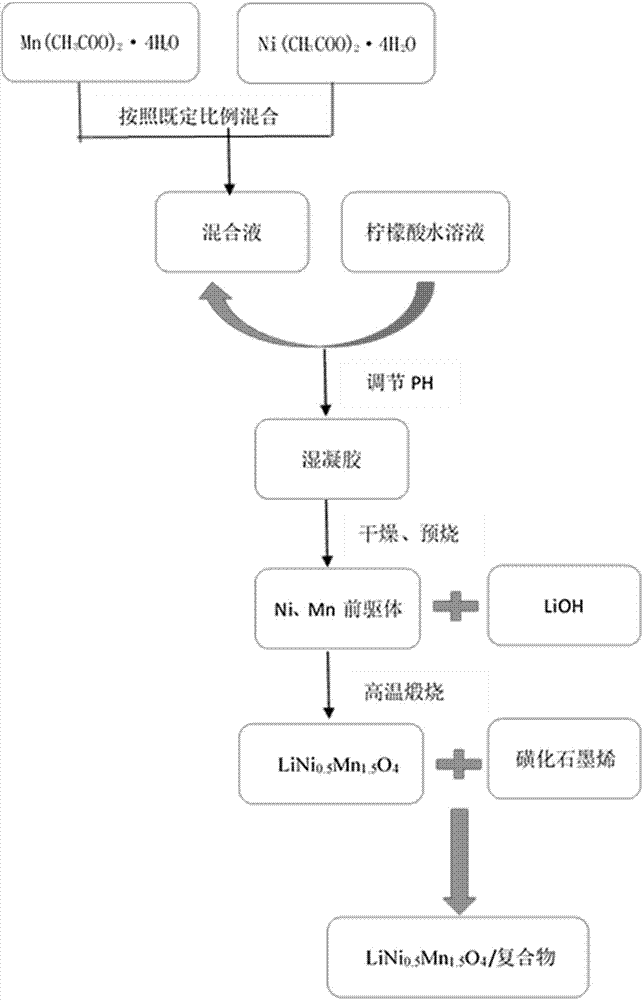

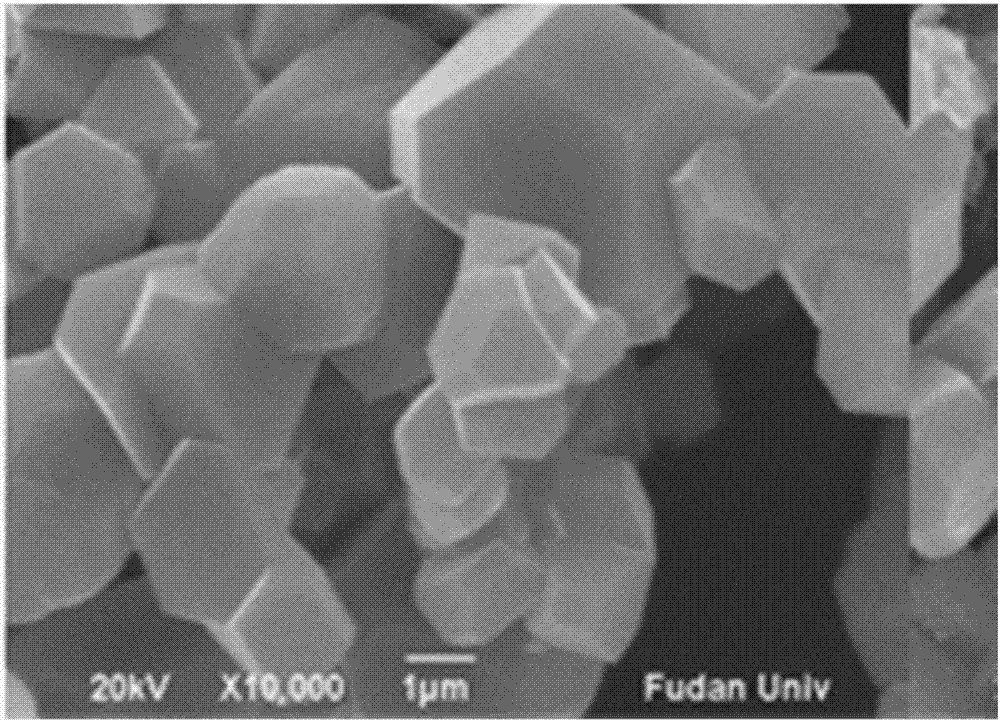

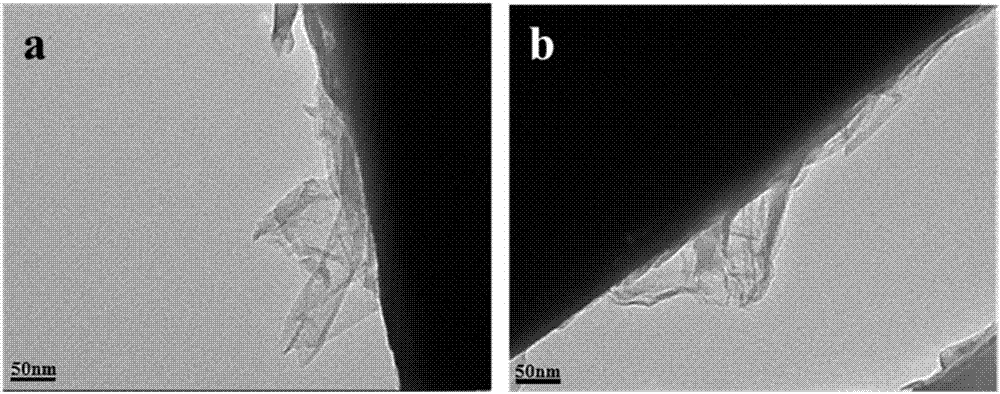

[0072] A kind of sulfonated graphene / lithium nickel manganese oxide composite material, the mass ratio of nickel manganese oxide lithium and sulfonated graphene in the composite material is 20:1, wherein, sulfonated graphene is coated on the lithium nickel manganese oxide surface, nickel The molecular formula of lithium manganate is LiNi 0.5 mn 1.5 o 4 , the process flow of its preparation is attached figure 1 As shown, the specific steps are as follows:

[0073] (1) 1.5mmol of Mn(CH 3 COO) 2 4H 2 O, 0.5mmol of Ni(CH 3 COO) 2 4H 2 O was dissolved in 10 mL of deionized water, and then 2 mmol of citric acid was dissolved in 10 mL of deionized water. Under high-speed magnetic stirring, pour the citric acid solution into the manganese acetate and nickel acetate solutions to obtain a green solution. Adjust the pH value to 7.0-8.0 with ammonia water. After stirring for 30 minutes, heat the solution to 80°C and keep the stirring speed at 400r / min until green wet gel is form...

Embodiment 2

[0081] A kind of sulfonated graphene / lithium nickel manganese oxide composite material, the mass ratio of nickel manganese oxide lithium and sulfonated graphene in the composite material is 30:1, wherein, sulfonated graphene is coated on the lithium nickel manganese oxide surface, nickel The molecular formula of lithium manganate is LiNi 0.5 mn 1.5 o 4 , the specific preparation steps are as follows:

[0082] (1) 1.5mmol of Mn(NO 3 ) 2 , 0.5mmol of Ni(NO 3 ) 2 Dissolve in 10mL ionized water, then dissolve 2mmol citric acid in 10mL ionized water. Under high-speed magnetic stirring, pour the citric acid solution into the manganese nitrate and nickel nitrate solutions to obtain a green solution. Adjust the pH value to 7.0-8.0 with ammonia water. After stirring for 30 minutes, heat the solution to 75°C and keep the stirring speed at 300r / min until green wet gel is formed. The wet gel was transferred to a vacuum oven, dried at 110°C for 15 hours, and the obtained dry gel wa...

Embodiment 3

[0090] A kind of sulfonated graphene / lithium nickel manganese oxide composite material, the mass ratio of lithium nickel manganese oxide and sulfonated graphene is 10:1 in the composite material, wherein, sulfonated graphene is coated on the lithium nickel manganese oxide surface, nickel The molecular formula of lithium manganate is LiNi 0.5 mn 1.5 o 4 , the specific preparation steps are as follows:

[0091] (1) 1.5mmol of MnCl 2 , 0.5mmol of NiCl 2 Dissolve in 10mL ionized water, then dissolve 2mmol citric acid in 10mL ionized water. Under high-speed magnetic stirring, pour the citric acid solution into the manganese chloride and nickel chloride solutions to obtain a green solution. Adjust the pH value to 7.0-8.0 with ammonia water, and after stirring for 30 minutes, heat the solution to 85°C and maintain the stirring speed at 500r / min until the green wet gel is formed. The wet gel was transferred to a vacuum oven, dried at 100°C for 15 hours, and the obtained dry gel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com