Lithium nickel manganese oxide positive electrode material as well as preparation method and application thereof

A cathode material, lithium nickel manganese oxide technology, applied in battery electrodes, structural parts, electrical components, etc., can solve problems such as being unfavorable to large-scale commercial production, difficult to control the experimental process, and unfavorable to large-scale production. The effect of improving battery cycle performance, good capacity rate performance and cycle performance, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The present invention also provides a preparation method for preparing the above-mentioned lithium nickel manganate positive electrode material, which is used to explain the preparation process of the above-mentioned lithium nickel manganate positive electrode material, but the preparation of the above-mentioned lithium nickel manganate positive electrode material is not limited to this method. The preparation method used for example includes but is not limited to the following steps:

[0080] S1: Mix and stir the precursor, lithium source and single crystal dispersant evenly.

[0081] Wherein, the molecular formula of the precursor is: Ni β Mn 2-β (OH) 4 , where 0.4≤β≤0.6; the precursor has at least one of the following characteristics: the D50 of the precursor is 2-8 μm; the specific surface area of the precursor is 10-30 m 2 / g; the tap density of the precursor is 0.8-1.5g / cm 3 .

[0082] Alternatively, the β may be 0.4, 0.5 or 0.6.

[0083] Optionally, the D...

Embodiment 1

[0110] (1) 1000g precursor Ni 0.5 Mn 1.5 (OH) 4 , 205.6g lithium carbonate and 3g single crystal dispersant V 2 O 5 Add it into a high-speed mixer to mix and stir evenly. The stirring speed is 800rpm and the stirring time is 20min. After mixing, it is placed in an atmosphere box furnace for the first sintering. During the first sintering, the rate is 3 °C / min. 900°C, hold for 8h; then cool down to 650°C at a rate of 0.5°C / min, hold at 650°C for 10h, and naturally drop to room temperature.

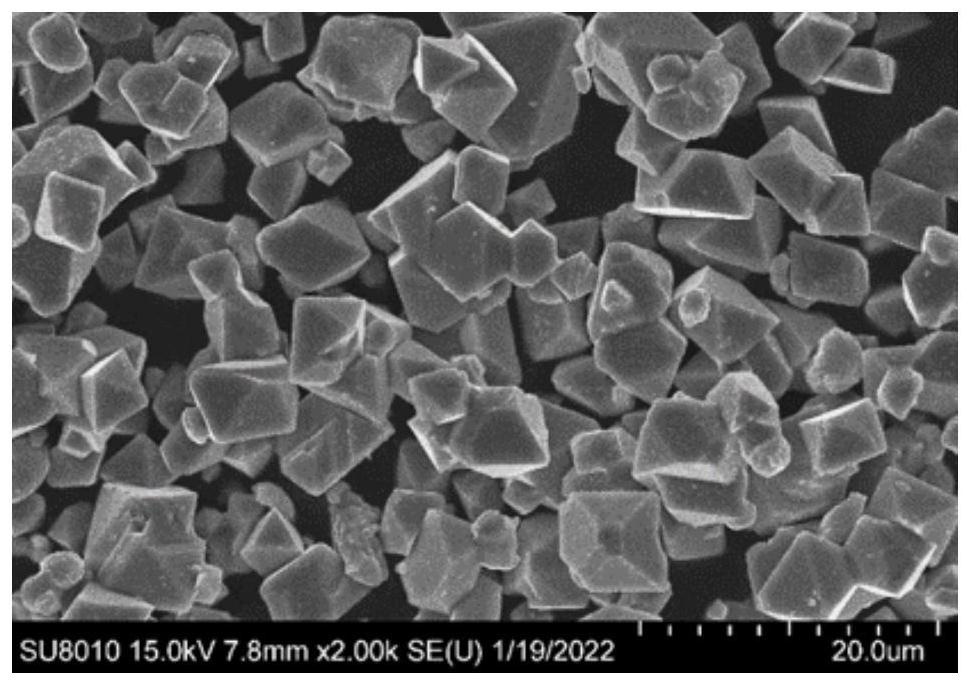

[0111] (2) Pulverize and sieve the product after the first sintering to obtain a high-voltage nickel-manganese material with high single crystal dispersibility, the chemical formula is LiNi 0.5 Mn 1.5 V 0.0059 O 4 ; The BET of the sample after the first firing is 0.37m 2 / g, SEM scan as figure 1 , it can be seen that V 2 O 5 When used as a single crystal dispersant, the single crystal dispersion effect is good.

[0112](3) 1000g of high single-crystal dispersity lithium nickel m...

Embodiment 2

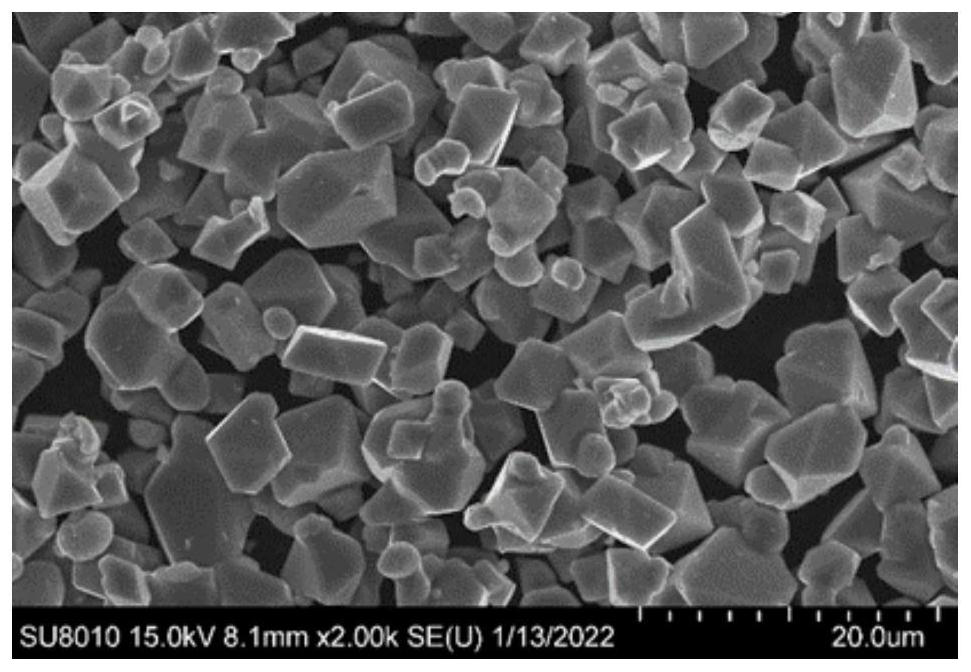

[0117] The difference between Example 2 and Example 1 is that the single crystal dispersant used in Example 2 is Nb 2 O 5 , the BET of the sample after the first firing is 0.36m 2 / g, SEM scan as figure 2 , it can be seen that Nb 2 O 5 When used as a single crystal dispersant, the single crystal dispersion effect is good. The coated lithium nickel manganate cathode material LiNi is obtained 0.5 Mn 1.5 Nb 0.0041 O 4 / P. The coated sample has a BET of 0.45m 2 / g, ICP test was performed on the coated lithium nickel manganate positive electrode material, and the coating amount of P was 1500 ppm.

[0118] The all-electric preparation is the same as that of Example 1. The initial capacity of 0.33C is 131.2mAh / g, the capacity retention rate of 500 cycles is 72.9%, and the gas production is 5.8mL / Ah.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com