Positive electrode material, preparation method thereof and lithium ion battery

A positive electrode material and high-nickel technology, applied in the field of positive electrode materials and their preparation, can solve the problems of high cost, unstable structure of positive electrode materials, high Co content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] According to the second aspect of the present invention, there is provided a method for preparing the aforementioned high-nickel and low-cobalt single crystal positive electrode material, wherein the preparation method includes:

[0045] (1) Under the protection of nitrogen, the mixed salt solution containing nickel salt and manganese salt, optional A salt solution, alkali solution and ammonia water are contacted and reacted in parallel to obtain a solid-liquid mixed slurry; After the solid-liquid mixed slurry is washed, press-filtered and dried, the precursor is obtained;

[0046] (2) contacting the precursor, the lithium source and the optional dopant D for the first mixing and then the first calcination treatment to obtain the positive electrode material intermediate;

[0047] (3) Contacting the positive electrode material intermediate, the nano-cobalt-containing compound, and the optional coating agent E for a second mixing, and then performing a second calcination ...

Embodiment approach

[0075] According to a particularly preferred embodiment of the present invention, a method for preparing a high-nickel and low-cobalt single crystal positive electrode material comprises:

[0076](1) Under the protection of nitrogen, the mixed salt solution containing nickel salt and manganese salt, optional A salt solution, alkali solution and ammonia water are contacted and reacted in parallel to obtain a solid-liquid mixed slurry; The solid-liquid mixed slurry is washed, filtered and dried to obtain a precursor; wherein, the concentration of the nickel salt is 1.8-2.2mol / L, and the concentration of the manganese salt is 1.8-2.2mol / L, The concentration of the A salt solution is 0.2-0.3mol / L, and the concentration of the alkali solution is 7.5-8mol / L; the doped A salt can be A-containing sulfate and / or nitrate; the mixed salt The molar ratio of the amount of the solution to the A salt solution is 1: (0.01-0.015); the pH value of the solid-liquid mixed slurry is 12.3-12.4; the...

Embodiment 1

[0091] This example is to illustrate the cathode material prepared by the method of the present invention.

[0092] (1) Using nickel sulfate and manganese sulfate as raw materials, according to the molar ratio Ni:Mn=90:10, a uniform nickel and manganese salt mixed solution of 2mol / L is prepared, and Ce of 0.2mol / L is prepared. 2 (SO 4 ) 3 solution, deploy 8mol / L NaOH solution as a precipitating agent, and use 25% ammonia water directly as a complexing agent.

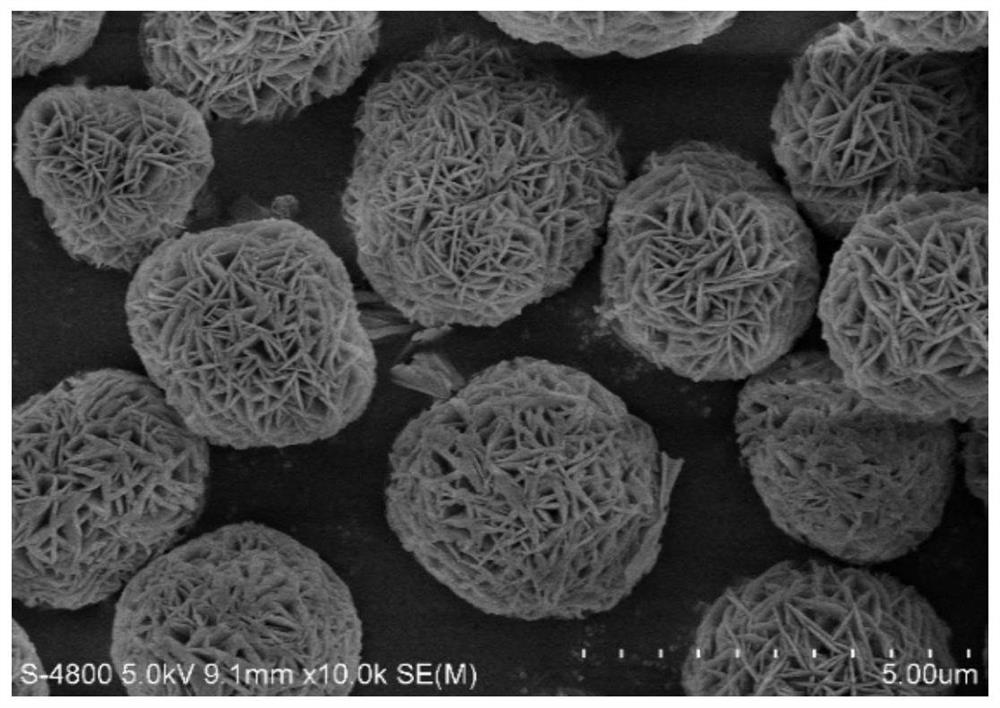

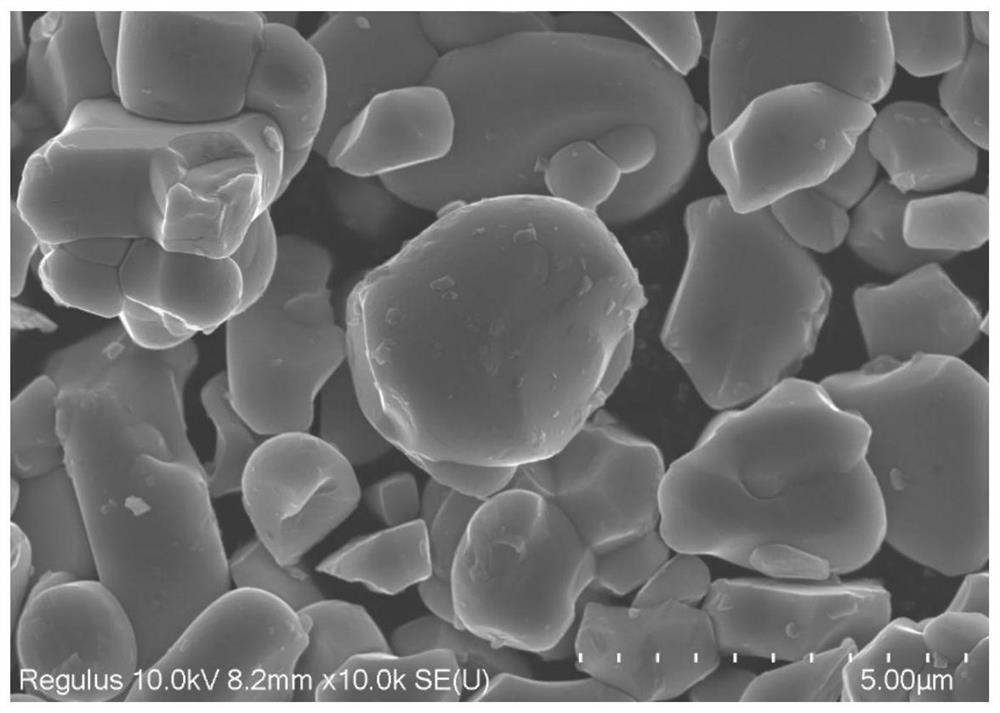

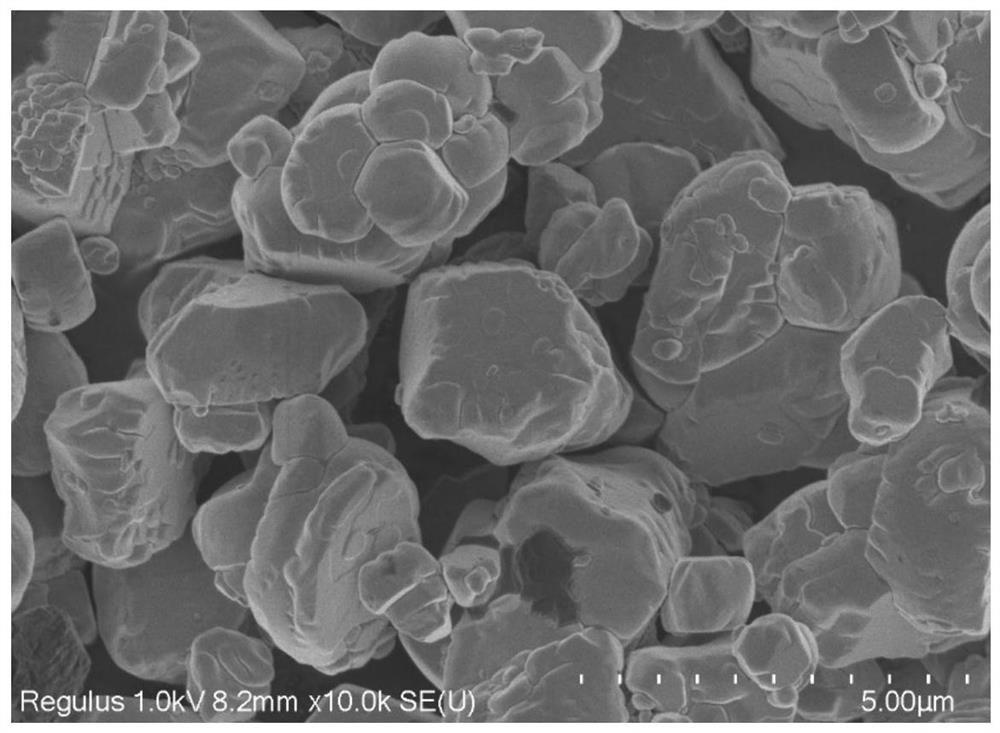

[0093] Under the protection of nitrogen, the above solution was passed into the reactor in a co-current manner, controlled [n(Ni)+n(Mn)]: n(Ce)=1:0.01, the stirring speed was 200rpm, and the reaction temperature was maintained at 55 °C, the pH value is 12.3, the co-current time is 23h, and the aging time is 20h. After pressing, washing, and drying at 120°C for 5 hours, D 50 It is a 4.0μm nickel-manganese hydroxide precursor containing dopant Ce. The precursor is a spherical or quasi-spherical single particle with a l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com