Preparation method of lithium iron phosphate positive electrode material, positive electrode material and battery

A technology for lithium iron phosphate and positive electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of limited raw material sources and high production costs, achieve uniform coating effect, improve conductivity, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

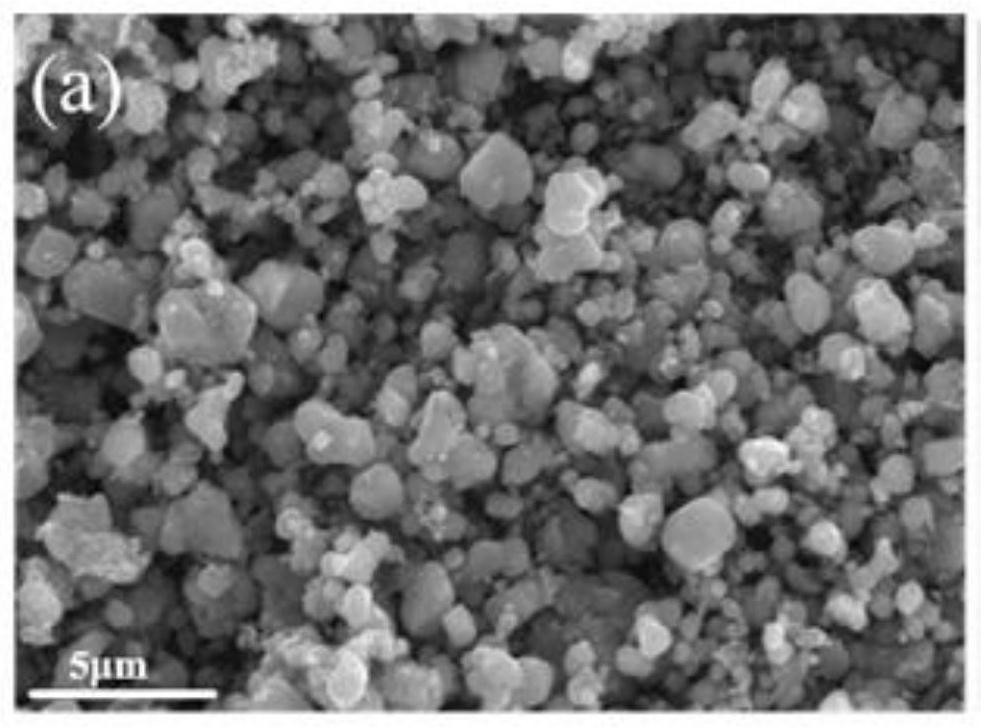

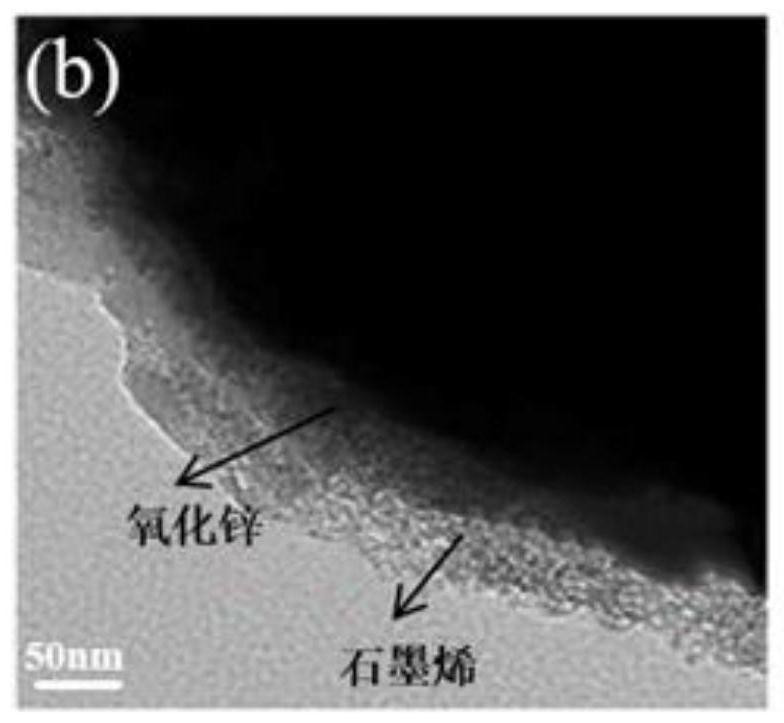

[0062] The invention provides a method for preparing a lithium iron phosphate positive electrode material. The preparation method is a method for preparing a lithium iron phosphate positive electrode material with nano-zinc oxide and graphene double coating layers sequentially from the inside to the outside by comprehensively utilizing blast furnace ash. The method specifically includes the following steps:

[0063] (1) Concentrate and tailings are obtained by crushing, screening and flotation of blast furnace ash; the concentrate produced by flotation is carbon powder, and the tailings are the part mainly containing iron and zinc elements.

[0064] (2) Activated carbon powder is obtained: the concentrate obtained in step (1) is treated with an active agent to obtain activated carbon powder; specifically, the following method is adopted: the concentrate obtained by step (1) flotation is immersed in the active agent Stir for 60-120 minutes, the mass ratio of active agent to con...

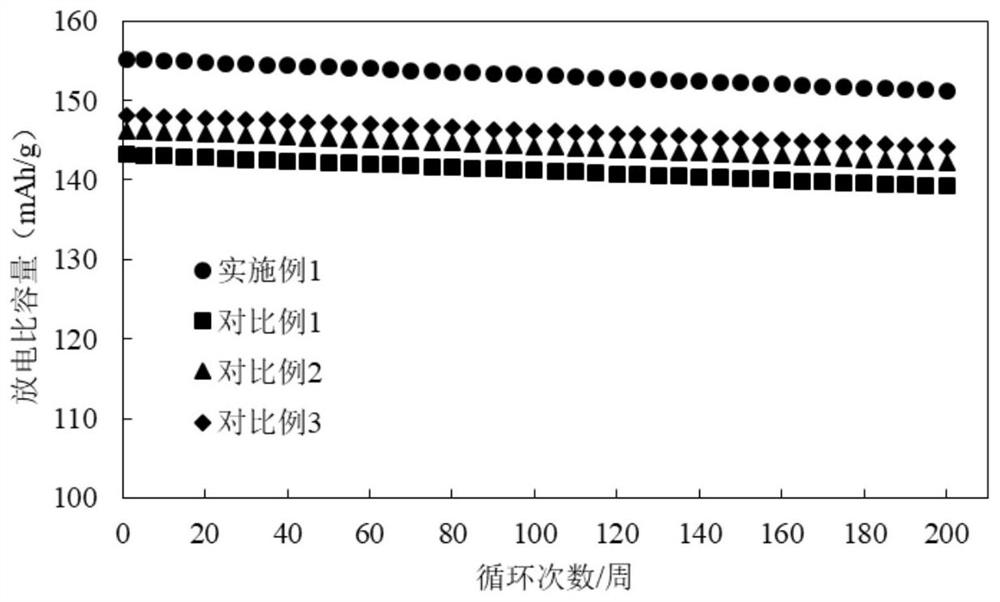

Embodiment 1

[0083] This embodiment provides a method for preparing a lithium iron phosphate positive electrode material, comprising the following steps:

[0084] (1) The crushed and screened blast furnace ash is directly subjected to flotation to obtain concentrates and tailings; the concentrates obtained from flotation are carbon powder, and the tailings mainly contain iron and zinc elements.

[0085] (2) Preparation of activated carbon powder: Stir the flotation concentrate and phosphoric acid for 60 minutes according to the mass ratio of 1:1, after filtering, heat in a vacuum oven at 400°C for 60 minutes, then wash and dry with deionized water, that is Get activated carbon powder.

[0086] (3) Zinc metal vapor and iron-containing raw materials are obtained: the tailings floated out in step (1) and the active carbon powder of step (2) are mixed in a mass ratio of 1:0.5, placed in a tube furnace, Reduction at 800°C for 60 minutes in an argon atmosphere, collecting the reduced zinc metal...

Embodiment 2

[0092] This embodiment provides a method for preparing a lithium iron phosphate positive electrode material, comprising the following steps:

[0093] (1) The crushed and screened blast furnace ash is directly subjected to flotation to obtain concentrates and tailings; the concentrates obtained from flotation are carbon powder, and the tailings mainly contain iron and zinc elements.

[0094] (2) Preparation of activated carbon powder: Stir the flotation concentrate and phosphoric acid for 100 minutes according to the mass ratio of 1:2, filter, heat in a vacuum oven at 450°C for 70 minutes, and then wash and dry with deionized water, that is Get activated carbon powder.

[0095] (3) Zinc metal vapor and iron-containing raw materials are obtained: the tailings in the step (1) and the active carbon powder of the step (2) are mixed in a mass ratio of 1:0.8, placed in a tube furnace, Reduction at 900°C for 100 min in an argon atmosphere, the reduced zinc metal vapor was collected, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com