Circuit board wet-lamination method and device

A technology of wet laminating film and circuit boards, which is applied in lamination devices, chemical instruments and methods, lamination auxiliary operations, etc. It can solve problems such as pits on the surface of circuit boards and low yields at scratches, and achieve coating water volume Stable and reliable, improved binding force, stable and reliable coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in combination with specific implementation examples.

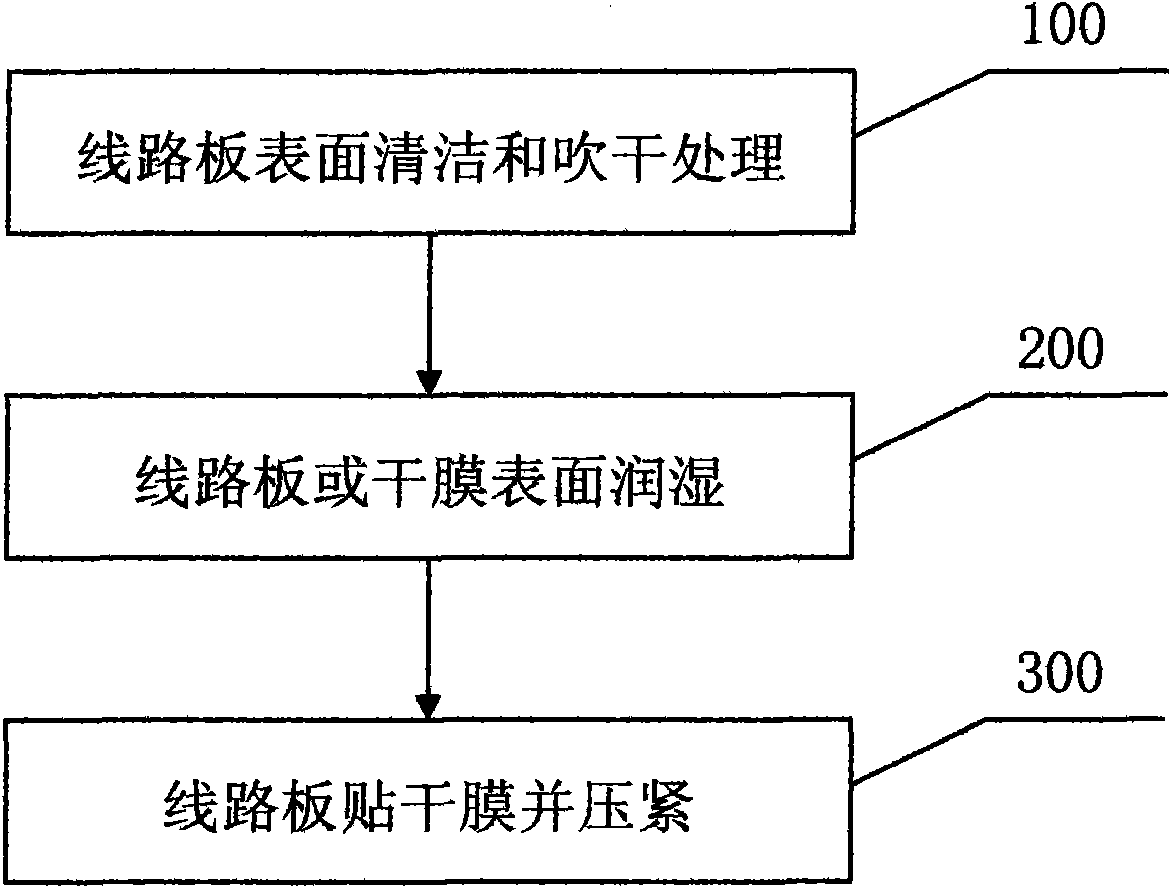

[0032] Such as figure 1 As shown, the specific embodiment of the present invention is: provide a kind of circuit board wet-process film sticking method, comprise the steps:

[0033]Step 100: Clean and dry the surface of the circuit board: first clean the surface of the circuit board. This cleaning process is usually composed of a series of processes, which include physical cleaning and chemical cleaning and subsequent washing cleaning. Physical cleaning The methods include grinding with nylon brush, grinding with nylon brush and volcanic ash, grinding with nylon brush and emery (that is, aluminum oxide), grinding with non-woven cloth, etc. After grinding, it needs to be cleaned with clean water; the method of chemical cleaning is to go through degreasing agent first After degreasing treatment, use ordinary micro-etching method or ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com