Automatic gluing device for ceramic tiles

A gluing device and automatic technology, which is applied to the surface coating liquid device, coating, construction, etc., can solve the problems of unstable construction quality, low construction efficiency, high labor cost, etc., to improve construction efficiency and construction quality , reduce labor intensity, reduce the effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

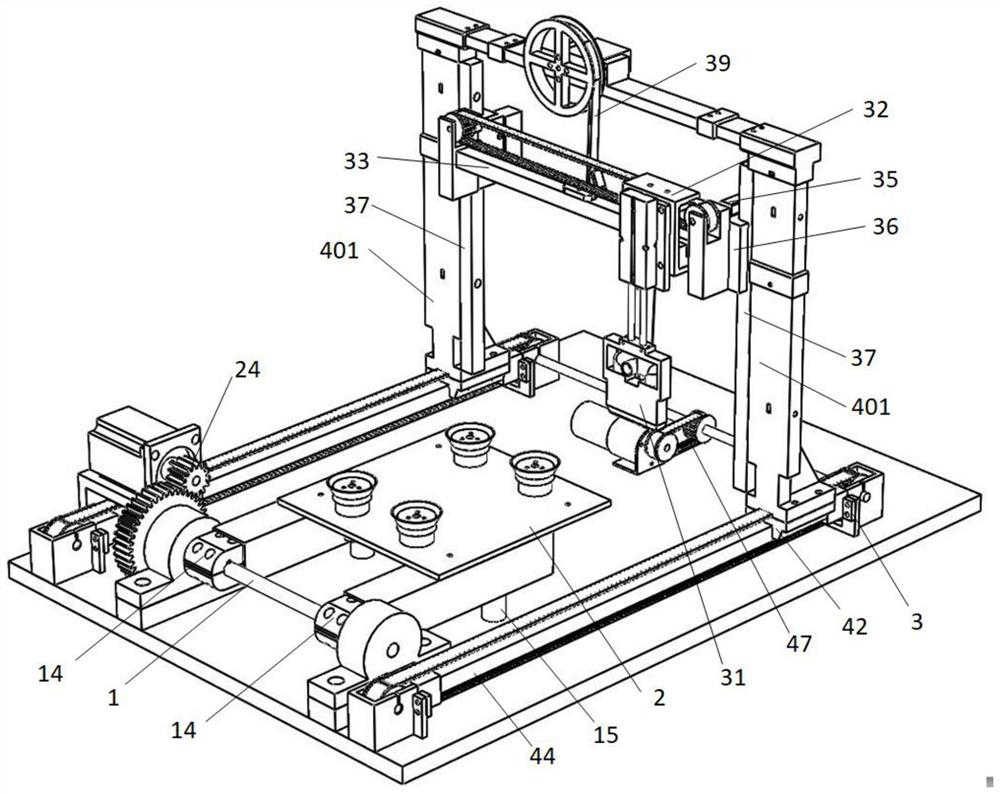

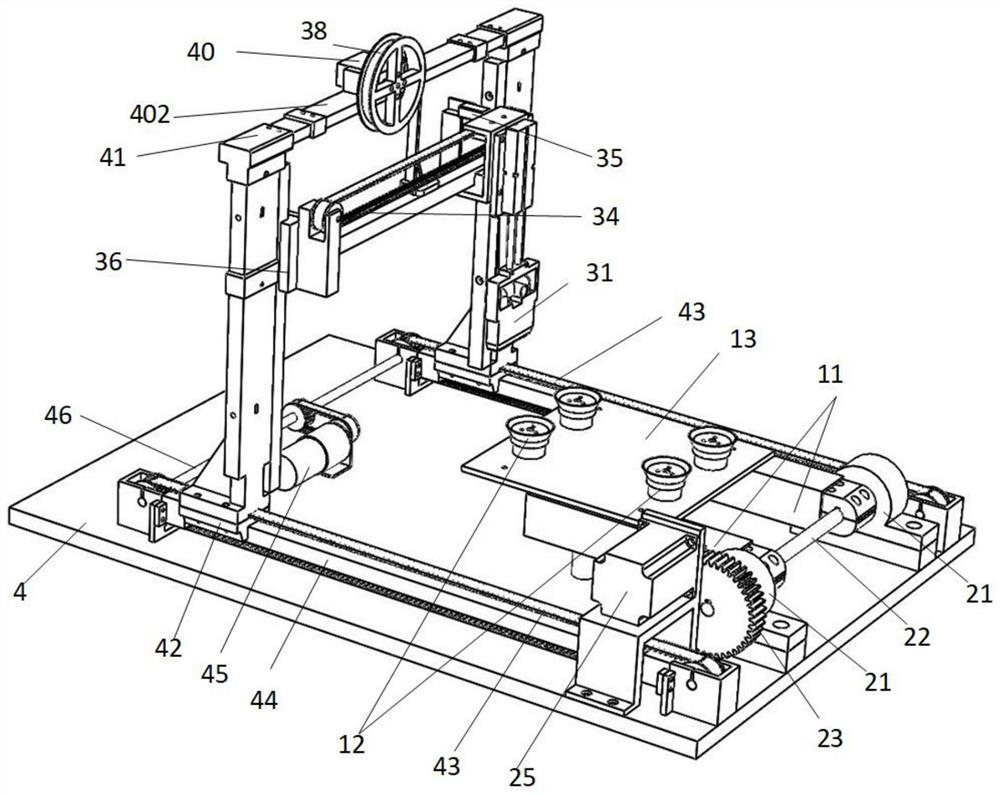

[0032] refer to Figure 1-3 , the present invention provides a technical solution, an automatic gluing device for ceramic tiles, including a pick-up part 1, a turning part 2, a gluing part 3 and a platform 4, the pick-up part 1 is used to pick up the tiles and fix them on the device , and then there is the turning part 2 to turn over the tiles, and then the gluing part 3 performs the gluing operation according to the set procedure, and the platform 4 plays a supporting role;

[0033] The turning part 2 comprises a bearing seat 21, a turning lever 22, a first turning gear 23, a second turning gear 24 and a turning motor 25, the bearing seat 21 is fixed on one end of the platform 4, and the two ends of the turning lever 22 are rotatably arranged in the bearing seat 21, One end of the overturning lever 22 is fixedly connected with the first overturning gear 23, the second overturning gear 24 is connected with the drive shaft of the overturning motor 25, the first overturning gear...

Embodiment 2

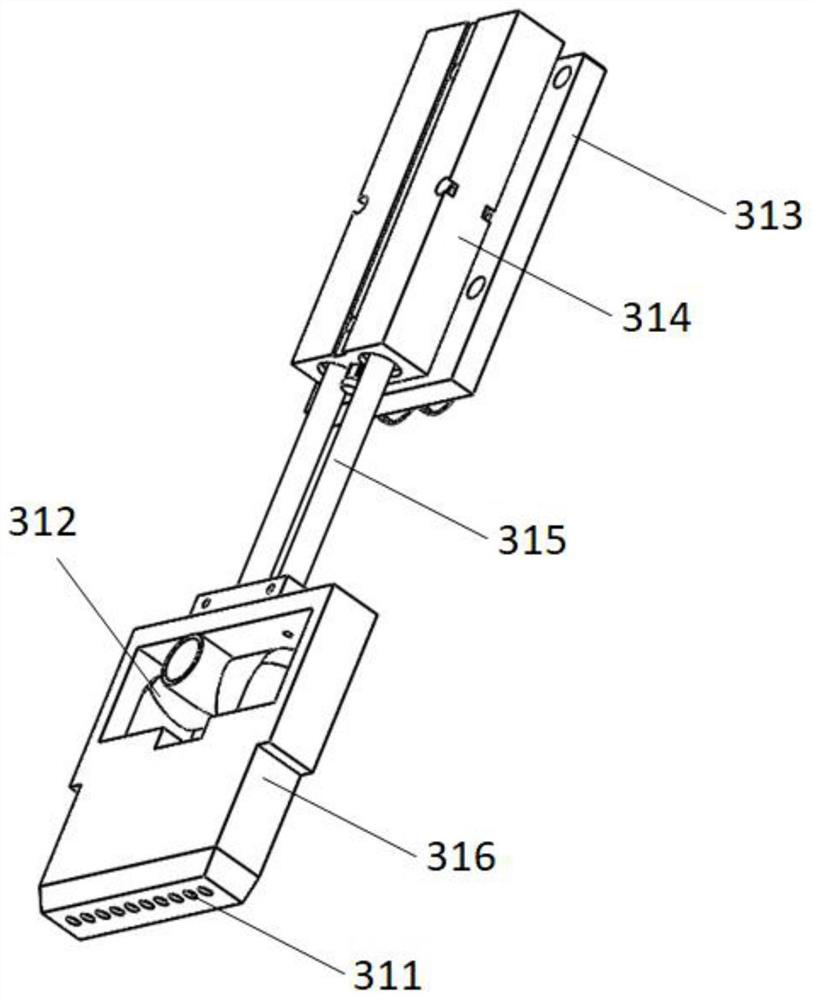

[0045] refer to Figure 1-4 , the present invention provides a technical solution. On the basis of Embodiment 1, the coating device 31 is connected with the splint 32 through the connecting plate 313, the connecting plate 313 is provided with a cylinder 314, and the bottom end of the piston rod 315 of the cylinder 314 is connected with a groove Body 316, the bottom of the tank body 316 is provided with several glue outlets 311, one end of the glue delivery pipe 312 extends into the tank body 316 to communicate with the glue outlet 311, and the other end is connected to the tile adhesive supply device, the bottom side wall of the tank body 316 A spring hinge 317 is installed, and a clockwork spring box 318 is arranged at the bottom end of the connecting plate 313. The spring hinge 317 is connected with the cover plate 319, and the cover plate 318 is connected with the clockwork spring box 318 by a wire rope 320.

[0046] The tile adhesive will solidify when it is exposed to the...

Embodiment 3

[0048] refer to Figure 1-5 , the present invention provides a technical solution, the tile adhesive supply device is a rubber barrel 5, the glue delivery pipeline 312 is externally connected to the glue outlet 51 of the glue barrel 5, and the glue barrel 5 is provided with a safety valve 52, a pressure regulating valve 53 and a pressure relief valve 54. There is a heating coil inside the rubber bucket 5, and the rubber bucket 5 is connected with an air compressor. Setting the air compressor helps to adjust the coating pressure and improve the coating quality. The rubber bucket 5 is good for storing colloids, and the heating coil ensures The adhesive will not solidify within a certain period of time to ensure the quality of glue application. The safety valve 52, the pressure regulating valve 53 and the pressure relief valve 54 are used to adjust the pressure to ensure the safety of construction operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com