Vinyl chloride acrylonitrile copolymer fibre and glass fibre coading core yarn and jet spinning processing method thereof

A technology of acrylic fiber and glass fiber, which is applied in the direction of yarn, spinning machine, textile and paper making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

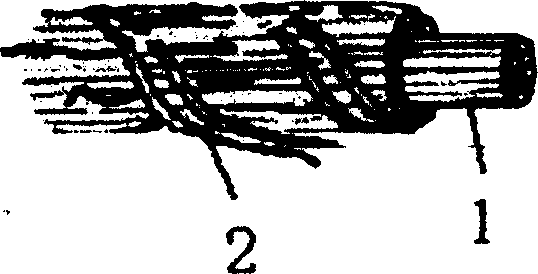

[0011] Product Specifications: 21 S Core-spun yarn, acrylic fiber + 90D glass fiber filament core-spun yarn, the blending ratio is 65% acrylic fiber and 35% glass fiber filament. It is a yarn for knitting and weaving, and can be used for large circular knitting machines. Mattress covering fabric, etc.

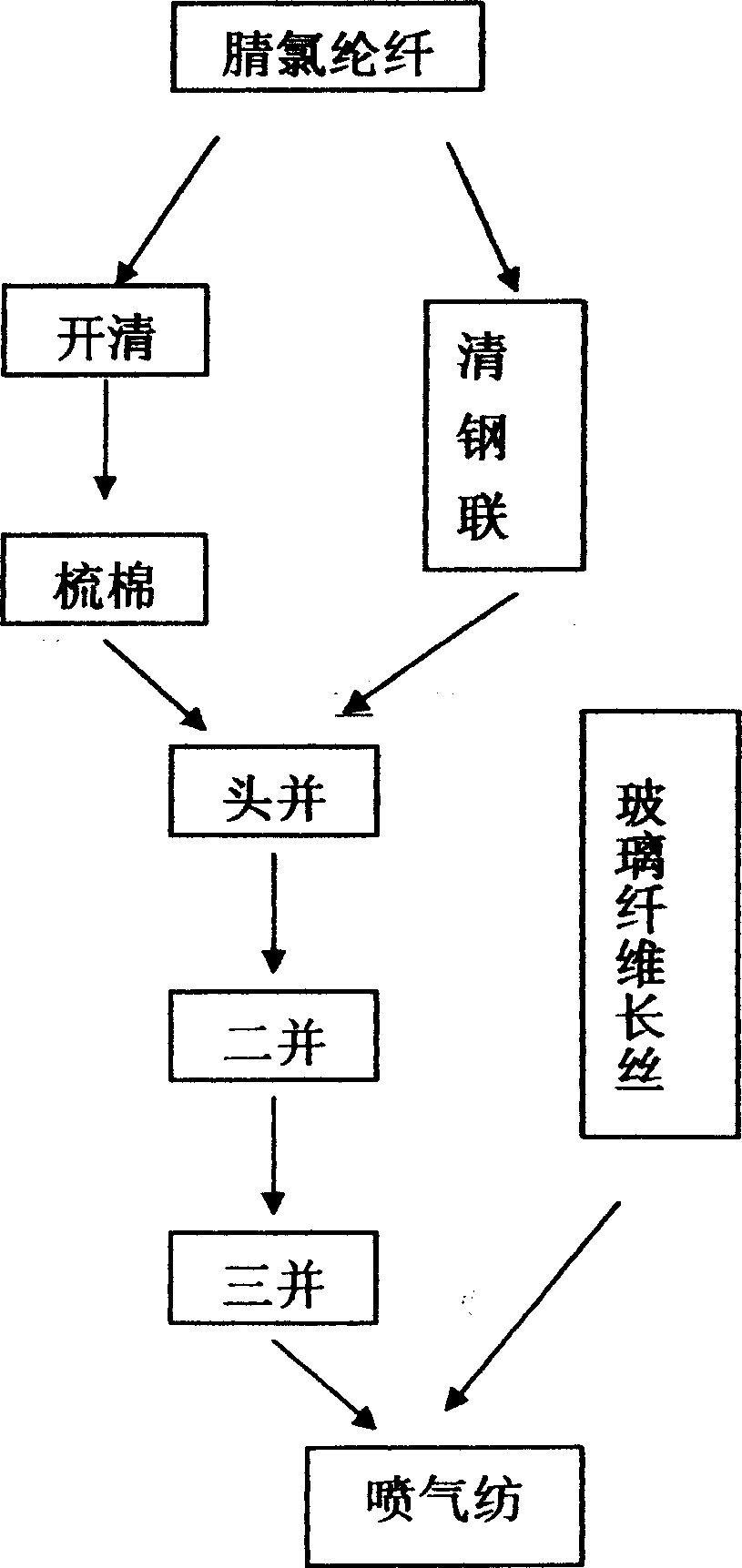

[0012] The production process is as follows: figure 2 As shown, the acrylic fiber is packaged separately, and after opening and cleaning (A200 type grabbing machine—→A006B cotton box mixing machine—→A036 type cotton opener—→A092A cotton box feeding machine—→A076C type single beater Coiling machine)—→A186D carding machine—→A272 type drawing frame head paralleling—→A272 type drawing frame two paralleling—→A272 type drawing frame three paralleling, making sliver separately, the weight of the sliver is 2.8g / m; then feed the acrylic fiber slivers and glass fiber filaments into the same nozzle of MURATEC NO.802HR air-jet spinning equipment. The process parameters of the air-jet ...

Embodiment 2

[0014] Product Specifications: 11 S Core-spun yarn, acrylic fiber + 198D glass fiber filament core-spun yarn, the blending ratio is 60% acrylic fiber and 40% glass fiber filament; used for woven fabrics, home decoration curtains, etc.

[0015] The production process is as follows: figure 2 As shown, the acrylic fiber is packaged separately, and after opening and cleaning (A200 type grabbing machine—→A006B cotton box mixing machine—→A036 type cotton opener—→A092A type cotton box feeding machine—→A076C type Single hand coiling machine)—→A186D carding machine—→A272 type draw frame head parallel—→A272 type draw frame two parallel—→A272 type draw frame three parallel, separately made sliver, the sliver quantitative is 3.5 g / m; Then feed the acrylic fiber slivers and glass fiber filaments into the same nozzle of MURATEC NO.802HR air-jet spinning equipment. The process parameters of the air-jet spinning equipment are: the first nozzle pressure N1=0.40MPA; the second nozzle pressur...

Embodiment 3

[0017] Product Specifications: 28 S Core-spun yarn, acrylic fiber + 50D glass fiber filament core-spun yarn, the blending ratio is 74% acrylic fiber and 26% glass fiber filament, used for woven fabrics, home decoration covers, sofa bottoms cloth etc.

[0018] The production process is as follows: figure 2 As shown, the acrylic fiber is packaged separately, and is combined by Qingganglian (A006C—→TF30—→FA103—→FA028A—→FA111A—→FA151—→ZFA177A—→FA221B)—→FA311 drawing frame head—→ FA311 type drawing frame two paralleling—→FA311 type drawing frame three paralleling, separately make acrylic fiber slivers, the weight of the sliver is 2.1g / m; then feed the acrylic fiber slivers and glass fiber filaments together In the same nozzle of MURATEC NO.802HR air-jet spinning equipment. The process parameters of the air-jet spinning equipment are: the first nozzle pressure N1=0.37MPA; the second nozzle pressure N2=0.50MPA; the feeding ratio from the first delivery roller to the front roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com