Air-jet spinning processing method for modacrylic fiber and glass fiber core-spun yarn

A technology of acrylic fiber and glass fiber, which is applied in the field of cotton spinning engineering. It can solve the problems of hard fabric, insufficient comfort for users, and uncomfortable wearing, etc., and achieve the effect of enhanced softness, increased tensile strength, and soft fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

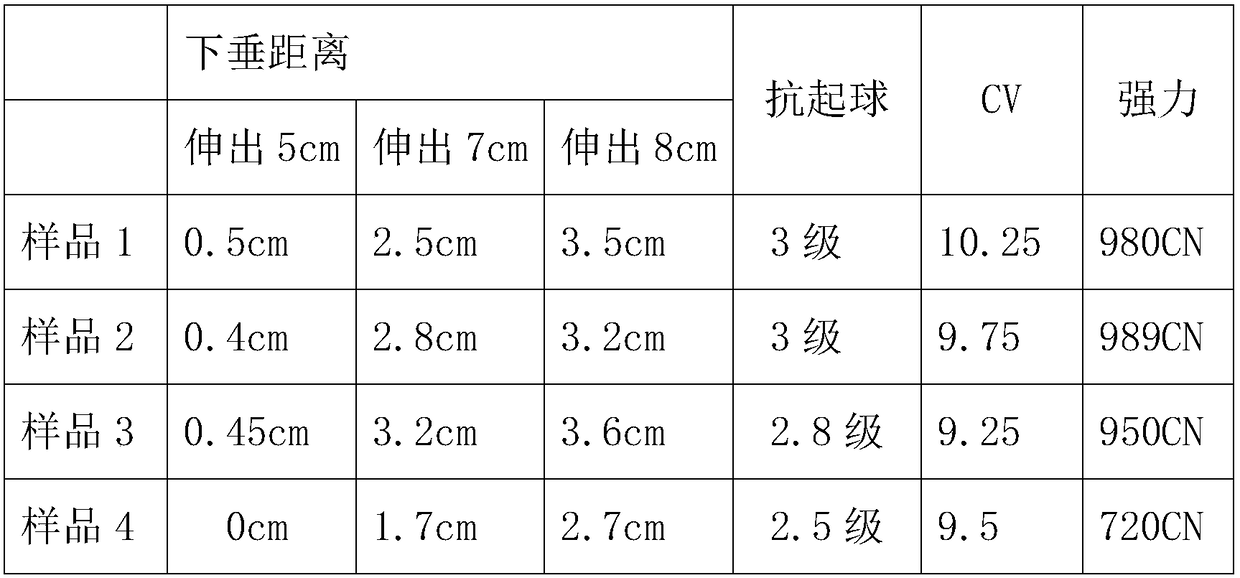

Embodiment 1

[0010] Product specifications: 21 counts core-spun yarn, acrylic fiber + 100D glass fiber filament core-spun yarn, the blending ratio is 60% acrylic fiber and 40% glass fiber filament, used for knitting and weaving.

[0011] The production process is as follows: the acrylic fiber is individually packaged, and after opening and cleaning (A200 type grabbing machine → A006B cotton box mixing machine → A036 type cotton opener → A092A type cotton box feeding machine → A076C type single beater hand roll Machine) → A186D carding machine → A272 type draw frame head parallel → A272 type draw frame two parallel → A272 type draw frame three parallel, make sliver separately, the sliver quantitative is 3.06g / m; The fiber slivers and fiberglass filaments are fed into the same nozzle of MURATEC NO.802HR air-jet spinning equipment. The process parameters are: the first nozzle pressure is N1=0.23MPA; the second nozzle pressure is N2=0.42MPA; the feeding ratio of the first output roller to the ...

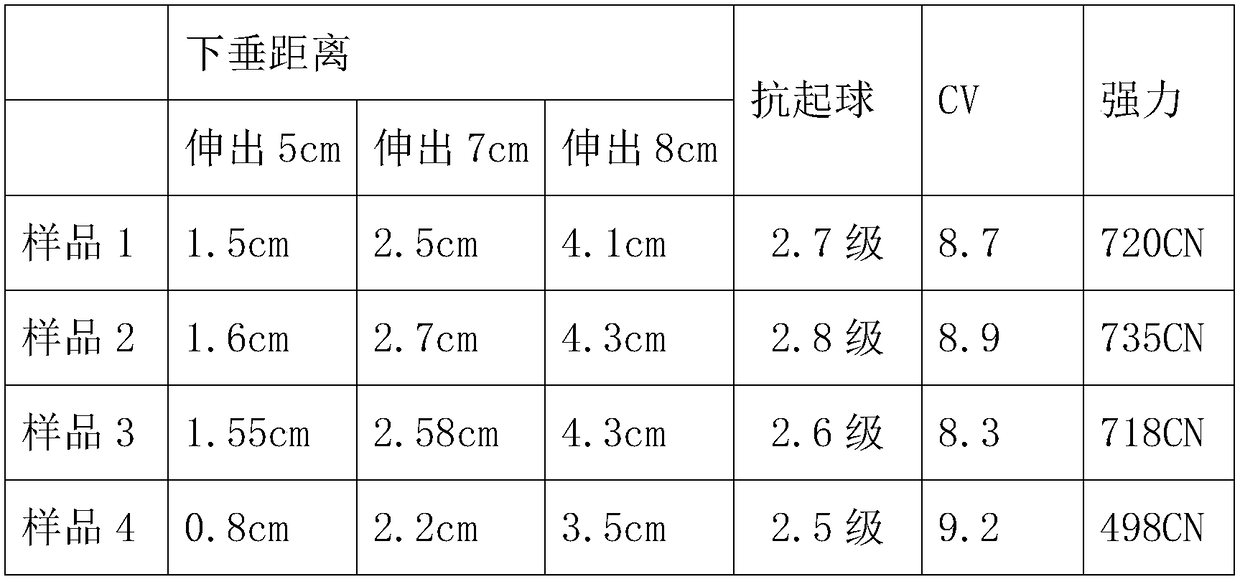

Embodiment 2

[0013] Product specifications: 11 core-spun yarns, acrylic fiber + 198D glass fiber filament core-spun yarn, the blending ratio is 60% acrylic fiber and 40% glass fiber filament; used for woven fabrics.

[0014] The process is as follows: pack the acrylic fiber separately, after opening and cleaning (A200 type grabbing machine → A006B cotton box blending machine → A036 type cotton opener → A092A type cotton box feeding machine → A076C type single beater lapping machine )→A186D carding machine→A272 type drawing frame head paralleling→A272 type drawing frame two paralleling→A272 type drawing frame three paralleling, make slivers separately, the sliver weight is 5g / m; then the acrylic fiber Sliver and glass fiber filaments are fed into the same nozzle of MURATEC NO.802HR air-jet spinning equipment. The process parameters are: the first nozzle pressure is N1=0.35MPA; the second nozzle pressure is N2=0.45MPA; the feeding ratio of the first output roller to the front roller is 0.98;...

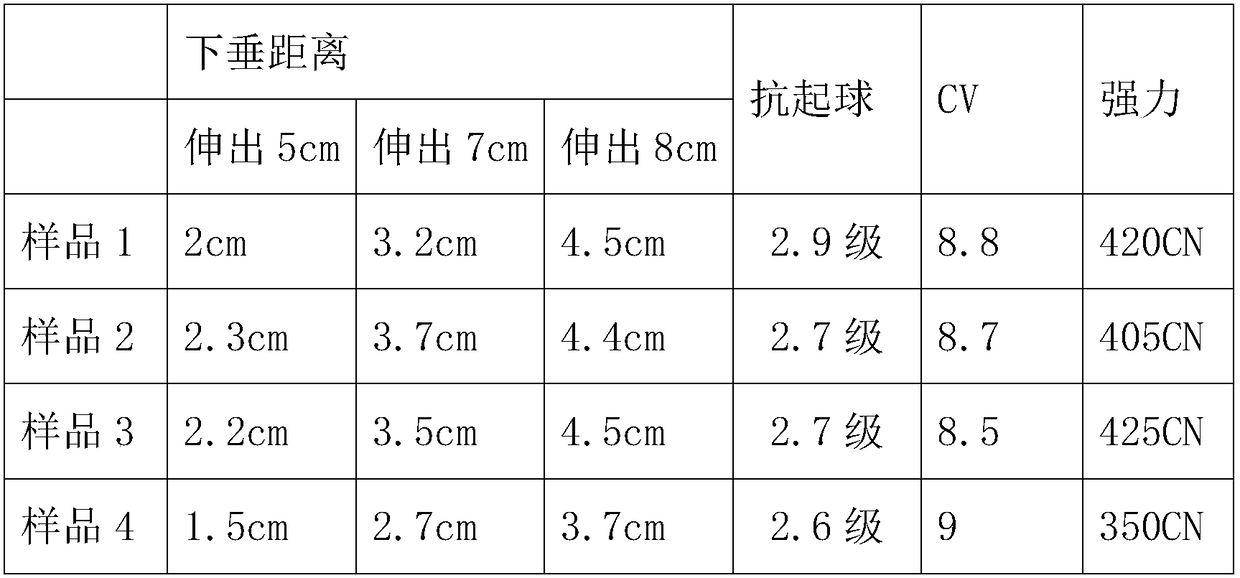

Embodiment 3

[0016] Product specifications: 32 core-spun yarns, acrylic fiber + 66D glass fiber filament core-spun yarn, the blending ratio is 60% acrylic fiber and 40% glass fiber filament, used for woven fabrics.

[0017] The process is as follows: pack the acrylic fiber separately, after opening and cleaning (A200 type grabbing machine → A006B cotton box blending machine → A036 type cotton opener → A092A type cotton box feeding machine → A076C type single beater lapping machine )→A186D carding machine→A272 type drawing frame head paralleling→A272 type drawing frame two paralleling→A272 type drawing frame three paralleling, make sliver separately, the sliver weight is 2.7g / m; Fiber slivers and glass fiber filaments are fed into the same nozzle of MURATEC NO.802HR air-jet spinning equipment. The process parameters are: the first nozzle pressure is N1=0.20MPA; the second nozzle pressure is N2=0.4MPA; the feeding ratio of the first output roller to the front roller is 0.98; the winding of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com