Carbon coated metal doped lithium titanate composite material as well as preparation and application thereof

A composite material and metal doping technology, which is applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of severe microwave reaction, poor coating uniformity, and difficult control of the process, and achieve good electrochemical performance. The effect of performance, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

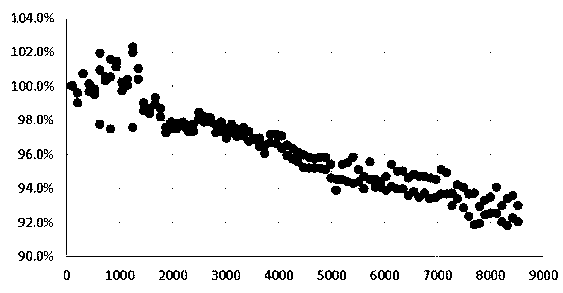

Image

Examples

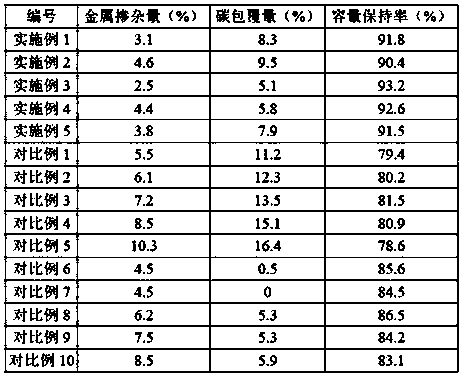

Embodiment 1

[0035] The preparation method of the carbon-coated metal-doped lithium titanate composite material in this embodiment comprises the following steps:

[0036] S01, preparation of precursor: add lithium hydroxide and tetrabutyl titanate to absolute ethanol (the molar ratio of lithium ions to titanium ions is 0.82:1), and stir at 1200r / min for 30min to form a colorless transparent sol. Then add the ethanol solution of aluminum nitrate (the molar ratio of aluminum ions to lithium ions in the aluminum nitrate ethanol solution is 0.2:1), continue stirring, and then add sodium hydroxide solution (the pH value of the sodium hydroxide solution is 13), and the mixed solution Adjust the pH value to 10 and let it stand still to obtain a precipitate, which is filtered, washed, and dried to obtain a precursor;

[0037] S02, carbon-coated precursor: add the precursor prepared in S01 to the solvent, add glucose, adjust the reaction temperature to 95°C, stir at 300r / min for 30min, then let it ...

Embodiment 2

[0041] The preparation method of the carbon-coated metal-doped lithium titanate composite material in this embodiment comprises the following steps:

[0042] S01, preparation of precursor: add lithium hydroxide and tetrabutyl titanate into pure water (the molar ratio of lithium ions to titanium ions is 0.82:1), stir at 1200r / min for 30min to form a white suspension, and then add Ethanol solution of ferric nitrate (the molar ratio of iron ions to lithium ions in the ferric nitrate ethanol solution is 0.3:1), continue to stir, and then add sodium hydroxide solution (pH value of sodium hydroxide solution is 13), adjust the pH value of the mixed solution After standing still for 8 days, a precipitate was obtained, and the precipitate was filtered, washed, and dried to obtain a precursor;

[0043] S02, carbon-coated precursor: add the precursor prepared in S01 to the solvent, add polyvinyl alcohol, adjust the reaction temperature to 100°C, stir at 300r / min for 30min, let stand, and...

Embodiment 3

[0047] The preparation method of the carbon-coated metal-doped lithium titanate composite material in this embodiment comprises the following steps:

[0048] S01, preparation of precursor: add lithium hydroxide and tetrabutyl titanate into absolute ethanol (the molar ratio of lithium ion to titanium ion is 0.84:1), stir at 1200r / min for 30min, and form a colorless transparent sol. Then add an aqueous solution of cerium nitrate (the molar ratio of cerium ions to lithium ions in the aqueous cerium nitrate solution is 0.2:1), continue stirring, and then add sodium hydroxide solution (the pH value of the sodium hydroxide solution is 13), and the pH value of the mixed solution Adjust to 12 and then stand still to obtain a precipitate, which is filtered, washed, and dried to obtain a precursor;

[0049] S02, carbon-coated precursor: add the precursor prepared in S01 to the solvent, add phenolic resin, adjust the reaction temperature to 100°C, stir at 300r / min for 30min, let stand, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com