Preparation method of anhydrous iron phosphate and preparation method of lithium iron phosphate carbon composite material

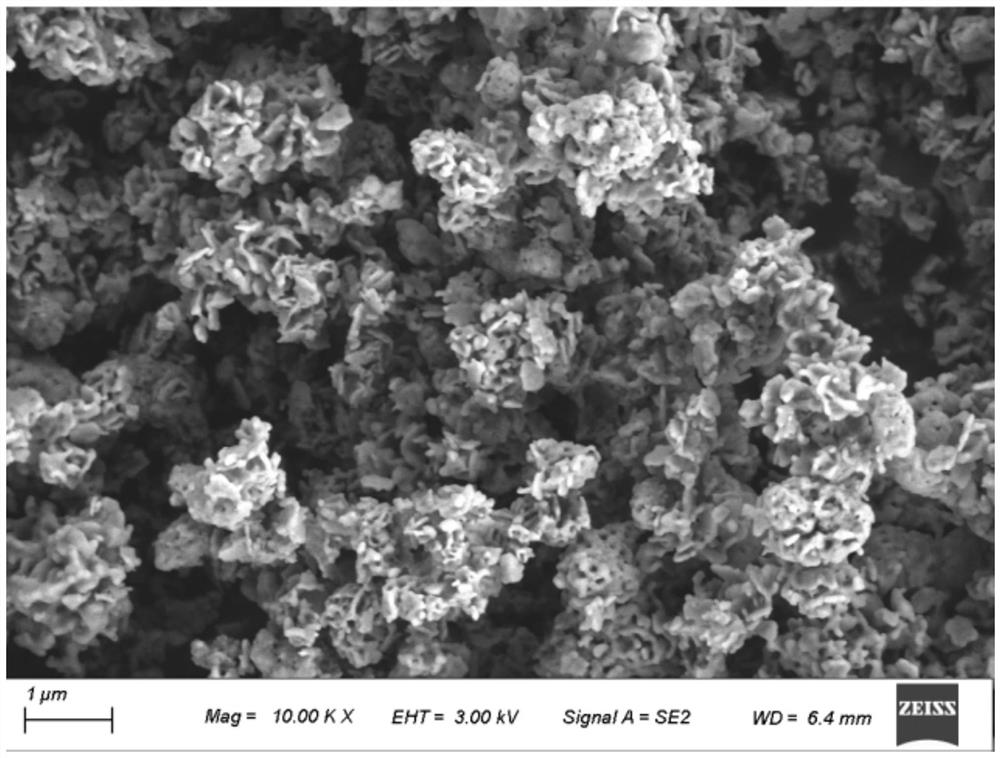

A technology of carbon composite materials and anhydrous phosphoric acid, applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of large primary particles, unclear primary particle boundaries, unfavorable processing of lithium iron phosphate, etc., to achieve optimized crystal The degree of melting, good coating effect, and the effect of reducing sanding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment provides a preparation method of anhydrous iron phosphate, comprising the following steps:

[0042] 1) At normal temperature, dissolving the titanium dioxide by-product in deionized water and diluting, removing impurities, filtering, removing the filter cake, leaving the clear liquid, and configuring the iron ion concentration to be 3%;

[0043] 2) Configure phosphate dripping solution: take 1mol iron as a reference, first dissolve APP (nitrogen-phosphorus binary compound fertilizer) in deionized water containing phosphoric acid for hydrolysis, pay attention to controlling the water temperature at 30 °C, APP:phosphoric acid: go The ratio of ionized water is controlled within 4:1:50, PO4 3- :1mol;

[0044] 3) On the basis of step 2, add phosphoric acid, hydrogen peroxide again, add ammonia water after cooling, NH 3 The number of moles is in 1mol, H 2 O 2 The number of moles in 0.3mol. NH 4 + with PO 4 3- The ratio of phosphate solution is ...

Embodiment 2

[0049] The present embodiment provides a preparation method of anhydrous iron phosphate, comprising the following steps:

[0050] 1) At normal temperature, the titanium dioxide by-product is dissolved in deionized water to dilute, remove impurities, filter, remove the filter cake, leave the clear liquid, and configure the iron ion concentration at 4%;

[0051] 2) Configure phosphate dripping solution: take 1mol iron as a reference, first dissolve APP (nitrogen-phosphorus binary compound fertilizer) in deionized water containing phosphoric acid for hydrolysis, pay attention to control the water temperature at 35°C, APP:phosphoric acid: go to The ratio of ionized water is controlled within 4:1:50, PO4 3- :1.2mol;

[0052] 3) On the basis of step 2, add phosphoric acid, hydrogen peroxide again, add ammonia water after cooling, NH 3 The number of moles is 1.5mol, H 2 O 2 The number of moles in 0.5mol, NH 4 + with PO 4 3- The ratio of phosphate solution is controlled within...

Embodiment 3

[0056] The present embodiment provides a preparation method of anhydrous iron phosphate, comprising the following steps:

[0057] 1) At normal temperature, the titanium dioxide by-product is dissolved in deionized water to dilute, remove impurities, filter, remove the filter cake, leave the clear liquid, and configure the iron ion concentration at 5%;

[0058] 2) Configure phosphate dripping solution: take 1mol iron as a reference, first dissolve APP (nitrogen-phosphorus binary compound fertilizer) in deionized water containing phosphoric acid for hydrolysis, pay attention to controlling the water temperature at 40 °C, APP:phosphoric acid: go The ratio of ionized water is controlled within 4:1:50, PO4 3- :1.5mol;

[0059] 3) On the basis of step 2, add phosphoric acid, hydrogen peroxide again, add ammonia water after cooling, NH 3 The number of moles is 2mol, H 2 O 2 The number of moles in 1mol. NH 4 + with PO 4 3- The ratio of phosphate solution is controlled within ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com