Multi-rotor frequency-changing sand mixer and sand mixing method

A sand mixer and multi-rotor technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

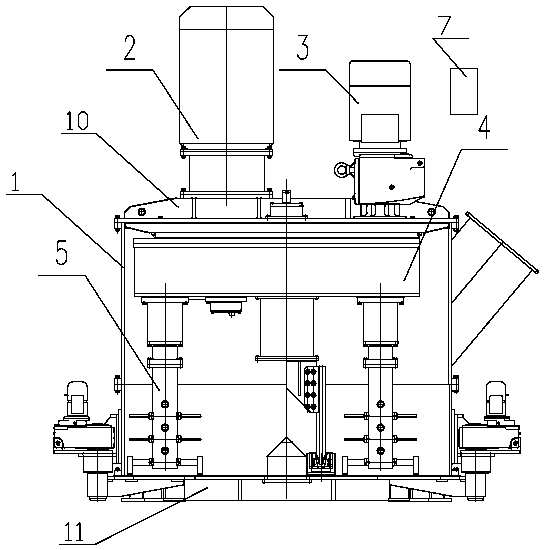

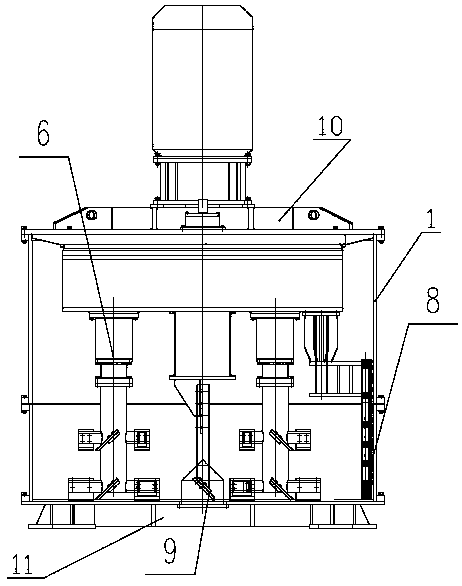

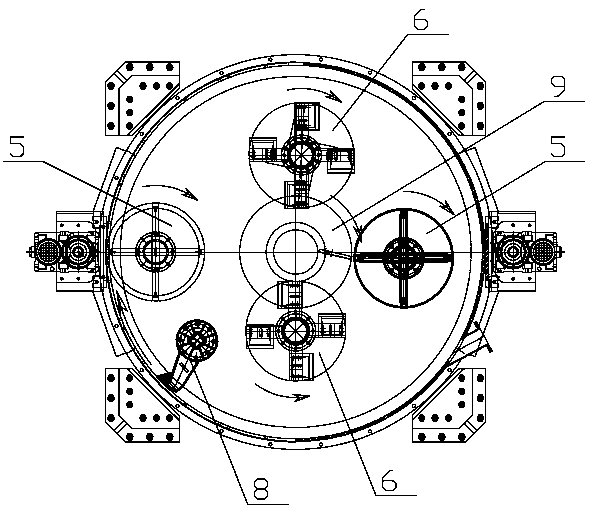

[0028] Such as Figure 1-3 As shown, a multi-rotor frequency conversion sand mixer includes a fixed top cover 10, a cylinder body 1 and a chassis 11, the top cover 10 is equipped with a main motor 2 and a rotary motor reducer 3, the main motor 2 and the gear box 4 The planetary gear set 4-1 in the transmission fits, and its innovative point is that in the barrel 1, two sets of rod rotor cutters 5 and two sets of scraper rotors are connected through the rotation of the planetary gear set 4-1 in the gearbox 4. The cutter 6 and the center scraper 9; the rotary motor reducer 3 drives the gear box 4 to rotate along the center of the cylinder body 1, and the wall scraper cutter 8 is fixedly connected to the gear box 4; the main motor 2 and the rotary motor reducer 3 are powered on A variable frequency controller 7 is connected.

[0029] Two sets of rod-type rotor cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com