Engine

An engine and fuel technology, applied in combustion engines, engine control, machines/engines, etc., to solve problems such as deterioration of exhaust emissions and deterioration of fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the accompanying drawings.

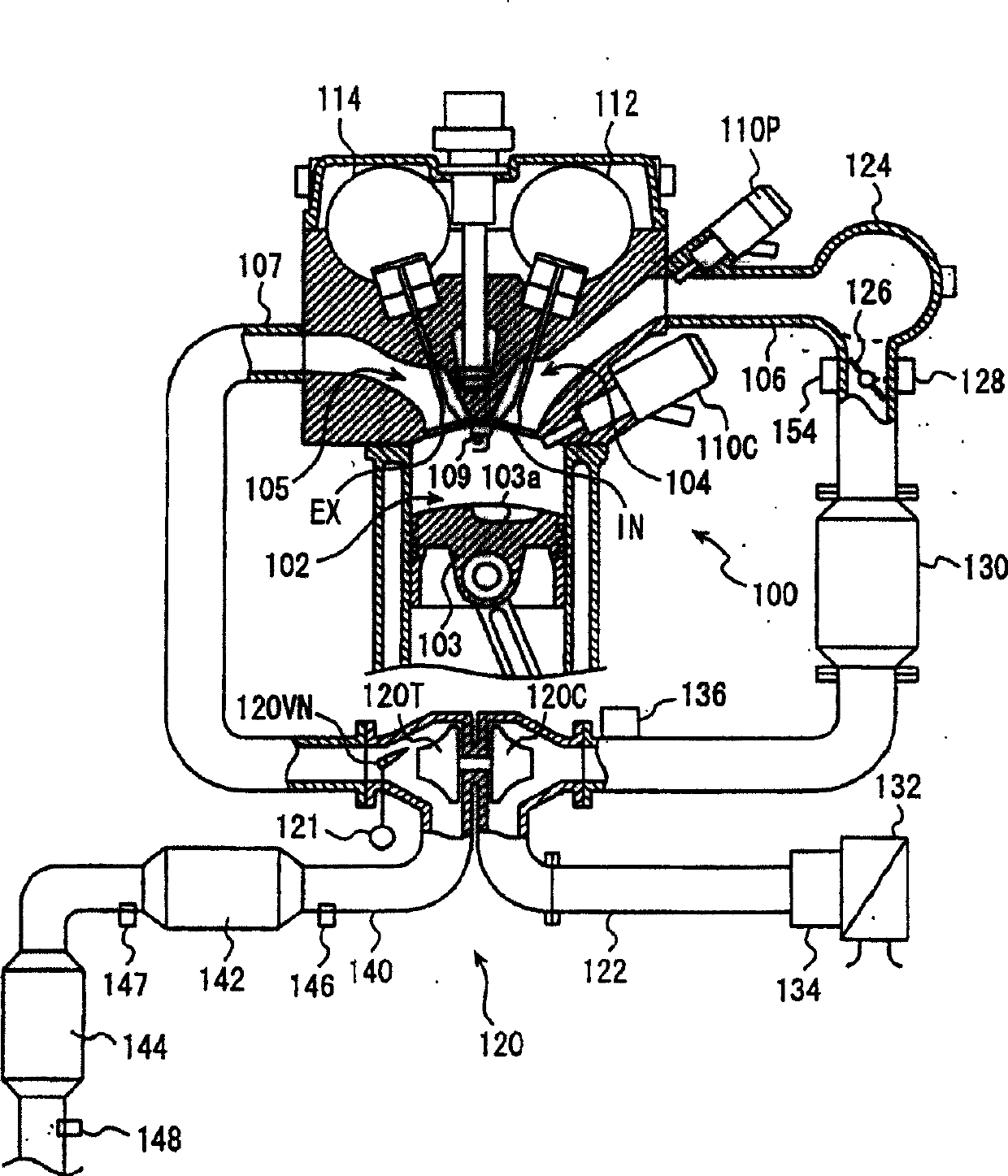

[0028] figure 1 A system structure is schematically shown, which roughly illustrates a lean-burn engine equipped with a supercharger, wherein the engine uses a turbocharger as a supercharger, and according to the first and second embodiments of the present invention applied to the system. figure 1 The illustrated engine 100 is configured as a multi-cylinder engine (eg, a four-cylinder engine, however figure 1 Only one cylinder is shown), an air-fuel mixture is combusted in each combustion chamber 102 to reciprocate a piston 103, thereby deriving power from a crankshaft (not shown). Note that the engine may not have a supercharger.

[0029] Each combustion chamber 102 of engine 100 communicates with an intake port 104 and an exhaust port 105 . An intake manifold 106 is connected to the intake port 104 . An exhaust manifold 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com