Special cladding titanium dioxide for ink and preparation method of titanium dioxide

A technology of titanium dioxide and special packaging, applied in the direction of ink, chemical instruments and methods, applications, etc., can solve the problems of easy air bubbles, easy yellowing, complicated steps, etc., achieve excellent wettability and fluidity, uniform coating effect, The effect of great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

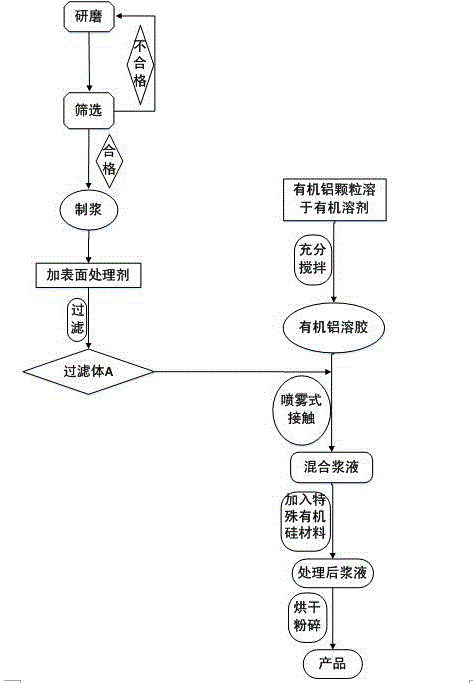

[0032] Such as figure 1 As shown, the present invention discloses a special coated titanium dioxide for ink and a preparation method thereof, comprising the following steps:

[0033] (1) TiO 2 Rutile TiO without surface coating treatment 2 Firstly, coarse titanium dioxide powder is ground, and the ground titanium dioxide is classified by screening, and the particles with a particle size larger than the predetermined particle size are returned to the coarse grinding device for regrinding, and the particles meeting the predetermined particle size are used as the base material. In the coating, the screened titanium dioxide particles are dissolved in an organic solvent to make slurry, the organic solvent is at least one of ethanol or propylene glycol, and the concentration of the titanium dioxide slurry is 200-400g / L.

[0034] As an embodiment of the present invention, the grinding, screening and pulping of the titanium dioxide are carried out at normal temperature and pressure,...

Embodiment 1

[0051] First, take 1Kg of qualified TiO after screening 2 , slurried in 4 L of propylene glycol, prepared containing TiO 2 organic solution;

[0052] Next, after fully stirring, the organic slurry is filtered to obtain filtered crystal A;

[0053] Next, put 1 mol of aluminum isopropoxide into 100 mL of ethanol at normal temperature and pressure to prepare an organoaluminum sol, and stir the ethanol at the same time during the process of adding aluminum isopropoxide, the stirring speed is 80 rpm, and the stirring time is 30min.

[0054] Next, the filtered crystal A was sprayed into the organoaluminum sol through a nozzle, and 50 g of the filtered crystal A was put into 1 L of the organoaluminum sol and stirred.

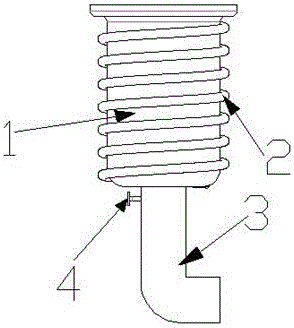

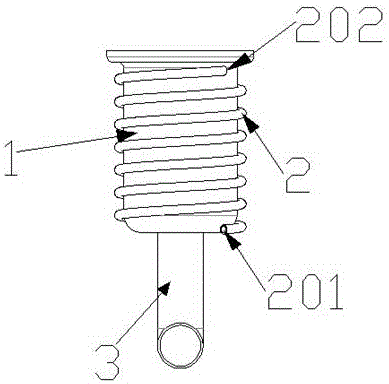

[0055] Then, dry the fully contacted titanium dioxide and organoaluminum sol in a drying device, pass water vapor / hot water into the vent pipe 2, and adjust the flow rate of water vapor / hot water through the control switch to make the container The temperature in t...

Embodiment 2

[0058] First, take 1Kg of qualified TiO after screening 2 , slurried in 4 L of propylene glycol, prepared containing TiO 2 organic solution;

[0059] Next, add 50 mL of a surface treatment agent that satisfies the volume ratio into the organic slurry, and stir thoroughly for 20 minutes;

[0060] Then, after fully stirring, the organic slurry is filtered to obtain the filtered crystal A;

[0061] Next, put 1 mol of aluminum isopropoxide into 100 mL of ethanol at normal temperature and pressure to prepare an organoaluminum sol, and stir the ethanol at the same time during the process of adding aluminum isopropoxide, the stirring speed is 80 rpm, and the stirring time is 30min.

[0062] Next, the filtered crystal A was sprayed into the organoaluminum sol through a nozzle, and 100 g of the filtered crystal A was put into 1 L of the organoaluminum sol and stirred.

[0063] Then, dry the fully contacted titanium dioxide and organoaluminum sol in a drying device, pass water vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com