Assembly device and operation method for reducing axial eccentricity of tensile test piece

A technology of assembly device and operation method, which is applied in the direction of connecting components, material gluing, mechanical equipment, etc., to achieve the effects of controlling uniformity, reducing axial eccentricity, and facilitating reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

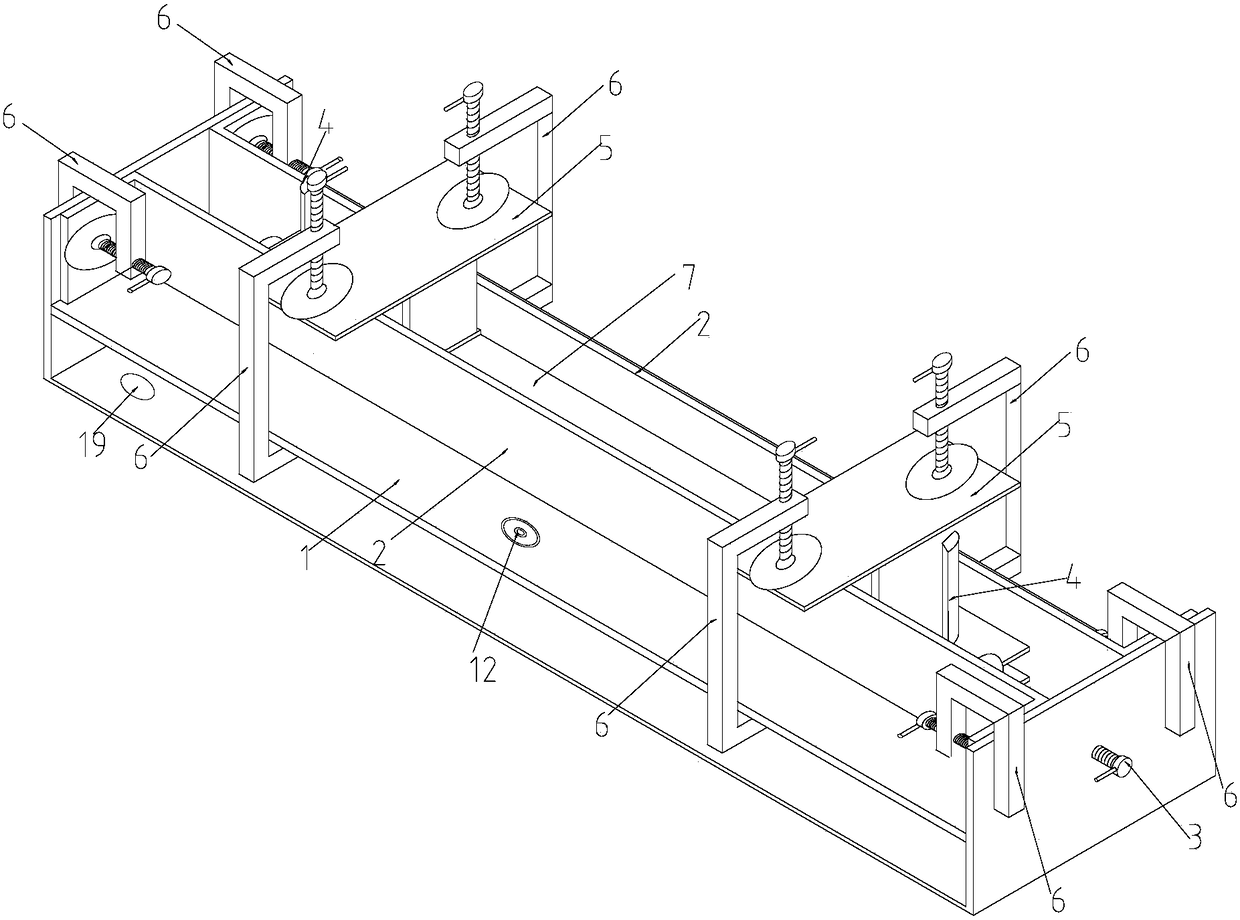

[0033] The present invention will be further described in detail below in conjunction with specific implementation methods and accompanying drawings.

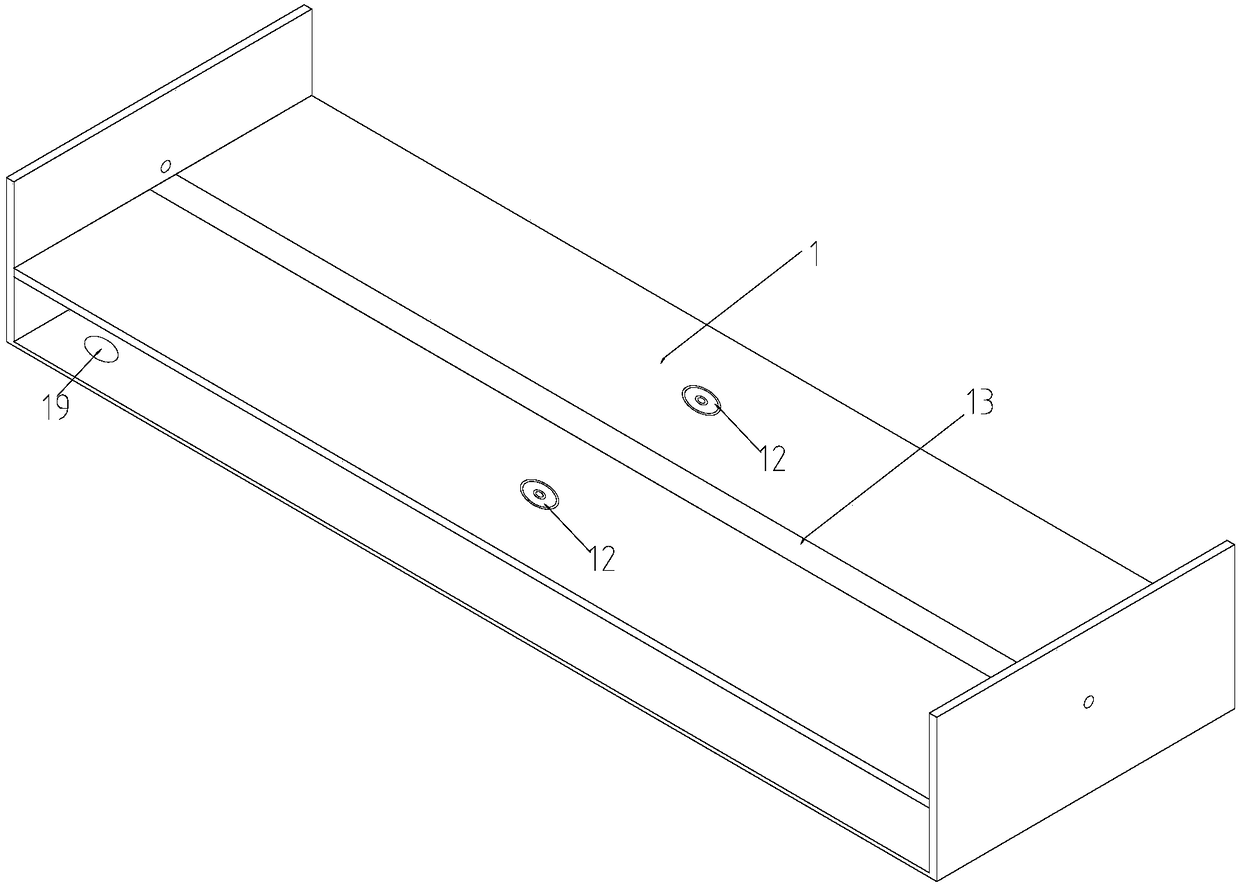

[0034] In the first step, use a brush to apply oil on the steel platform (1) for assembly of the test piece, and spread a layer of plastic film evenly to prevent the bonding material from overflowing when the steel sheet is pasted on the end of the pretreated test piece (7). Stick to the test piece assembly steel platform (1);

[0035] The second step is to place the test piece assembly steel platform (1) on a horizontal plane, adjust the adjusting screw rods (19) at the four corners of the supporting steel plate at the bottom of the test piece assembly steel platform (1), and observe the bubbles in the circular vial (12). position, to ensure that the specimen assembly steel platform (1) is in a horizontal position;

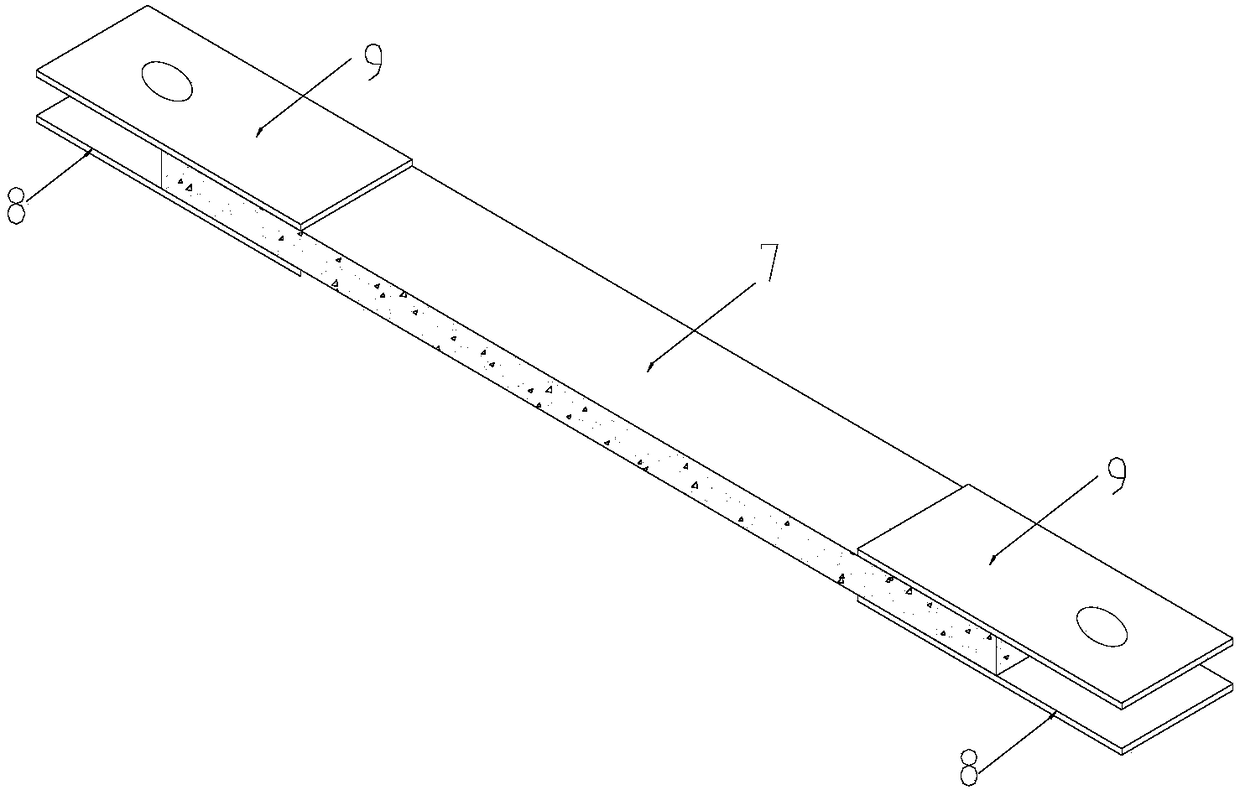

[0036] In the third step, the pretreatment test piece (7) is placed at the corresponding position of the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com