Ferrite attaching jig

A technology for combining fixtures and ferrite, which is applied in the field of ferrite lamination of flexible circuit boards, can solve the problems of poor ferrite rework, slow ferrite lamination speed, and partial lamination defects, so as to improve lamination efficiency and solve Poor sticking problem, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

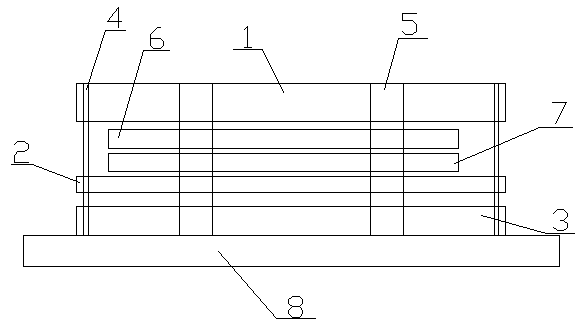

[0010] A ferrite bonding jig, comprising a cover plate 1, a take-off plate 2 and a bottom plate 3 arranged parallel to each other, the take-off plate 2 is arranged between the bottom plate 3 and the cover plate 1, and vertical The positioning pin 4 arranged, the middle part of the base plate 3 is provided with a positioning block 5, and the taking plate 2 and the cover plate 1 are respectively provided with a positioning hole I and a positioning hole II cooperating with the positioning pin 4 and the positioning block 5. The positioning pin 4 is inserted in the positioning hole I, and the positioning block 5 is inserted in the positioning hole II; the lower end of the bottom plate 3 is provided with a supporting plate 8 riveted therewith.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com