Adjustable adhesive tape pasting tool

An adjustable and glue-applying technology, which is applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problems of adhesive strip bonding bending, etc., and achieve the effect of good straightness of pasting, safe operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

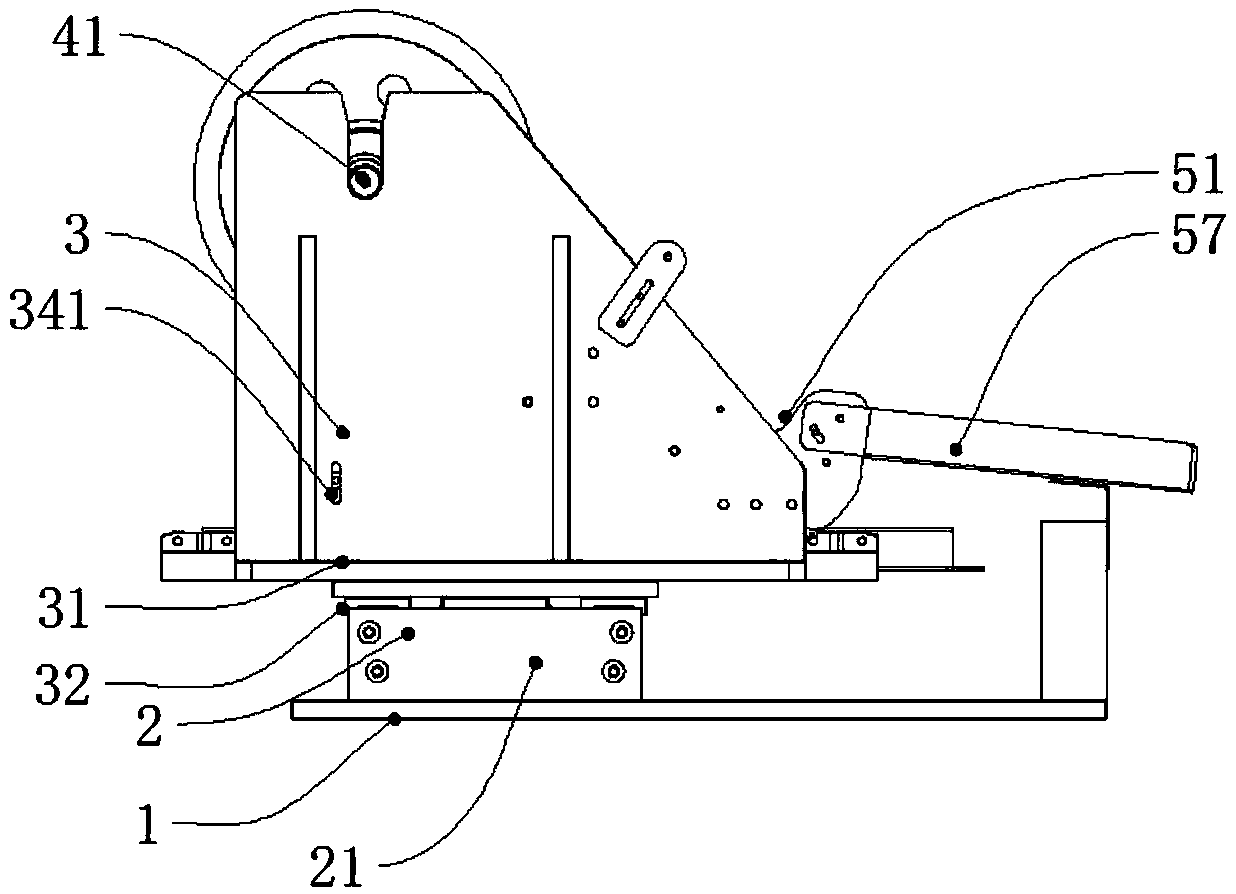

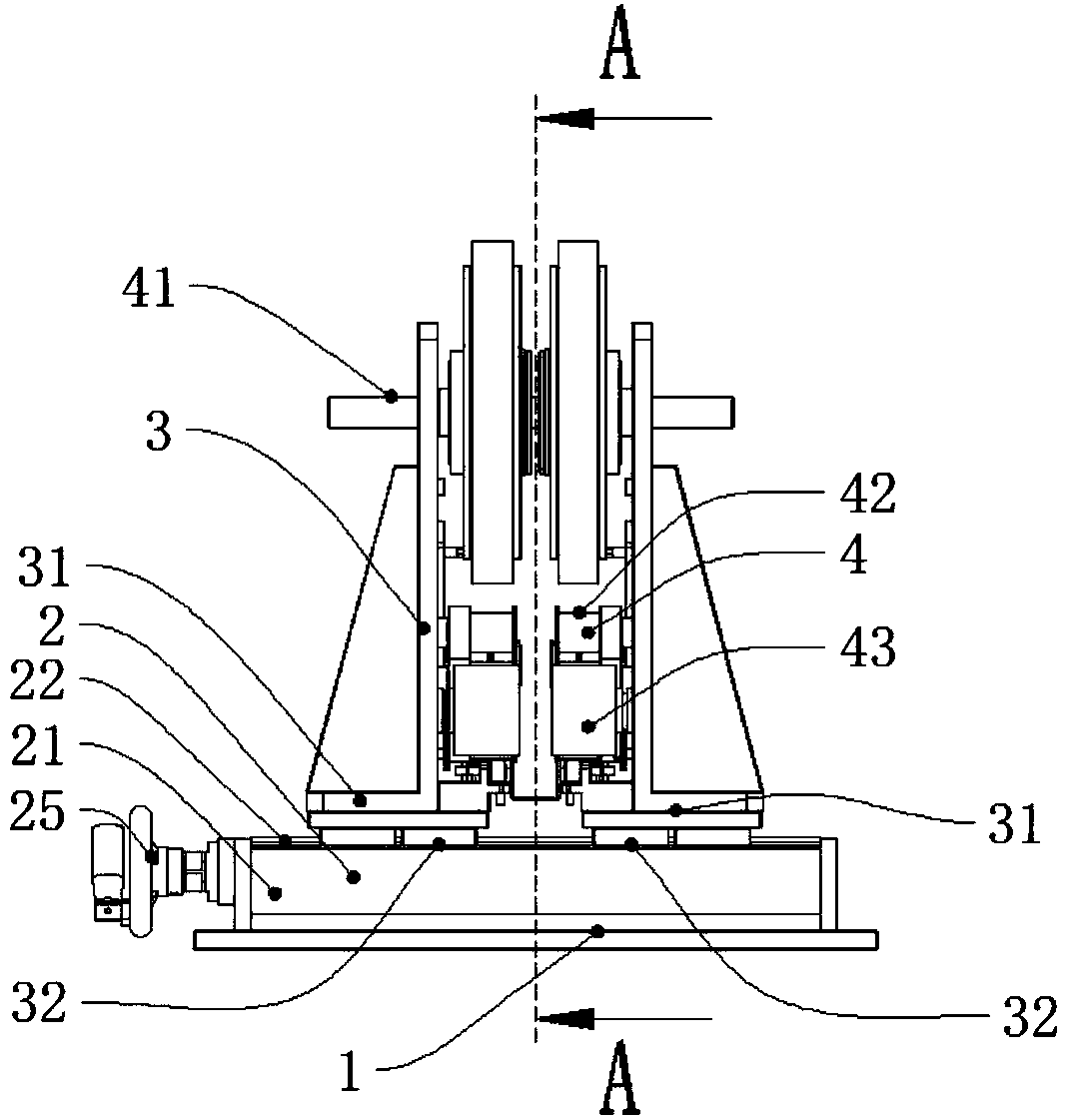

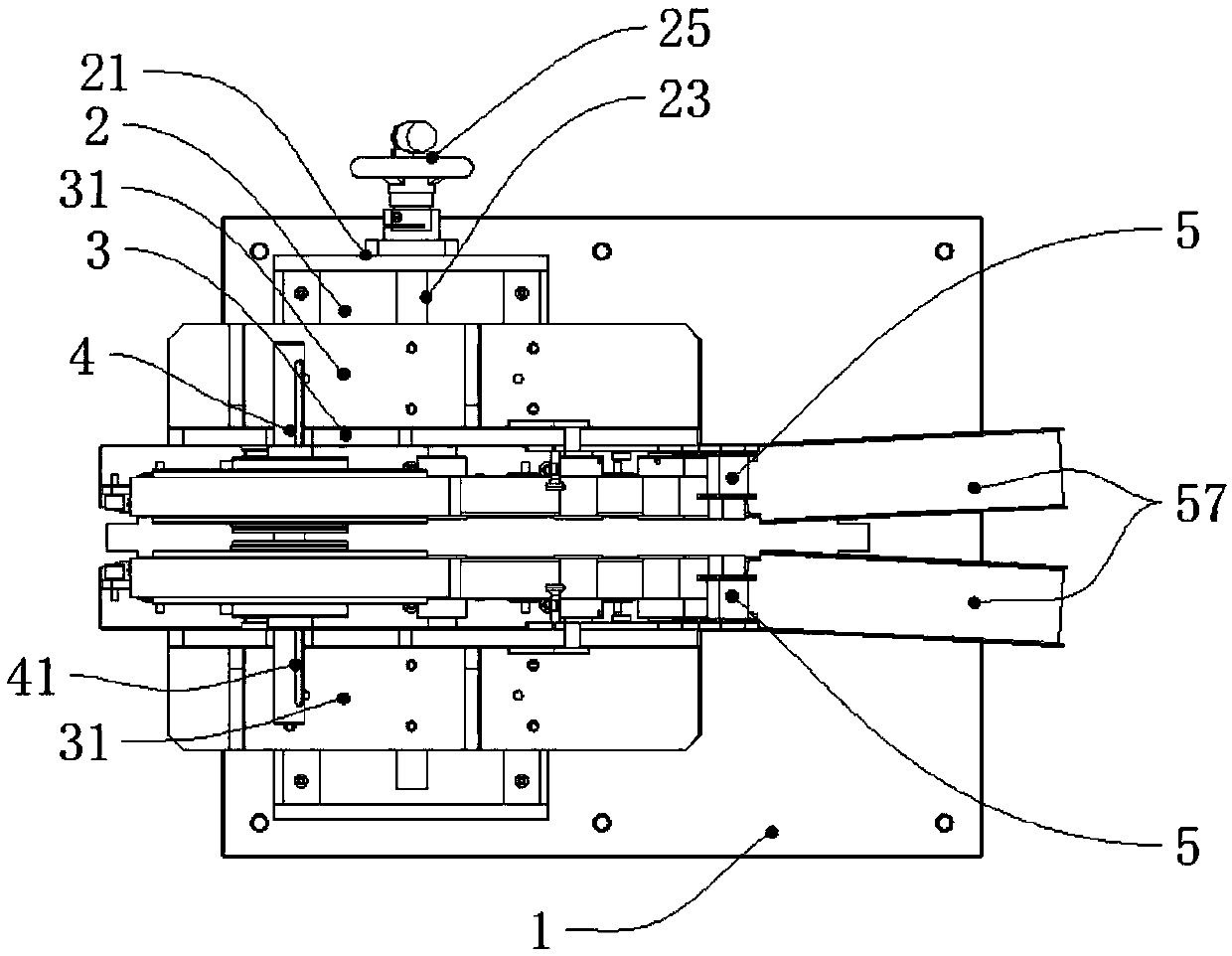

[0025] See Figure 1-5 , an adjustable glue application tool, which includes: a bottom plate 1, an adjustment mechanism 2, a vertical plate 3, a roller 4, a glue application roller mechanism 5, and a support rail 6;

[0026] The adjustment mechanism 2 is arranged on the bottom plate 1, and the adjustment mechanism 2 is provided with a vertical plate 3; the adjustment mechanism 2 can adjust the distance between the two vertical plates 3;

[0027] The adjustment mechanism 2 includes: a frame 21, a guide rail 22, a lead screw 23, a lead screw nut 24, and a handle 25;

[0028] The frame 21 is rectangular, and the lead screw 23 is installed on the frame 21;

[0029] The lead screw 23 is arranged parallel to the bottom plate, and the handle is mounted on the lead screw 23;

[0030] The two ends of the screw 23 are provided with threads with opposite directions of rotation;

[0031] Described leading screw nut 24 is installed on the leading screw 23;

[0032] A screw nut 24 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com