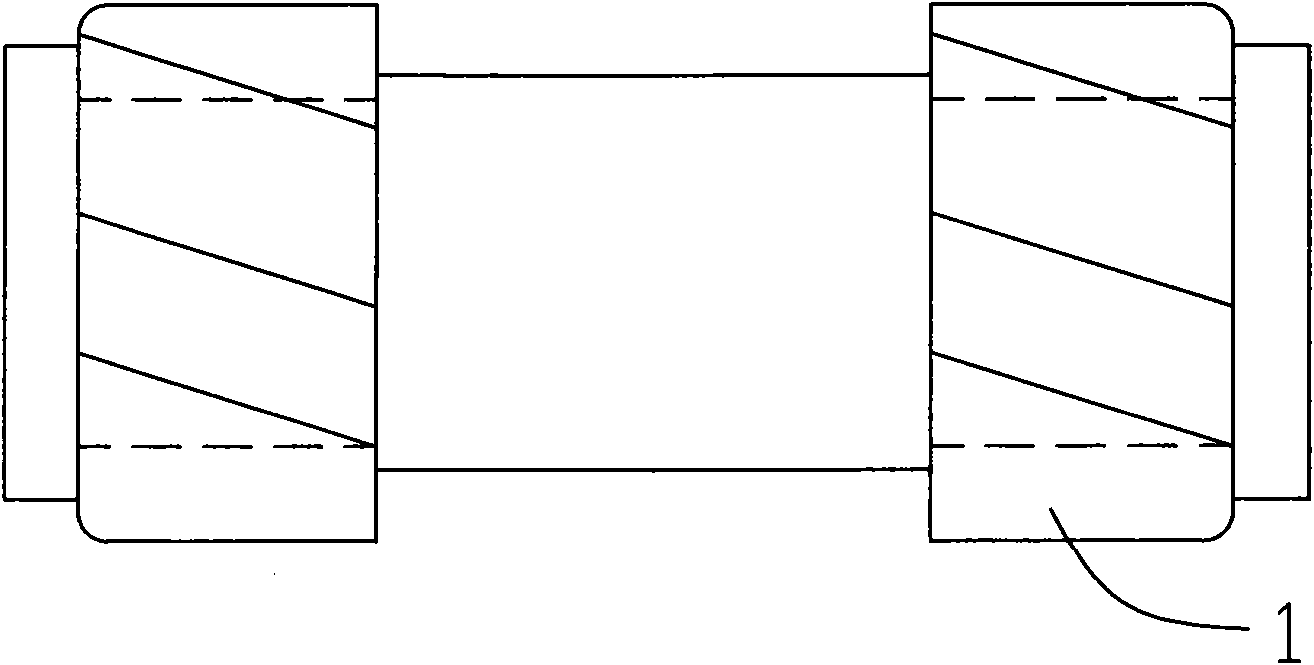

Bi-directionally sliding pup-joint coupling centralizer

A technology of centralizers and pup joints, which is applied in the direction of drilling equipment, earthwork drilling, drill pipes, etc., can solve the problems of increased load and large friction, and achieve the effects of reducing friction, enhancing passing capacity, and reducing dead load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

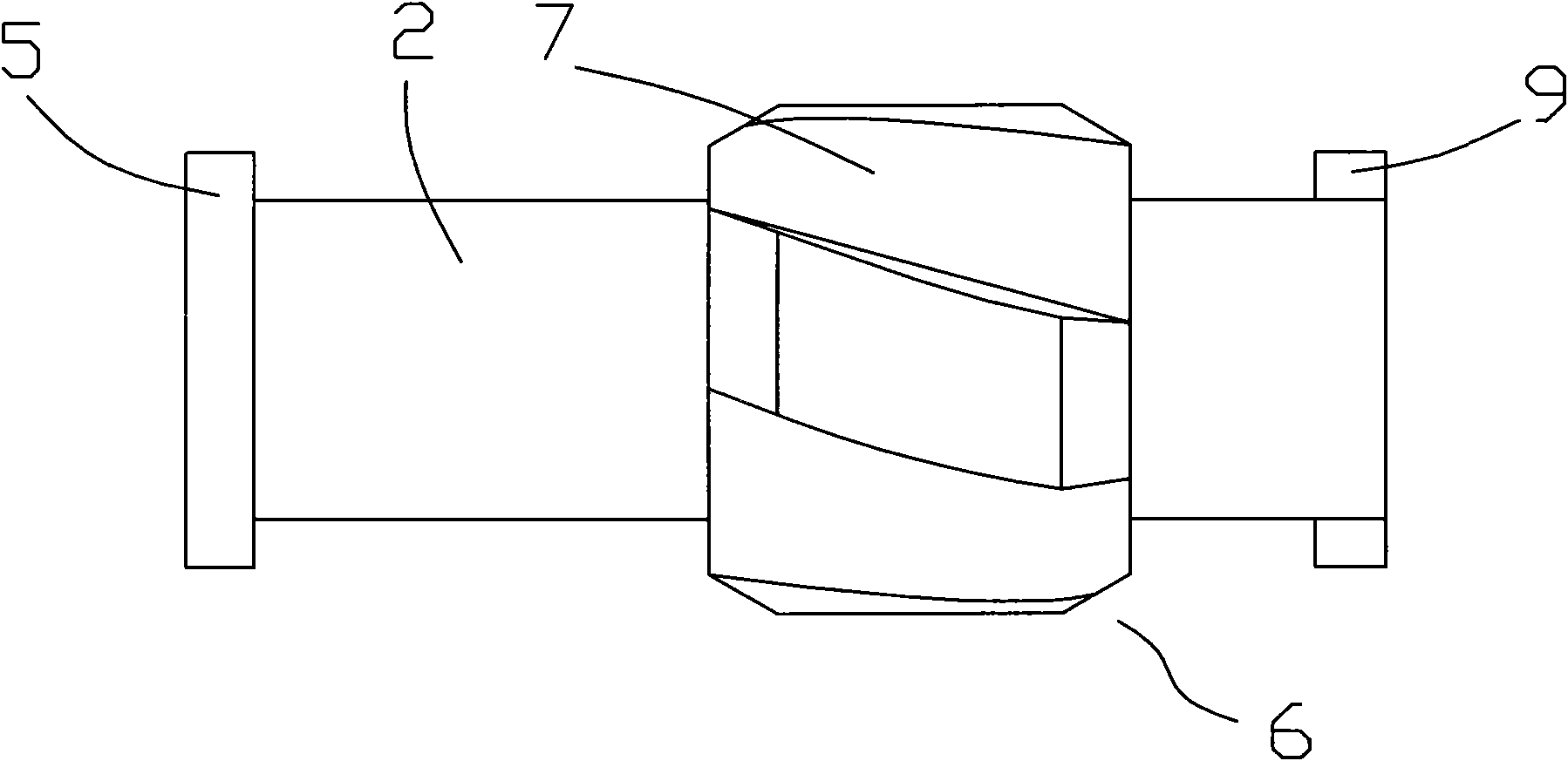

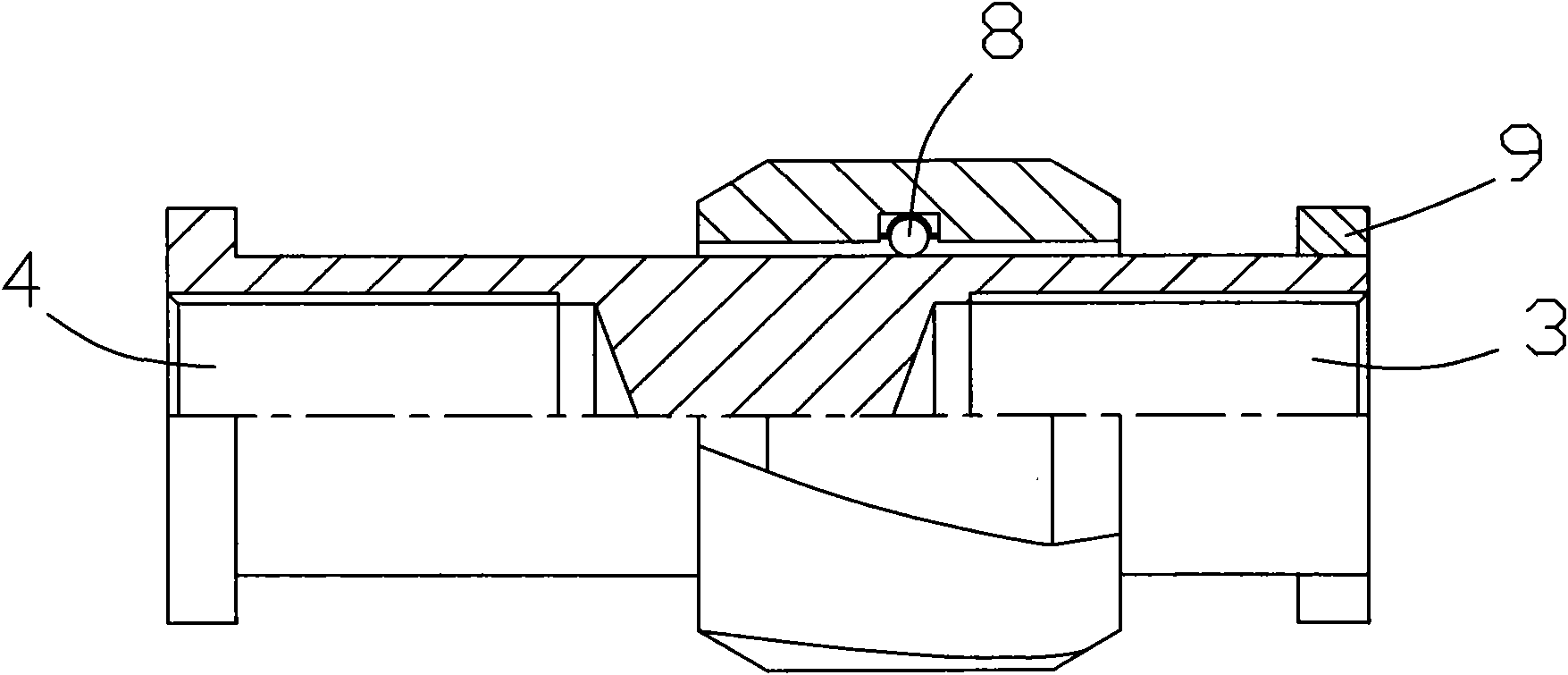

[0015] Such as figure 2 , image 3 As shown, a two-way sliding nipple coupling centralizer of the present invention includes a centralizer body 2, which is used for sucker rod couplings, and the two ends of the centralizer body 2 are respectively provided with an upper connector 3 and a lower connector 4 , in this embodiment, the connecting head 3 and the lower connecting head 4 are internally threaded connecting hole structures, the upper connecting head 3 and the lower connecting head 4 can also be designed into other structural forms according to actual requirements, the upper connecting head 3 and the lower connecting head 4 are all used for being connected with sucker rod.

[0016] Both ends of the centralizer body 2 are provided with a positioning step 5 and a positioning step 9, wherein the positioning step 5 is integrally made with the centralizer body 2, and the positioning step 9 is fixed with the centralizer body 2 through interference fit. A centralizer block 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com